Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "After treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

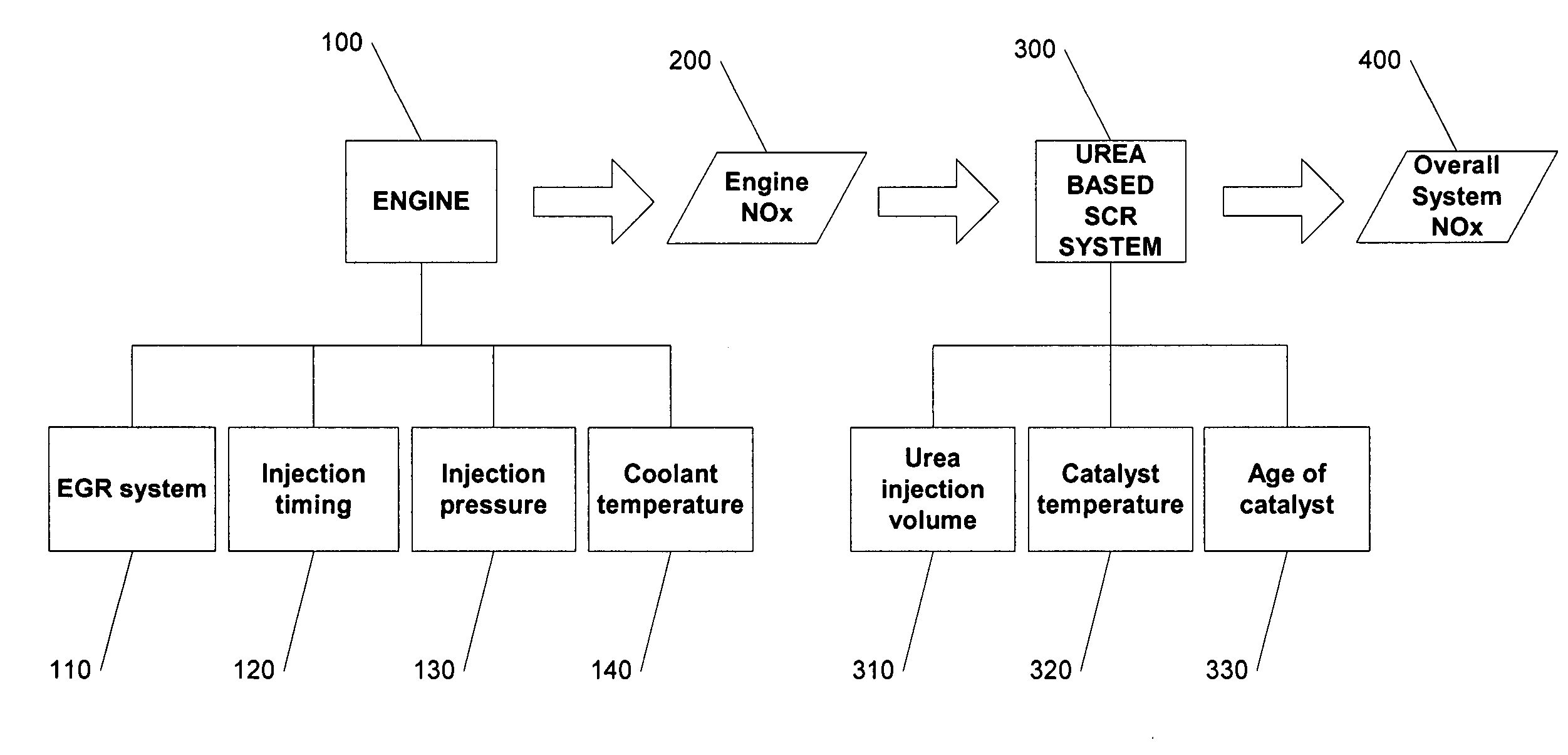

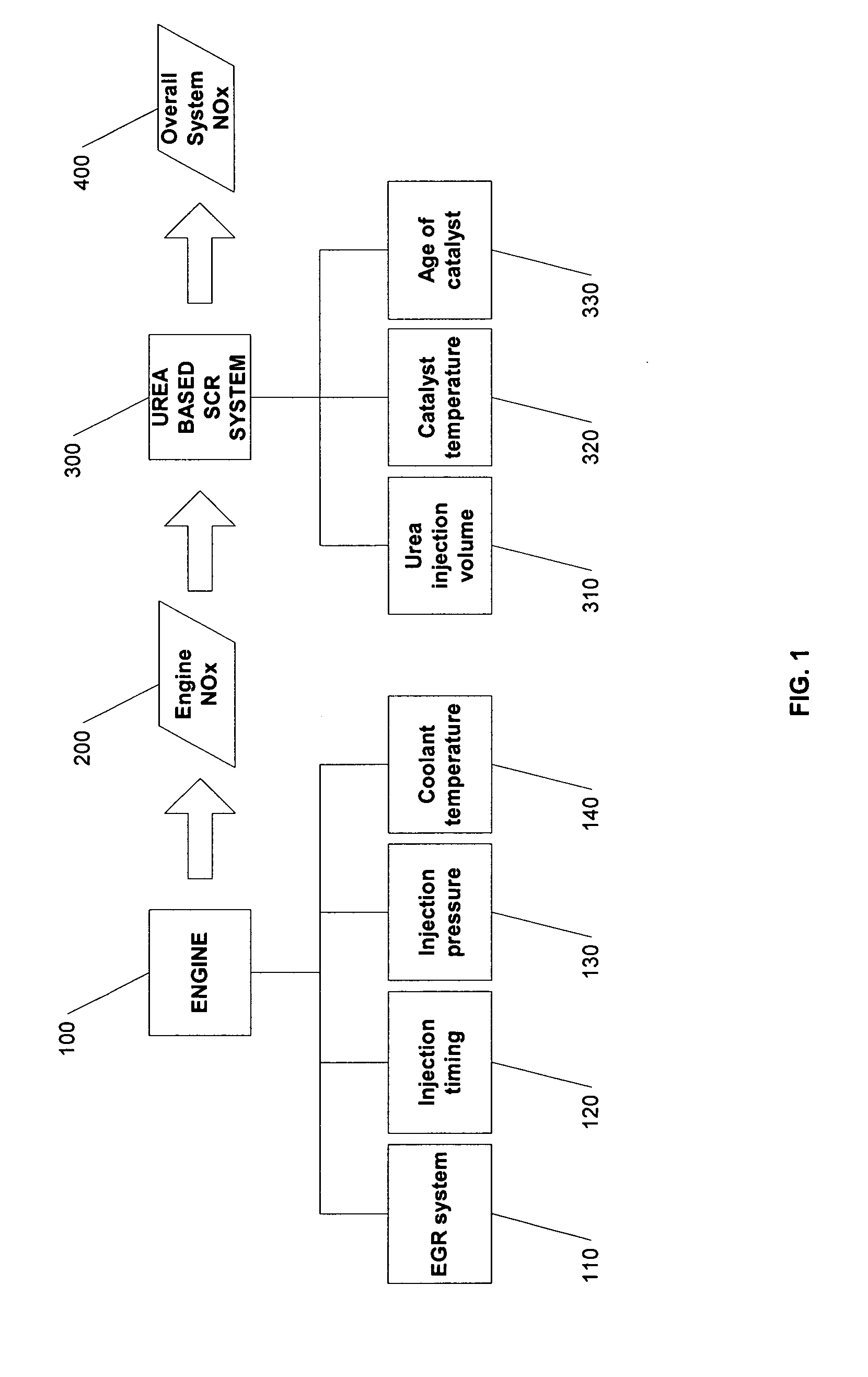

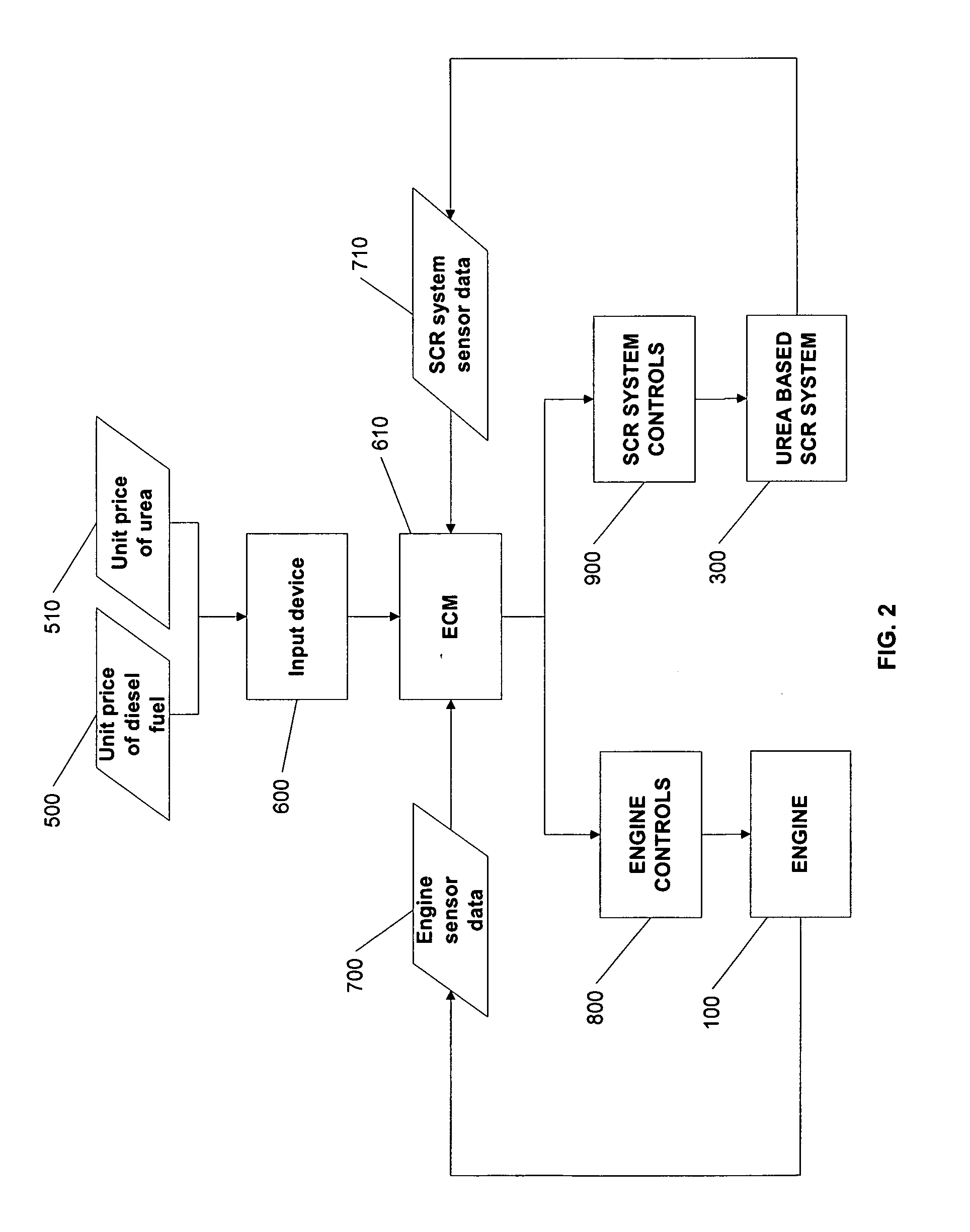

System and method for NOx reduction optimization

ActiveUS20070163244A1Reduced fuel efficiencyReduce nitrogen oxide contentAnalogue computers for vehiclesElectrical controlExhaust gas recirculationDiesel engine

Owner:CUMMINS INC

Ecological bacteriostatic breathable smooth tatting fabric

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Method for producing double-color short pile fabric

The invention provides a production method of a two-color short plush fabric, which belongs to the technical field of textile fabrics. It includes the following steps: step (1), select the yarn to be used, the type of yarn used is polyester semi-gloss FDY, polyester semi-gloss light net DTY, cationic FDY; step (2), use warping machine for warping; Step (3), use the warp knitting machine for weaving; step (4), arrange and change the weaving process according to the designed production process sheet; step (5), check; step (6), blank inspection; step (7) , stacking blanks; step (8), setting the shape, setting the fabric; step (9), napping; step (10), dyeing, dyeing the shaped fabric; step (11), post-processing, after Post-processing creates a two-tone short plush fabric. The invention realizes the production of the fabric similar to the wavy pattern, forms the two-color short plush fabric, has a simple production method and high production efficiency.

Owner:TONGXIANG LONGXIANG TEXTILE

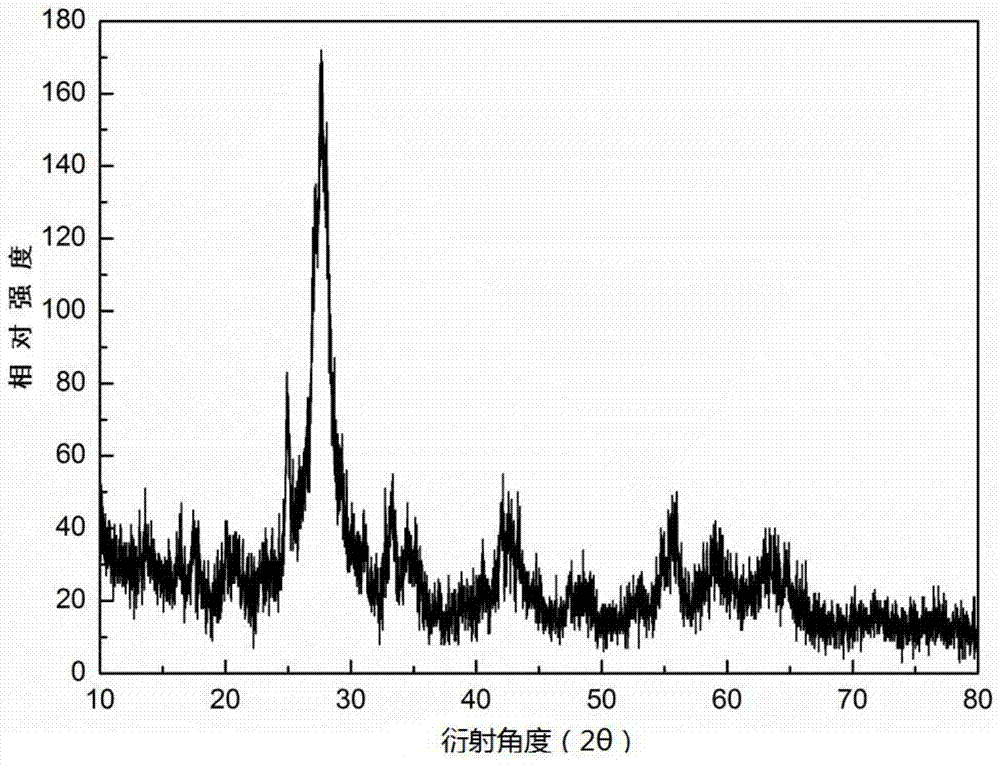

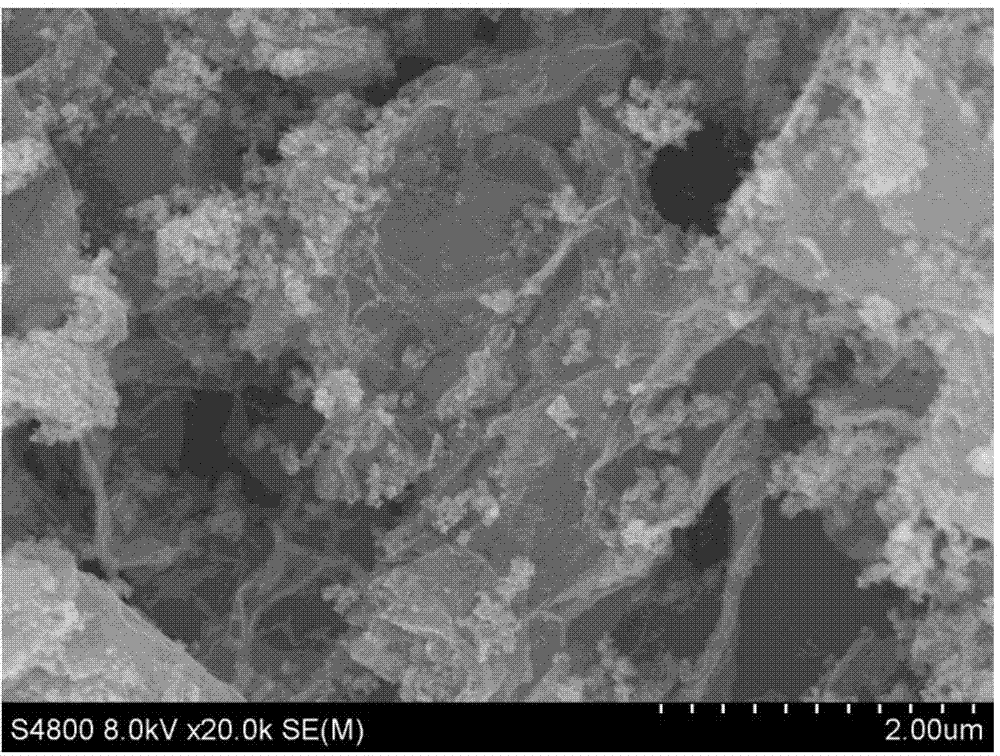

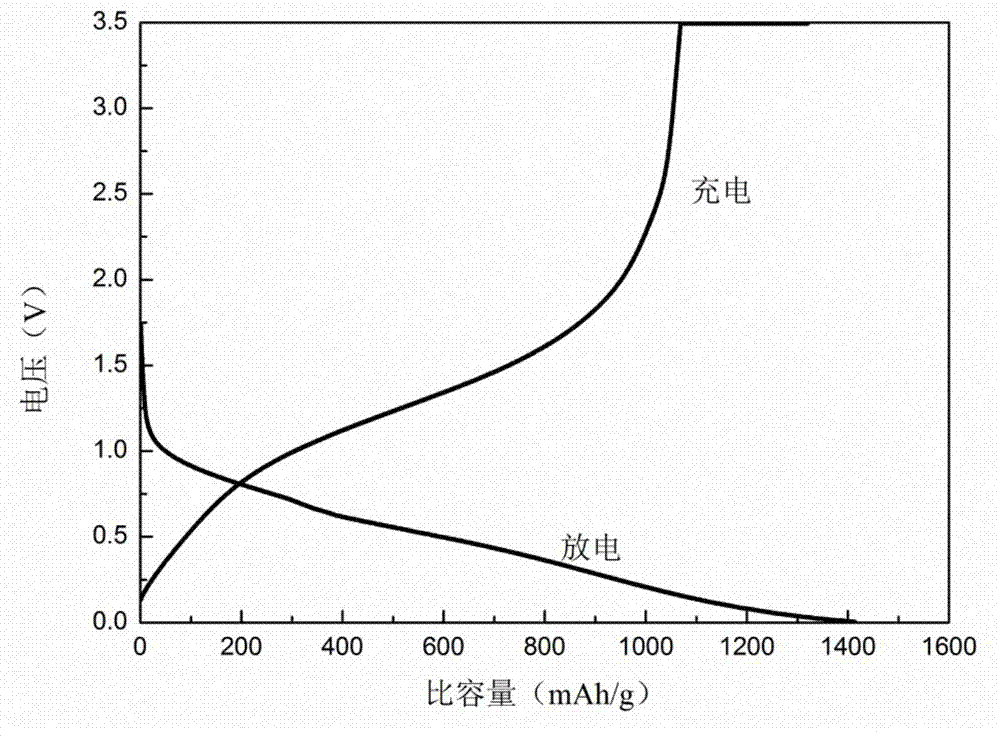

Method for preparing ferric vanadate-graphene negative electrode composite material

ActiveCN104766975AUniform textureGood dispersionNegative electrodesSecondary cellsDispersityReaction rate

Owner:SHENZHEN PANGU ENVIRONMENTAL PROTECTION TECH CO LTD

Composition with effect of treating gout

InactiveCN102000159AHeat-clearing and detoxifyingWith swelling and pain reliefAntipyreticAnalgesicsDiseaseAfter treatment

Owner:TIBET UNIV

Oxidative degradation method for cyanide in cyaniding tailings

InactiveCN107890622AReduce consumptionPromote decomposition and releaseChemical protectionVacuum extractionHigh pressure

Owner:FUJIAN SHUANGQISHAN MINING +1

Production process for rubber of spherical hinge

InactiveCN108084513AImprove anti-aging propertiesImprove fatigue resistanceCoatingsAfter treatmentVulcanization

Owner:南通市弘达轨道交通配件有限公司

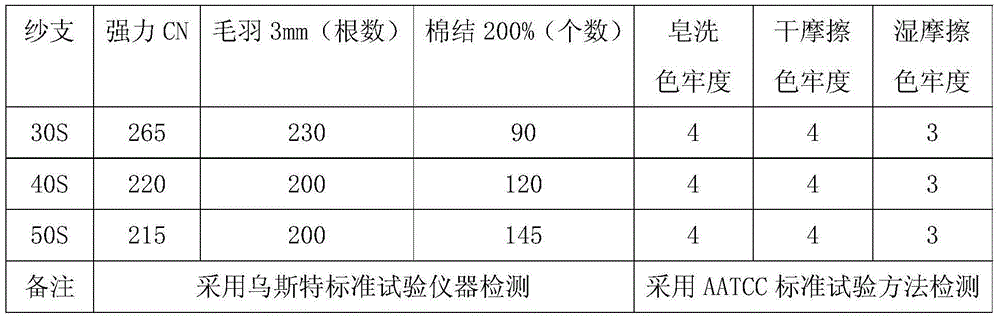

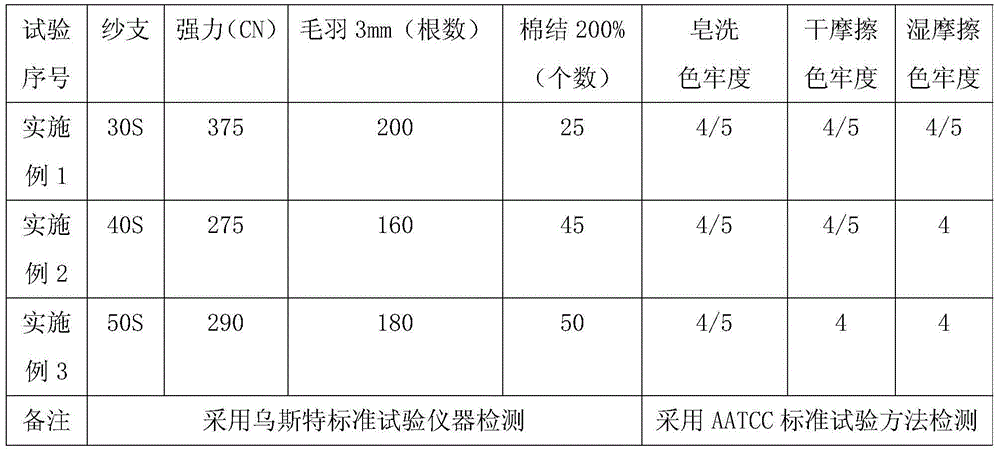

Pure cotton cheese dyeing method

Owner:LUTAI TEXTILE

Blended fabric treated by using water-saving dyeing method

Owner:HANGZHOU QICHENG TECH CO LTD

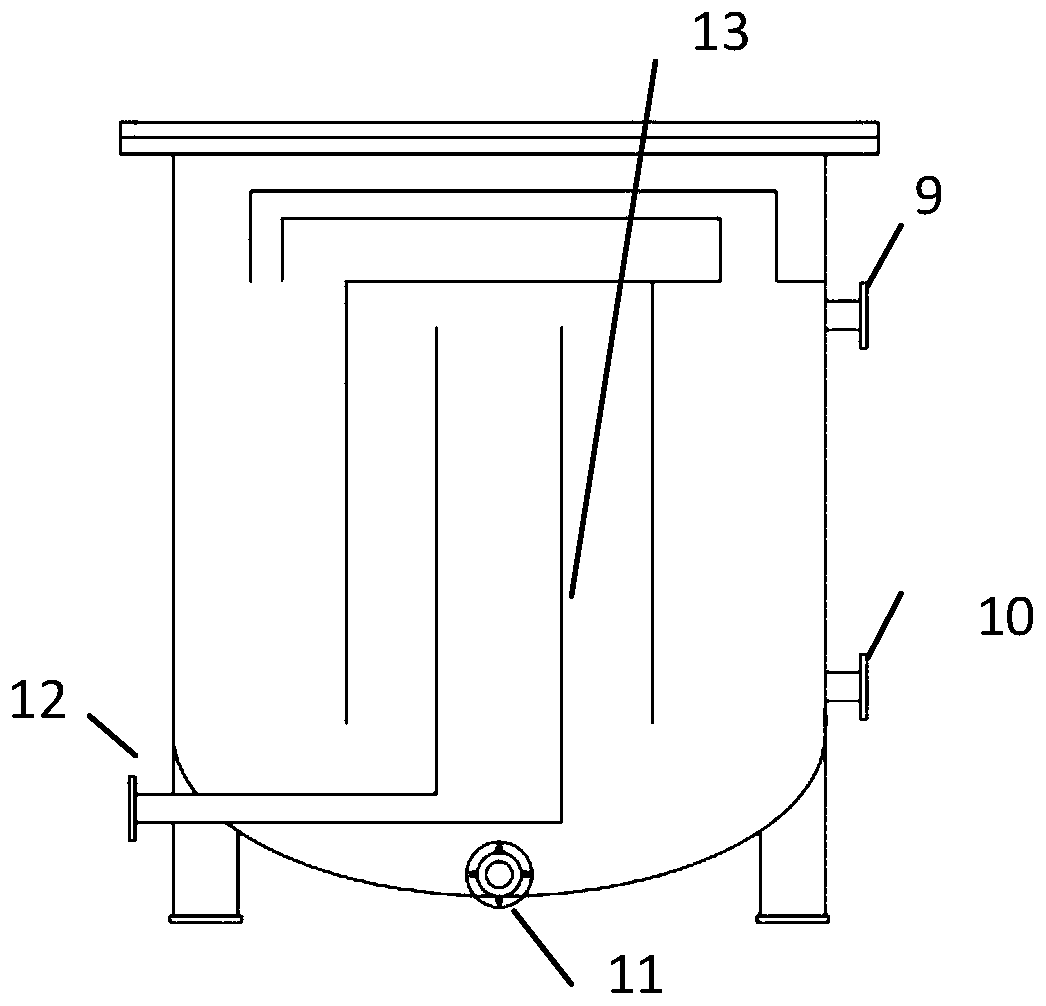

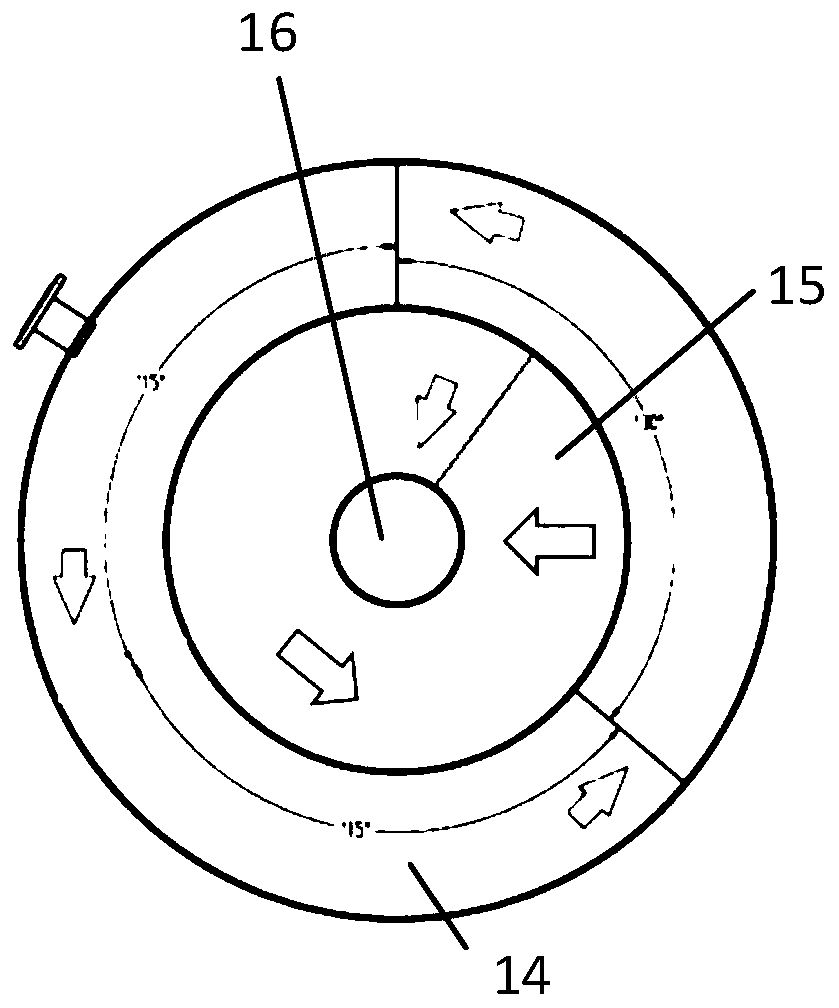

Treatment system and method for mixed waste liquid of drilling wastewater and fracturing flowback fluid

InactiveCN110078251AAchieve re-useWell mixedWater contaminantsScale removal and water softeningLiquid wasteIon exchange

Owner:PETROCHINA CO LTD

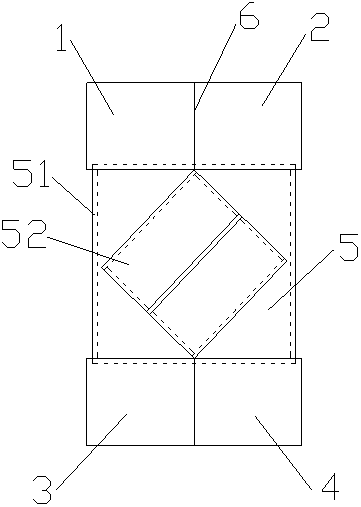

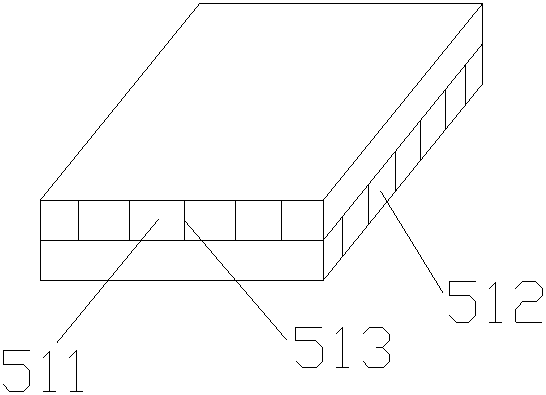

TSS (total suspended solid) sewage treatment system

ActiveCN103304099ANo sludgeNo electricity requiredMultistage water/sewage treatmentWater qualityDigestion

The invention discloses a TSS (total suspended solid) sewage treatment system. The TSS sewage treatment system comprises a pre-treatment device, an after-treatment device and a water storage groove, wherein the pre-treatment device comprises a first digestion tank, a second digestion tank and a pre-filter tank which are sequentially connected; the after-treatment device comprises a waterproof tube or a rubber mould on the lower part, a breathable filter material at the middle, and a non-woven fabric on the upper part; the water storage groove is used as a treated water quality observation-inspection groove. The TSS sewage treatment system is low in maintenance cost, saving in labour, simple in construction, easily-available in materials, low in cost, and pollution-free to underground water; the treated water can be cyclically utilized as reclaimed water, and odour and hydrogen sulphide are avoided during the treatment process.

Owner:SHANDONG PACIFIC ENVIRONMENTAL PROTECTION

Air exhausting white smoke eliminating device for setting machine

PendingCN108458356ALighting and heating apparatusCombustion technology mitigationProduct gasAfter treatment

Owner:江苏奥巴新能源科技股份有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap