Pulverization-free, dampness-resistant, coke tar-free biomass gasification oven preventing burning out

A technology for biomass and gasification furnaces, which is applied in coking ovens, educts, and the petroleum industry. It can solve the problems of inability to input biomass and small furnace openings, improve adaptability and use effects, reduce pollution, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

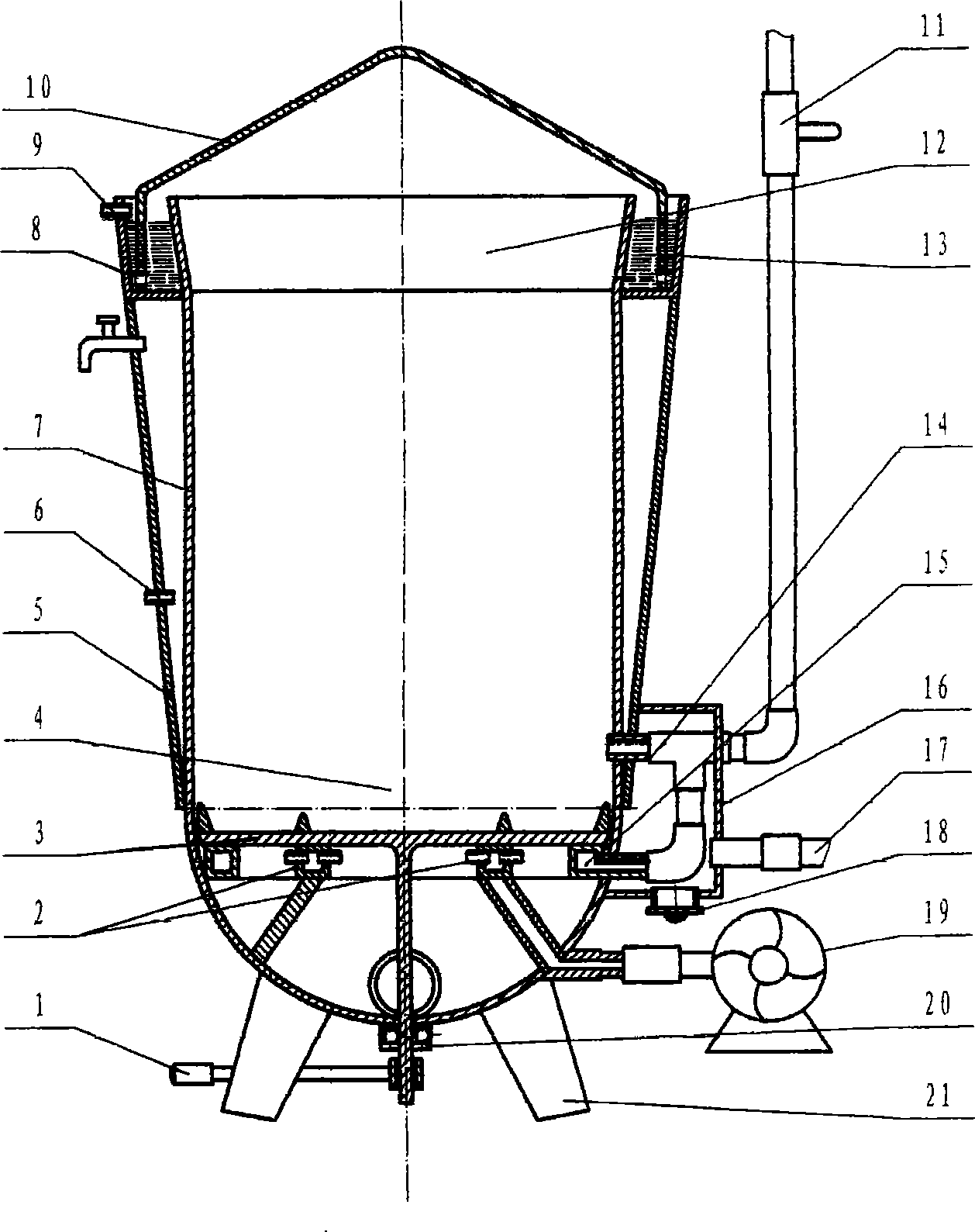

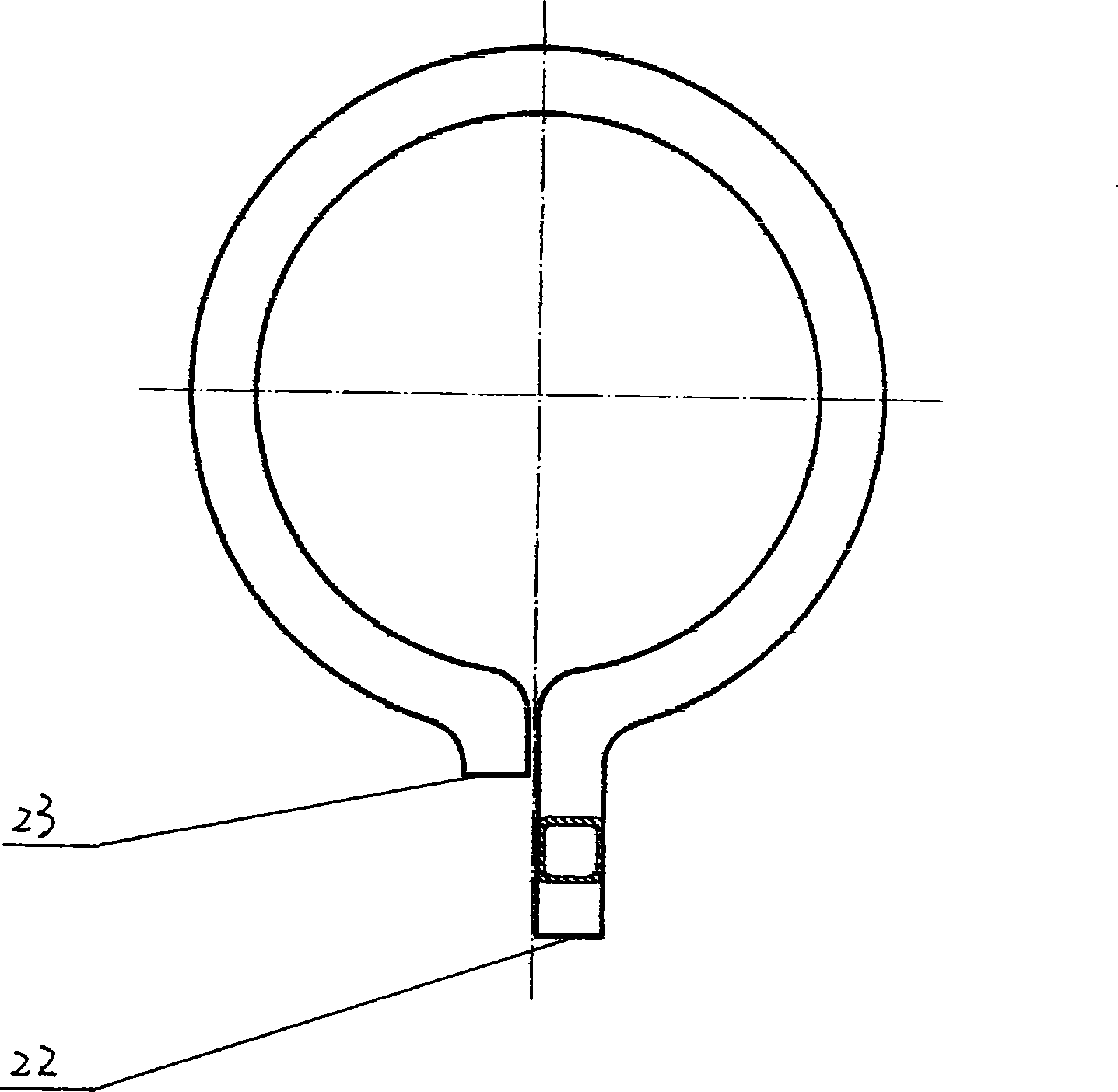

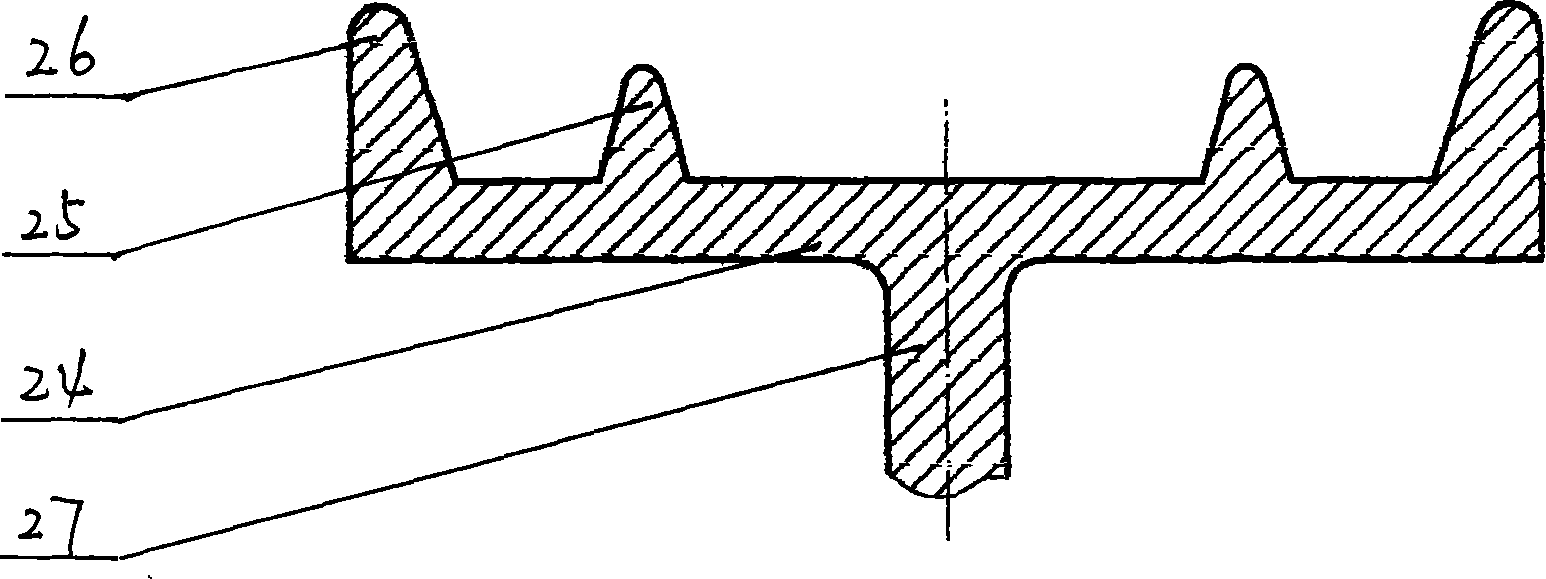

[0018] exist figure 1 Among them, the upper part of the furnace body (7) has a free-open feeding port (12), and there is an annular water tank (13) and a condensed water overflow pipe (9) around the free-open feeding port, and the top is a conical condensed water collecting furnace cover (10), there are many condensed water circulation holes (8) around the bottom, and the lower combustion high-temperature zone (4) of the furnace body is provided with a gas guide port (14) connected to the smoke exhaust valve (11) and the high-temperature gas retention delay The ring road (15), the high-temperature gas retention time-delay ring road is fixed on the lower peripheral wall of the furnace body, and the gas outlet ( figure 2 Middle 23) is set to pass into the gas filter chamber (16), and one end of the annular rotating air inlet device (2) installed on the same plane is fixed on the air inlet pipe connecting the blower fan (19), and the other end is provided with a support column. Th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap