Pure cotton cheese dyeing method

A dyeing method and yarn technology, applied in the field of pure cotton yarn dyeing, can solve the problems of many neps, poor color fastness, low strength, etc., and achieve the effects of less neps, less hairiness and good soaping fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: Select 10kg of pure cotton 30S bobbins and dye them with reactive dyes, the dyeing concentration is 0.5%, and the liquor ratio is 1:10.

[0013] 1. Auxiliary application process: Cotton yarn is auxiliaries on SSM loose winder, DT-50B water-repellent weak cationic softener (manufactured by Shijiazhuang Lianlian Kete Chemical Co., Ltd.) for textile finishing is 5000ml, and the package is dyed Use 500ml of LT cationic color fixing agent (produced by Tianjin Hongliyuan Industry and Trade Co., Ltd.), the speed of SSM yarn winding machine is 800 rpm, the speed of oil tanker is 2 rpm, and the density of loose yarn is 0.39g / cm 2 ;

[0014] 2. Package yarn dyeing, package yarn dyeing uses reactive dyes, in the package yarn dyeing machine, there is no pre-scouring treatment, and normal post-treatment after normal dyeing;

[0015] 3. Drying, radio frequency drying after dehydration, the speed of the conveyor belt is 5 meters per hour.

Embodiment 2

[0016] Example 2: 8 kg of pure cotton 40S bobbins were selected and dyed with reactive dyes, the dyeing concentration was 2.5%, and the liquor ratio was 1:13.

[0017] 1. Auxiliary application process: Cotton yarn is auxiliary on SSM loose winder, DT-50B water-repellent weak cationic softener (manufactured by Shijiazhuang Lianlian Kete Chemical Co., Ltd.) for textile finishing 2000ml, bobbin dyeing Use 1000ml of LTG‐8080 cationic color fixing agent (produced by Shanghai Liantan Chemical Co., Ltd.), the speed of SSM yarn winding machine is 600 rpm, the speed of tanker is 10 rpm, and the density of loose yarn is 0.411g / cm 2 ;

[0018] The bobbin dyeing process and drying process are the same as in Example 1.

Embodiment 3

[0019] Example 3: Select 40kg of pure cotton 50S bobbins and dye them with reactive dyes, the dyeing concentration is 7.5%, and the liquor ratio is 1:8.

[0020] 1. Auxiliary application process: auxiliary yarn on SSM winding machine, 5000ml of water-repellent weak cationic softener DT-50B (manufactured by Shijiazhuang Lianlian Kete Chemical Co., Ltd.) for finishing, cationic color-fixing agent for bobbin dyeing FSN (produced by Tianjin Hongliyuan Industry and Trade Co., Ltd.) 5000ml, SSM winder speed 600 rpm, tanker speed 18 rpm, loose yarn density 0.403g / cm 2 ;

[0021] The bobbin dyeing process and drying process are the same as in Example 1.

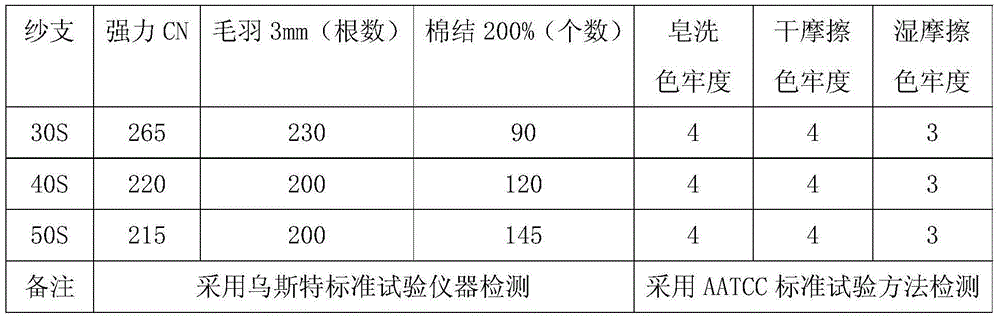

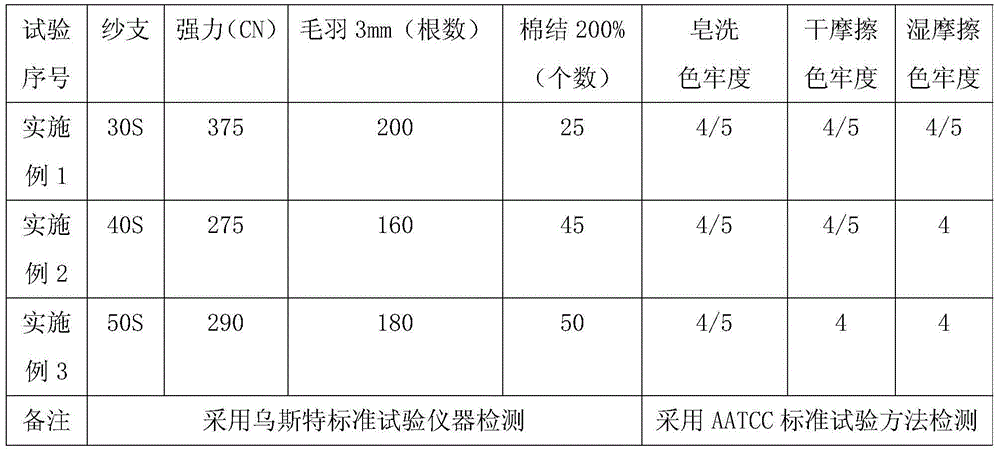

[0022] After testing: using the present invention to process the above pure cotton yarn bobbins, the indicators are as follows:

[0023]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap