High-strength marine rubber fender

A rubber string protection, high-strength technology, applied in the rubber field, can solve the problems of surface deformation, cracking, affecting the string protection, etc., and achieve the effect of improving the tensile breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

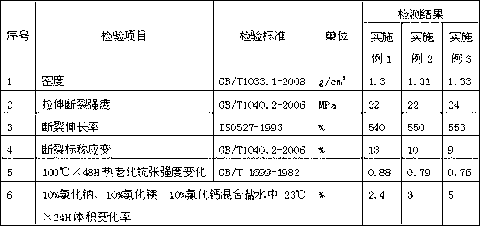

Examples

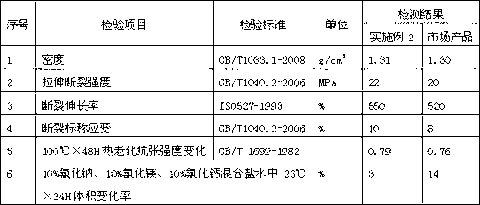

Embodiment 2

[0031] The production process of embodiment 2 is identical with embodiment 1, and difference is that the ratio of rubber material components is different, and the rubber material composition of embodiment 2 is as follows by weight component: 80 parts of 1# natural rubber, 40 parts of 21 type neoprene rubbers 2.5 parts of stearic acid, 1.5 parts of paraffin, 3.5 parts of vaseline, 20 parts of hard carbon black, anti-aging agent DTPD (domestic name: anti-aging agent 3100, Chinese name: N,N'-xylyl-p-phenylenediamine mixture ) 2.3 parts, vulcanizing agent TRA (also known as DPTT, Chinese name: bispentamethylene thiuram tetrasulfide, molecular formula: C12H20N2S4) 2.4 parts, calcium carbonate 25 parts, zinc oxide 4 parts, magnesium oxide 4.5 parts, accelerator DM (Chinese name: 2,2'-dithiodibenzothiazole, molecular formula: C 14 h 8 N 2 S 4 ) 0.4 parts, accelerator TT (Chinese name: Tetramethylthiuram disulfide, molecular formula: C 6 h 12 N 2 S 4 ) 1.2 parts, antioxidant 4010

Embodiment 3

[0032] The production process of embodiment 3 is identical with embodiment 1, and difference is that the rubber material composition ratio is different, and the rubber material composition of embodiment 3 is as follows by weight component: 1# natural rubber 90 parts, 21 type neoprene rubber 50 , 3 parts of stearic acid, 2 parts of paraffin, 5 parts of vaseline, 25 parts of hard carbon black, anti-aging agent DTPD (domestic name: anti-aging agent 3100, Chinese name: N,N'-xylyl-p-phenylenediamine mixture ) 2.3 parts, vulcanizing agent TRA (also known as DPTT, Chinese name: bispentamethylene thiuram tetrasulfide, molecular formula: C12H20N2S4) 2.4 parts, calcium carbonate 30 parts, zinc oxide 5 parts, magnesium oxide 5 parts, accelerator DM (Chinese name: 2,2'-dithiodibenzothiazole, molecular formula: C 14 h 8 N 2 S 4 ) 0.5 parts, accelerator TT (Chinese name: Tetramethylthiuram disulfide, molecular formula: C 6 h 12 N 2 S 4 ) 1.3 parts, antioxidant 4010 (Chinese name: N-phen

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap