Method of burning gel of stearic acid for preparing Nano LaCo03 in type of perovskite

A perovskite, stearic acid technology, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the problems of uneven distribution and large particle size, and achieve uniform particle size distribution, small particle size distribution, The effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

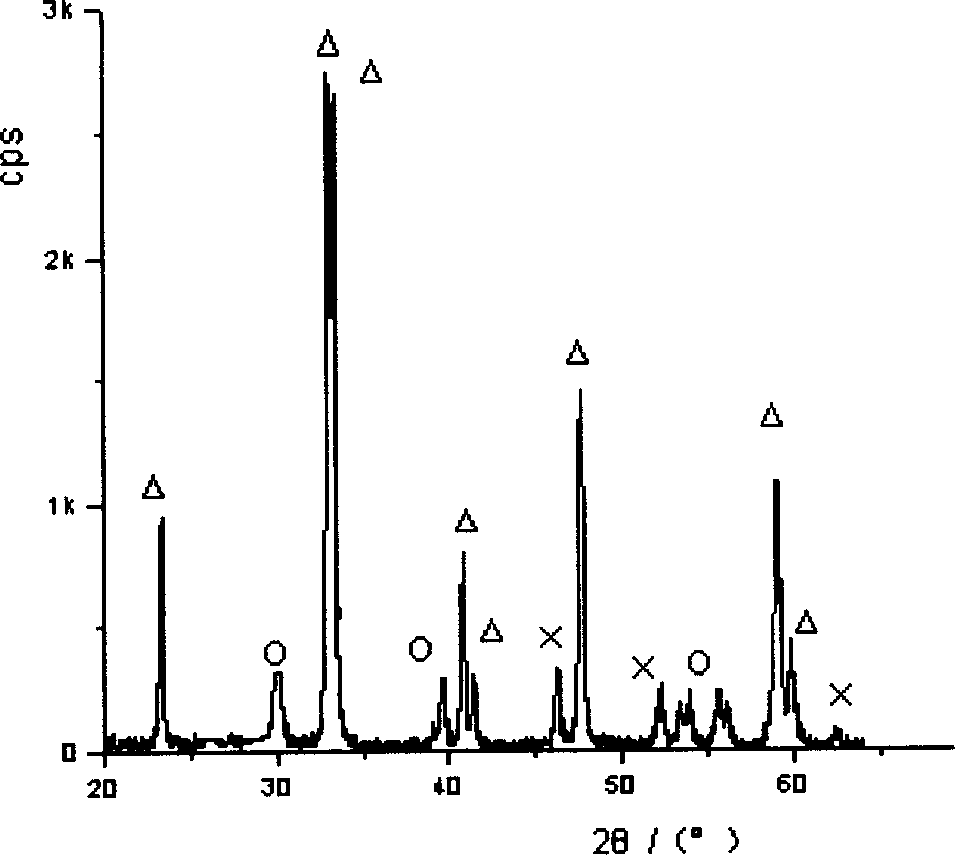

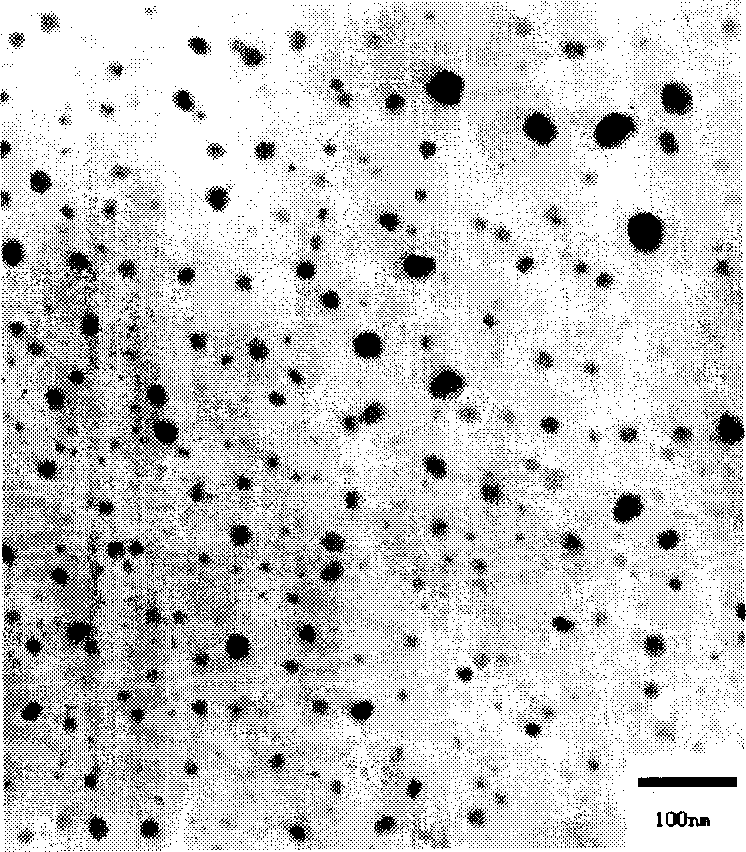

[0023] Weigh a certain amount of lanthanum nitrate, cobalt nitrate, and stearic acid respectively so that the molar ratio is 1:1:10. First, under the condition of constant temperature oil bath heating, stearic acid is dissolved, under constant temperature magnetic stirring, the solid mixture of lanthanum nitrate and cobalt nitrate is dissolved in molten stearic acid, the temperature is controlled at 115 ° C, and the reaction time is 3 hours. into a gel. The gel was burned at 450°C. After burning, the product was taken out and ground and put into a muffle furnace, and calcined at 850°C for 3 hours to obtain the following: image 3 The nanopowder LaCoO shown 3 . The shape is spherical, the particle size distribution is uniform, and the size is about 10nm-30nm.

Embodiment approach 2

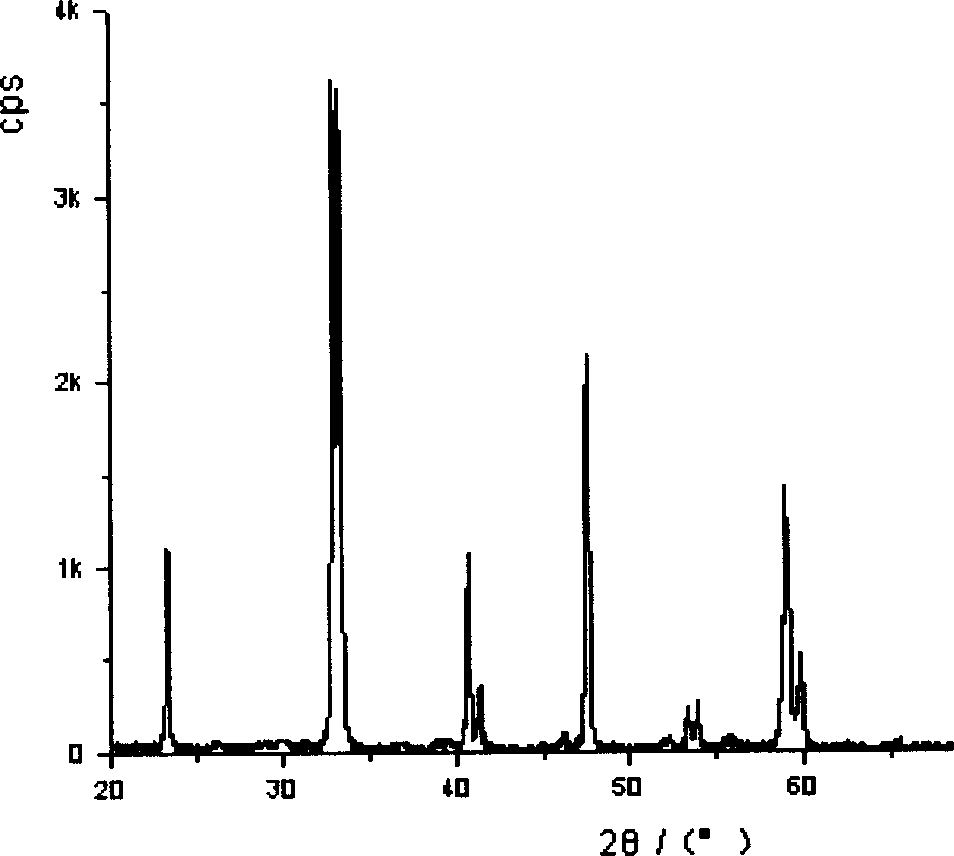

[0025] Weigh a certain amount of lanthanum nitrate, cobalt nitrate, and stearic acid respectively so that the molar ratio is 1:1:11.2. First, under the condition of constant temperature oil bath heating, stearic acid is dissolved, and under constant temperature magnetic stirring, the solid mixture of lanthanum nitrate and cobalt nitrate is dissolved in molten stearic acid, the temperature is controlled at 113 ° C, and the reaction time is 3 hours. turns into a gel. The gel was burned at 450°C. After burning, the product was taken out and ground and put into a muffle furnace, and calcined at 850°C for 3 hours to obtain the following: Figure 4 Medium and nanometer powder LaCoO 3. The shape is spherical, the particle size distribution is uniform, and the size is about 10nm-20nm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap