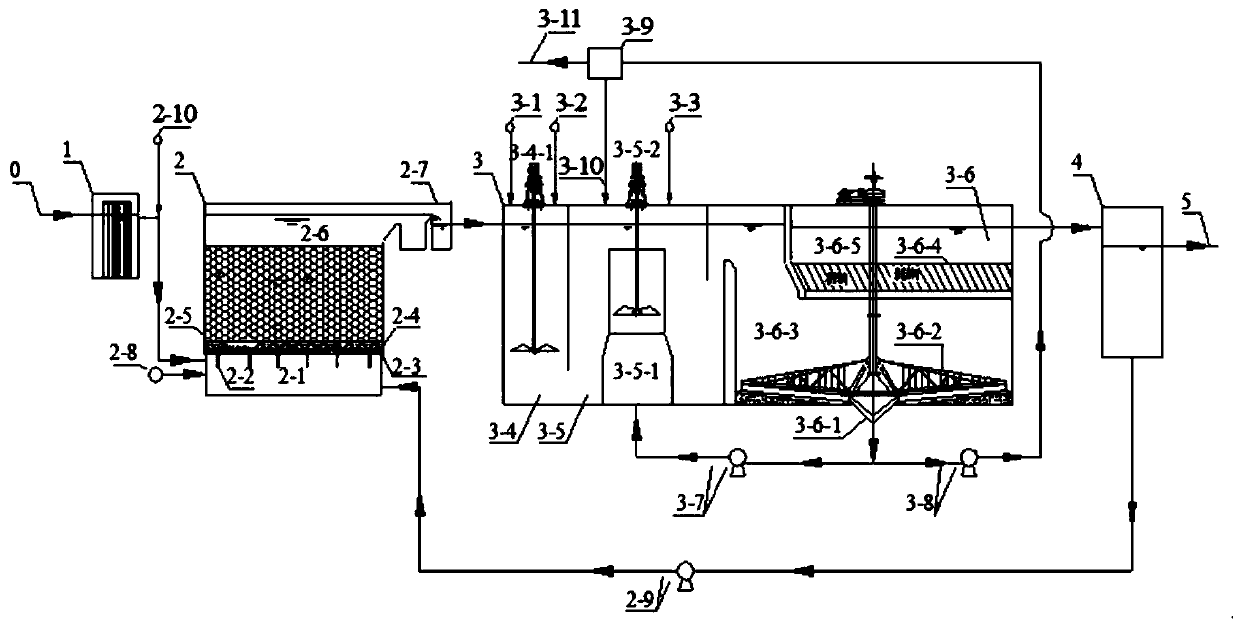

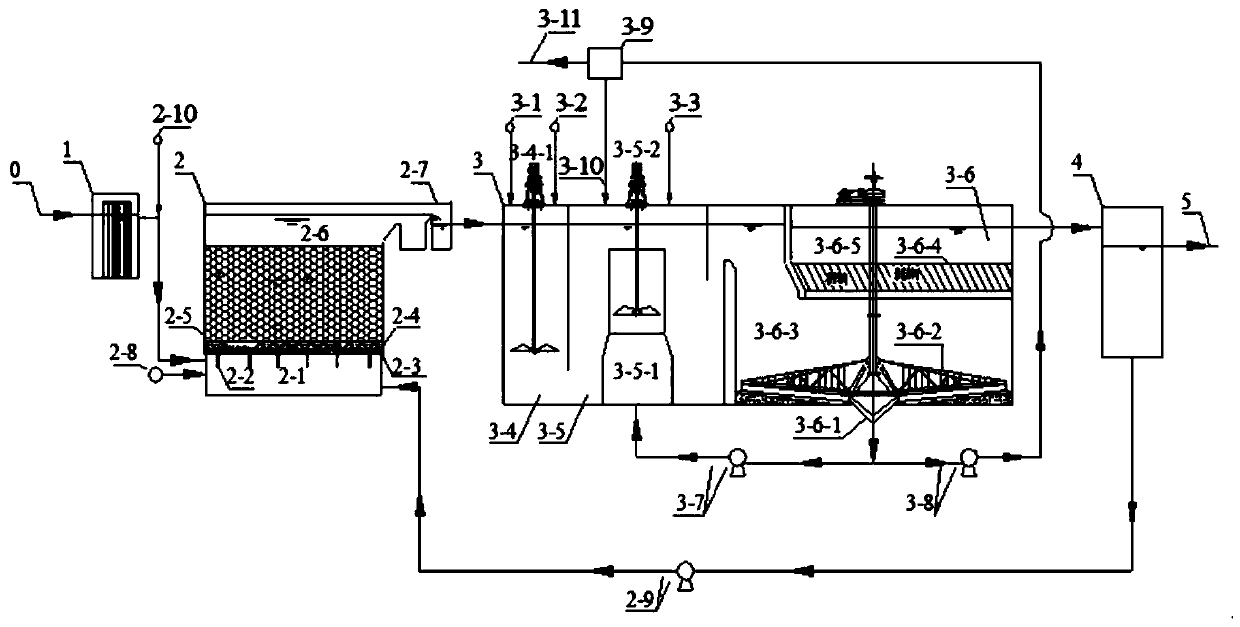

Ultrahigh-filtering-speed IV-class water upgrading standard transformation nitrogen and phosphorus removal device and a treatment process thereof

A technology for denitrification, dephosphorization, and filtration speed, which is applied in the field of water pollution control, can solve the problems of increasing filter material resistance, reducing filter treatment effect, filter head clogging, etc. Dealing with the effect of high filtration rate or load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The treatment flow rate of a sewage treatment plant in Jiangsu Province is 150,000m3 / d. The original core process is the "oxidation ditch + secondary sedimentation tank" process. The pollutant index of the secondary treatment effluent before entering this process is: TN=18mg / L, SS= 80mg / L, TP=3.5; after this process, the effluent water quality indicators are: TN=2.5mg / L, SS=2mg / L, TP=0.1mg / L.

Embodiment 2

[0037] A municipal sewage treatment plant in Anhui Province has a treatment flow rate of 50,000m3 / d. The original main process is the "AAO+secondary sedimentation tank" process. The pollutant indicators before the secondary treatment effluent enters this process are: TN=18mg / L, SS=30mg / L, TP=2.5; after being treated by this process device, the effluent water quality indicators are: TN=2.5mg / L, SS=3mg / L, TP=0.1mg / L.

Embodiment 3

[0039] A sewage treatment plant in a chemical industry park in Nanjing, Jiangsu Province, has a treatment flow rate of 10,000m3 / d. The original main process is the process of "hydrolytic acidification + AAO + secondary sedimentation tank + ozone". The pollutant index before the secondary treatment effluent enters this process is: TN=13mg / L, SS=30mg / L, TP=2.7; after being treated by this process device, the effluent water quality index is: TN=2.6mg / L, SS=3mg / L, TP=0.05mg / L, and the effluent can reach Class IV water standard,.

[0040] The invention solves the problem that the filter head of the traditional aerobic nitrification biological filter is easily blocked due to fibrous impurities; it solves the problem of blockage of the upward flow denitrification biological filter and the problem of high processing load and low load, heavy medium and heavy medium loading The treatment effect of the high-efficiency flocculation clarification tank is obviously better than tha

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap