Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Coal tar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used on the hair/scalp to treat dandruff and other scaly, itchy skin conditions (psoriasis or seborrheic dermatitis).

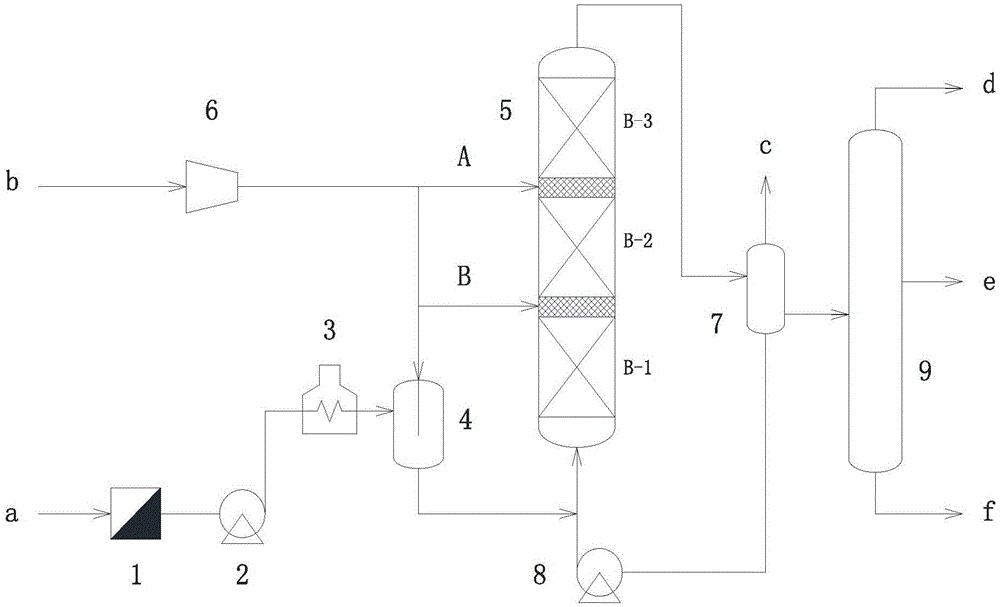

Method for extracting multiple chemical products from coal-tar oil

ActiveCN101139527AIncrease added valueQuality improvementTar working-up by water removalTar working-up by distillationAnthraceneHigh concentration

The invention discloses a method for extracting a plurality of chemicals from a coal tar, which comprises such procedures as heating the coal tar to 120-130 DEG C, dehydrating, fore running, separating, fine rectifying, and heavy-oil distilling, and getting 95 naphthalene, methyl naphthalene, anthracene oil, asphalt and heavy oil. The invention is of simple process, easy operation, rectifies coal tar several times; the extracted chemical products are of steady quality, the naphthalene is of high concentration, and the asphalt is of good quality. The invention is of low energy consumption, hence improves better the added value in processing coal tar in China.

Owner:ZHEJIANG MEIYANG INTL PETROCHEMICAL MEDICINE DESIGN CO LTD

Directional pyrolysis method of combustible wastes

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Process for selectively dealkylating aromatic compounds

A process for selectively dealkylating aromatic compounds includes providing a coal tar stream comprising aromatic compounds and hydrotreating the coal tar stream to reduce a concentration of one or more of organic sulfur, nitrogen, and oxygen in the coal tar stream, and to hydrogenate at least a portion of the aromatic compounds in the coal tar stream. The process further includes hydrocracking the hydrotreated coal tar stream to further hydrogenate the aromatic compounds and to crack at least one ring of multi-ring aromatic compounds to form single-ring aromatic compounds. The single-ring aromatic compounds present in the hydrocracked stream are then dealkylated to remove alkyl groups containing two or more carbon atoms.

Owner:UOP LLC

Pulverization-free, dampness-resistant, coke tar-free biomass gasification oven preventing burning out

InactiveCN101240904AWide variety of sourcesWon't clogProductsDomestic stoves or rangesBiomass gasifierOxygen

Owner:沈桀

Preparation method of hydrogenation catalyst

ActiveCN103769147AReasonable hole structureSurface acidity is suitableCatalyst carriersTreatment with hydrotreatment processesPore distributionCombined method

Owner:CHINA PETROLEUM & CHEM CORP +1

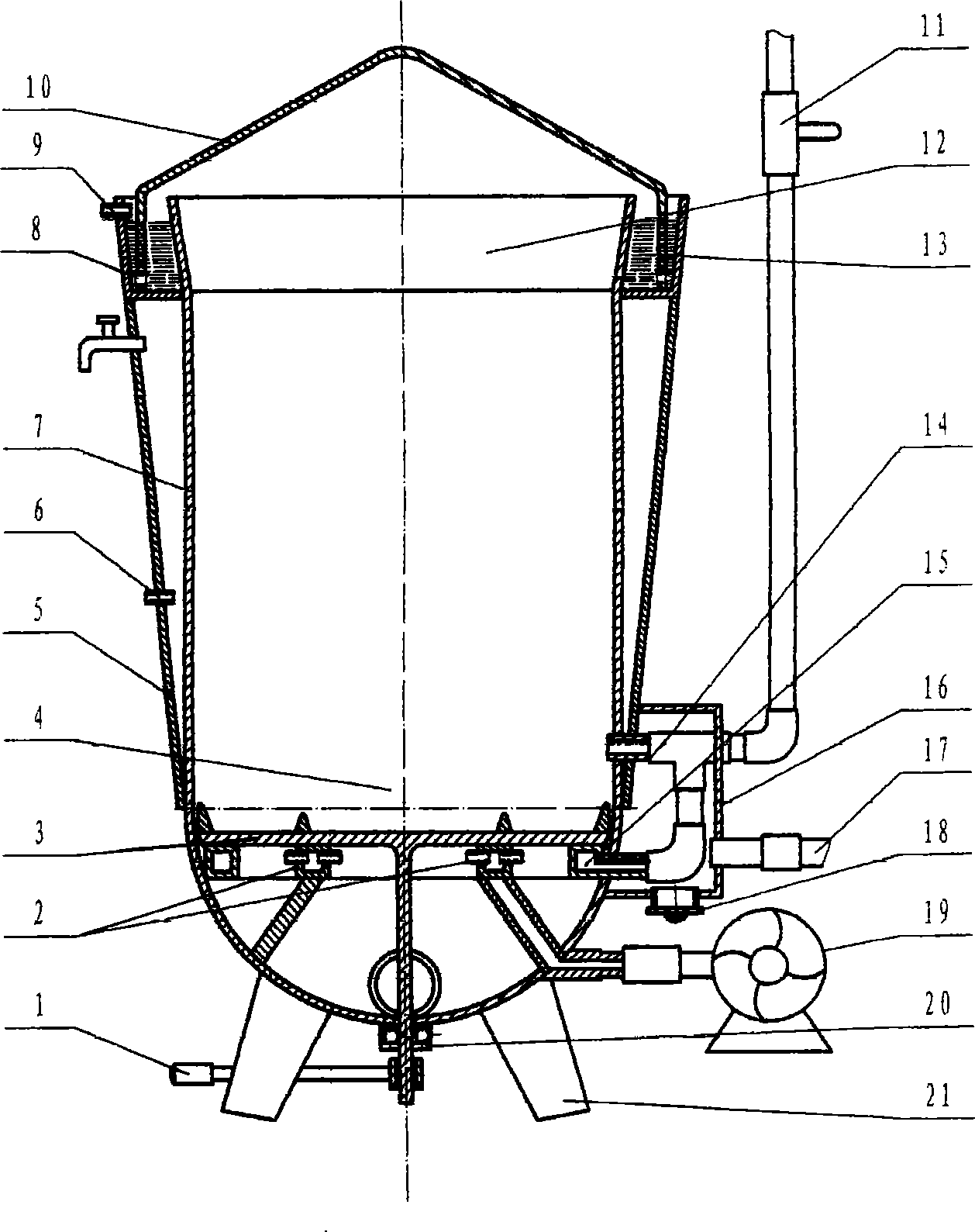

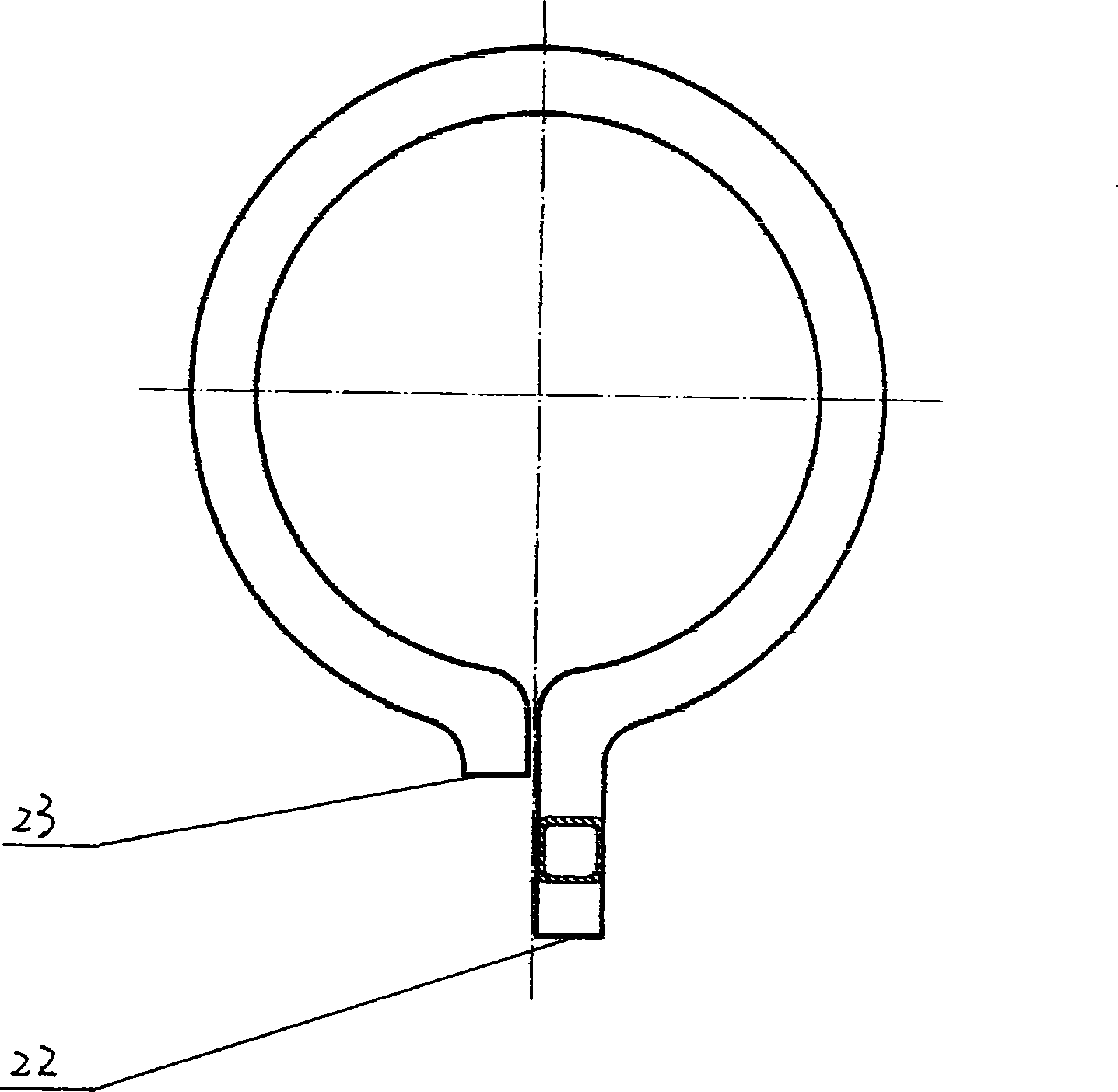

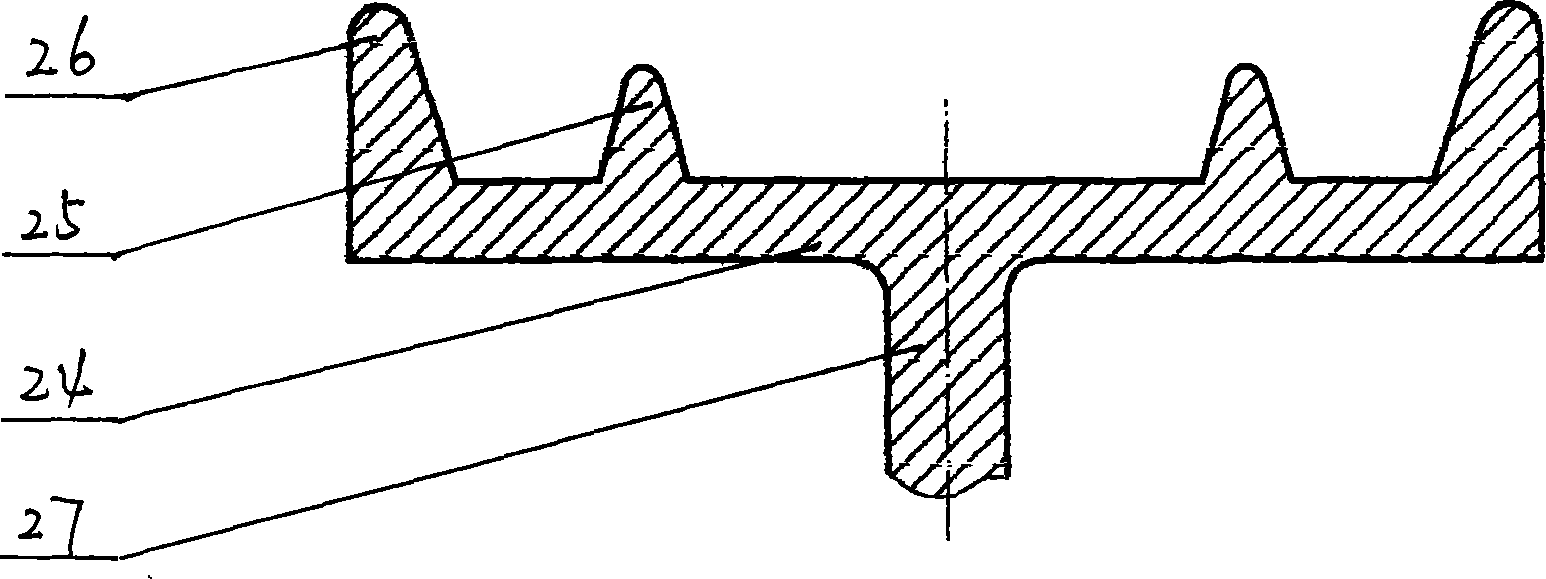

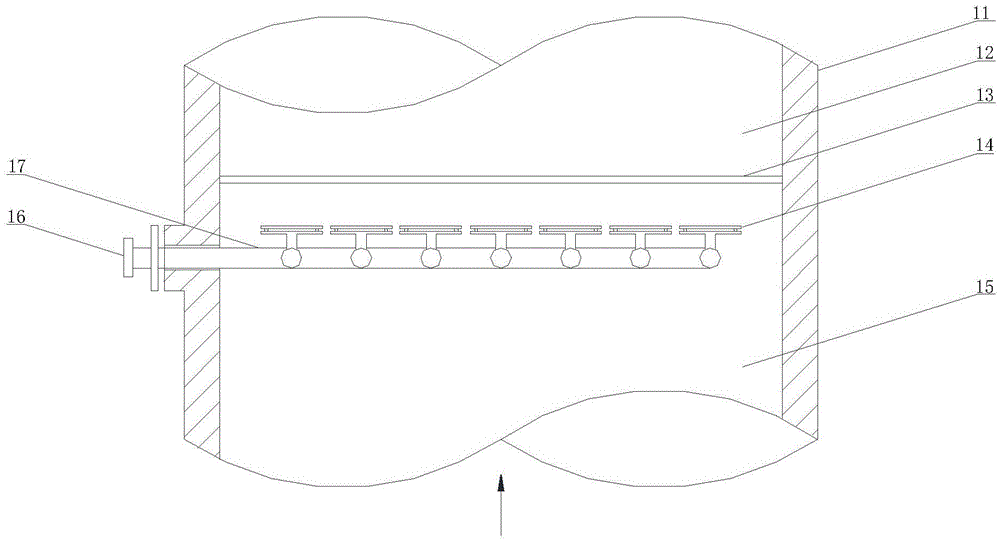

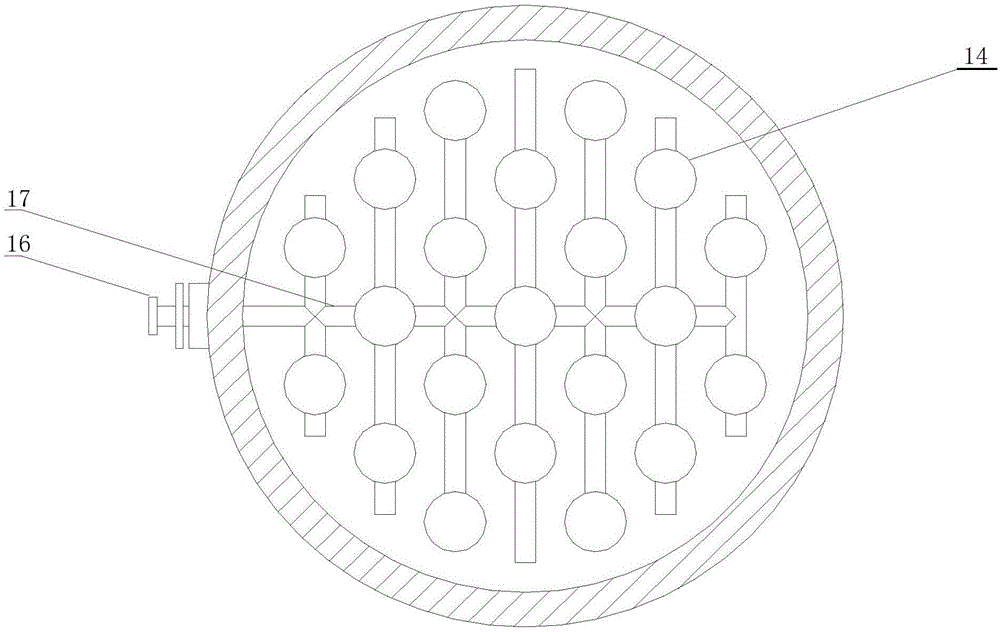

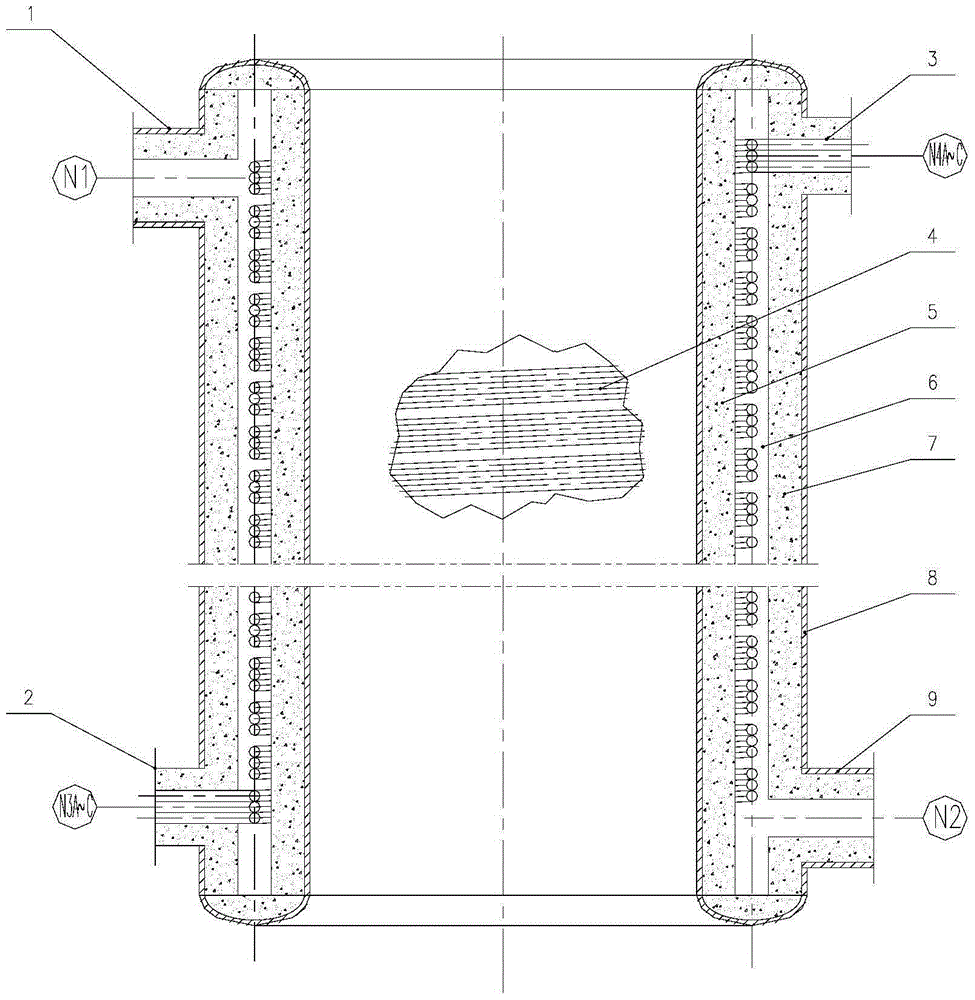

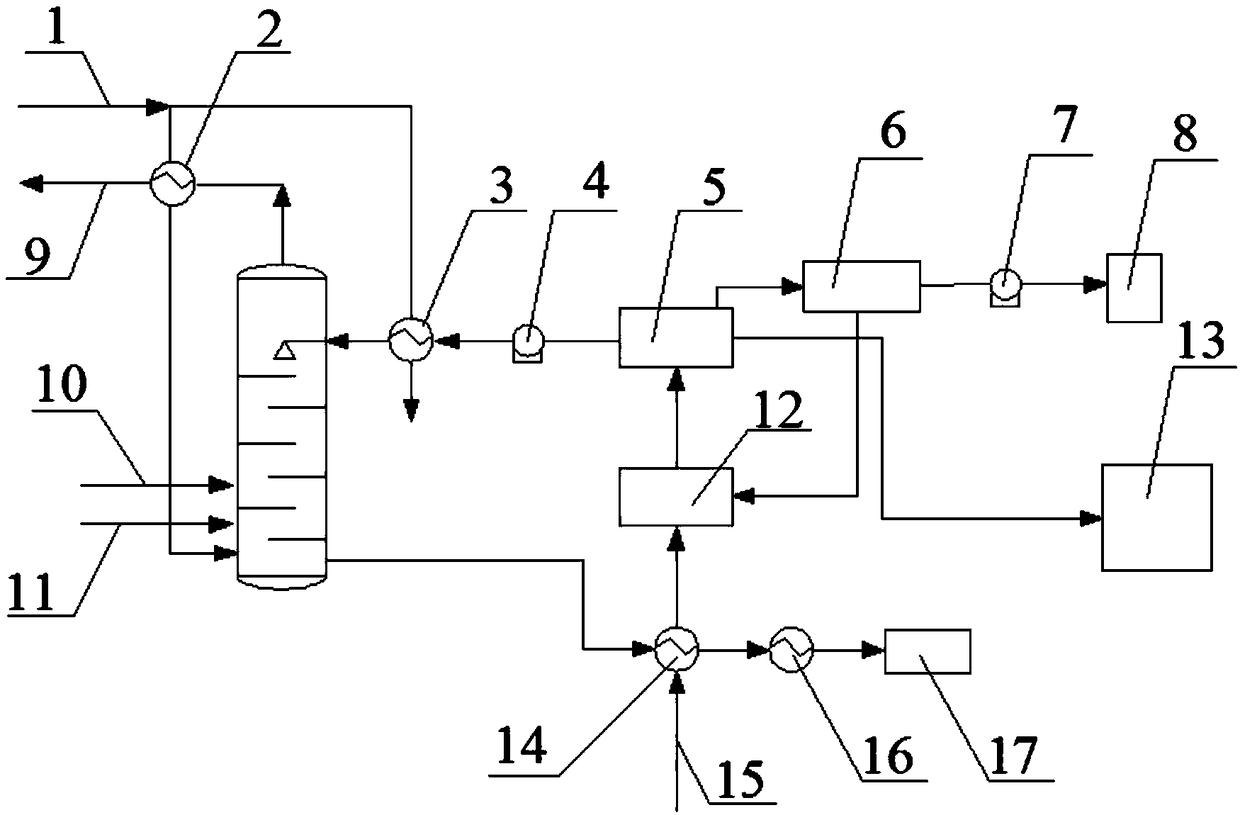

Coal tar all-fraction liquid-phase hydrogenation system and method

InactiveCN105087066AImprove internal space utilizationLess investmentTreatment with hydrotreatment processesHydrogenPre treatment

Owner:SHAANXI MEISILIN ENERGY SCI & TECH RES INST

Water-proof roof glue

InactiveCN101225288AImprove waterproof and thermal insulation performanceGood weather resistanceBituminous material adhesivesHydrocarbon polymer adhesivesAdhesivePolystyrene

The invention relates to a building waterproof material, in particular to a waterproof roof adhesive, which aims to solve the problems in prior roof waterproof material of poor weatherability, easy bubbling and peeling, and poor permeability and air permeability, comprising asphalt, coal tar, waste polystyrene foam, lime and sawdust. Firstly, the waste polystyrene foam is ground to particles; secondly, the coal tar is added into a vessel and heated to 650 to 700 degrees; and the asphalt is added into the vessel, and then the former mixture is agitated homogeneously and keep on warming up to 750 degrees, after the asphalt is dissolved, the mixture is cooled to 400 to 500 degrees; at last, waste polystyrene foam, lime and sawdust are added into mixture successively, the mixture is agitated homogeneously and cooled to a paste shape, and then the finished product is obtained. The building waterproof material has the advantages that: the building waterproof material integrates the advantages of waterproof, heat preservation and heat insulation and has admirable waterproof and heat preservation effect, good weatherability, no fluid and cracks, high adhesive strength; meanwhile, the material meet the national specified standard; more importantly, the aim of waste reuse, pollution treatment, environment protection and cost saving are realized by using the waste polystyrene foam.

Owner:亢吉田

Data obtaining method and electronic cigarette

InactiveCN110169595AIncrease or decrease intake substance parametersEasy to controlTobacco devicesTarElectronic cigarette

The invention discloses a data obtaining method and an electronic cigarette. The data obtaining method comprises the steps that the time, the temperature and the concentration of tobacco tar sucking of a cigarette holder are obtained under the situation that tobacco tar in an electronic cigarette body is atomized; the time, the temperature and the concentration are determined as intake substance parameters; and the intake substance parameters are sent to a data processing terminal. Through the data obtaining method and the electronic cigarette, the technical problems that in the prior art, tobacco tar is stilled generated when the tobacco tar burns, and the intake amount of the tobacco tar cannot be monitored are solved.

Owner:JOUZ LTD

Coil pipe type coal pyrolysis device

ActiveCN105219410AIndirect heating destructive distillationSpecial form destructive distillationCoal pyrolysisCoal tar

Owner:CHANGZHENG ENG

Emission technology of vapor containing nitrogen oxide and tar

ActiveCN108854458AImprove the efficiency of absorbing harmful components in exhaust gasPrevent control failure problems caused by errorsGas treatmentDispersed particle separationAtmospheric airExhaust gas emissions

The invention discloses an emission technology of vapor containing nitrogen oxide and tar. The emission technology comprises the following steps: opening a cutoff valve, a circulating water pump and an exhaust fan, wherein the circulating water pump starts a water circulation process; opening a discharging valve and releasing calcium hydroxide into water in a stepped overflow pool, and opening thedischarging valve when the pH value of the water in the stepped overflow pool is smaller than or equal to 8.0; closing the discharging valve when the pH value of the water in the stepped overflow pool is greater than or equal to 8.7; when an adjustment target is to prevent haze and the temperature of exhaust gas is greater than or equal to 90 DEG C, stopping the temperature-regulating operation;opening the temperature-regulating operation again when the temperature of the exhaust gas is smaller than 80 DEG C; stopping the temperature-regulating operation again when the adjustment target is to prevent thermal pollution and the difference value between the temperature of the exhaust gas and the atmospheric temperature is smaller than 3 DEG C; opening the temperature-regulating operation when the difference value between the temperature of the exhaust gas and the atmospheric temperature is greater than 6 DEG C. The emission technology disclosed by the invention can efficiently remove sulfur dioxide and nitrogen oxide from water, the weak alkalinity of water is maintained on the premise of ensuring safety and the emission temperature of the exhaust gas is correspondingly controlled according to different adjustment targets.

Owner:HENAN SONGYUE CARBON

Flame-retardant ethylene propylene diene monomer

Owner:佛山市高明区生产力促进中心

Gas liquor purification treatment system after coal gasification

PendingCN108911345AReduce contentReduce pollutionWater treatment parameter controlFatty/oily/floating substances removal devicesEngineeringImpurity

Owner:SHANXI HEIMAO JIAOHUA CO LTD

Filter Cigarette Holder

InactiveUS20180360105A1Increasing the thicknessIncrease airflowCigarette manufactureTobacco smoke filtersFiltrationTar

This invention relates to a filtering device for use with cigarettes and other smoking products. Embodiments of the invention include a cigarette holder equipped with pressure filtering. Embodiments may be smaller than about 20 mm, include a separate semi-closed collection chamber to prevent “backwash” of tar which would otherwise occur due to the filter's small size, require less material than current cigarette filters, enable more effective filtration, increase filter capacity for holding tar, and provide additional benefits resulting from the greater likelihood of use by smokers. Another embodiment would include the replacement of the plastic casing with paper, creating a filter made mostly of naturally biodegradable material.

Owner:HIGGINS EUGENE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap