Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Chemical products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting multiple chemical products from coal-tar oil

ActiveCN101139527AIncrease added valueQuality improvementTar working-up by water removalTar working-up by distillationAnthraceneHigh concentration

The invention discloses a method for extracting a plurality of chemicals from a coal tar, which comprises such procedures as heating the coal tar to 120-130 DEG C, dehydrating, fore running, separating, fine rectifying, and heavy-oil distilling, and getting 95 naphthalene, methyl naphthalene, anthracene oil, asphalt and heavy oil. The invention is of simple process, easy operation, rectifies coal tar several times; the extracted chemical products are of steady quality, the naphthalene is of high concentration, and the asphalt is of good quality. The invention is of low energy consumption, hence improves better the added value in processing coal tar in China.

Owner:ZHEJIANG MEIYANG INTL PETROCHEMICAL MEDICINE DESIGN CO LTD

Compound fruit fragrance and flower fragrance essence for daily chemicals and preparation method thereof

InactiveCN105316109AImprove stabilityMeet the needs of material and cultural lifeEssential-oils/perfumesBenzoic acidDamascone

Owner:广东铭康香精香料有限公司

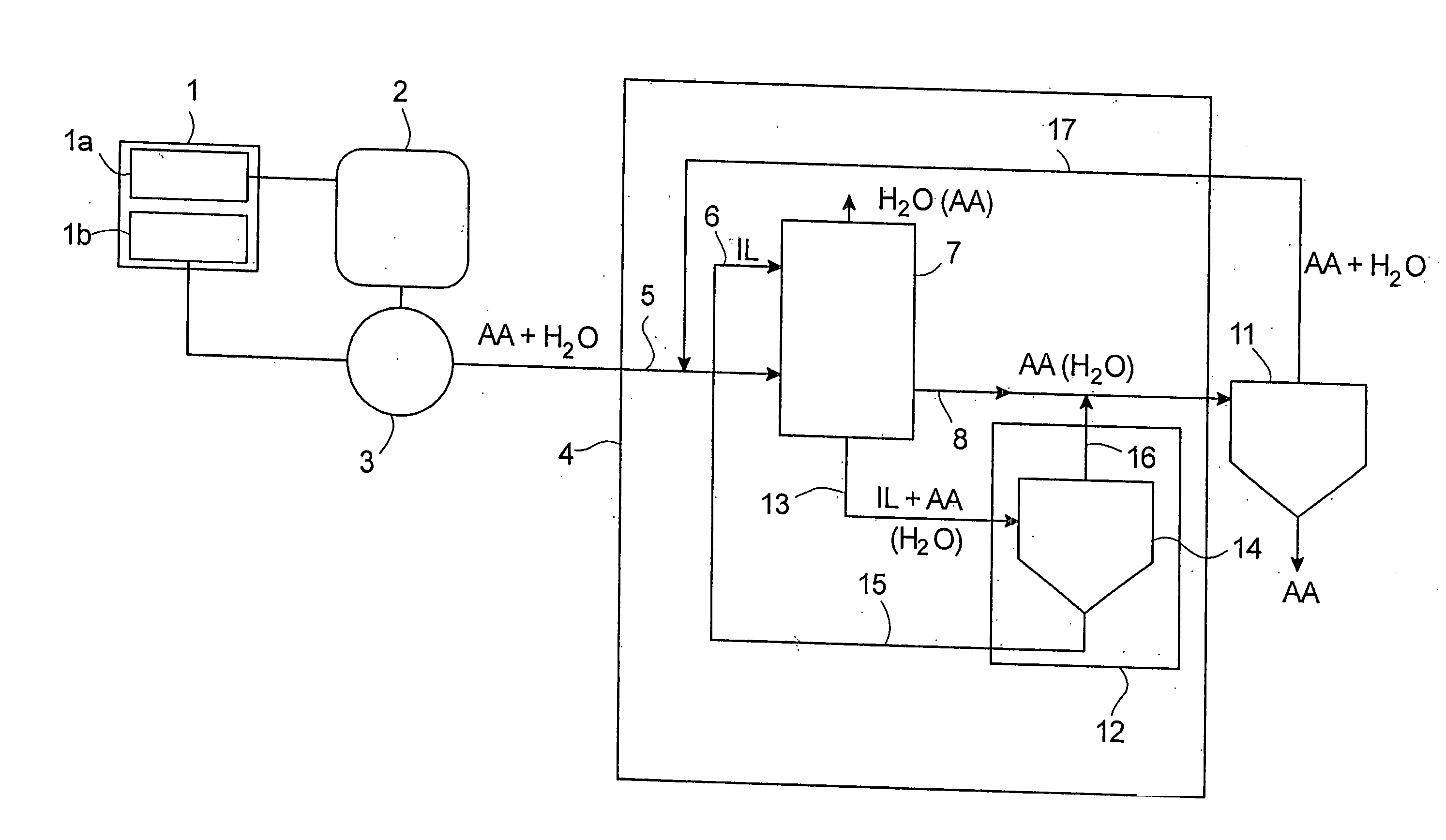

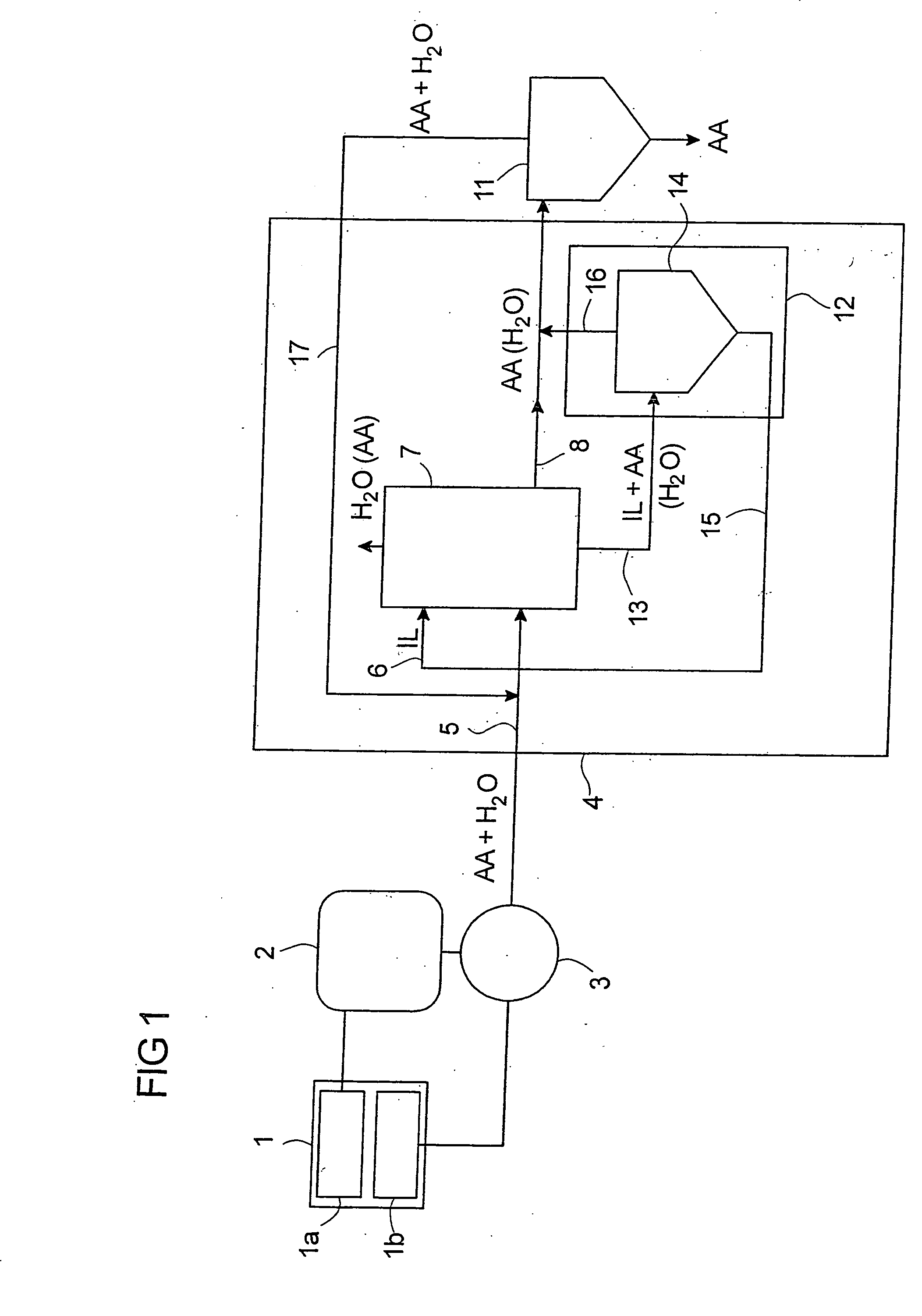

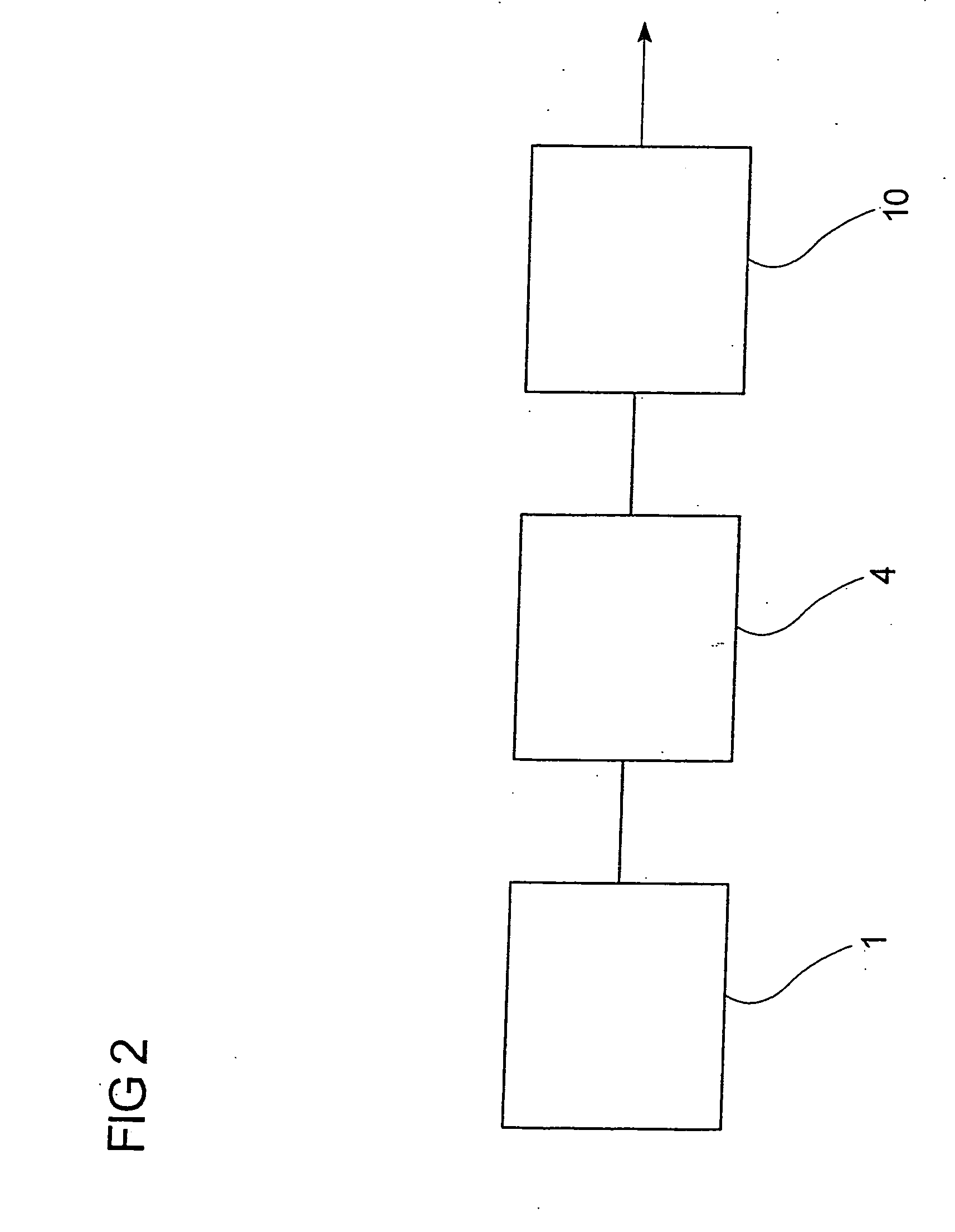

Method for the separation of monomers from a composition containing a monomer

InactiveUS20070004903A1High purityIncrease moistureCarboxylic compound separation/purificationMeth-Double bond

Owner:STOCKHAUSEN GMBH & CO KG

Method for preparing pirfenidone

InactiveCN102558040AReduce energy consumptionSimple and fast operationOrganic chemistryPurification methodsChemical products

The invention discloses a method for preparing pirfenidone, comprising the following steps: subjecting 2-amino-5-methylpyridine which is a starting material to inverse diazotization and hydrolysis, extracting with extraction solvent, and recrystallizing with recrystallization solvent to obtain 2-hydroxy-5-methylpyridine; heating the 2-hydroxy-5-methylpyridine together with iodobenzene in the presence of anhydrous potassium carbonate and active copper to subject the 2-hydroxy-5-methylpyridine and the iodobenzene to nucleophilic substitution reaction to generate a target compound which is the crude pirfenidone; and recrystallizing the crude pirfenidone for one time for purification with recrystallization solvents which are ethyl acetate and anhydrous ethyl alcohol to obtain the pure pirfenidone. Compared with the prior art, the method for preparing the pirfenidone has the characteristics that: the 2-amino-5-methylpyridine which is the starting material is a commercial chemical product, is cheap and is easy to get, the inverse diazotization replaces the conventional diazotization reaction so that the operation is simple, and the purification methods of the 2-hydroxy-5-methylpyridine and the end product which is the pirfenidone are easy to operate and have high yield. The method for producing the pirfenidone consumes less energy, and the production cost is lowered due to the adoption of the method.

Owner:CISEN PHARMA

Synthesis method of 2-(2-chloroethoxy) acetic acid

InactiveCN101844978AZero costSimple and fast operationOrganic compound preparationCarboxylic compound preparationAcetic acidOrganic solvent

The invention relates to a synthesis method of 2-(2-chloroethoxy) acetic acid, which belongs to the technical field of the preparation and the application of fine chemical engineering products. The invention particularly belongs to the synthesis method of 2-(2-chloroethoxy) acetic acid. The invention uses 2-chloroethoxy ethanol as starting materials, uses water as solvents, and uses nitric acid for direct oxidization to obtain products. The reaction process is shown as the accompanying drawing. The invention adopts water as the solvents, and uses the nitric acid as oxidizing agents for efficiently oxidizing the 2-chloroethoxy ethanol into corresponding acids. The method has the advantages of simple operation, low price of raw materials, easy acquisition of raw materials, simple requirement on equipment, simple after treatment and the like. In addition, the use of the organic solvent has nearly zero cost, and the invention conforms to the environmental protection industrial production requirements, so the invention has wide application prospects.

Owner:NANKAI UNIV

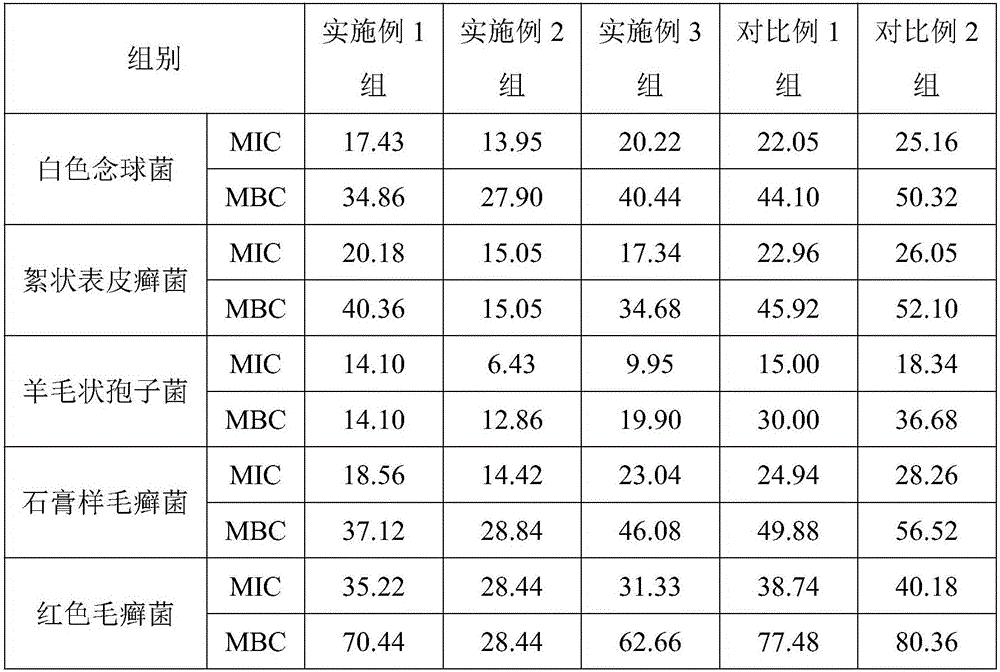

Bacteriostatic foot powder and preparation method thereof

InactiveCN106619519AMild performanceEffective treatmentPowder deliveryCosmetic preparationsResistAllergy

Owner:叶宗瑞

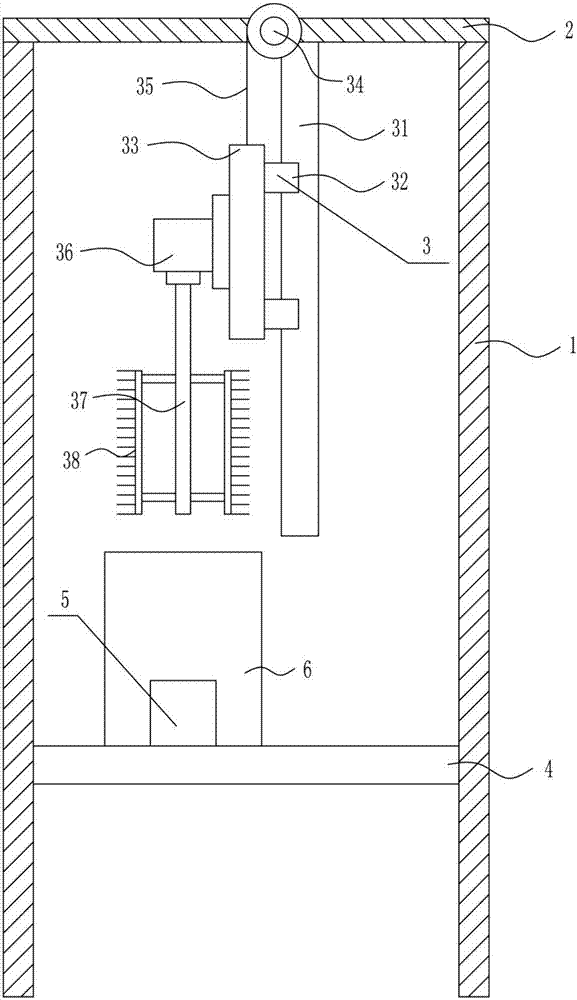

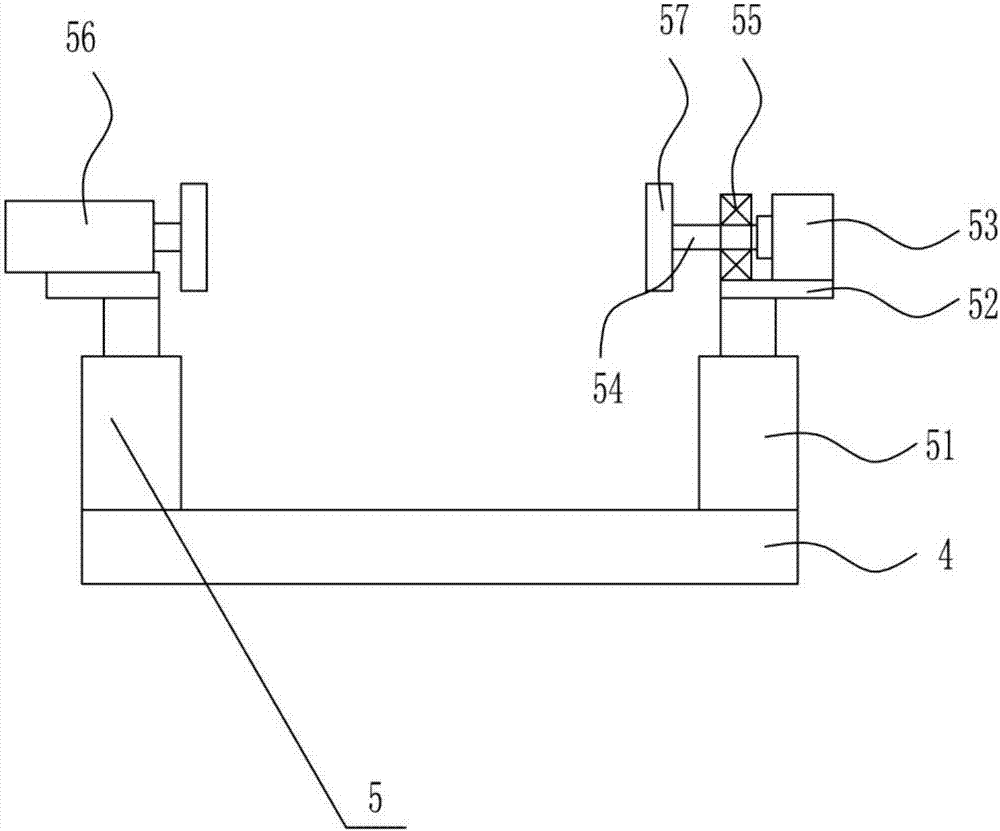

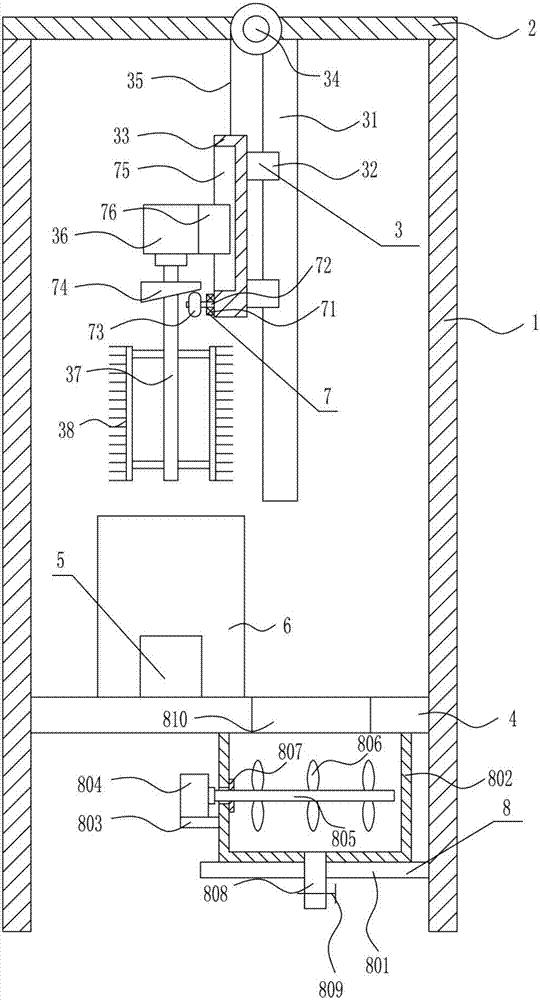

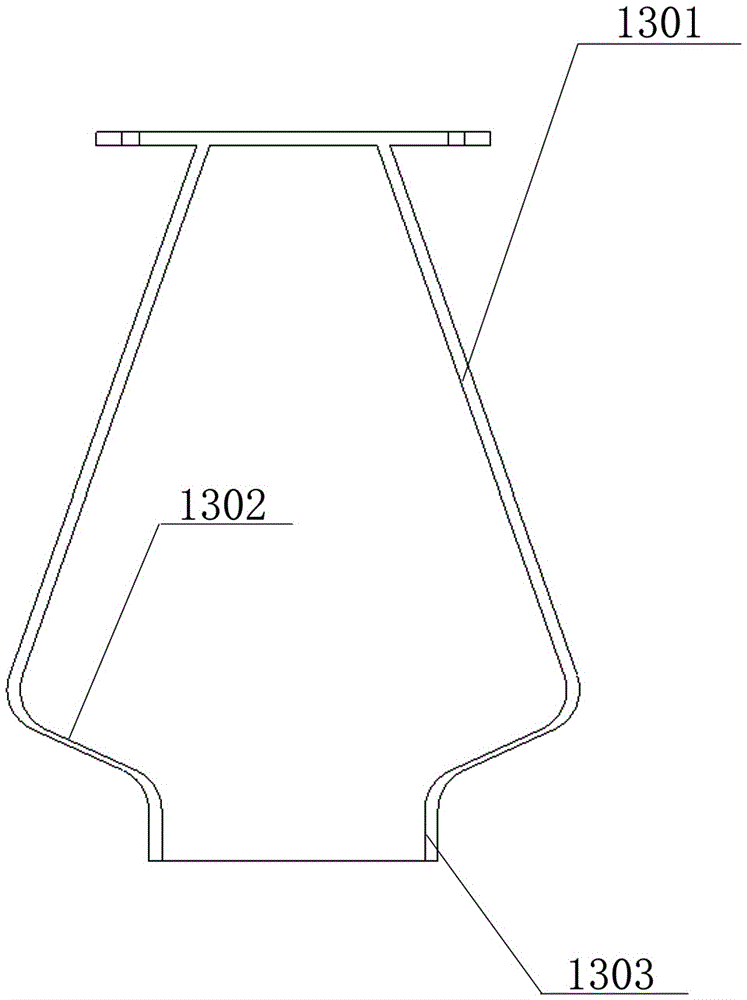

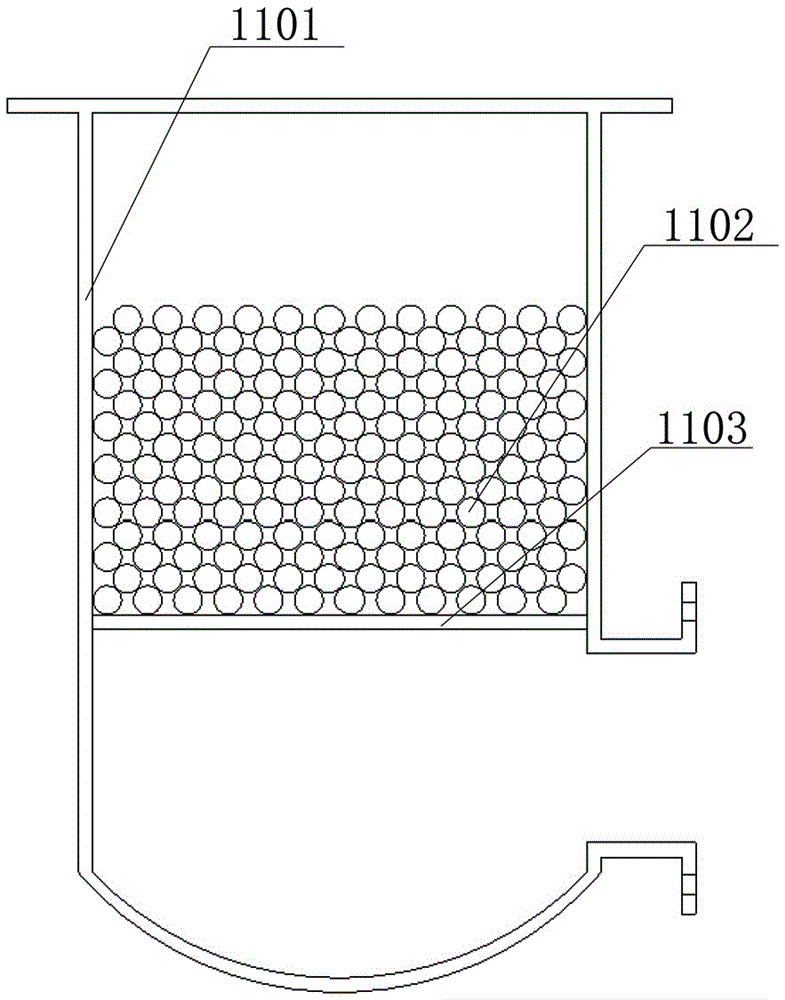

Inert chemical product charging bucket cleaning device

The invention relates to a cleaning device for chemical products, in particular to an inert chemical product charging bucket cleaning device. According to the technical purposes of the inert chemicalproduct charging bucket cleaning device, the cleaning effect is good, operation is easy and convenient, and injuries to human bodies are small. In order to achieve the technical purposes, the inert chemical product charging bucket cleaning device is provided and comprises supporting legs and the like; a first supporting plate is horizontally placed on the tops of the left and right side supportinglegs; a cleaning mechanism is installed in the middle of the bottom of the first supporting plate; and a second supporting plate is connected to the position, close to the upper portion, of the bottom between the left and right side supporting legs, and is provided with an overturning and tipping mechanism. According to the inert chemical product charging bucket cleaning device, due to mutual cooperation of the cleaning mechanism and the overturning and tipping mechanism, recycled charging barrels are cleaned, and meanwhile, by means of optimization of an auxiliary mechanism and a secondary treatment mechanism, the effects that the cleaning effect is good, operation is easy and convenient, and injuries to human bodies are small are achieved.

Owner:饶胜智

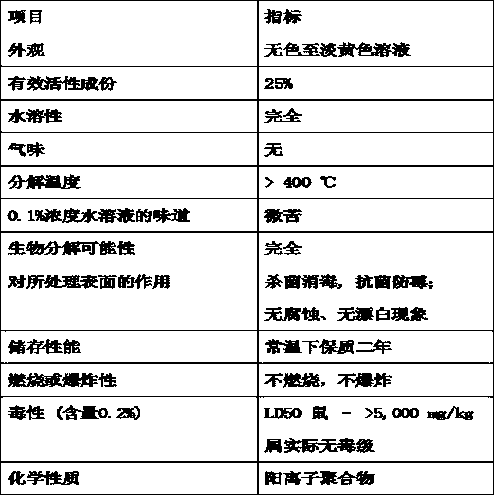

Multi-functional pet shower lotion

InactiveCN109833239AImprove bactericidal efficacyImprove effective activityCosmetic preparationsHair cosmeticsChemical productsLotion

Owner:盘锦佳合晟世医药科技有限公司

Organic fertilizer for fruits and vegetables and preparation method of organic fertilizer

InactiveCN107235771ANutritional diversityImprove the immunityBio-organic fraction processingExcrement fertilisersLivestock manureArtemisia vulgaris

Owner:赵静

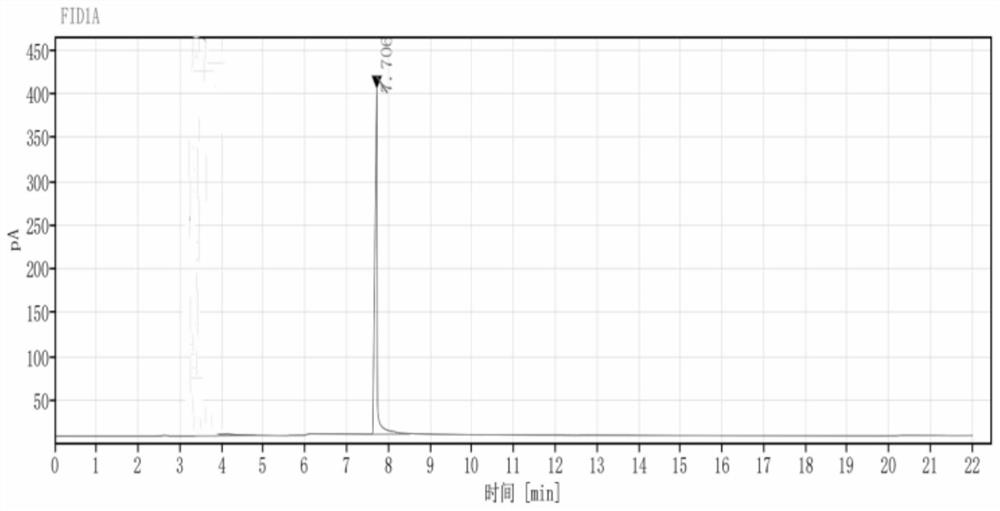

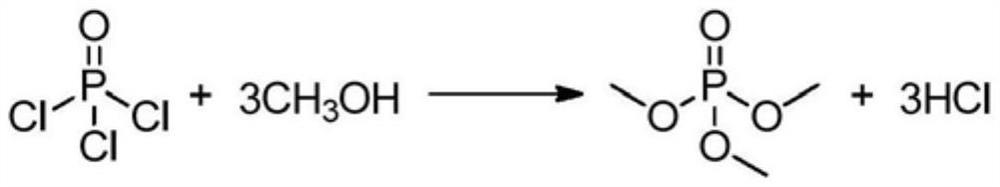

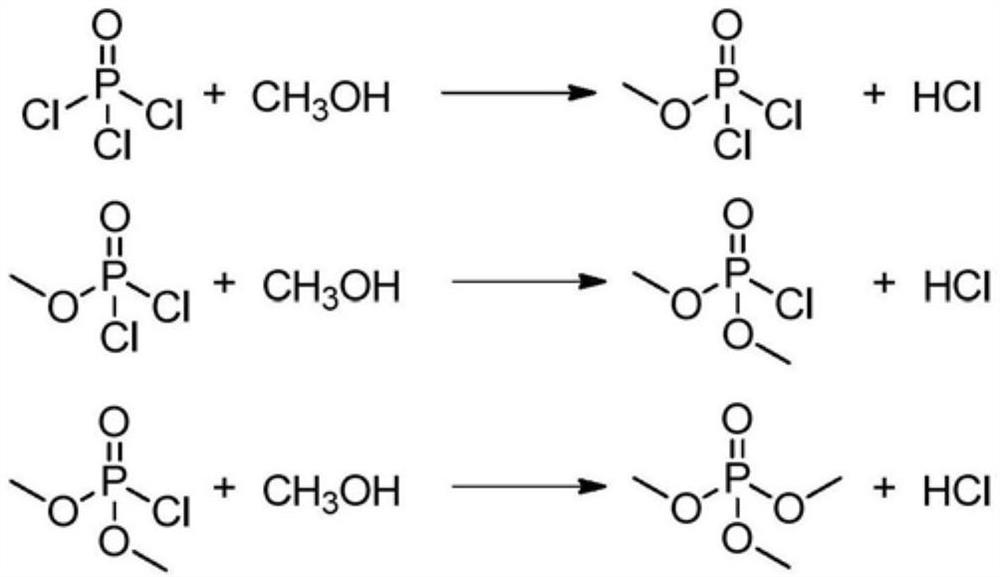

Method for preparing trimethyl phosphate without adding alkali

InactiveCN112920217AReduce processing costsImprove protectionGroup 5/15 element organic compoundsDistillationPhosphoric acid

Owner:NANJING ADVANCED BIOLOGICAL MATERIALS & PROCESS EQUIP INST CO LTD

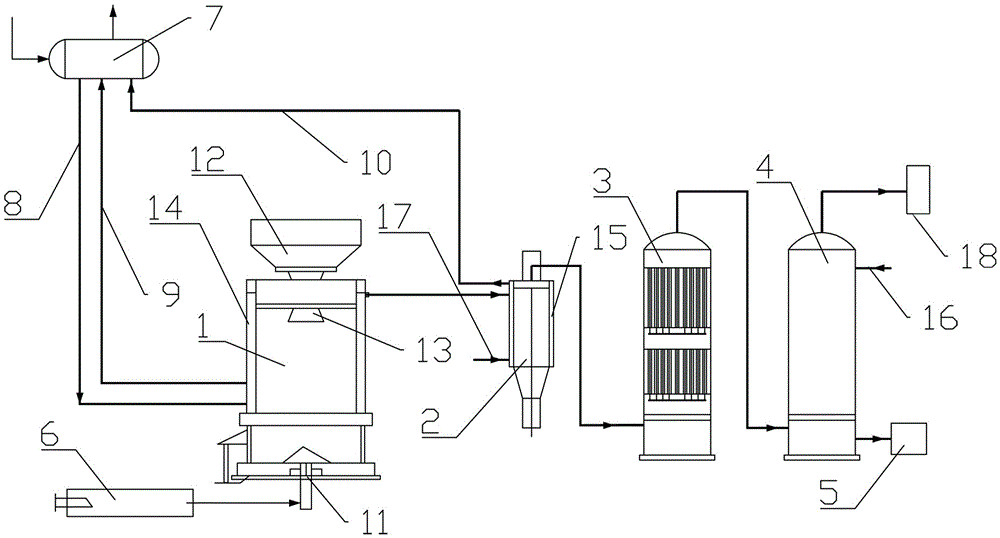

Fixed-bed pure-oxygen continuous gasification device and process adaptable to diversified coals

ActiveCN105542860AImprove decomposition rateHigh effective gas contentChemical industryGasification processes detailsAdditive ingredientFixed bed

Owner:河南顺达新能源科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap