Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104 results about "Wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear Resistance. the resistance of materials to wear. The wear resistance of parts is evaluated in bench tests or under operating conditions according to the duration of the operation of the tested materials or products to a preset level of or maximum wear.

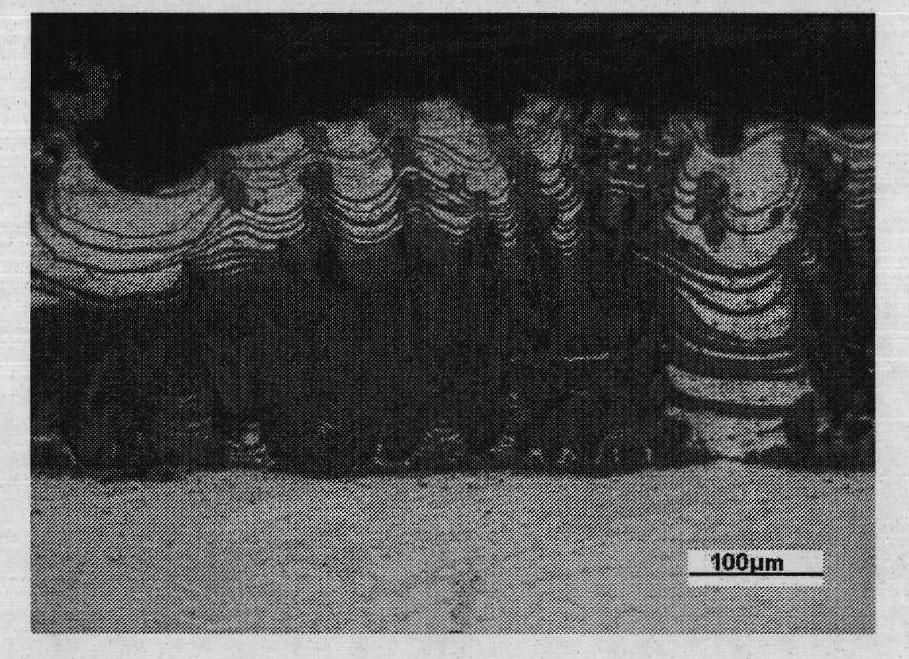

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

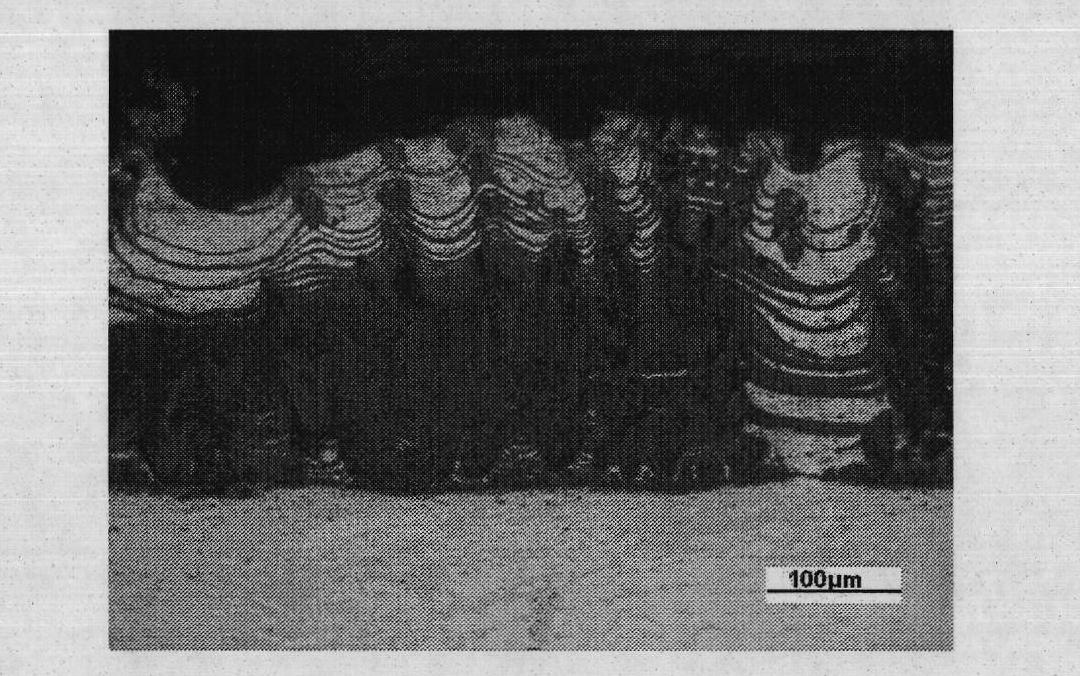

Boron-containing semi-high speed steel cold roller and manufacturing method thereof

InactiveCN101407891AReduce manufacturing costReduce the amount addedProcess efficiency improvementElectric furnaceIngotMolten steel

The invention relates to a boron-containing semi high-speed steel cold roller and a manufacturing method thereof and belongs to the field of steel rolling technology. The existing cold rollers have the problems of poor wear-resistance, high production cost and the like. The invention obtains the boron-containing semi high-speed steel cold roller by pouring the molten steel with the compositions of the following weight percentages of 0.30 to 0.45 of C, 3.8 to 4.2 of Cr, 0.2 to 0.6 of Si, 0.2 to 0.6 of Mn, 0.5 to 0.8 of Mo, 0.2 to 0.4 of Ni, 0.3 to 0.6 of Cu, 0.6 to 1.0 of B, 0.3 to 0.7 of V, 0.6 to 0.8 of Ti, 0.1 to 0.3 of Nb, 0.03 to 0.10 of N, 0.25 to 0.45 of Al, less than 0.03 of S, less than 0.04 of P and the residual quantity of Fe into an outer layer of the cold roller and adopting ductile cast iron as a core part or directly pouring the molten steel into ingots. The roller has the advantages of high hardness and intensity, good toughness and wear-resistance, simple production process, low cost, etc.

Owner:BEIJING UNIV OF TECH

Molded Article for Clean Room and Method for Producing Same

Owner:FUJI BAKELITE +2

Production method of permanent ultraviolet protecting, moisture absorbing and sweat removing fabric

ActiveCN104799458AReduce surface tensionImprove permeabilitySingeingHeating/cooling textile fabricsFiberPolyester

The invention discloses a production method of a permanent ultraviolet protecting, moisture absorbing and sweat removing fabric. The method comprises the steps of blending and weaving; singeing; desizing-scouring-bleaching; mercerizing; sizing; dyeing; softening and tentering; pre-shrinking and arranging. The fabric manufactured by the production process is outstanding in permanent ultraviolet resisting function; the UPF is not less than 150; micro pores of CTATEX super-comfortable polyester fibers can be opened fully by the desizing-scouring-bleaching and mercerizing, holes in the fibers are smooth, the moisture absorbing and breathing performances of the fabric can be improved under the absorbing effect of hole cores, and the water drops can be absorbed within 3 seconds according to the test; the fuzzing and pilling resistance of the fabric is more than 4 grades; the advantages of wearing resistance, non-ironing, wrinkle preventing and quick drying of the polyester fibers are remained to the maximum; the fabric is particularly suitable for wearing when working and living outdoor in a hot season.

Owner:SWOTO PROTECTION & TECH CO LTD +1

Method for preparing diamond-like composite coating on surface of piston ring

InactiveCN101665940AImprove wear resistanceImprove the lubrication effectVacuum evaporation coatingSputtering coatingLow temperature plasmaMagnetic filtration

The invention relates to a method for preparing a diamond-like composite coating with high hardness and good abrasion proof and self lubricating properties on the surface of a piston ring. In the method, a nitriding layer with high bonding strength, high hardness and good abrasion resistance is formed on the surface of the piston ring by the low-temperature plasma nitriding treatment, a non-hydrogen diamond-like surface layer with solid lubricating property is deposited by the combination of magnetic filtration cathode arc and magnetic control sputtering, and finally the nitriding / diamond-likecomposite coating, which is dense and smooth and possesses excellent abrasion proof and self-lubricating properties, is obtained on the surface of the piston ring. Compared with the durionising piston ring or CrN plating piston ring, the coating of the piston ring of the invention has higher comprehensive performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

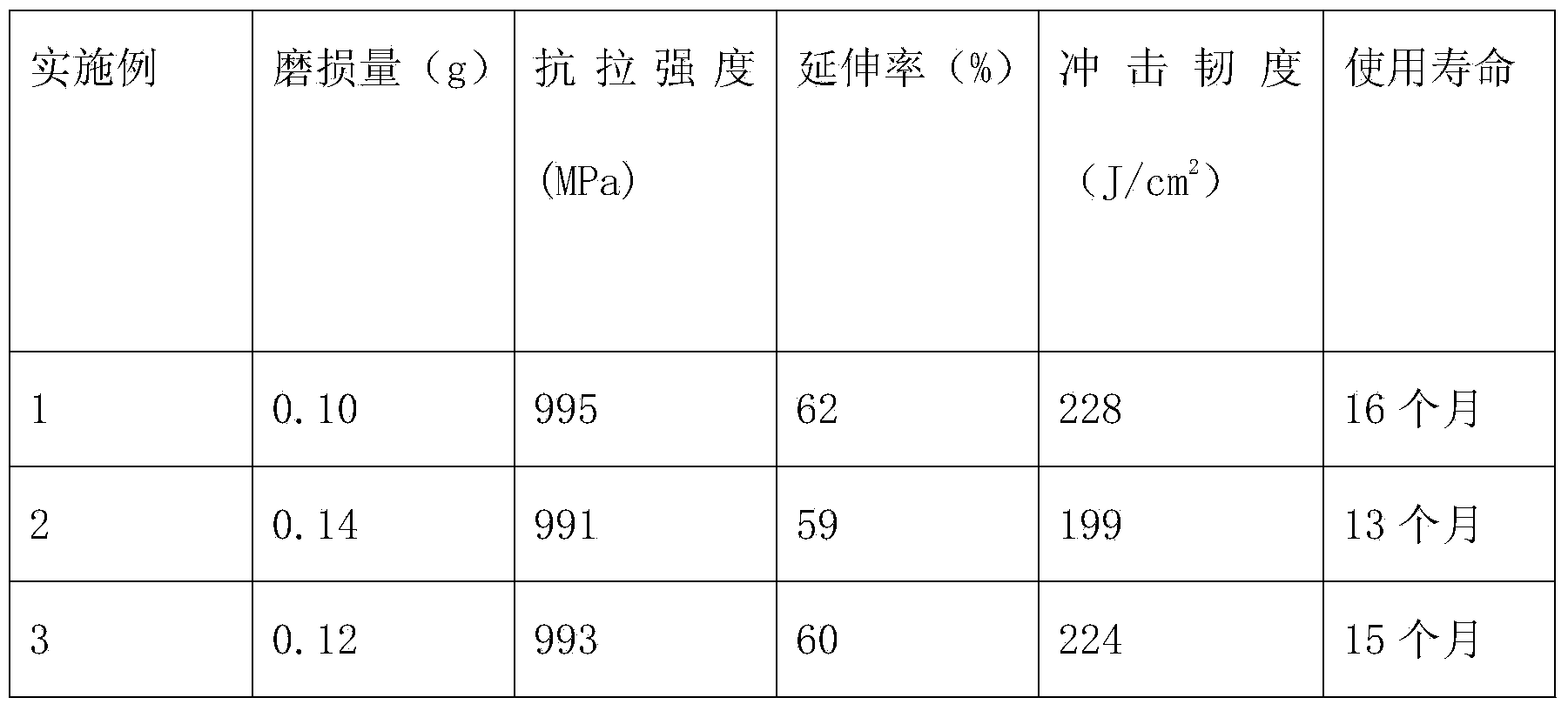

Ceramics particle strengthened composite material lining metal tube and manufacturing method thereof

InactiveCN101900227AExtended service lifeImprove wear resistanceCorrosion preventionPipe protection against corrosion/incrustationPolyesterManufacturing technology

The invention discloses a ceramics particle strengthened composite material lining metal tube and a manufacturing method thereof, belonging to the field of composite wear-resistant tubes. 4,4-Diphenylmethane diisocyanate (MDI), polyester glycol, 1,4-butanediol (BD), ceramics particles and the like serve as raw materials to prepare composite material liquid castables, and a centrifugal casting technology is adopted to cast polyurethane base ceramics particle strengthened composite material lining layers on the inner wall of an outer thimble. The invention has the beneficial effect that the prepared ceramics particle strengthened composite material lining metal tube has excellent abrasive resistance and corrosion-resistance and greatly improves service life. The raw materials of the invention are easy to be obtained, manufacturing technology is simple, cost is low and economic benefit is obvious and practical application and mass production are beneficial for factories.

Owner:XUZHOU SHENGHAI MACHINERY MFG TECH

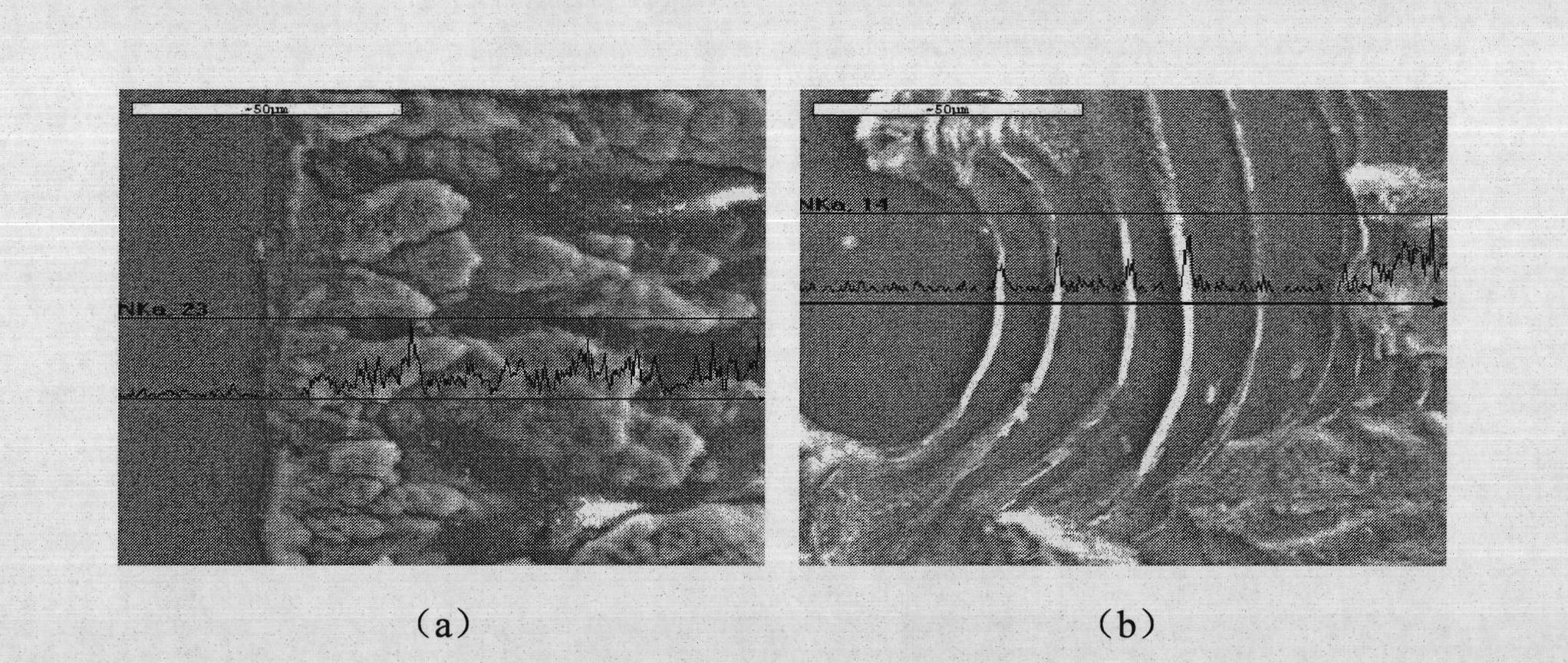

Aluminum and aluminum alloy matrix aluminum nitride reinforced gradient composite surface layer

InactiveCN101880854AImprove wear resistanceSolid state diffusion coatingSurface gradientSurface layer

Owner:JILIN UNIV

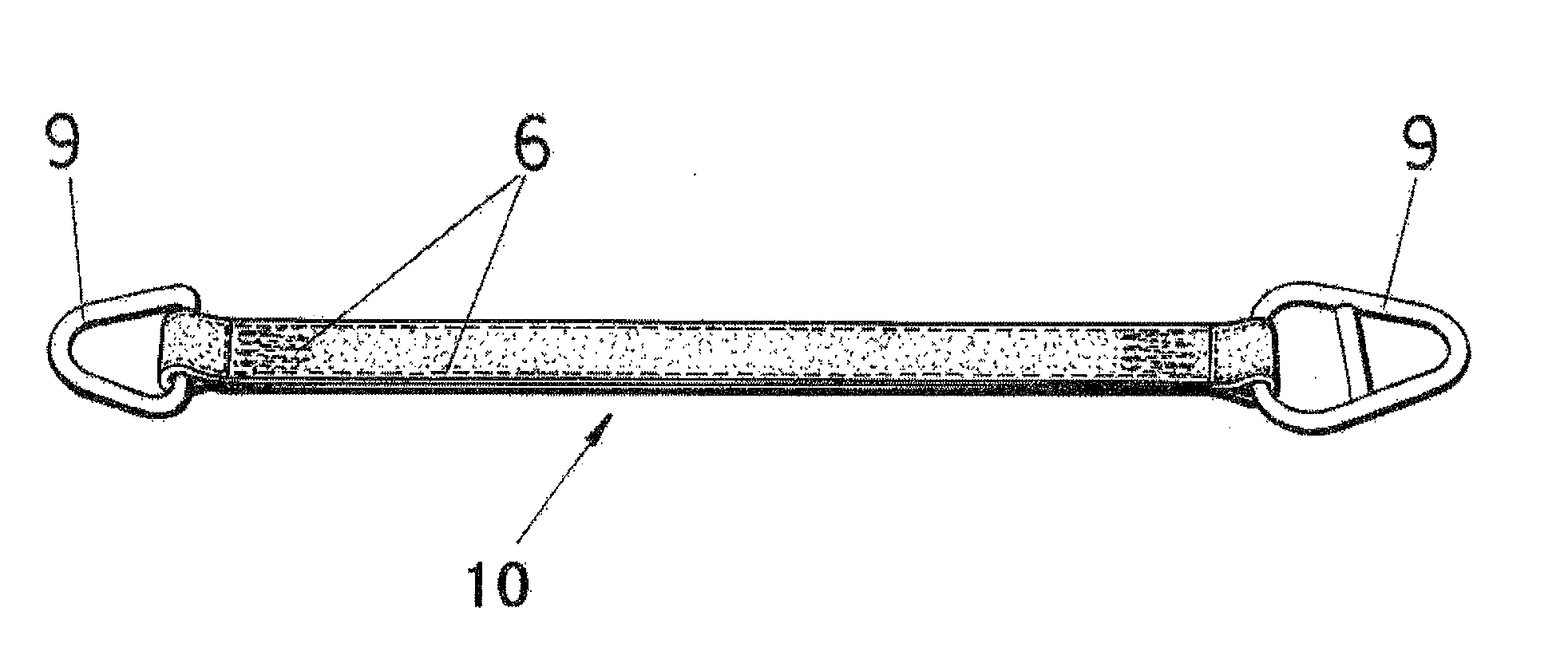

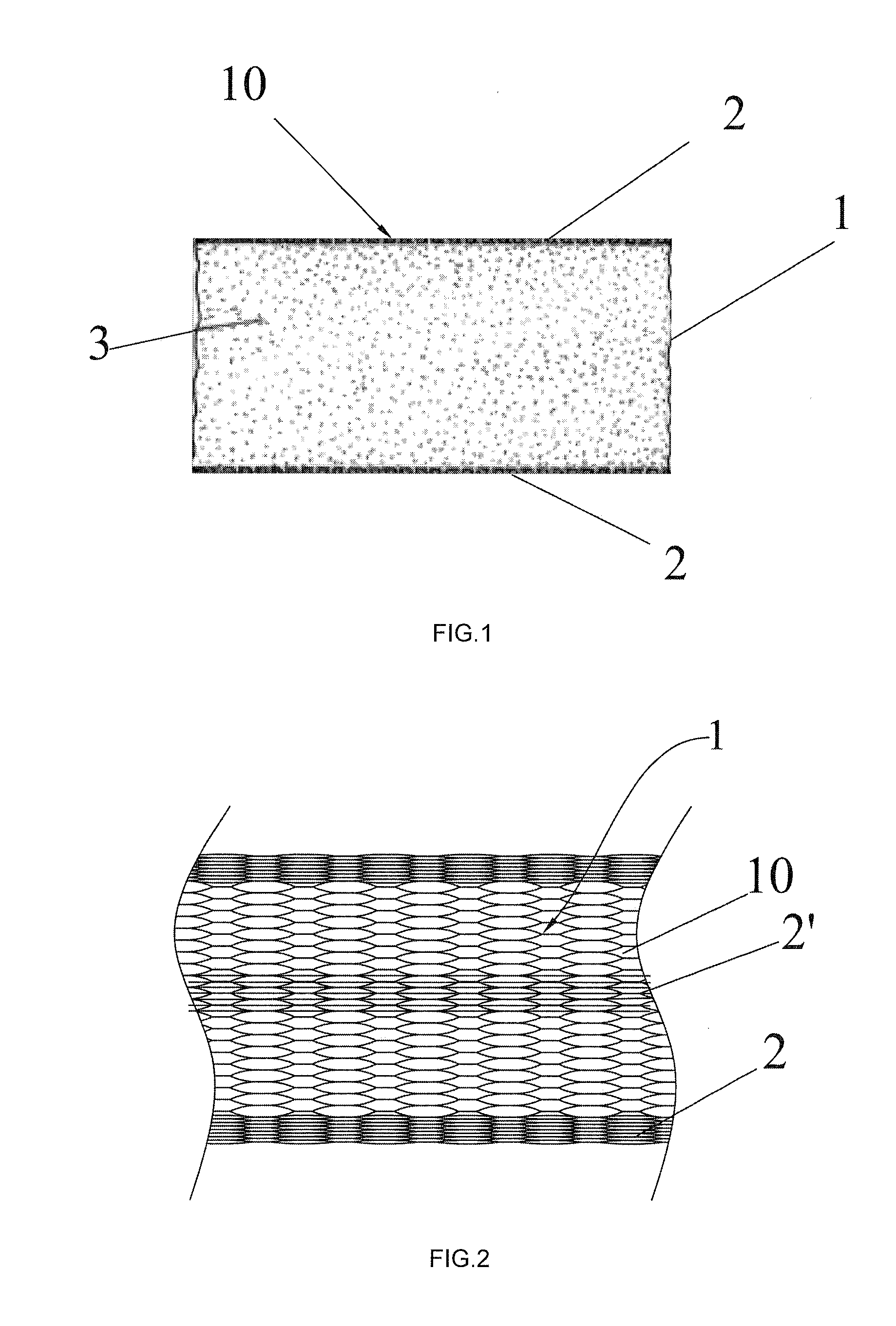

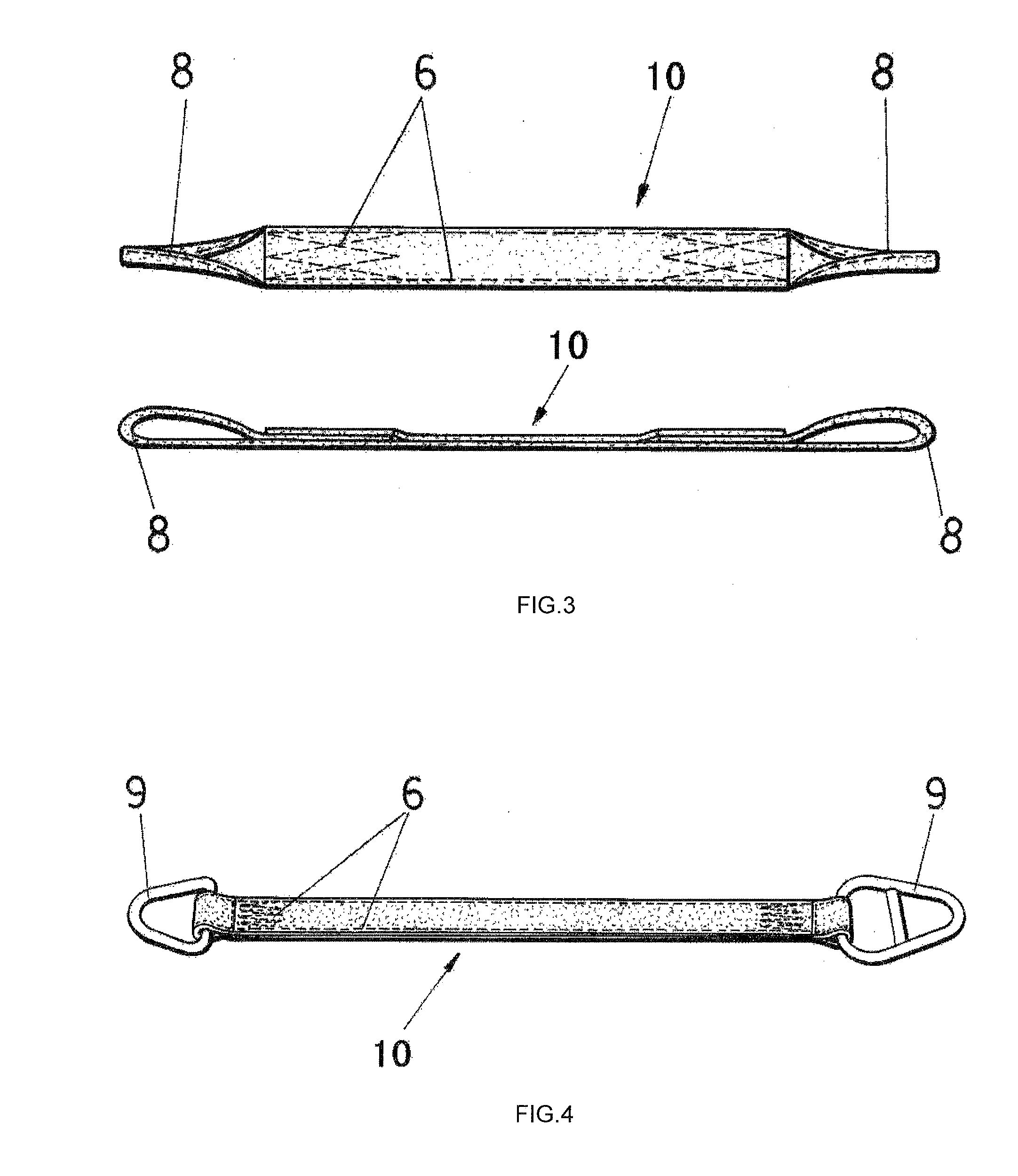

Textile sling and method of manufacturing same

InactiveUS20100327615A1Tough to abrasionTough to cutLoomsDrying machines with progressive movementsYarnPolyurethane dispersion

Owner:DONGGUAN PONSA TEXTILE

Cutting elements, methods for manufacturing such cutting elements, and tools incorporating such cutting elements

The present disclosure relates to cutting elements incorporating polycrystalline diamond bodies used for subterranean drilling applications, and more particularly, to polycrystalline diamond bodies having a high diamond content which are configured to provide improved properties of thermal stability and wear resistance, while maintaining a desired degree of impact resistance, when compared to prior polycrystalline diamond bodies, hi various embodiments disclosed herein, a cutting element with high diamond content includes a modified PCD structure and / or a modified interface (between the PCD body and a substrate), to provide superior performance.

Owner:SMITH INT INC

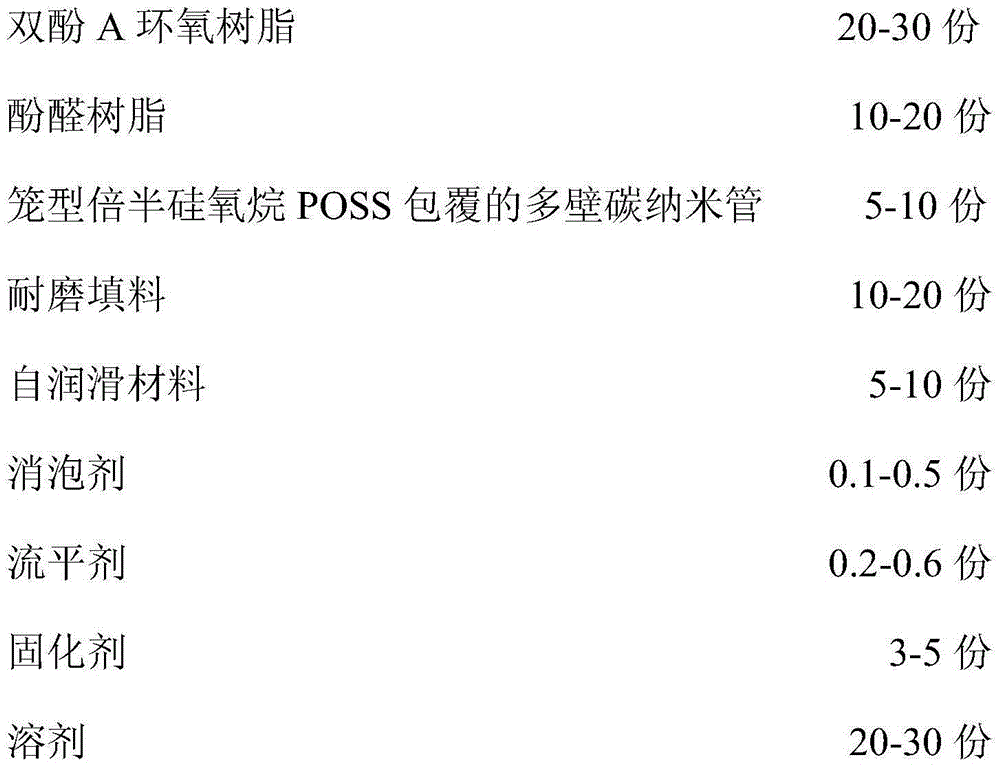

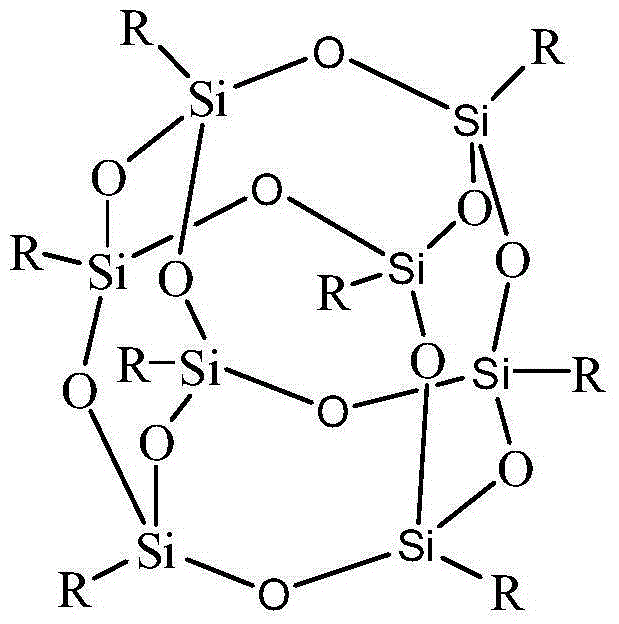

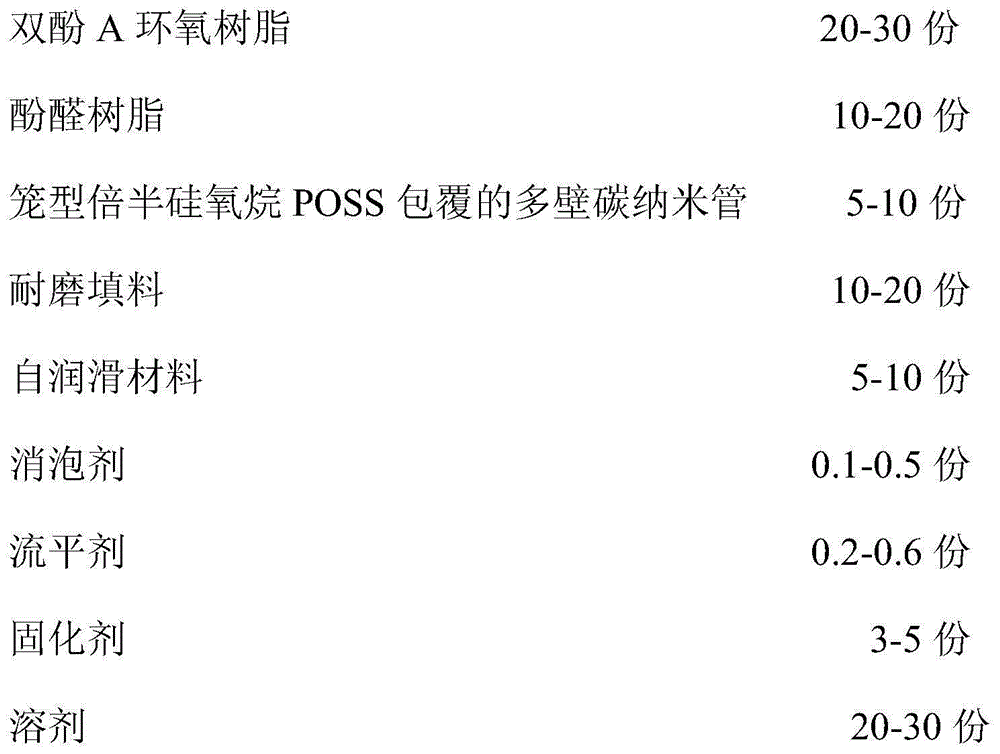

Anti-corrosion and wear-resisting coating for throwing disc of pneumatic type feeder and preparation method of coating

InactiveCN105062300AImprove corrosion resistanceImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsMultiwalled carbonRoom temperature

Owner:JINHU JIEDA MACHINERY MFR

Wear resistant sole material

InactiveCN103483677ADoes not affect elasticityDoes not affect resilienceSolesEnvironmental resistanceFoaming agent

The invention relates to a wear resistant sole material. The wear resistant sole material comprises, by weight, 35-45 parts of EVA, 4-8 parts of styrene butadiene rubber, 1-8 parts of butadiene rubber, 1-4 parts of a vulcanizing agent, 2-5 parts of a reinforcing agent, 1-4 parts of an activator, 1-4 parts of an accelerant and 0.5-3 parts of a foaming agent. The wear resistant material greatly improves the wear resistance of a sole without influencing the elasticity, the resilience, the portability or the like of the sole, and also has the advantages of non-toxicity, no pollution, safety and environmental protection.

Owner:KUNSHAN CHUNBAI PRECISE HARDWARE CO LTD

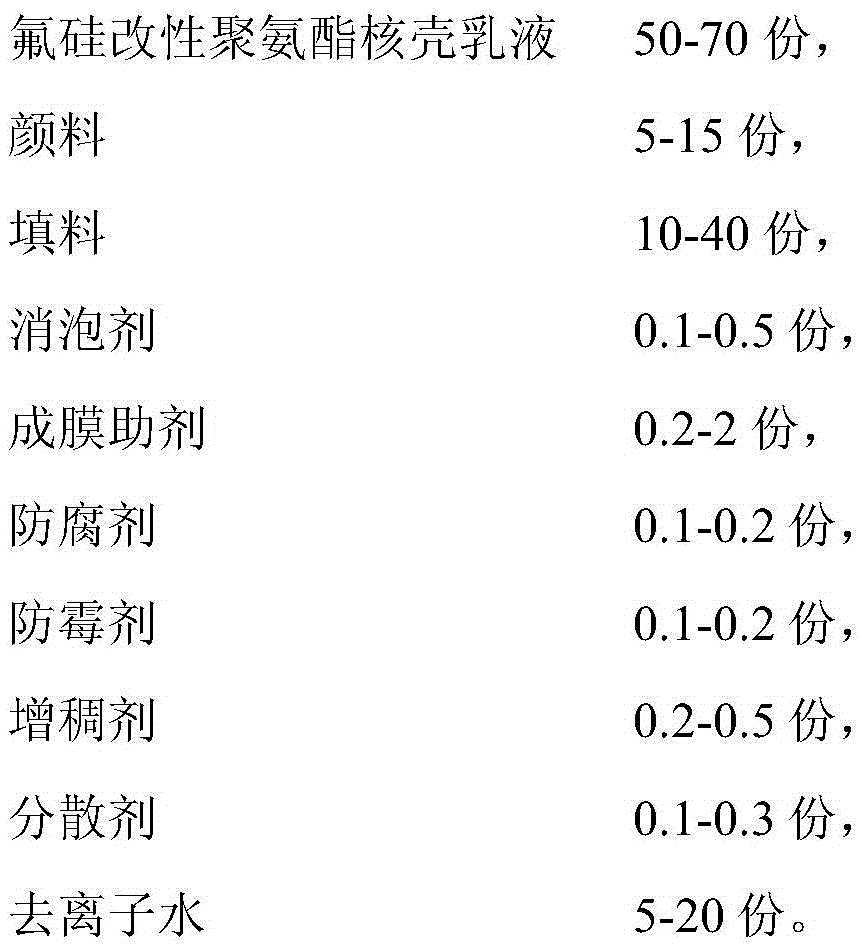

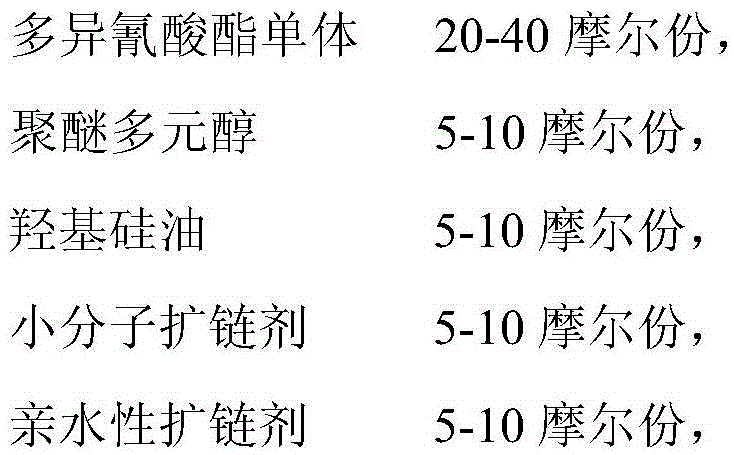

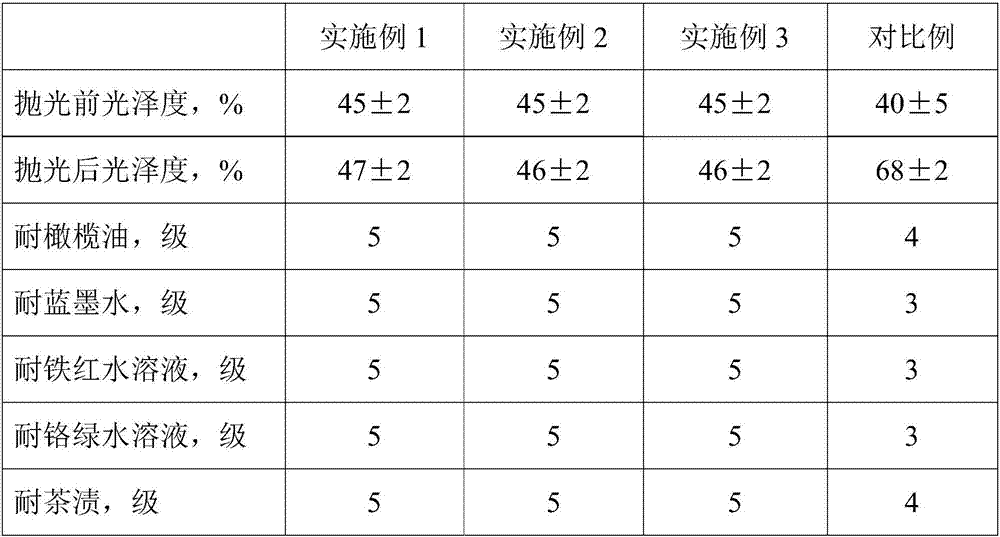

Water-based anti-doodling paint and preparation method thereof

ActiveCN105482604ALow VOC emissionsLow weather resistanceAntifouling/underwater paintsPaints with biocidesWater basedDefoaming Agents

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

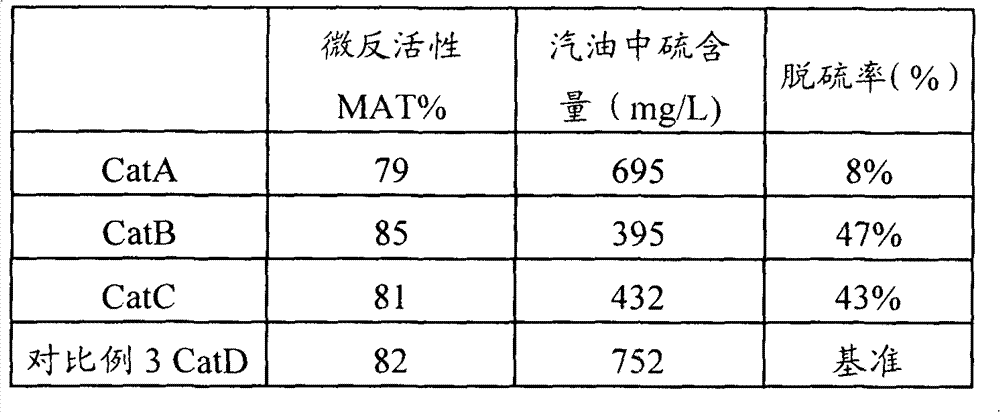

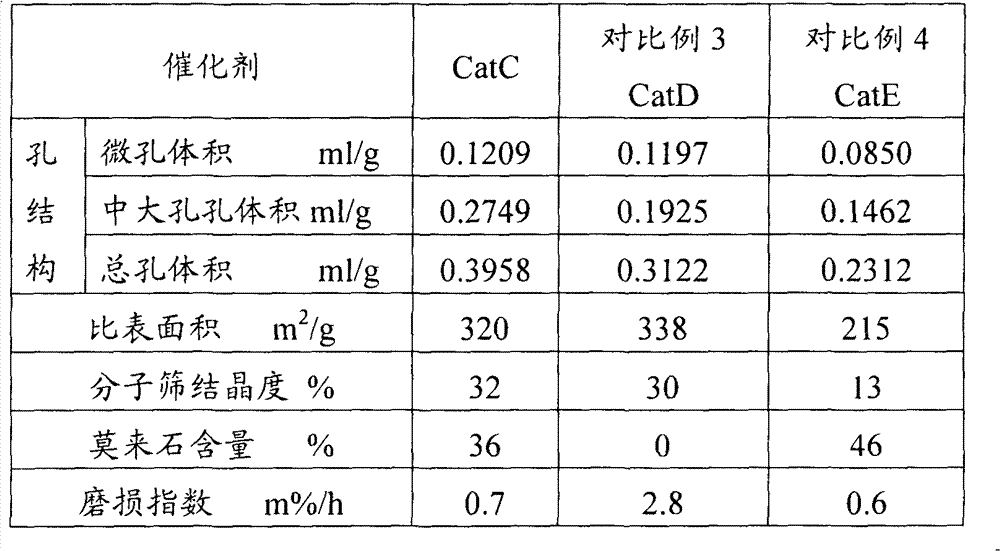

Wear-resistant heavy oil catalytic cracking catalyst capable of reducing sulfur content of gasoline and preparation method thereof

ActiveCN103028432AImprove wear resistanceHigh activityCatalytic crackingMolecular sieve catalystsMicrosphereWear resistant

Owner:EAST CHINA UNIV OF SCI & TECH +1

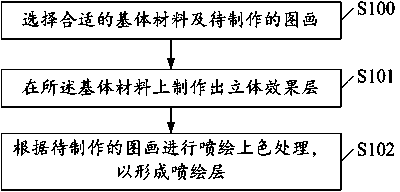

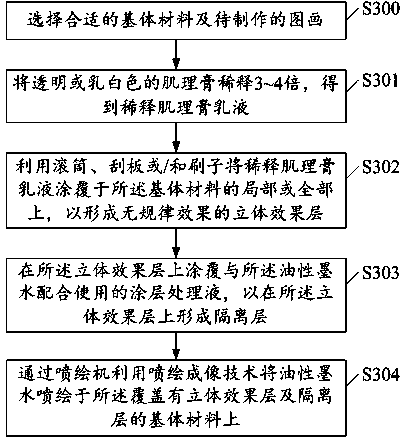

Method for manufacturing three-dimensional craft painting

ActiveCN103407319AImprove waterproof performanceGood sun protectionDecorative surface effectsSpecial ornamental structuresHigh volume manufacturingEngineering

Owner:XIAMEN HAOSHIDUO IND & TRADE CO LTD

Method for making coated filter cloth through wet process

InactiveCN103952914AHigh porosityHigh Solids RetentionFibre treatmentFiltration separationPorosityYarn

Owner:刘冠利

Double metal alloy barrel material and producing technology thereof

InactiveCN107312962AModerate hardnessImprove high temperature performanceChromium carbideMetal alloy

The invention discloses a double metal alloy barrel material. Raw material powder of the double metal alloy barrel material comprises, by mass, 25-50% of molybdenum, 2-10% of boron, 5-15% of chromium, 2-10% of nickel, 1-5 %of manganese, 0.1-1% of carbon, 0.8-3% of chromium carbide and the balance ferrum. The producing technology of the double metal alloy barrel material comprises the following steps of 1), raw powder ball-milling, 2), powder mixing and drying, 3), powder pressing for forming a green body, 4) green body machining and shaping, 5), vacuum degreasing and sintering, 6) semi-finished product shaping and machining, 7) green body heat covering treatment, and 8), inner hole machining treatment. A double metal alloy barrel produced by the above materials is moderate in rigidity, excellent in high temperature performance, good in bending strength, close to density of steel substrate, high in breaking tenacity, excellent in wear-resisting property and excellent in decay resistance, plastic molding can be more stable by using the producing technology, and the service life of the alloy barrel is greatly improved.

Owner:DONGGUAN JIEYU MASCH CO

Nickel-based alloy powder material for repairing crystallizer foot roller and repairing method

ActiveCN112680634AImprove antioxidant capacityImprove thermal shock resistanceIncreasing energy efficiencyMetallic material coating processesOxidation resistantWear resistance

The invention discloses a nickel-based alloy powder material for repairing a crystallizer foot roller. The nickel-based alloy powder material comprises the following chemical components in percentage by mass of 22-28% of Cr, 8-12% of Mo, 3-4% of Nb, 1.0-2.5% of Si, 0.8-1.6% of B, 0.8-2% of V, 0.05-0.08% of C and the balance of Ni. The invention further discloses a repairing method of the crystallizer foot roller. The method comprises the following steps of 1, rough turning; 2, pre-flaw detection; 3, laser cladding, wherein a cladding layer comprises two layers, a base coat is iron-based alloy powder, a functional layer is cladded on the base coat, and the functional layer is made of nickel-based alloy powder; 4, finish turning; 5, grinding; and 6, post-flaw detection. The crystallizer foot roller repaired by using the material and the method provided by the invention has the advantages that the properties such as high-temperature oxidation resistance, cold and hot fatigue resistance and wear resistance are obviously improved, and the corresponding service life is also greatly prolonged.

Owner:TAIER (ANHUI) IND TECH SERVICE CO LTD

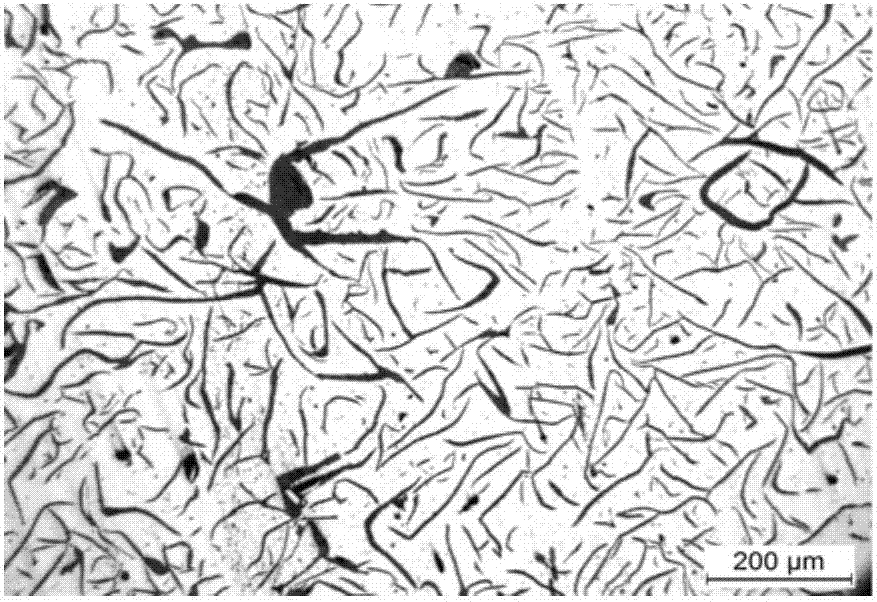

Alloy gray cast iron material for automobile brake disc, automobile brake disc and preparation method thereof

InactiveCN107345285AGood shape of graphiteFast heat conductionFriction liningActuatorsWear resistanceGraphite morphology

Owner:TONGFU HEAT TREATMENT KUNSHAN +1

Preparation method of graphene-butadiene-acrylonitrile rubber latex matting glove

InactiveCN109457465AWith body temperature far infraredImprove antibacterialGlovesLight resistant fibresVulcanizationPolymer science

The invention relates to a preparation method of a graphene-butadiene-acrylonitrile rubber latex matting glove. The preparation method comprises, S1, arranging a glove liner on a hand mould in a covering mode; S2, impregnating the glove liner into curing agent for 20-30 s; S3, totally immersing the glove liner into graphene-butadiene-acrylonitrile composite slurry at a latex viscosity of 600-700 cp for 10-15 s; S4, performing salt spray treatment on the immersed glove liner; S5, performing primary drying inside a vulcanization crosslinking drying oven; S6, washing the dried glove; S4, performing secondary drying on the washed glove inside the oven; S8, performing cooling and demoulding to obtain the graphene-butadiene-acrylonitrile rubber latex matting glove. The prepared graphene-butadiene-acrylonitrile rubber latex matting glove is high in wearing resistance, puncture resistance, tear resistance and cutting resistance, highly antibacterial, capable of achieving far infrared radiationand the like.

Owner:NANTONG JIADELI SAFETY PROD CO LTD

Plastics products and preparation method thereof

InactiveCN101396890AImprove wear resistanceFeel goodVacuum evaporation coatingSynthetic resin layered productsCopper coatingCeramic coating

The invention relates to a plastic product, comprising plastic substrate. The plastic product is characterized in that the product also comprises a copper coating, a nickel coating, a chrome coating and a ceramic coating from the surface of the plastic substrate to the outside in sequence; the ceramic coating is one or more layer of titanium nitride, titanium carbide and titanium carbonitride. The plastic product made by the invention has excellent wearing resistance, the film formed on the surface of the plastic product has excellent adhesiveness, and the plastic product that is obtained finally also has ceramic texture and good handfeel.

Owner:BYD CO LTD

Crease-resistant wear-resistant fabric

InactiveCN109532130AGood warmth retentionImprove breathabilitySynthetic resin layered productsClothingsYarnWear resistant

The invention provides a crease-resistant wear-resistant fabric, which comprises a fabric body, wherein the fabric body is of an double-rib composite double-layer tissue structure compounded by changeplain stitch and tuck stitch; an inner layer fabric of the fabric body is woven by spandex composite yarns; an outer layer fabric of the fabric body is woven by chinlon composite yarns; the inner layer fabric and the outer layer fabric are connected in series through the tuck stitch. The fabric uses a double-rib air layer structure; the spandex composite yarns are used as the inner layer fabric;the chinlon composite yarns are used as the outer layer fabric; the problems of poor wear resistant performance, poor durability and easy crease occurrence of the existing fabric are solved.

Owner:SWOTO PROTECTION & TECH CO LTD +1

High-hardness matte ceramic antifouling agent, and preparation method thereof

ActiveCN107400461AHas hydrophobic antifouling and antibacterial effectDoes not add glossAntifouling/underwater paintsPaints with biocidesCross-linkHydrogen

Owner:黄艳红

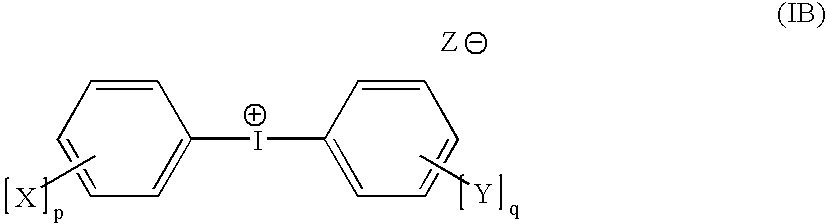

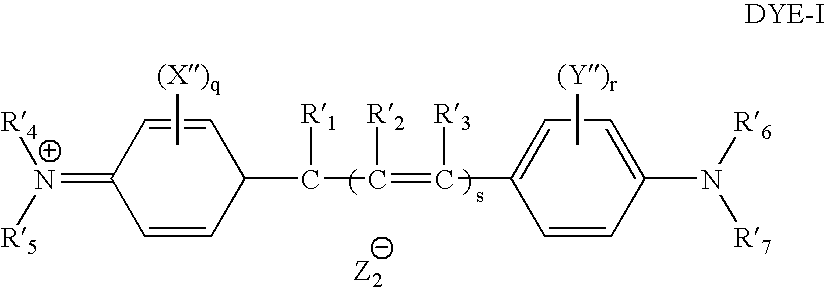

Negative-working imageable elements with improved abrasion resistance

ActiveUS20090233227A1Influence overall viscosityHigh viscosityPhotosensitive materialsDuplicating/marking methodsSilica particleFumed silica

Owner:EASTMAN KODAK CO

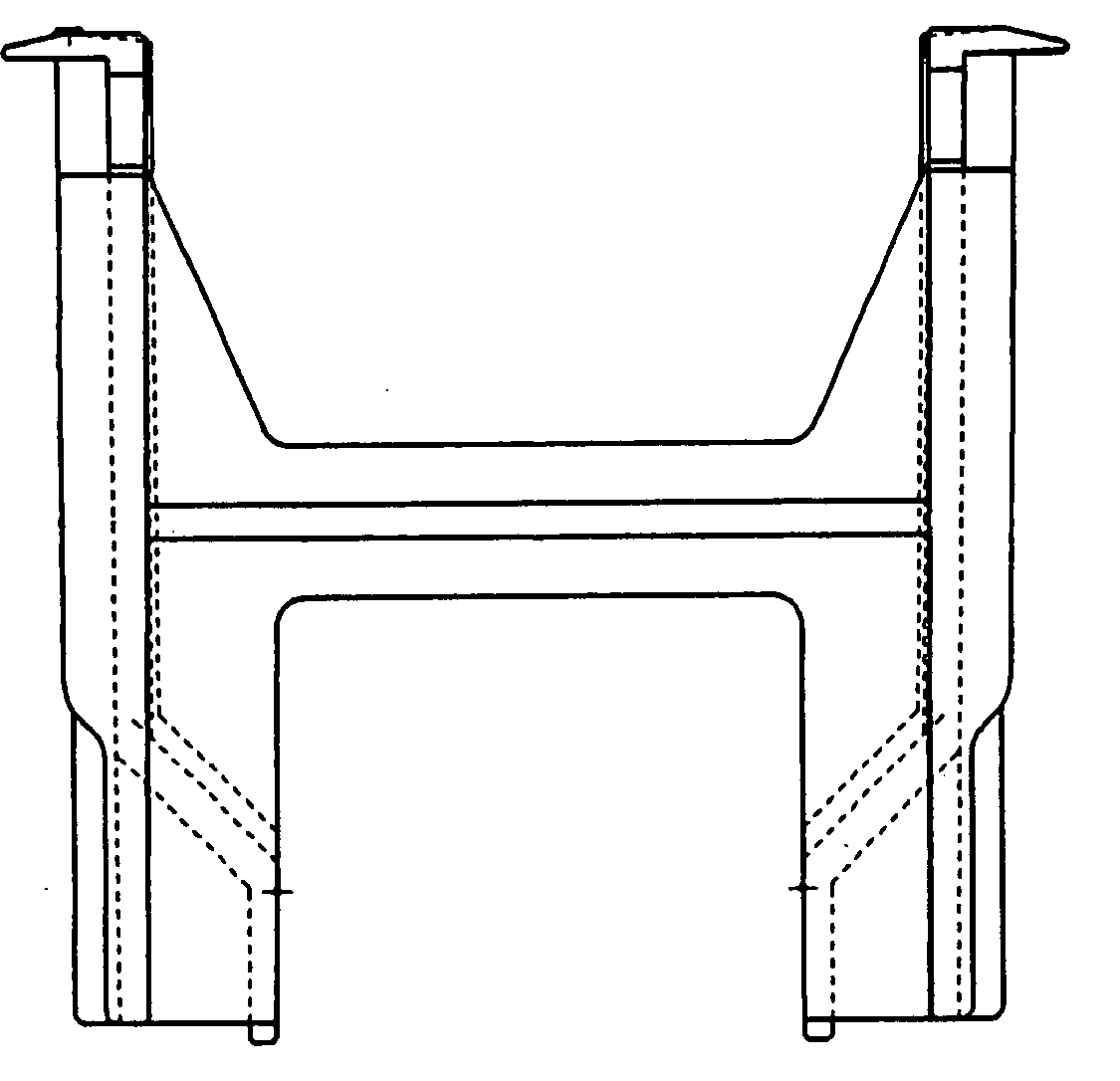

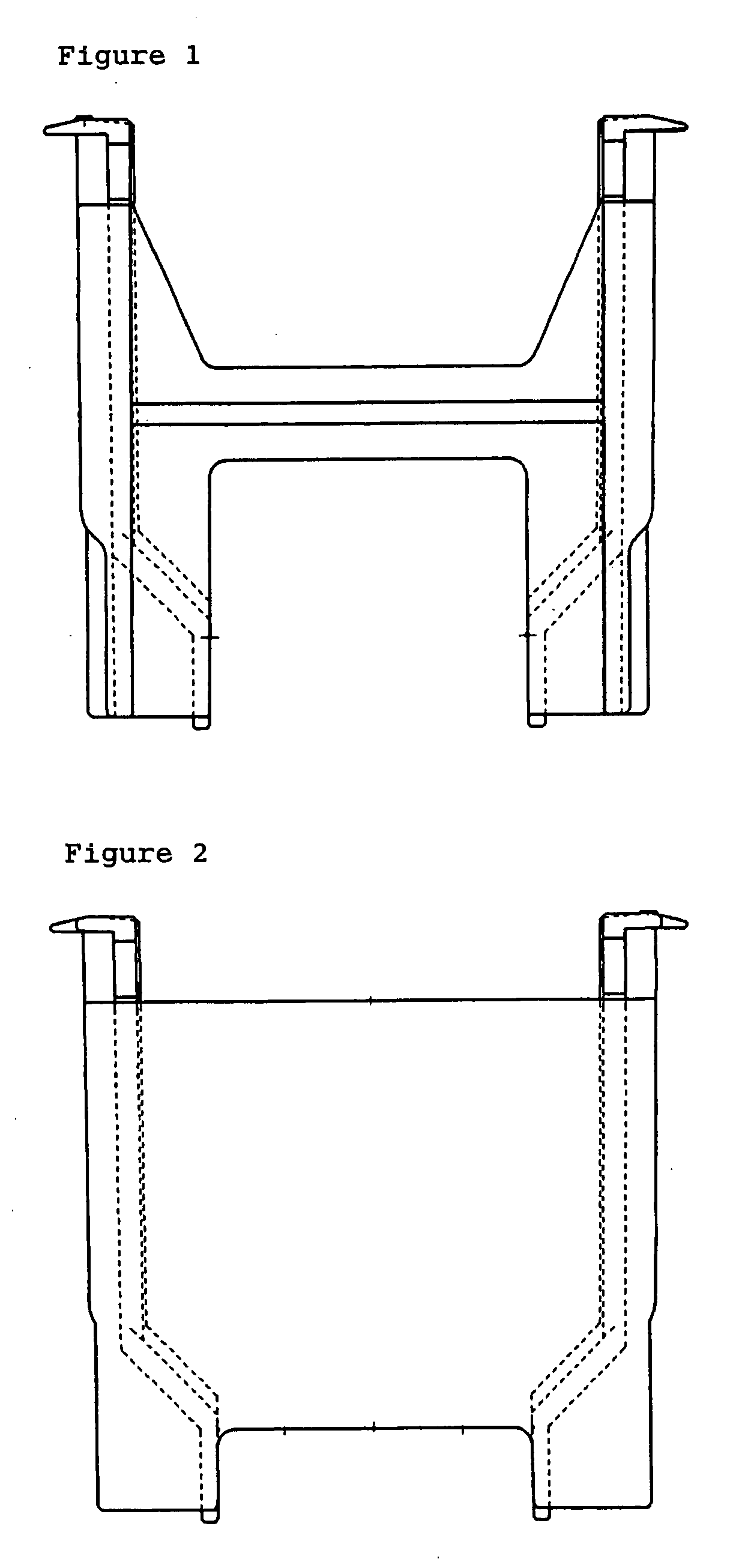

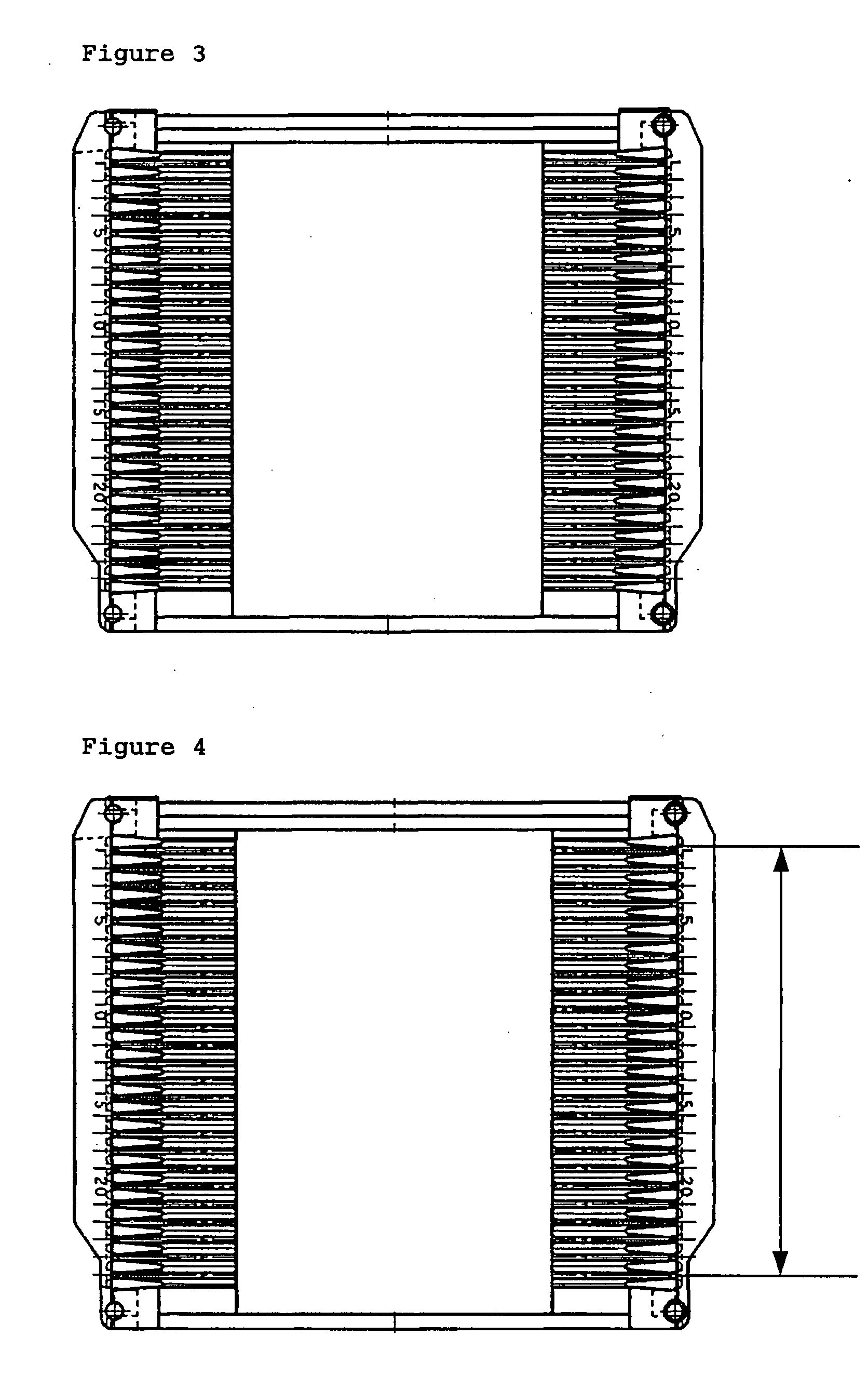

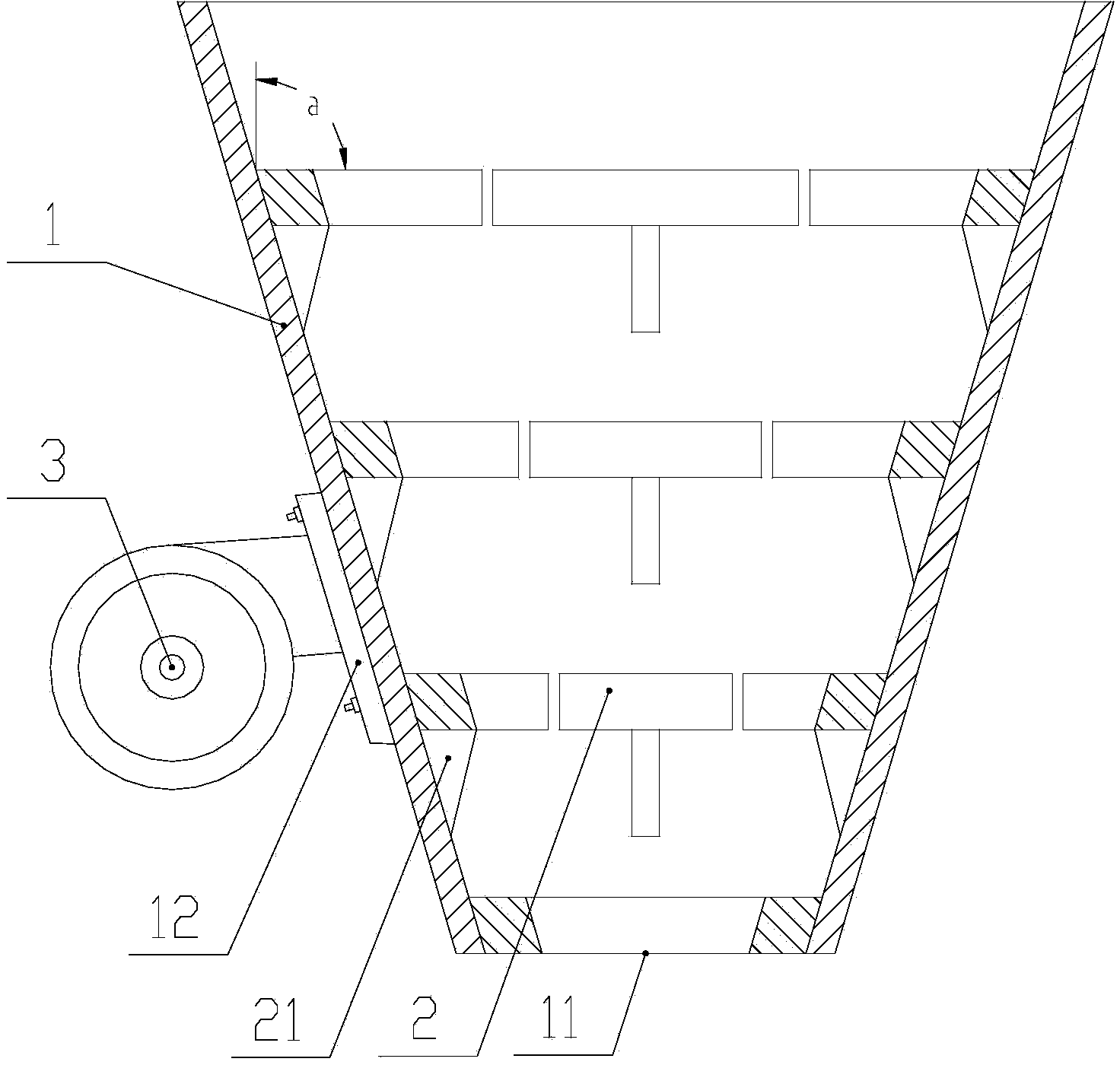

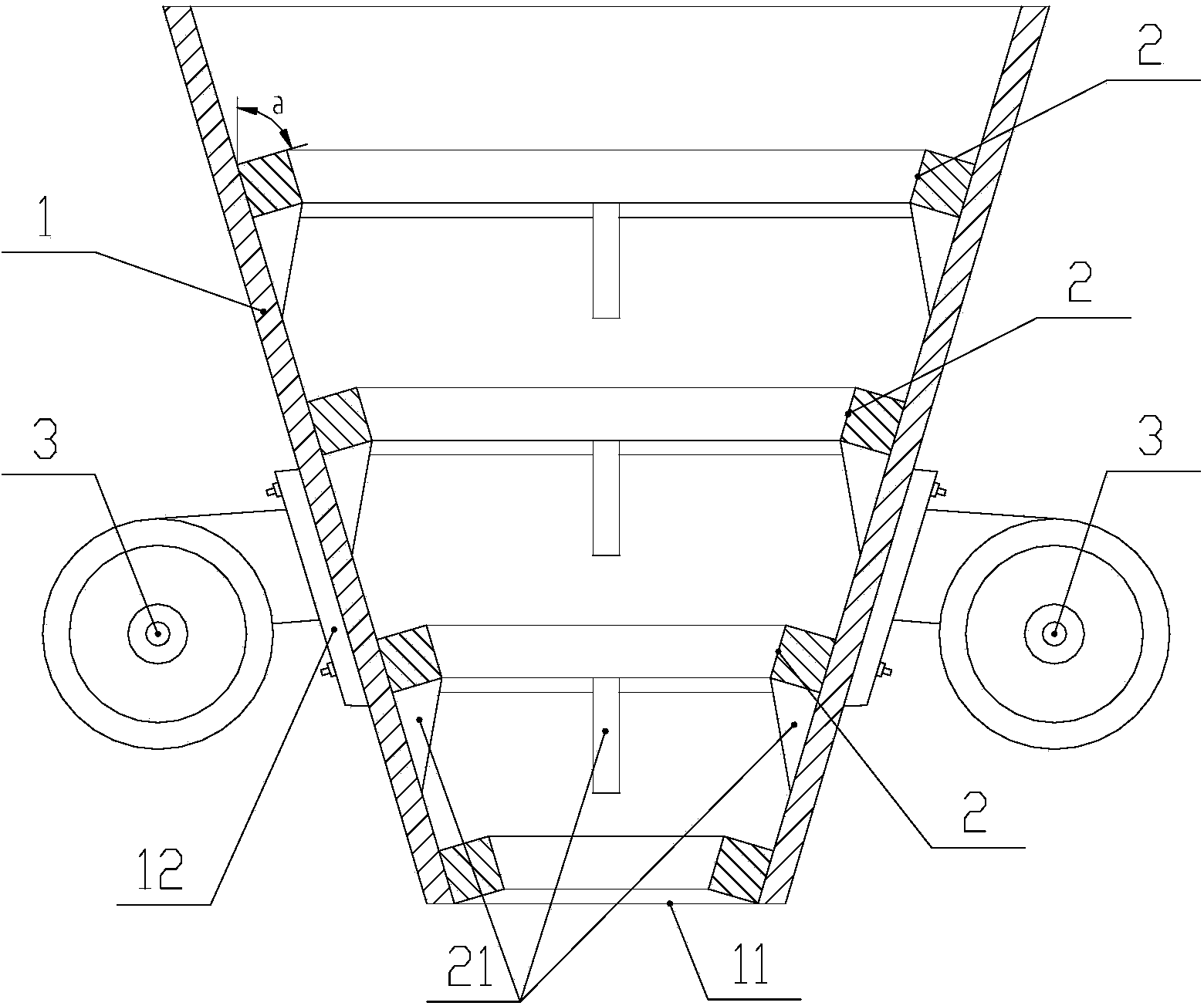

Ore feeding hopper device

Owner:四川安宁铁钛股份有限公司

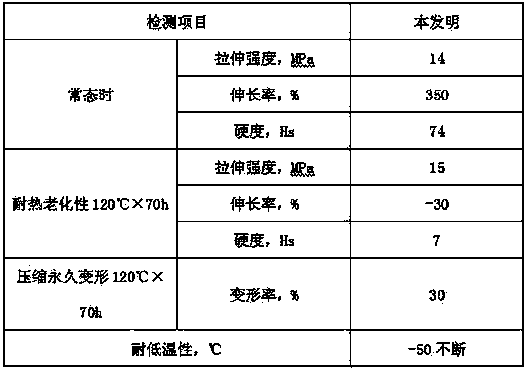

Rubber tube and preparation method thereof

ActiveCN104072973AImprove high temperature resistanceImprove low temperature resistancePolymer scienceAntimony trioxide

Owner:LIUZHOU YINGHANG AUTO PARTS

Anti-corrosion and anti-wear high manganese steel and preparation method thereof

Owner:江苏久华环保科技股份有限公司

Wear-resistant non-toxic modified plastic production method

Owner:CHUZHOU BETTYMA BABY CARRIER CO LTD

Pneumatic tire

ActiveUS20120193008A1Improve wear resistanceReduce rolling resistancePneumatic tyre reinforcementsSpecial tyresRolling resistanceShortest distance

There is provided a pneumatic tire having excellent uneven wear resistance performance, low rolling resistance and durability of side portion's appearance. The pneumatic tire comprises a carcass as a framework consisting of at least one carcass ply troidally extending between bead portions embedded with a pair of bead cores and turned around the bead cores from an inner side to an outer side in a tire width direction, a belt comprising at least one inclined belt layer and a tread successively disposed on a radially outer side of a crown portion of the carcass, wherein a ratio BD / BW is in a range between 0.01 and 0.04 in a section of the tire in the width direction in a state where the tire is mounted on an application rim, where BD is radius difference between radius at a central portion and radius at an end portion in the tire width direction of the outermost layer of the inclined belt layer and BW is a width of the outermost layer and CSEh is larger than SWh, where CSEh is a shortest distance from an end of a turn-up portion of the at least one carcass ply to a line drawn in parallel with a tire rotation axis at a bead toe and SWh is a shortest distance between a line drawn in parallel with the tire rotation axis at a maximum width position of the tire and the line drawn in parallel with the tire rotation axis at the bead toe.

Owner:BRIDGESTONE CORP

UV wax oil and preparation method thereof

InactiveCN110079198AIncrease productivityHigh coating hardnessWax coatingsAntifouling/underwater paintsVegetable oilUltraviolet

The invention discloses UV (ultraviolet) wax oil which comprises the following raw materials in percentage by mass: 40-60% of vegetable oil modified epoxy acrylate, 10-20% of Chinese wood oil, 5-10% of rosin, 5-10% of paraffin, 2-6% of beewax, 3-7% of palm wax, 3-6% of photoinitiator, 0.5-2% of assistant and 10-20% of wear-proof powder. The raw materials are combined together organically, so thatthe UV wax oil can be used for roller coating or rubbing coating and produced on a production line; and the production efficiency is greatly improved. The UV wax oil is free from VOC (volatile organiccompound) emission, belongs to an environment-friendly product, is high in film hardness, good in wear resistance, water resistance and fouling resistance, high in adaptability and low in productioncost, and can completely substitute the traditional common wax oil; the high-quality UV wax oil can be prepared through a series of operation of material preparation, ester addition, addition of the oil, the wax, the rosin and the like, re-charging, inspection and packaging; intensive mixing of the raw materials is facilitated; the raw materials are made full use of; and the production quality ofthe UV wax oil is improved.

Owner:YOUCAI (SHANDONG) ENVIRONMENTAL PROTECTION TECH CO LTD

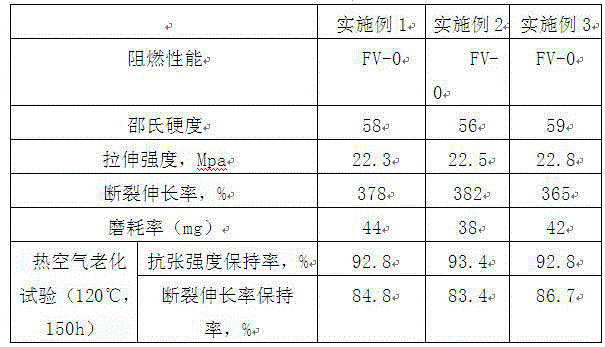

Flame-retardant and wear-resisting rubber material for borehole cable sheath and preparation method of flame-retardant and wear-resisting rubber material

InactiveCN105175824AImprove high temperature resistanceImprove wear resistanceRubber insulatorsPolymer scienceDibenzoyl Peroxide

Owner:华泓喆

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap