Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Stearic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stearic acid (/ˈstɪərɪk/ STEER-ik, /stiˈærɪk/ stee-ARR-ik) is a saturated fatty acid with an 18-carbon chain and has the IUPAC name octadecanoic acid. It is a waxy solid and its chemical formula is C₁₇H₃₅CO₂H. Its name comes from the Greek word στέαρ "stéar", which means tallow. The salts and esters of stearic acid are called stearates. As its ester, stearic acid is one of the most common saturated fatty acids found in nature following palmitic acid. The triglyceride derived from three molecules of stearic acid is called stearin.

Wax-based binder for compacting process in powder metallurgy as well as preparation method and application thereof

ActiveCN103642253AGood compatibility of ingredientsEfficient mixingPolyethylene vinyl acetateParaffin wax

Owner:HUNAN UNIV

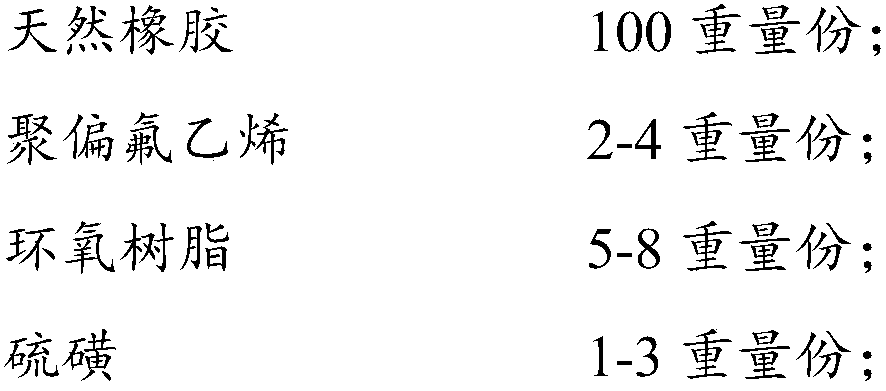

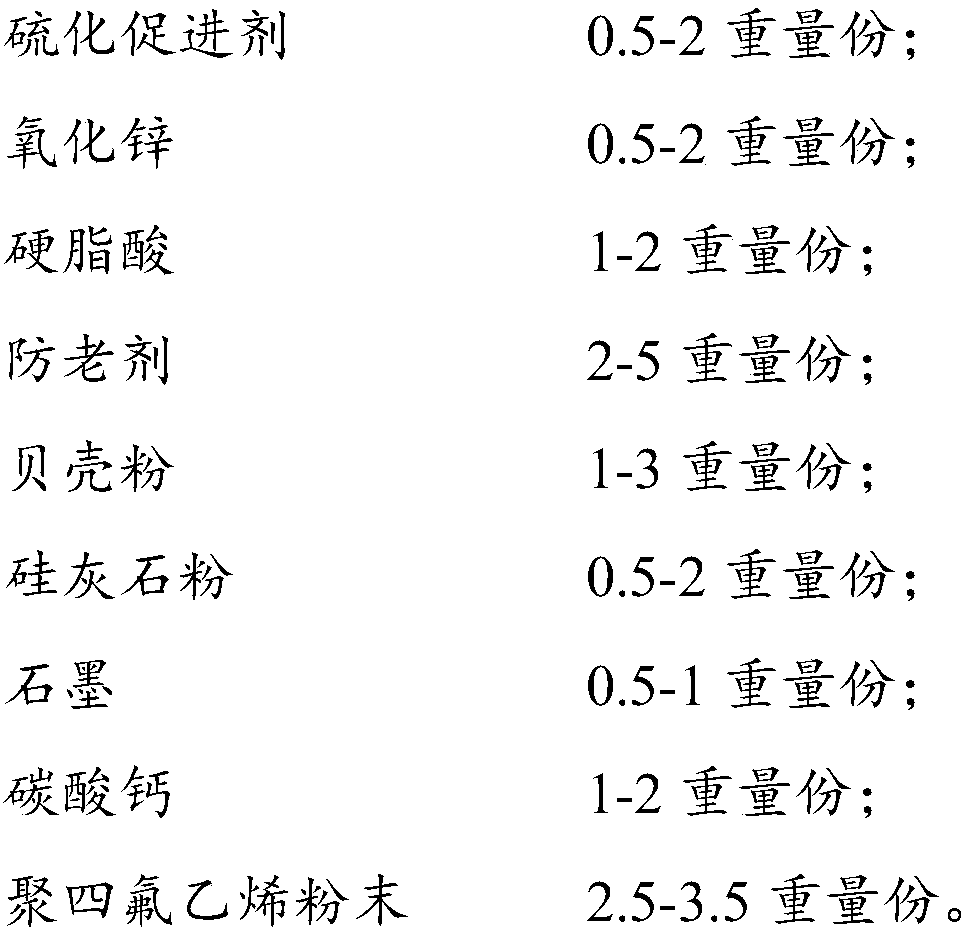

Wear-resistant rubber sole and preparation method thereof

Owner:ANHUI HONGXIANG SHOES

Formula of highly anti-fatigue automobile brake chamber rubber diaphragm material

ActiveCN101302311ASolve the blending problemImprove thermal stabilityPolytetramethylene terephthalateRubber material

The invention provides a rubber material formulation for a high fatigue resistant rubber diaphragm of an automobile brake chamber, which is mainly prepared by natural rubber (NR), styrene butadiene rubber (SBR), polybutylene terephthalate (PBT), vulcanizing agent, zinc oxides, stearic acid, anti-aging agent, dispersant, accelerant, carbon black, aromatic oil and white carbon black. The physical mechanical properties of the rubber diaphragm of the automobile brake chamber prepared by the rubber formulation all reach the novel standard drafted by the Society of Automotive Engineering (SAE) of America; the service life of a platform of the rubber diaphragm reaches over 2 million times; the platform has the advantages of high stress at definite elongation, strength and elongation property, compression fatigue resistivity, flexural deformation resistance and attrition resistance, and maintenance of small variation of the material characteristics within the wide use temperature between 55 and 100 DEG C when the material is used; and the service life of the platform is basically the same as that of an air brake assembly, and resource conservation is greatly promoted simultaneously, thereby realizing conversion of the platform from 'a wearing part' to 'a permanent part'.

Owner:GUIZHOU JINGZHONG RUBBER & PLASTIC IND CO LTD

High-temperature iron-based zeolite molecular sieve honeycomb type denitration catalyst and preparation method thereof

ActiveCN107519926AEvenly dispersedSimple preparation processMolecular sieve catalystsDispersed particle separationFerrous saltsStearic acid

Owner:VALIANT CO LTD

Method of burning gel of stearic acid for preparing Nano LaCo03 in type of perovskite

InactiveCN1915839AOvercome the shortcomings of large particle size and uneven distributionRaw materials are easy to getLithium compoundsCobalt compoundsCombustionNitrate

Owner:ZHONGBEI UNIV

Composite underwater sound transmission rubber material and preparation method thereof

Owner:TIANJIN RUBBER IND RES INST

Factory formula for aging-resistant rubber strip

Owner:JIANGSU DAHAI PLASTIC

High-damping rubber composition and preparation method therefor

InactiveCN105295211AGood vibration dampingGood comprehensive mechanical damping performancePolymer scienceAntioxidant

Owner:ZHEJIANG SHITAI IND CO LTD

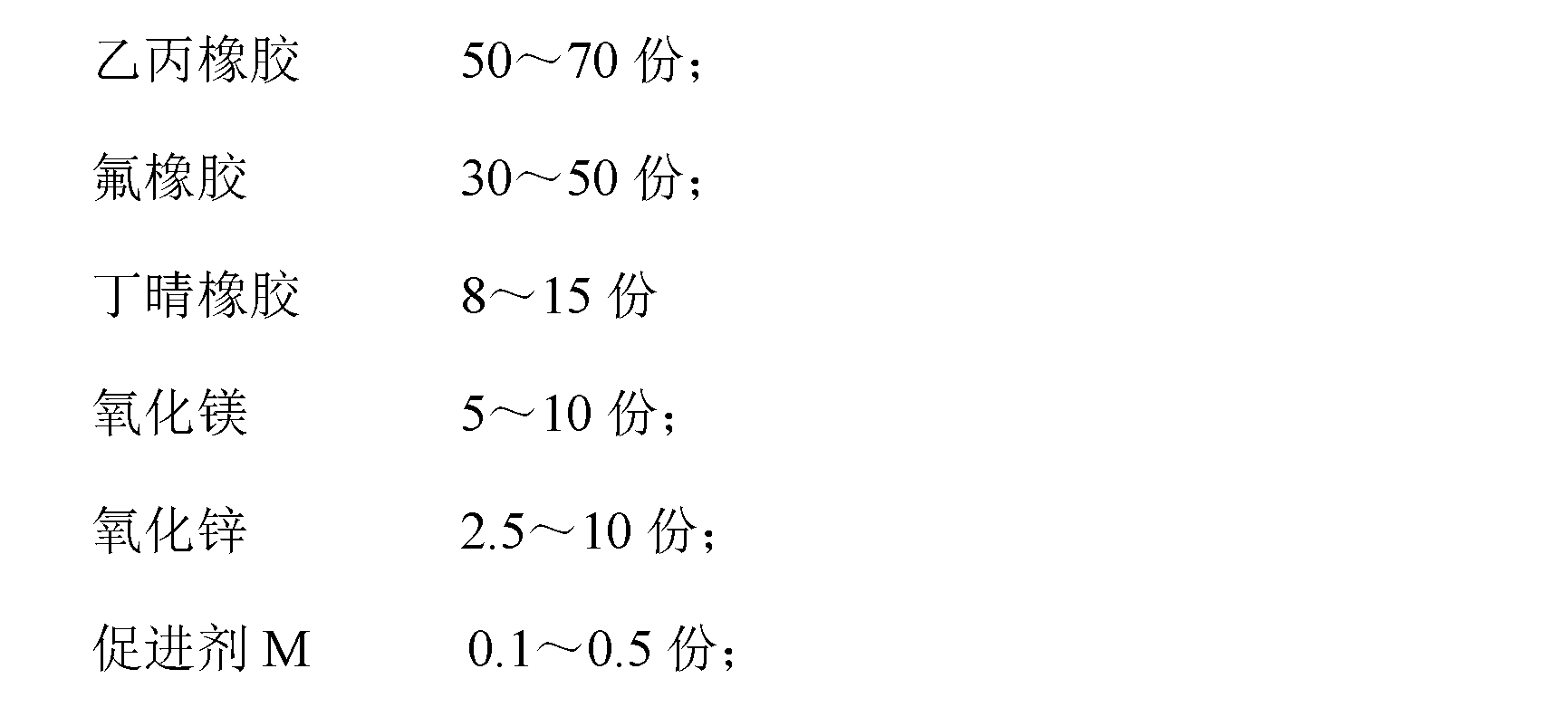

Formula of fluororubber-ethylene propylene rubber mixing rubber compound

ActiveCN103232643AImprove media resistanceImprove low temperature resistancePolymer scienceStearic acid

Owner:扬中市橡胶塑料厂有限公司

Fresh flower preservative and preparation method thereof

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

Temperature-sensitive wall material as well as microcapsule preparation and preparation method thereof

InactiveCN111226922AMany types of drug loadingStabilize each otherBiocideAnimal repellantsPyrrolidinonesGlycerol

Owner:SUZHOU FENGBEI BIOTECH CO LTD

Process for producing polyol fatty acid ester

ActiveCN1683314AStable and reliable productionStable productionOrganic compound preparationCarboxylic acid esters preparationPolyethylene glycolStearic acid

Owner:WENGFU (GRP) CO LTD

Microcapsule Type Thermochromic Pigment and Preparation Method and Use Thereof, Thermochromic Ink and Use Thereof

The disclosure provides a microcapsule type thermochromic pigment and a preparation method and use thereof, and a thermochromic ink and use thereof. The microcapsule type thermochromic pigment provided by the disclosure includes a core material and a wall material wrapping the core material, wherein the core material includes the following components: a leuco dye, a developer and stearic acid 2-[4-(phenylmethoxy)phenyl]ethyl ester, and the wall material is self-emulsifying polyurethane or self-emulsifying epoxy resin.

Owner:WUHAN ZHONGKE ADVANCED MATERIAL TECH CO LTD

Rubber tube and preparation method thereof

ActiveCN104072973AImprove high temperature resistanceImprove low temperature resistancePolymer scienceAntimony trioxide

Owner:LIUZHOU YINGHANG AUTO PARTS

Cracking-resistant iron-base powder metallurgy material used for valve and preparation method of cracking-resistant iron-base powder metallurgy material

The invention discloses a cracking-resistant iron-base powder metallurgy material used for a valve. The cracking-resistant iron-base powder metallurgy material used for the valve is prepared from the following raw materials in parts by weight: 0.2-0.4 part of stearic acid boron, 3-4 parts of aluminum nickel alloy powder, 3-4 parts of nickeling silicon carbide crystal whisker, 3-4 parts of TiO2, 1-1.5 parts of fumed silica, 0.4-0.6 part of palm wax, 1-2.6 parts of nanometer boron fiber, 1-1.5 parts of cordierite powder, 2-2.6 parts of aluminium titanate, 0.3-0.4 part of silane coupling agent kh-550, a proper quantity of 1% sodium carbonate solution, a proper quantity of water, 2.5-3.5 parts of sodium hypophosphite, 0.4-0.6 part of polyethylene glycol, 30-35 parts of 2mMol / L copper sulphate solution, 2-3 parts of wetting accessory ingredient and 77-82 parts of iron powder. The nanometer boron fiber and the nickeling silicon carbide crystal whisker are added into the valve material to increase compatibility and prevent cracking while the toughness, the heat resistance and the impact strength resistance of valve materials are increased.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Graphene-containing wear-resistant composite material and preparation method thereof

Disclosed are a graphene-containing wear-resistant composite material and a preparation method thereof. The composite material is in a sheet-layer shape, and by weight, 500 g of latex correspondinglycontains 3-5 g of calcium chloride, 10-20 g of zinc oxide, 15-25 g of analytically-pure magnesium oxide, 2-6 g of stearic acid, 1-3 g of an accelerator NA-22 and 20-30 g of large-radial-size graphenemicrochips, wherein calcium chloride, zinc oxide, analytically-pure magnesium oxide, stearic acid, the accelerator NA-22 and the large-radial-size graphene microchips are uniformly dispersed in the latex. The preparation method comprises the steps of preparation of the graphene microchips, preparation, preparation of rubber masterbatches and preparation of the sheet-layer composite material.

Owner:GUOHONG ZHONGJING GRP CO LTD

Tire inner liner rubber and preparation method thereof

Owner:DEZHOU LINGLONG TIRE

Novel powder metallurgical gear

InactiveCN106041095AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersALUMINUM STEARATES

Owner:黄宇

Aging-resistant polyvinyl chloride plastic

Owner:湖南凯誉电气科技有限公司

Tailor's chalk

The invention discloses a tailor's chalk which comprises the following components in percentage by weight: 60-65% of calcium sulfate, 15-17% of salicylic acid, 15-16% of calcium oxide, 3.2-5.0% of zinc stearate, 2-5% of calcium stearate, 0-10% of palmitic acid, 0-1% of amino acid, 0.2-0.3% of a demolding agent and the balance of impurities. The tailor's chalk disclosed by the invention is improved on the basis of the existing invisible tailor's chalk, and is researched and developed with the main component of calcium sulfate by combining the conventional tailor's chalk; and when the tailor's chalk is applied to a dress material, calcium sulfate is attached to the dress material, and because calcium sulfate is matched with other auxiliary materials, the main component namely calcium sulfate can fall off only by beating forcibly for a while, so that the tailor's chalk is very easy to remove.

Owner:刘桂芹

Wear-resistant and high-temperature resistant capacitor aluminum case film coating paint and preparation method thereof

InactiveCN102373006AEffective protectionExtended service lifePolyurea/polyurethane coatingsMeth-Ketone

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Preparation method of high-strength tire curing bladder

InactiveCN110698776AStrong responsivenessImprove adhesionDomestic articlesPolymer scienceActive agent

Owner:YONGYI RUBBER CO LTD

High-strength marine rubber fender

InactiveCN103012863AImprove tensile strength at breakRubber materialSulfide

Owner:XIAN ZHITAI RUBBER & PLASTIC IND

Foaming material with modifying filler

InactiveCN103613836AIncrease elasticityStrong sound insulationLinear low-density polyethylenePolyvinyl chloride

The invention discloses a foaming material with modifying filler. The foaming material is characterized by being prepared from the following raw materials in parts by weight: 80-90 parts of linear low density polyethylene, 12-16 parts of SG-5 polyvinyl chloride, 20-24 parts of calcium carbonate powder, 2-3 parts of stearic acid, 2-3 parts of zinc oxide, 4-5 parts of azodicarbonamide, 5-7 parts of chlorinated paraffin, 3-5 parts of polyethylene terephathalate, 4-6 parts of titanium dioxide powder, 2-3 parts of triphenyl phosphite and 6-8 parts of modifying filler. Due to addition of the modifying filler, the foaming material has excellent flame retardant effect, and is further endowed with excellent mechanical property, good rebound resilience and strong sound insulation performance. The polyvinyl chloride foaming material simultaneously has the characteristics of heat insulation, light weight, low water absorption and the like. The foaming material also has the advantages that the operation is simple, the raw materials are easily available, and the cost is low.

Owner:ANHUI AOLO DOOR & WINDOW SYST ENG CO LTD

Anti-corrosion power protection pipe

Owner:安徽盛华管业有限公司

Hair shampoo

InactiveCN104306264ADoes not destroy traitsPowerfulCosmetic preparationsHair cosmeticsBiotechnologyStearic acid

Owner:HARBIN HAIJIANG TECH DEV

Decorated curtain

Owner:CHANGSHU LIGHT IND DECORATION MATERIAL

Flame-retardant PVC threading pipe and preparation method thereof

Owner:广讯检测(广东)有限公司

Nose mask facilitating pore shrinking

InactiveCN103585061ANo side effectsNo damageCosmetic preparationsToilet preparationsSide effectAlcohol

Owner:曲肇勋

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap