System and method for NOx reduction optimization

a technology of optimization system and optimization method, applied in the field of nox reduction, can solve the problems of reducing fuel efficiency, placing fuel efficiency on the fuel, and high fuel price, so as to reduce the content of nox, reduce the temperature at combustion, and reduce the effect of nox conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

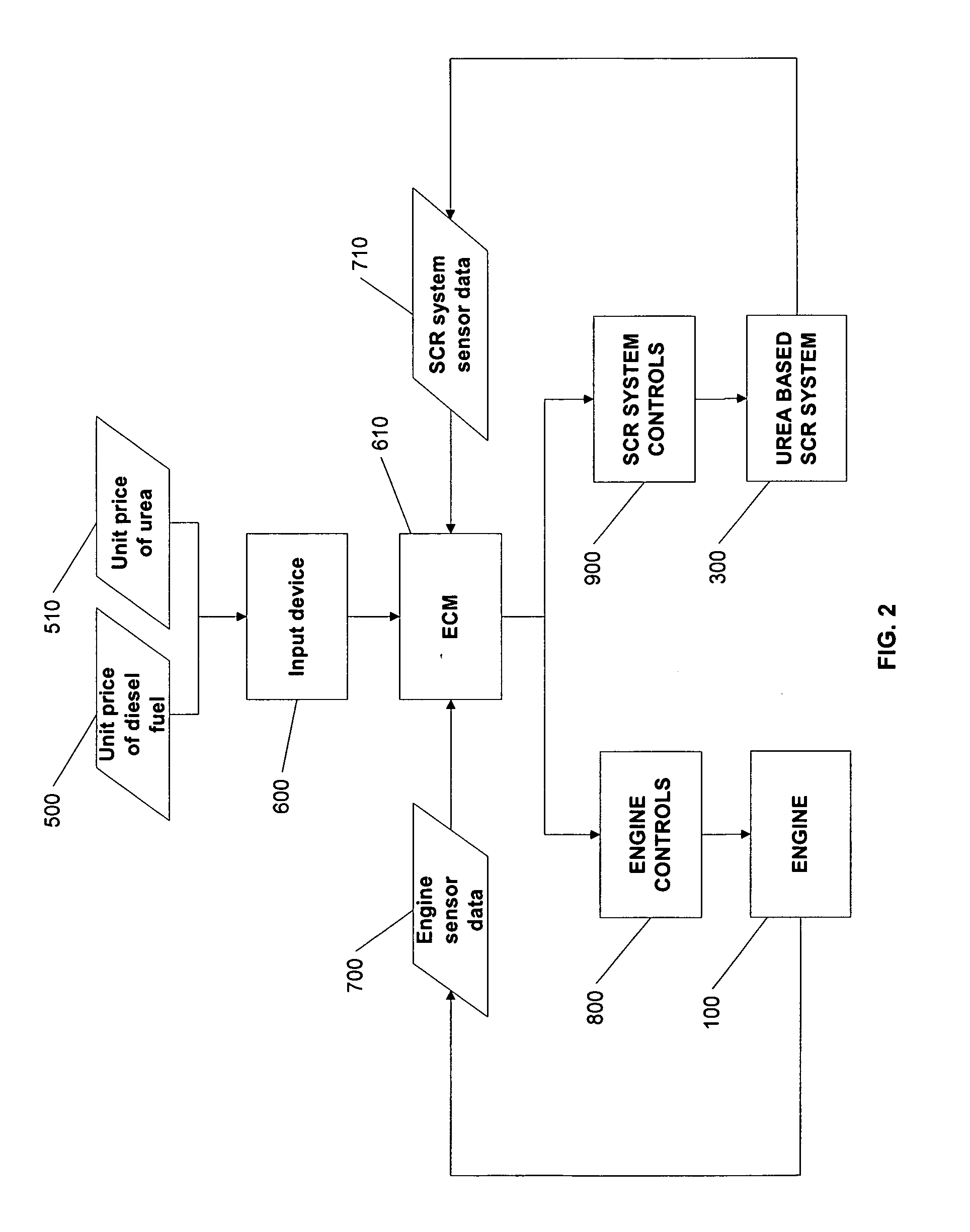

[0029]Engine controllers, such as ECM's, currently do not account for the monetary cost of operating the engine and the monetary cost of operating an after-treatment system. More specifically, price inputs for fuel and reductants, such as urea, are not currently specified for ECM algorithms. As a result, no ECM's, or the vehicles that use them, are able to dynamically adjust the use of fuel and reductants, such as urea, to achieve cost-effective operation of the vehicle while complying with emissions regulations.

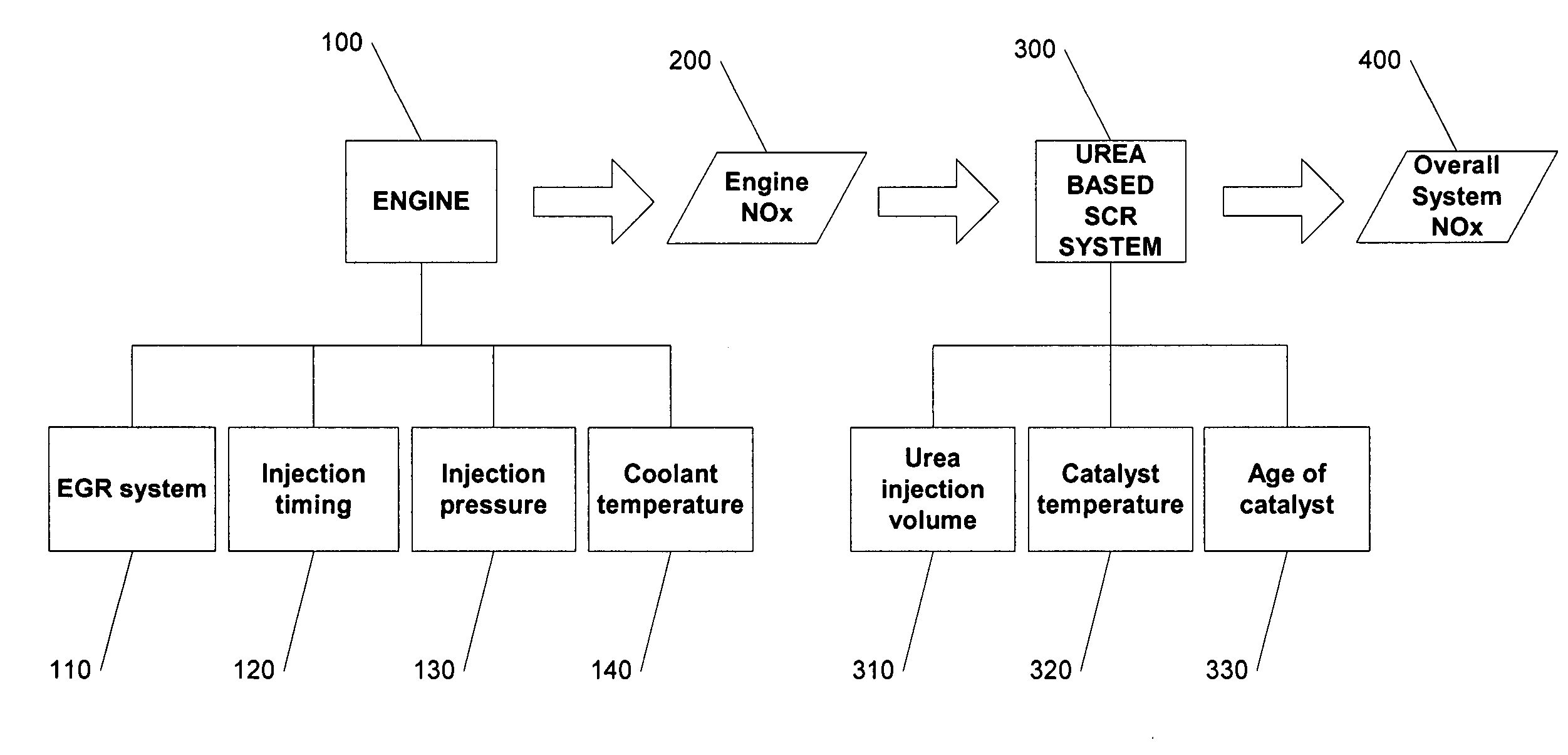

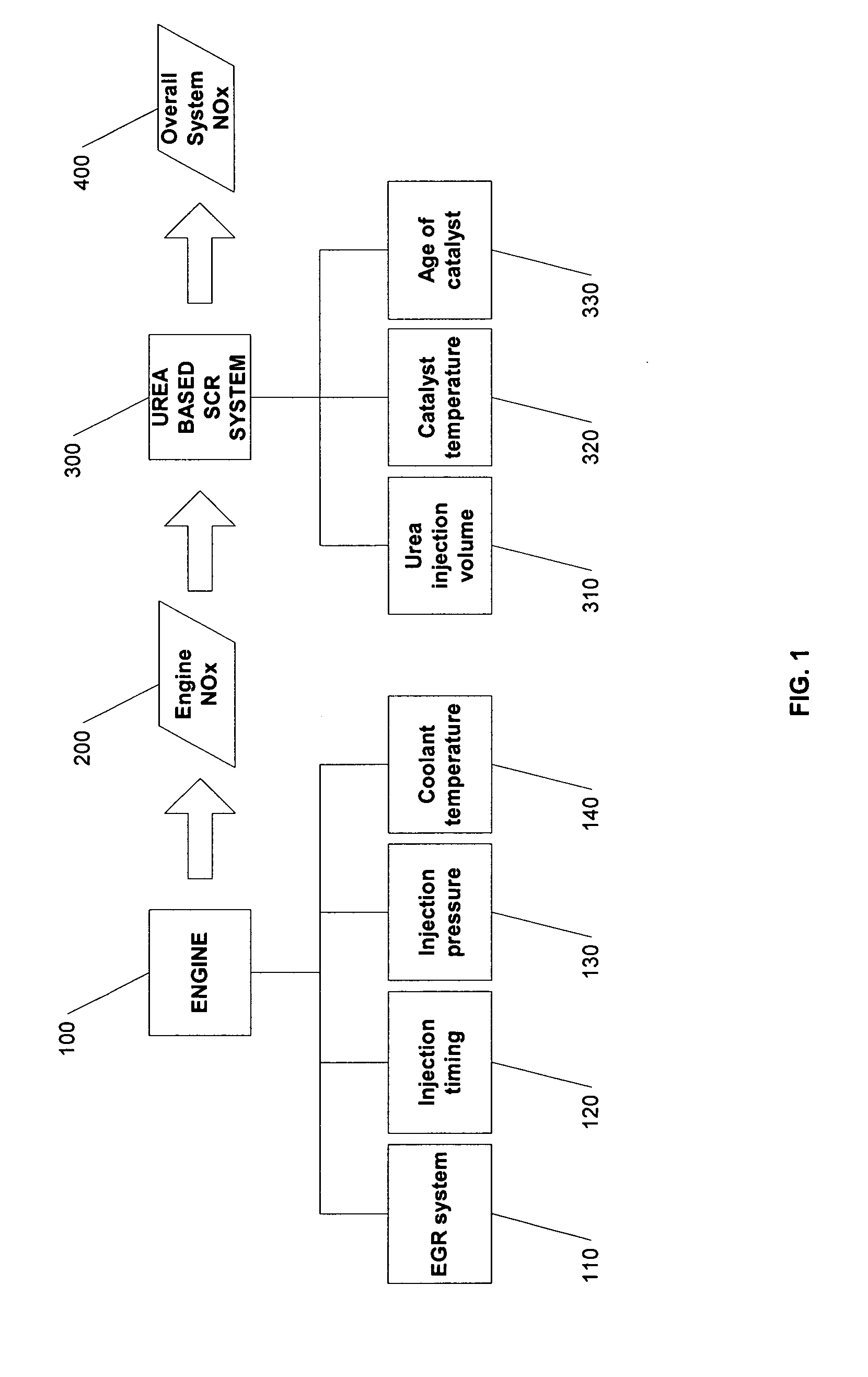

[0030]The following presents a detailed description of a system and method that determines the optimal operating parameters for an engine and an emissions after-treatment device according to the cost of operating the engine and the after-treatment device. To demonstrate the features of the present invention, the present invention is discussed in terms of an exemplary embodiment implementing an ECM to reduce total NOx exhaust emissions from a diesel engine by determining appropr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap