Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Naphthalene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Naphthalene is an organic compound with formula C₁₀H₈. It is the simplest polycyclic aromatic hydrocarbon, and is a white crystalline solid with a characteristic odor that is detectable at concentrations as low as 0.08 ppm by mass. As an aromatic hydrocarbon, naphthalene's structure consists of a fused pair of benzene rings. It is best known as the main ingredient of traditional mothballs.

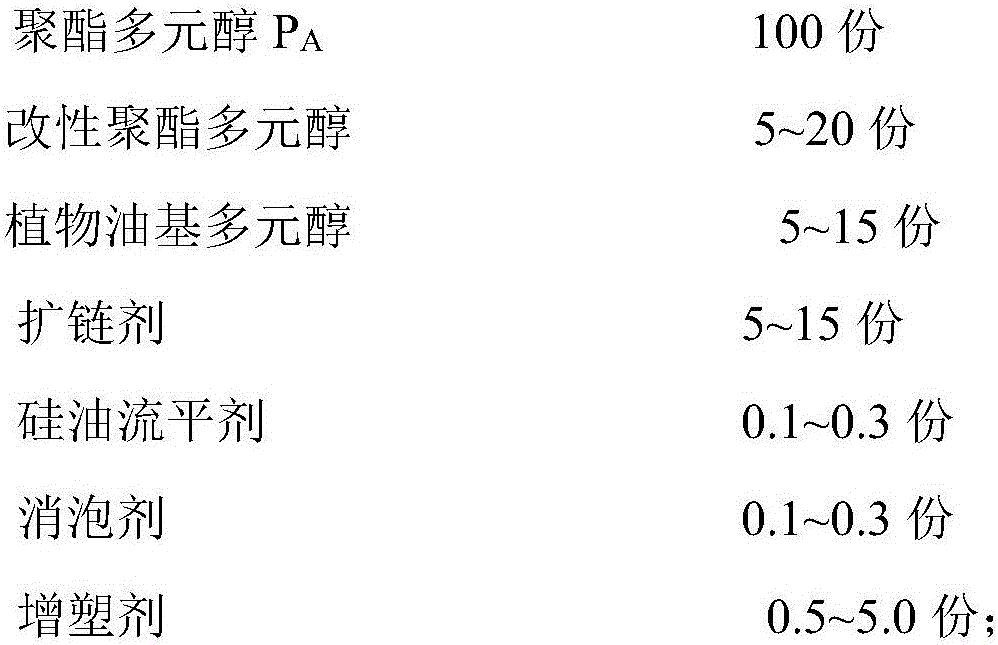

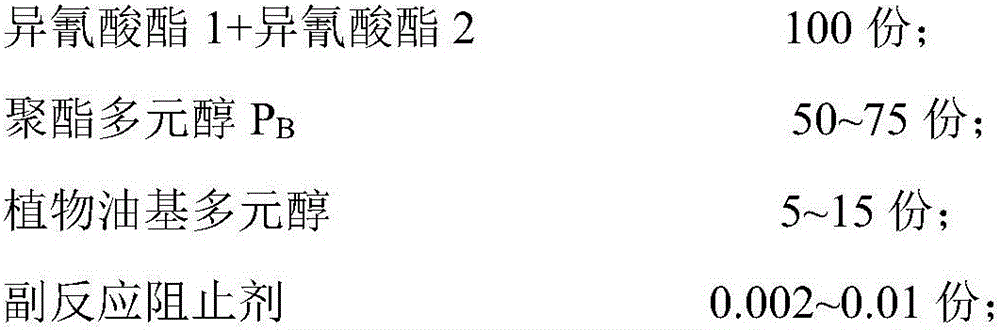

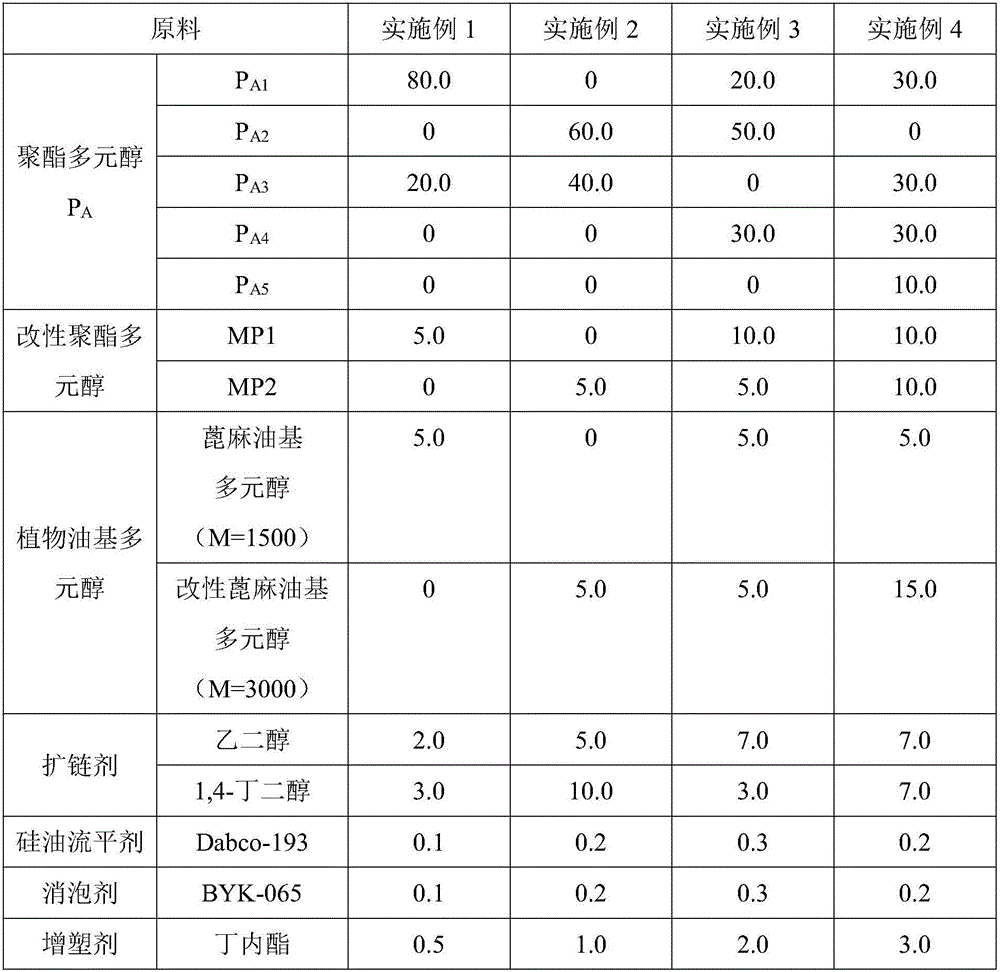

Environment-friendly polyurethane adhesive, and preparation method and applications thereof

ActiveCN106634778AOrderly rowsGood physical propertiesPolyureas/polyurethane adhesivesPolyurethane adhesiveOperability

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

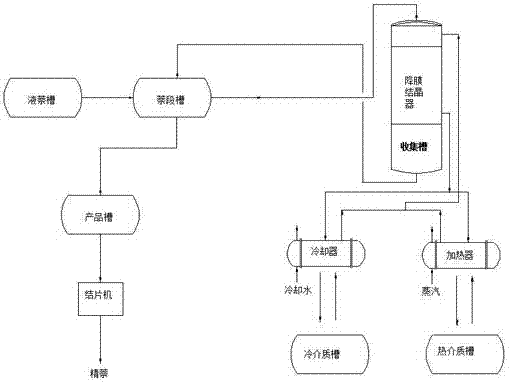

Method for extracting multiple chemical products from coal-tar oil

ActiveCN101139527AIncrease added valueQuality improvementTar working-up by water removalTar working-up by distillationAnthraceneHigh concentration

The invention discloses a method for extracting a plurality of chemicals from a coal tar, which comprises such procedures as heating the coal tar to 120-130 DEG C, dehydrating, fore running, separating, fine rectifying, and heavy-oil distilling, and getting 95 naphthalene, methyl naphthalene, anthracene oil, asphalt and heavy oil. The invention is of simple process, easy operation, rectifies coal tar several times; the extracted chemical products are of steady quality, the naphthalene is of high concentration, and the asphalt is of good quality. The invention is of low energy consumption, hence improves better the added value in processing coal tar in China.

Owner:ZHEJIANG MEIYANG INTL PETROCHEMICAL MEDICINE DESIGN CO LTD

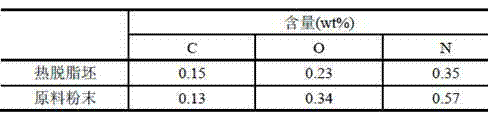

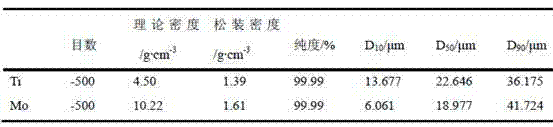

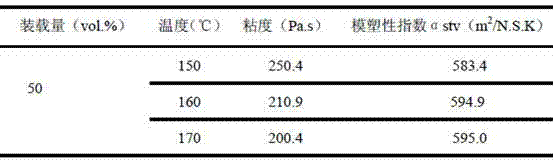

Wax-based binder for compacting process in powder metallurgy as well as preparation method and application thereof

ActiveCN103642253AGood compatibility of ingredientsEfficient mixingPolyethylene vinyl acetateParaffin wax

Owner:HUNAN UNIV

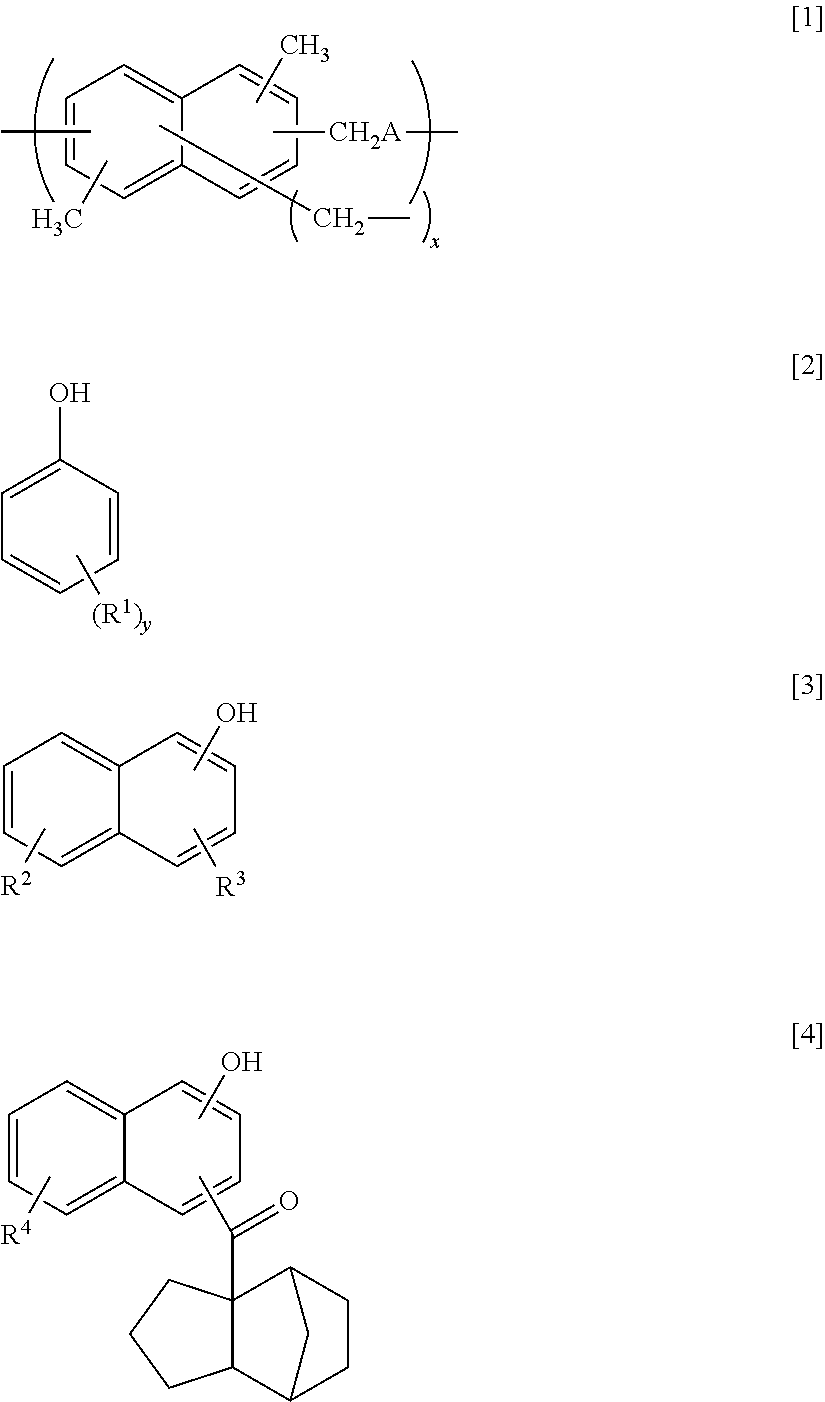

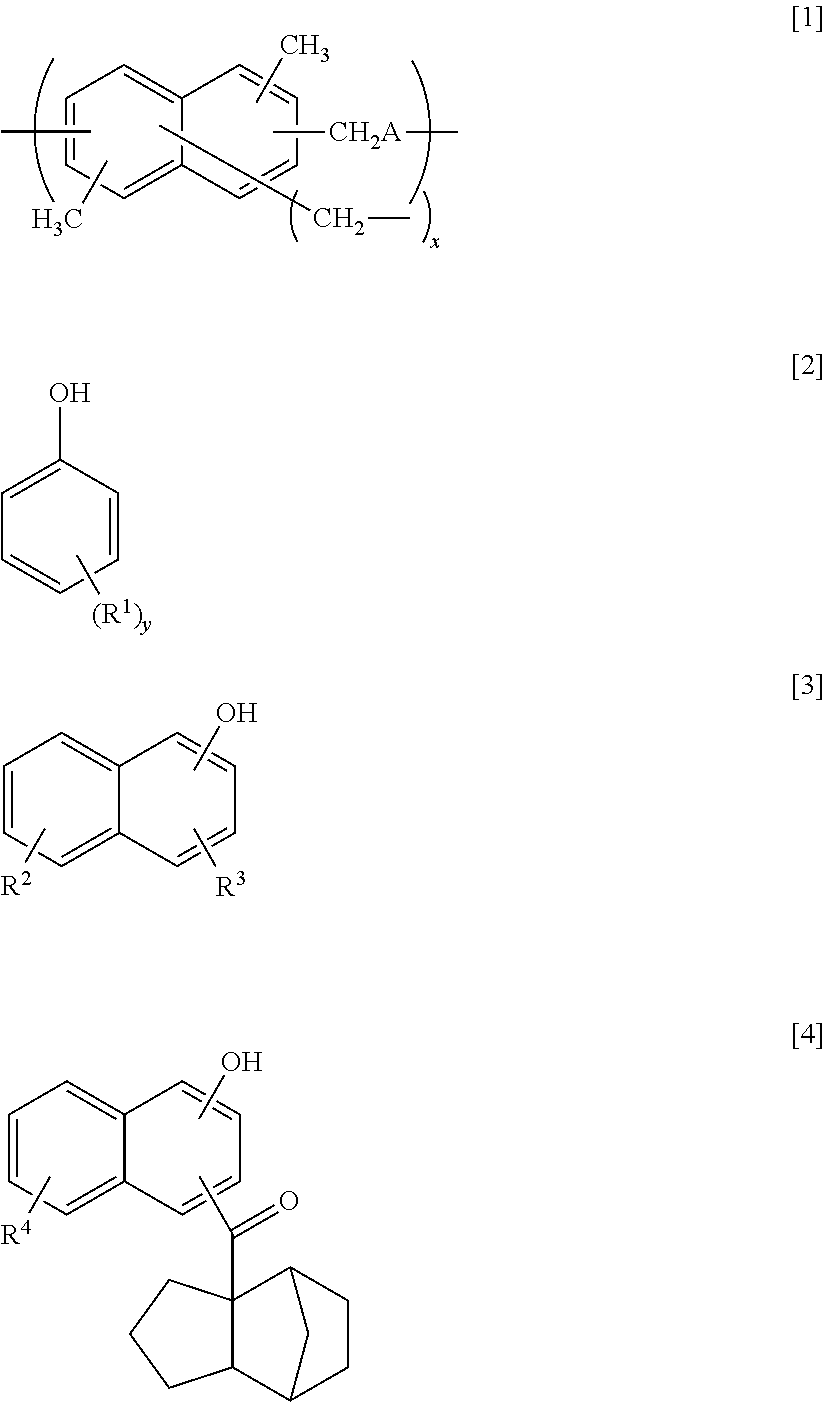

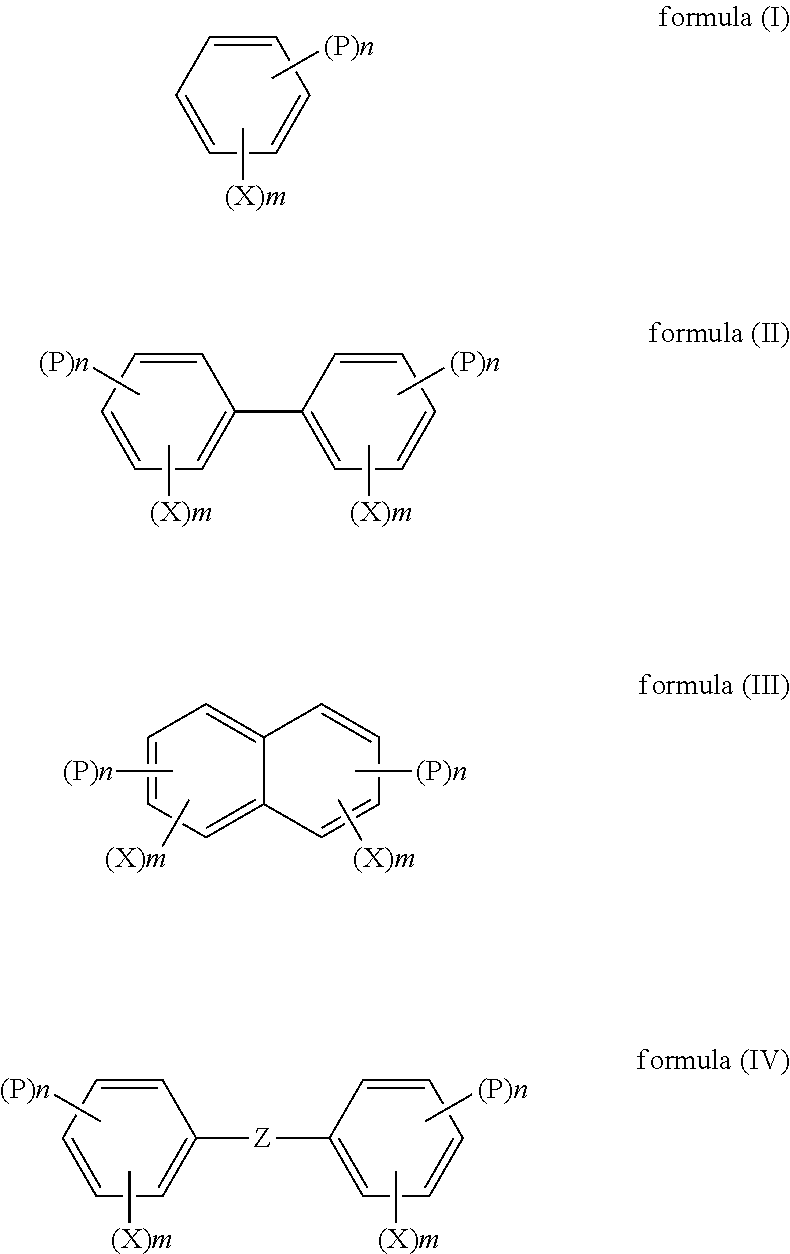

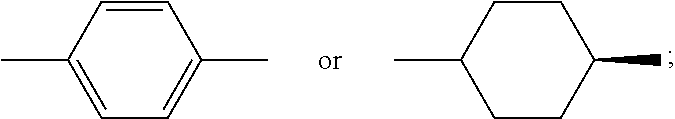

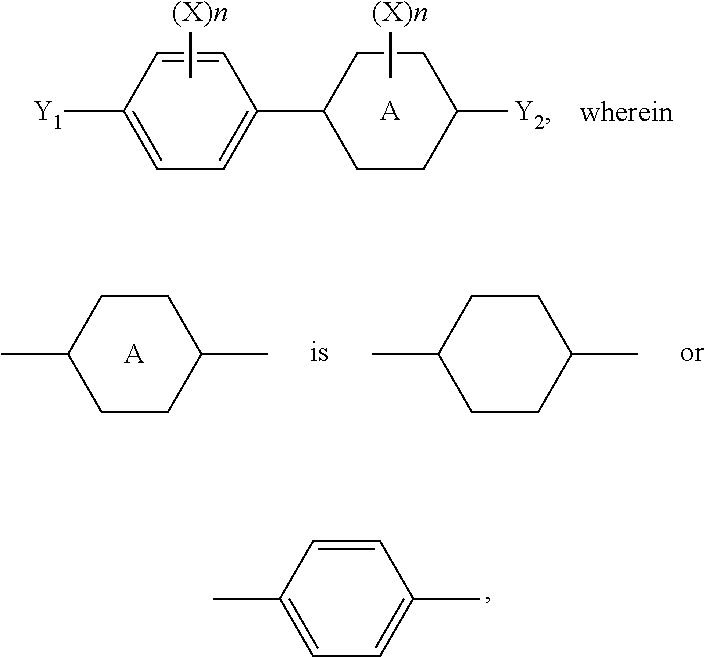

Modified naphthalene formaldehyde resin, tricyclodecane skeleton-containing naphthol compound and ester compound

ActiveUS20110009574A1Improve heat resistancePreparation from carboxylic acid halidesOrganic compound preparationFiberResist

Owner:MITSUBISHI GAS CHEM CO INC

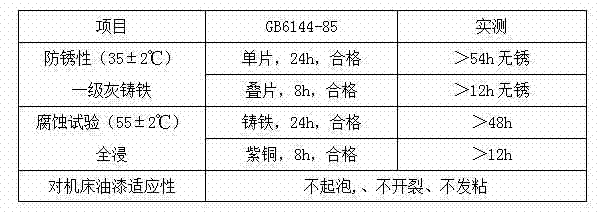

Abrasive-containing emulsifying compound metal cutting solution and preparation method thereof

ActiveCN104120020AExcellent lubricating and anti-wear propertiesImprove the lubrication effectLubricant compositionWater basedSodium metasilicate

Owner:山东斯瑞药业有限公司

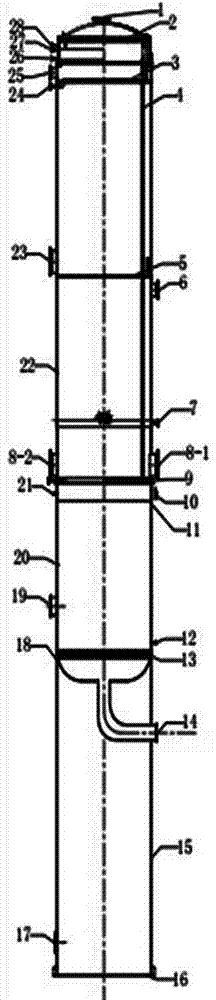

Dynamic crystallizer and processing process for producing high-purity refined naphthalene by utilizing same

PendingCN106890475APromote formationReduce distanceChemical industrySolution crystallizationDistributorEnergy consumption

Owner:兖矿科蓝凯美特化工有限公司

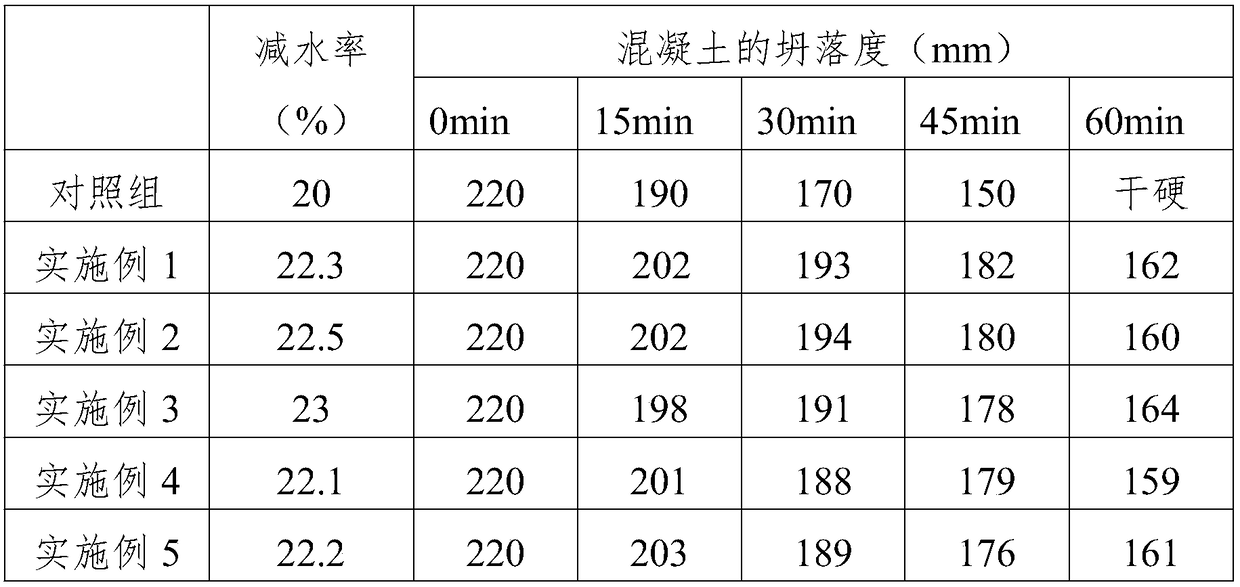

Method for preparing modified naphthalene-based superplasticizer from heavy fraction obtained in production process of ethyl alcohol

Owner:萧县沃德化工科技有限公司 +1

Medicament for preventing and controlling plant virus disease

InactiveCN101317577BPromote verticalPromotes horizontal divisionBiocidePlant growth regulatorsDiseasePropolis

Owner:TAIAN XIANHE AGRI TECH INST

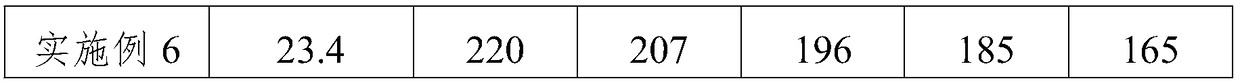

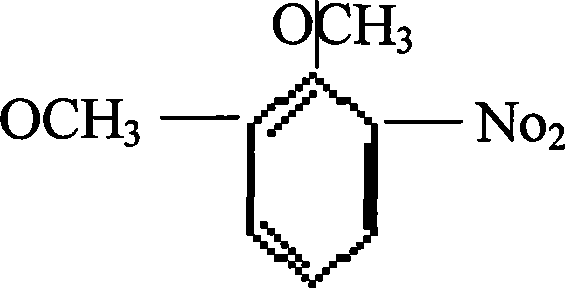

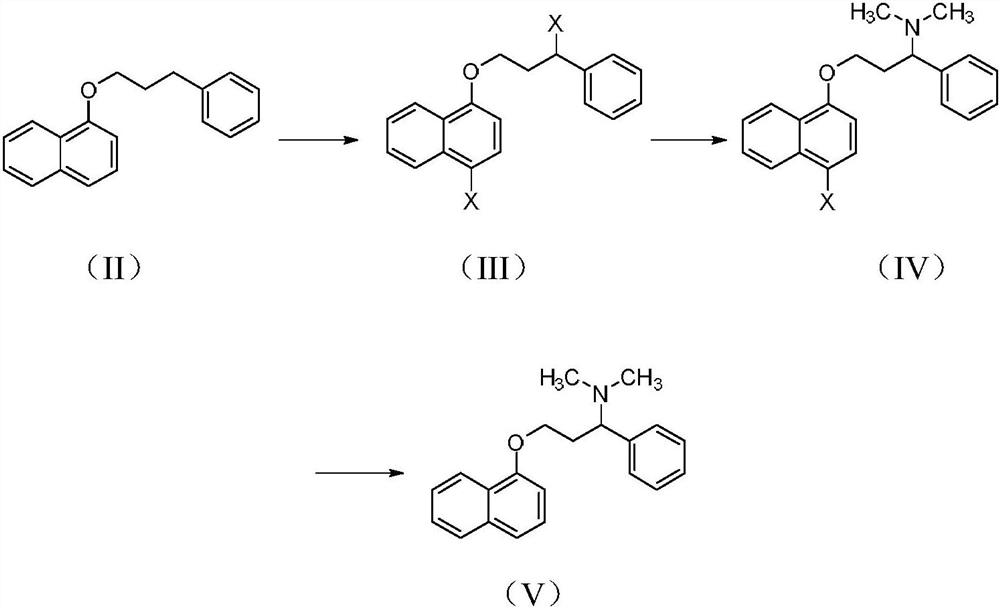

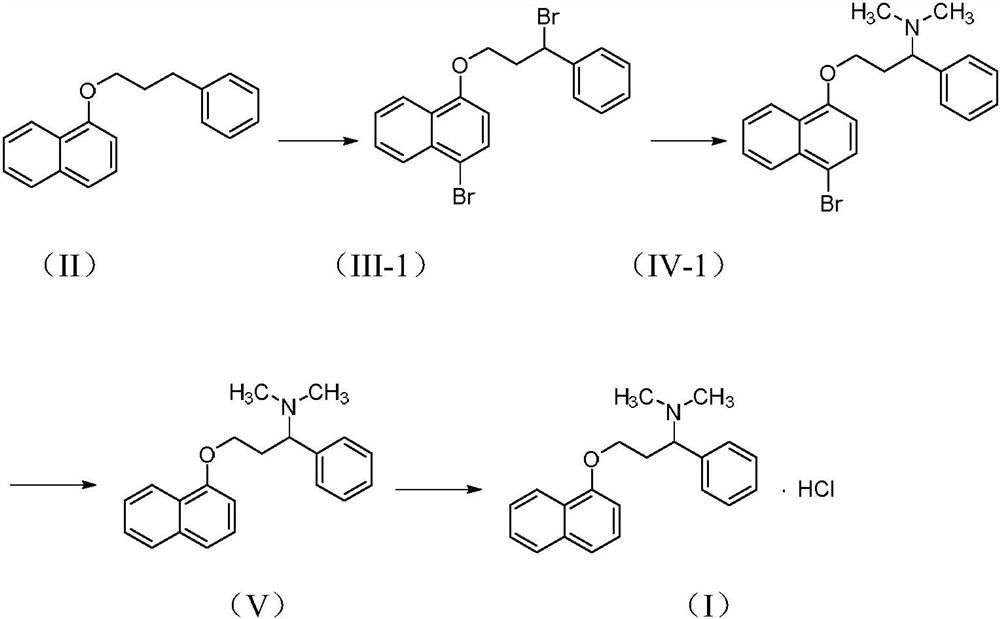

Preparation method of dapoxetine hydrochloride racemate

InactiveCN111646910AHigh yieldEasy post-processingOrganic compound preparationAmino-hyroxy compound preparationDapoxetine-N-oxideMedicinal chemistry

Owner:CHINA PHARM UNIV

Tunnel boring method

A process of boring a tunnel using an earth-pressure balance shield boring tunnelling machine having a cutting head, an excavation chamber for soil removed by boring and conveying means for removal of said soil from the excavation chamber; wherein there is injected into a stratum being bored at the cutting head a foamed aqueous solution, characterised in that (a) the aqueous solution contains two essential components which are (i) a sulphate- or sulphonate-containing anionic surfactant, and (ii) beta -naphthalene sulphonate-formaldehyde condensate; and in that (b) there is applied to the soil removed by boring in at least one of the excavation chamber and the conveyor a second aqueous solution containing essentially a high molecular weight polyethylene oxide and optionally a sulphate- or sulphonate-containing anionic surfactant. The process allows easy removal of soil from the cutting head to the excavation chamber and from the excavation chamber out of the machine. It is particularly effective for sticky soils with high proportions of clay and a high water content.

Owner:CONSTR RES & TECH GMBH

Liquid crystal composition and liquid crystal display panel thereof

InactiveUS20140293204A1Good optical performanceIncrease contrastLiquid crystal compositionsNon-linear opticsCrystallographyReaction rate

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

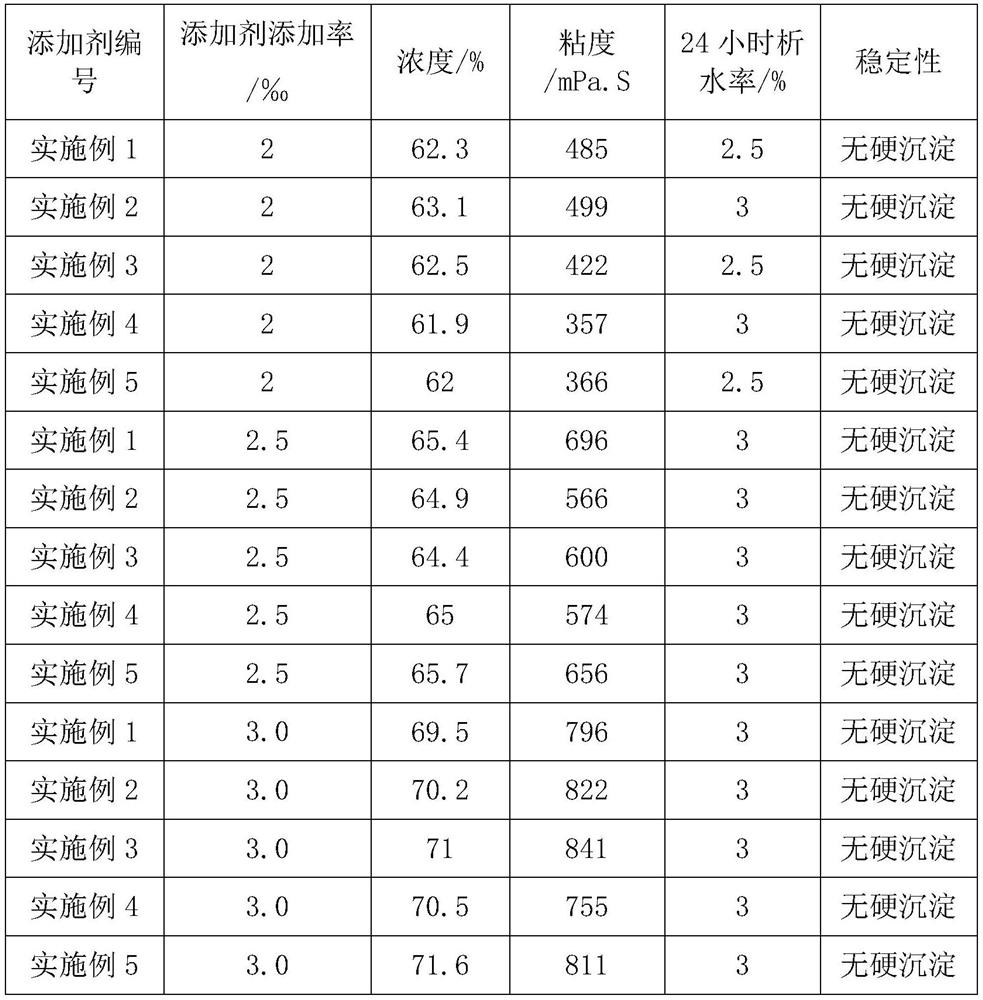

Method for producing high-sulfur petroleum coke slurry additive

PendingCN114540088AIncrease the concentration of char slurryEfficient use ofLiquid carbonaceous fuelsCelluloseSodium hydrogen sulphite

Owner:浙江石油化工有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap