Solar photovoltaic refrigeration assisted hydrate method carbon capture system

A solar energy and hydrate technology, which is applied to machines, refrigerators, refrigeration and liquefaction using solar energy, can solve the problems of high cost, low efficiency, slow speed, etc., to improve energy utilization, simple process flow, and environmental pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

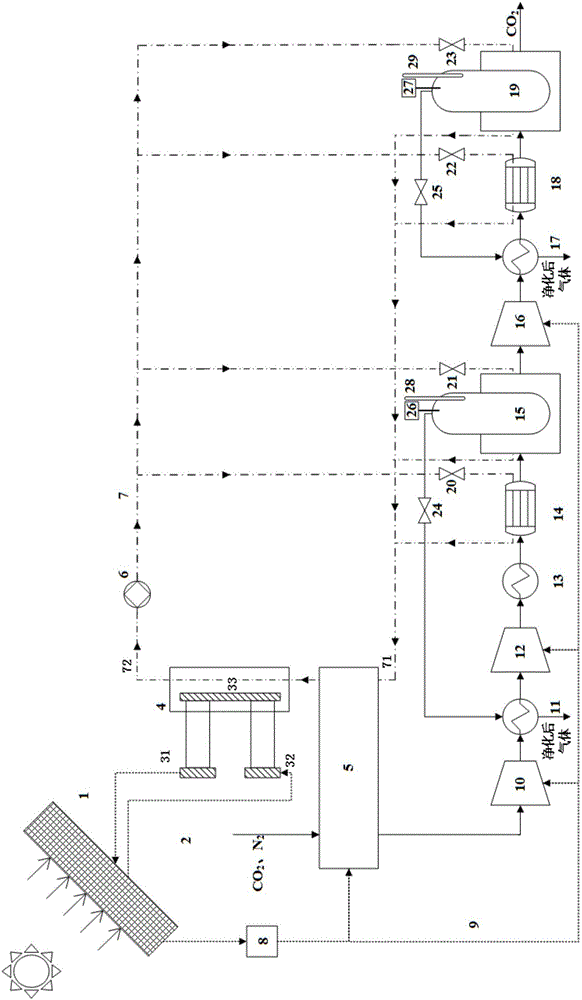

[0024] Such as figure 1 As shown, a solar photoelectric refrigeration assisted hydrate carbon capture system of the present invention includes a solar thermoelectric refrigeration subsystem, a solar power supply voltage control subsystem, a brine circulation subsystem, and a carbon dioxide capture subsystem.

[0025] The carbon dioxide capture subsystem is a two-stage carbon dioxide capture subsystem of the hydrate method;

[0026] The solar thermoelectric refrigeration subsystem includes a thermoelectric refrigeration device connected to one end of the solar power generation device 1. The thermoelectric refrigeration device includes a first hot end 31, a cold end 33 and a se

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap