Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29 results about "Rosin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rosin, also called colophony or Greek pitch (Latin: pix græca), is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene components. It is semi-transparent and varies in color from yellow to black. At room temperature rosin is brittle, but it melts at stove-top temperature. It chiefly consists of various resin acids, especially abietic acid. The term "colophony" comes from colophonia resina, Latin for "resin from Colophon", an ancient Ionic city.

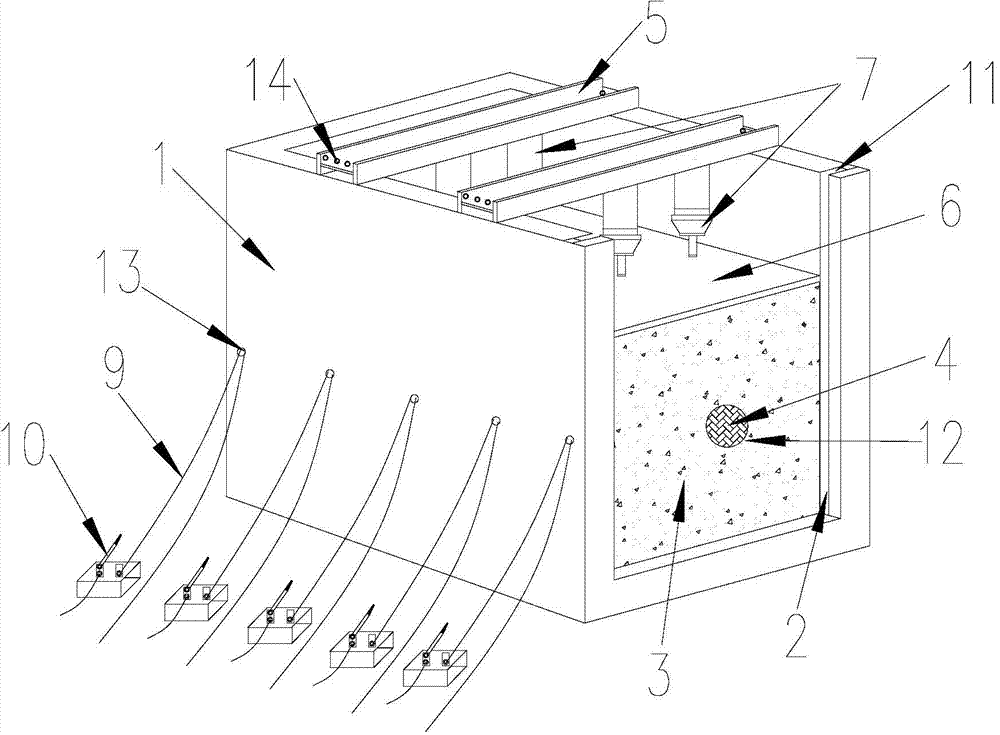

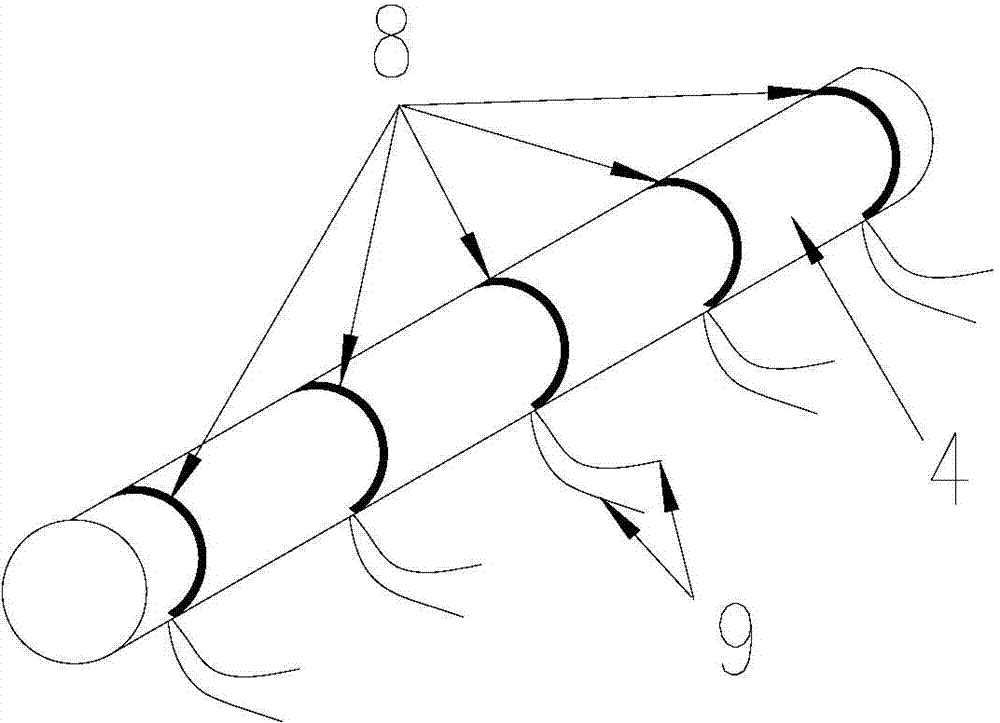

Laboratory model testing device for tunnel excavation

InactiveCN103616287AHigh simulationAvoid the influence of surrounding fillersMaterial strength using tensile/compressive forcesModel testingEngineering

Owner:HUNAN UNIV

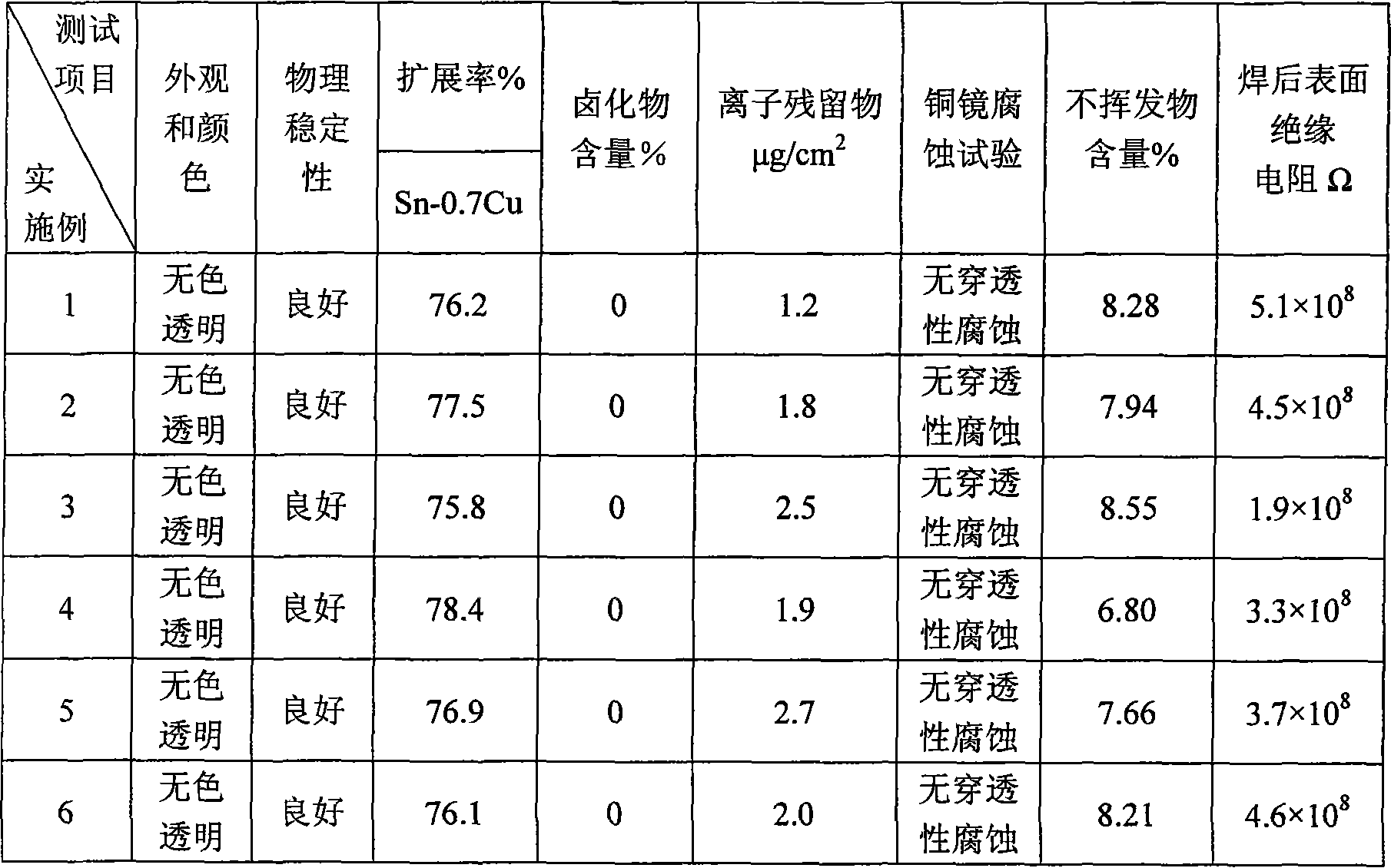

Free from cleaning soldering flux without halogen and rosin in use for solder without lead

InactiveCN101049661AImprove solderabilitySolderability is sufficientWelding/cutting media/materialsSoldering mediaHalogenSoldering

Owner:BEIJING UNIV OF TECH

Pressure-sensitive adhesive product

InactiveUS20060154097A1Easy to peelSynthetic resin layered productsEster polymer adhesivesParaffin waxRosin

Owner:NITTO DENKO CORP

Method of fast degradating pine dust rosin kind substance

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY +1

Tackifying resin prepared from rosinol recovery material and preparation method thereof

ActiveCN106519986ALow acid valueImprove stabilityNatural resin chemical modificationRosin adhesivesDistillationAdditional values

The invention discloses a method for preparing tackifying resin from a rosinol recovery material. The method comprises the following steps: firstly washing and then adsorbing rosinol, then enabling rosinol to react with dienophile to obtain adduct, heating the adduct, and then carrying out reduced pressure distillation to prepare liquid tackifying resin; meanwhile, the invention discloses tackifying resin prepared by the method. Through the method, the problems of environmental pollution and resource waste caused by rosinol in the esterification and production process of rosin are solved; the product additional value of the rosinol is increased.

Owner:JIANGXI JINAN FORESTY IND CO LTD

Concrete expansive agent

Owner:王嘉文

Method for preparing laser cladding layer through double-layer organic coating iron-based alloy powder

ActiveCN105081313AWith metallic lusterControl gas compositionMetallic material coating processesDistillationSlurry

The invention discloses a method for preparing a laser cladding layer through double-layer organic coating iron-based alloy powder. 15%-19% of chromium, 2%-9% of nickel, 0.05%-0.15% of boron, 0.1%-0.7% of silicon, carbon less than 0.3% and the balance iron are selected; and then rosin accounting for 0.06%-0.2% of the total weight of the iron-based alloy powder and industrial starch accounting for 0.15%-0.4% of the total weight of the iron-based alloy powder are selected. The selected rosin is added to absolute ethyl alcohol, and the iron-based alloy powder is added to the absolute ethyl alcohol with the dissolved rosin; and rosin film coated iron-based alloy powder is prepared through drying by distillation, drying and breaking. Then, the industrial starch is added to pure water to be heated and stirred to obtain an even pasty solution, and the rosin film coated iron-based alloy powder is put in the pasty industrial starch; secondary mixed slurry is obtained; and the double-layer organic coating iron-based alloy powder can be obtained through stirring, drying by distillation and breaking. The laser cladding layer of the powder is flat in surface, has metal luster and is high in comprehensive quality.

Owner:NANHUA UNIV

Soft solder for SnAgCuNiGe alloy solder paste

InactiveCN101176957AWeldablePrintableWelding/cutting media/materialsSoldering mediaActive agentMetallurgy

Owner:东莞市特尔佳电子有限公司

UV wax oil and preparation method thereof

InactiveCN110079198AIncrease productivityHigh coating hardnessWax coatingsAntifouling/underwater paintsVegetable oilUltraviolet

The invention discloses UV (ultraviolet) wax oil which comprises the following raw materials in percentage by mass: 40-60% of vegetable oil modified epoxy acrylate, 10-20% of Chinese wood oil, 5-10% of rosin, 5-10% of paraffin, 2-6% of beewax, 3-7% of palm wax, 3-6% of photoinitiator, 0.5-2% of assistant and 10-20% of wear-proof powder. The raw materials are combined together organically, so thatthe UV wax oil can be used for roller coating or rubbing coating and produced on a production line; and the production efficiency is greatly improved. The UV wax oil is free from VOC (volatile organiccompound) emission, belongs to an environment-friendly product, is high in film hardness, good in wear resistance, water resistance and fouling resistance, high in adaptability and low in productioncost, and can completely substitute the traditional common wax oil; the high-quality UV wax oil can be prepared through a series of operation of material preparation, ester addition, addition of the oil, the wax, the rosin and the like, re-charging, inspection and packaging; intensive mixing of the raw materials is facilitated; the raw materials are made full use of; and the production quality ofthe UV wax oil is improved.

Owner:YOUCAI (SHANDONG) ENVIRONMENTAL PROTECTION TECH CO LTD

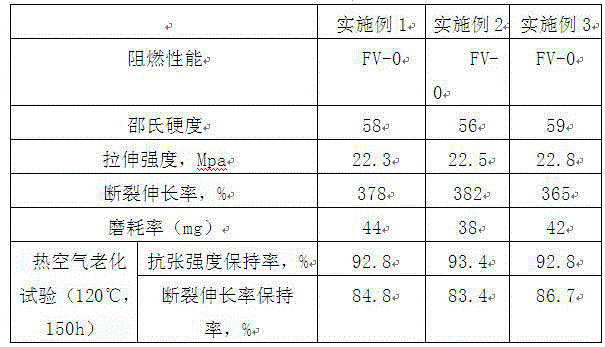

Flame-retardant and wear-resisting rubber material for borehole cable sheath and preparation method of flame-retardant and wear-resisting rubber material

InactiveCN105175824AImprove high temperature resistanceImprove wear resistanceRubber insulatorsPolymer scienceDibenzoyl Peroxide

Owner:华泓喆

Chemical pump inner cavity insulated oil paint and preparation method thereof

InactiveCN106046954AUniform textureGuaranteed to workRubber insulatorsRubber derivative coatingsRare earthPyrophosphate

Owner:安徽天富泵阀有限公司

Wood wax oil timber modifier and preparation method thereof

InactiveCN105881684AMaintain colorGuaranteed anti-corrosionWood impregnation detailsMoisture absorptionPolymerization

The invention discloses a wood wax oil timber modifier and a preparation method thereof. The modifier comprises the following components by mass percentage: 28-32% of tung oil, 8-12% of camphor wood oil, 17-22% of rosin-modified resin, 9-11% of orange oil, 4-6% of glass powder, and 22-27% of ethanol. The preparation method comprises the following steps: the tung oil, the camphor wood oil, rosin-modified resin, orange oil, and glass powder are placed in a reaction vessel, are subjected to a polymerization at the high temperature of 260-300 DEG C, then cooled to the temperature of 70-90 DEG C, ethyl alcohol is added for being stirred, and then the materials are cooled to the room temperature to obtain the product. The preparation method has simple process, the modifier does not contain toxic components such as triphenyl, formaldehyde and heavy metals, has no pungent smell, can keep original color when used on the timber, has the advantages of anticorrosion, insect resistance, non moisture absorption, non moistening, non deformation, and no influence on glues and paints.

Owner:董学明

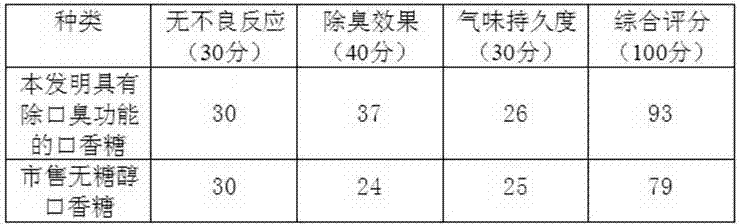

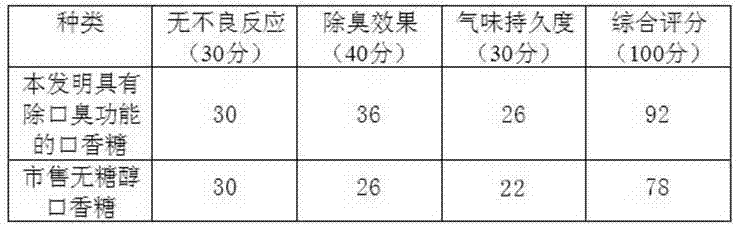

Chewing gum with halitosis dispelling effect

InactiveCN102919495AChewing gumParaffin waxRosin

Owner:HENAN UNIV OF SCI & TECH

Polyvinyl chloride floor reinforcing agent prepared from hydrophobic precipitated silicon dioxide

InactiveCN106366534ARosinVolcanic ash

Owner:ANHUI LONGQUAN SILICON MATERIAL

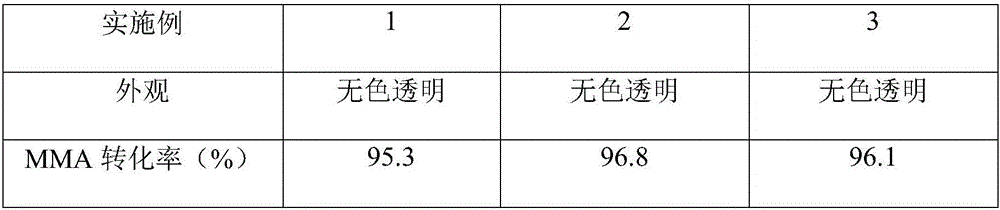

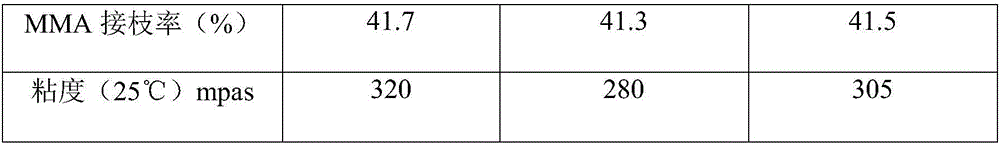

SBS grafted odor-removing mattress spraying glue and preparation method thereof

ActiveCN107177332AIncrease forceReduce the numberMacromolecular adhesive additivesGraft polymer adhesivesElastomerMethyl isobutyl ketone

Owner:佛山市东方树新材料科技有限公司

Filter paper with high filtering efficiency, and preparation method thereof

InactiveCN103437249AEvenly distributedFacilitate cross-linkingSynthetic cellulose/non-cellulose material pulp/paperFiltration separationFiberFiltration

The invention relates to filter paper with high filtering efficiency, and a preparation method thereof. The filter paper with high filtering efficiency disclosed by the invention is composed of the following raw materials by weight: 50-60 parts of jute pulp, 45-50 parts of wood pulp, 20-25 parts of polystyrene fibers, 3-5 parts of sodium carboxymethyl cellulose, 3-4 parts of a nano carbon powder, 1-2 parts of feldspar powder, 1-2 parts of alum powder, 1-2 parts of 4,4'-diphenylmethane diisocyanate, 2-3 parts of diethylene triamine, 2-3 parts of polyamide wax micropowder, 0.8-1 part of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 0.4-0.6 part of an antioxidant DSTP, 0.5-0.6 part of sodium persulfate, 2-3 parts of ethylene glycol, 6-7 parts of rosin, 15-20 parts of absolute ethyl alcohol, 3-4 parts of nano diatomite, 0.8-1 part of polyoxyethylene octyphenyl ether, 0.3-0.4 part of Gamma-(2,3-epoxypropoxy)propyl trimethoxysilane and a proper amount of water. The filter paper produced by the invention has high filtration precision, high filtration efficiency, small air resistance and strong pollutant-holding capacity, and is environment-friendly.

Owner:BENGBU PIONEER FILTER

Phthalocyanine blue and manufacturing process

Owner:滨海康益医药化工有限公司

Reactive permeable tack coat material special for water permeable pavement

InactiveCN108949087ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerRosin

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +2

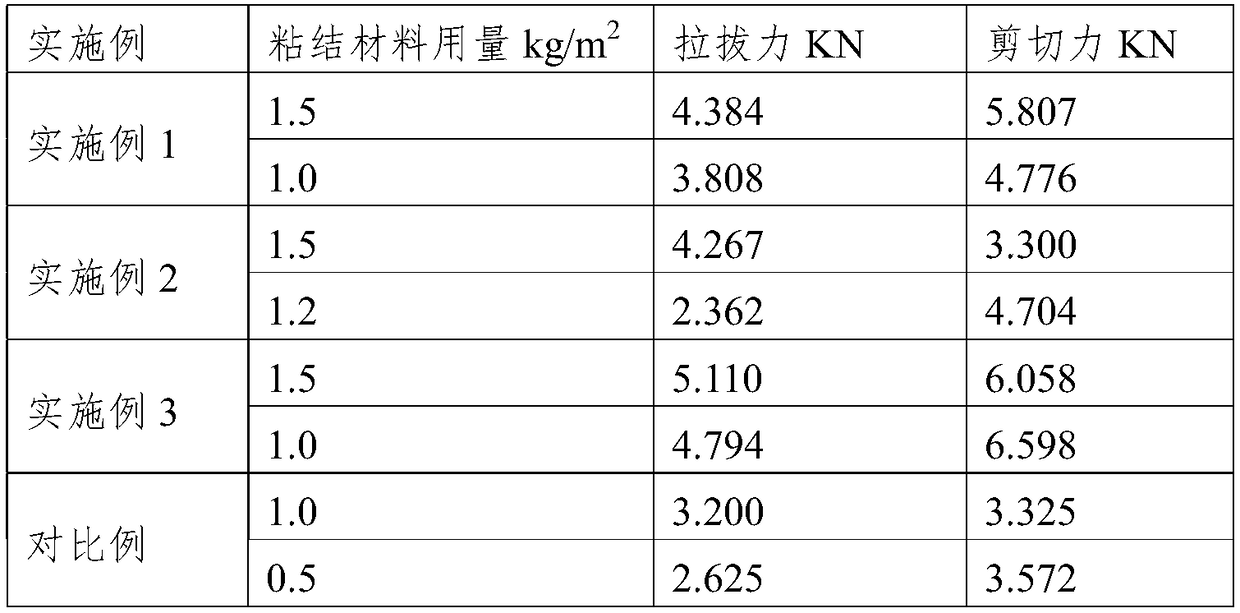

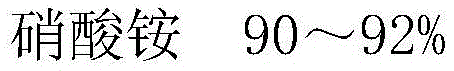

Environmental-friendly powder emulsion explosive and preparation method thereof

InactiveCN105566018ASacrifice distance increasedHigh intensityEnergy inputExplosive working-up apparatusWaxAdditive ingredient

Owner:HUBEI SHUAILI CHEM

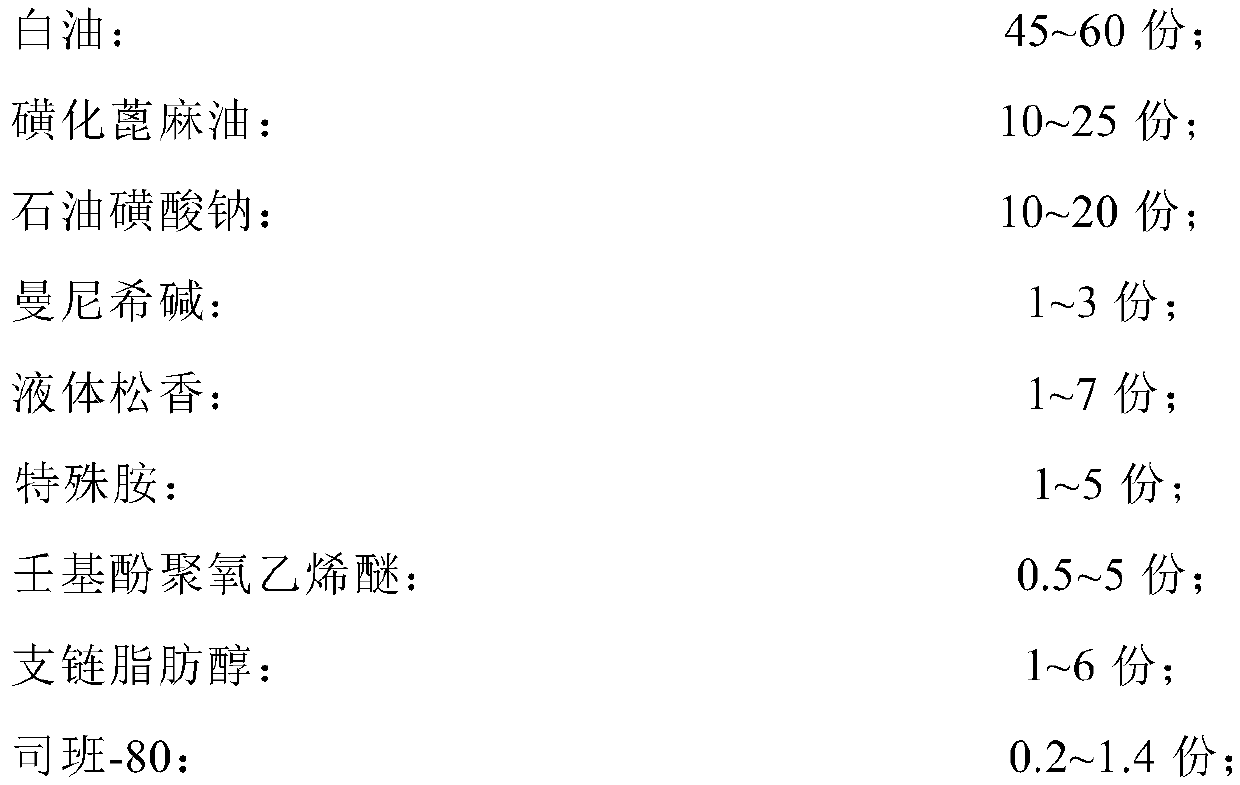

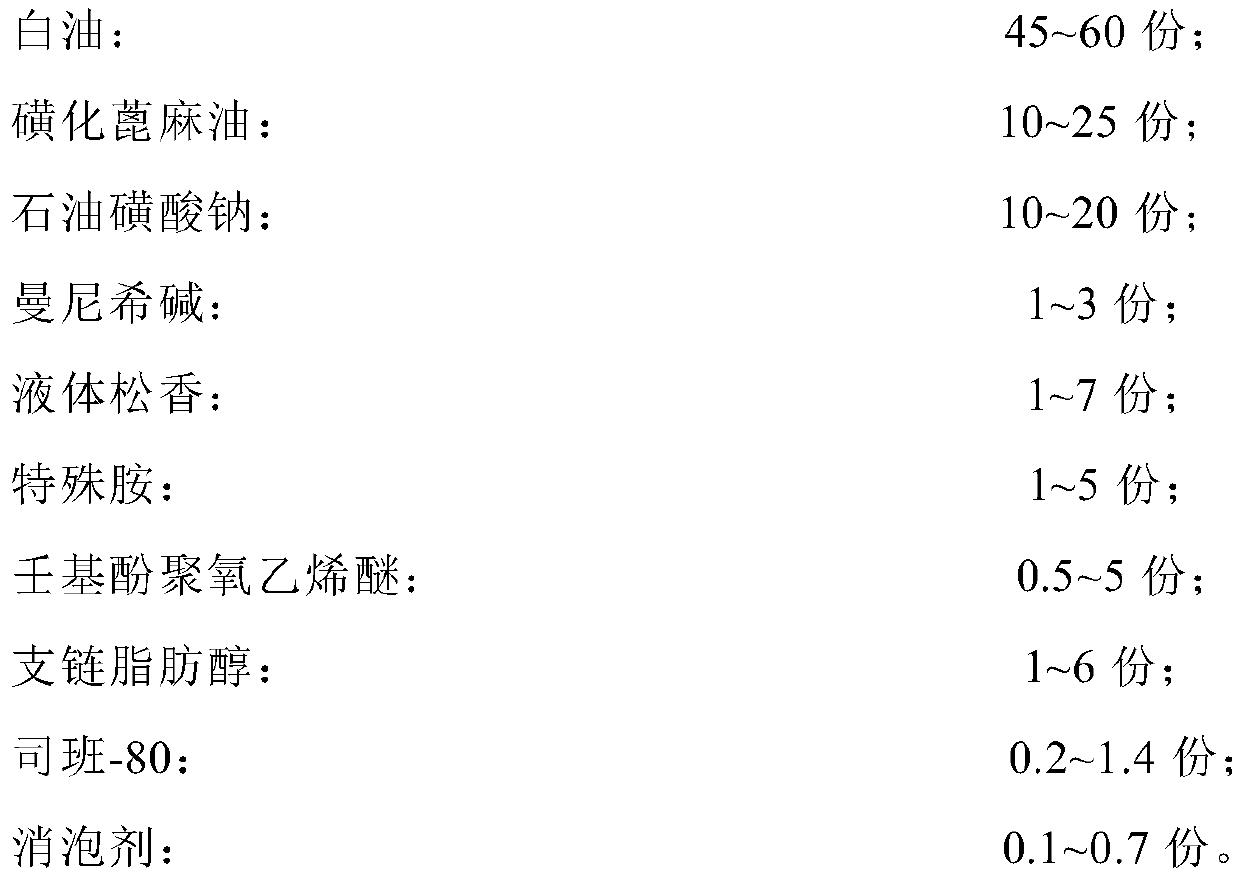

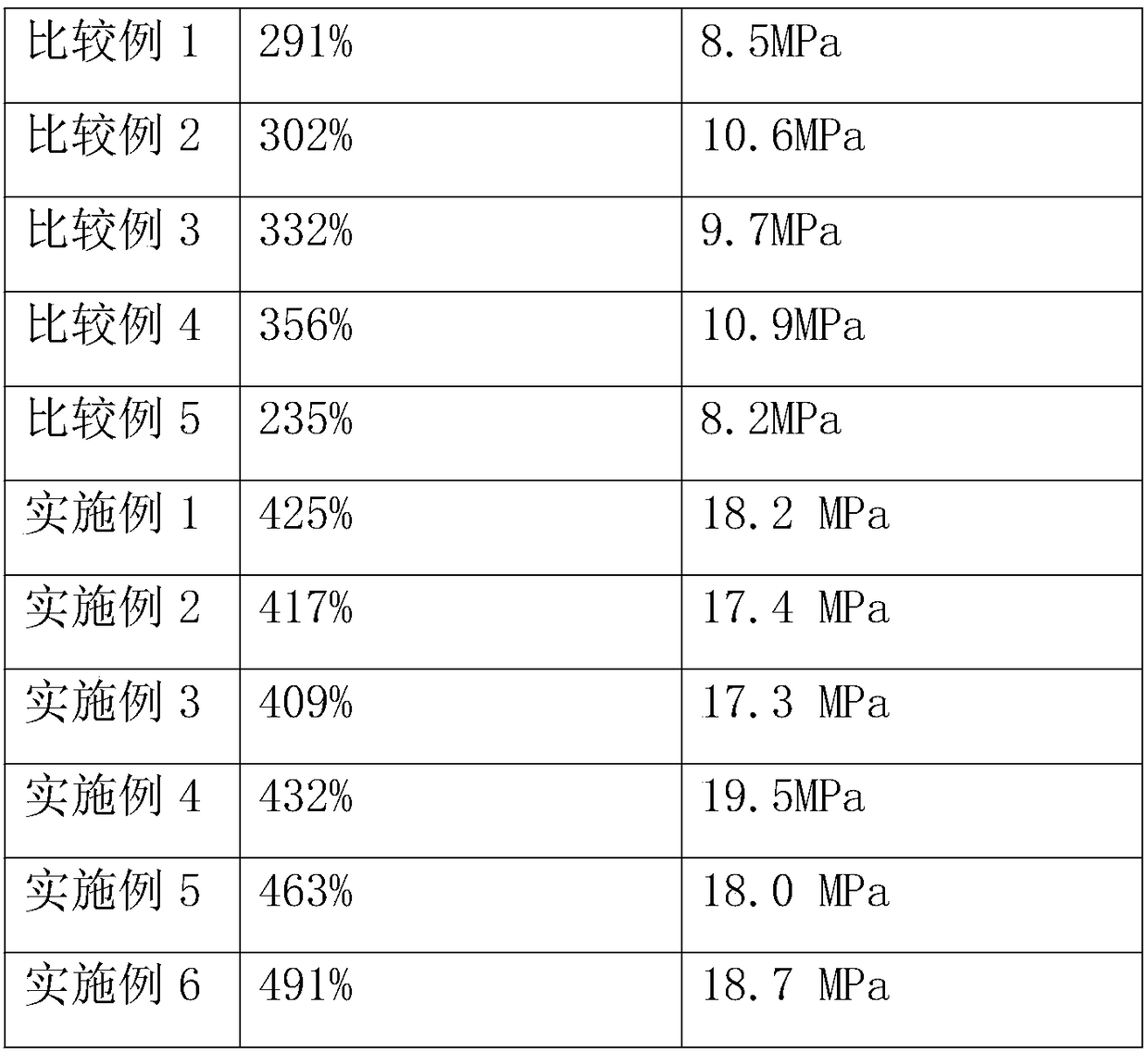

Copper alloy cutting fluid composition and preparation method thereof

Owner:上海樱花化研化工科技有限公司

Odorless high-strength regenerated rubber

Owner:四川省隆昌海燕橡胶有限公司

Colorful special coating for building

Owner:RUGAO CHANGJIANG SCI & TECHCAL IND CO LTD

Modified PET tangle film and manufacturing method thereof

The invention discloses a modified PET tangle film and a manufacturing method thereof. The modified PET tangle film comprises the following raw materials in parts by weight: 10 to 20 parts of modifiedPET material, 4 to 6 parts of polyamide resin, 3 to 4 parts of modified maleic resin, 1.6 to 2.4 parts of modified Dama resin, 1 to 2 parts of erucyl amide, 2 to 3 parts of propylene glycol monomethyl ether, 2 to 3 parts of tributyl citrate, 1 to 2 parts of diacetone diamine, 0.3 to 0.5 part of styrene, 1 to 2 parts of dioctyl sebacate, 0.2 to 0.4 part of tricresyl phosphate, 2 to 4 parts of aziridine, 0.1 to 0.2 part of ammonium molybdate, 1 to 2 parts of isobutyl methacrylate and 5 to 7 parts of rosin resin. The manufacturing method comprises the following steps: mixing and drying the aboveraw materials, plasticizing and melting, extruding to form a film sheet, performing rapid-cooling shaped on a cooling roller, preheating by a heating roller, performing longitudinal stretching of 1:(2-5) between a low-speed roller and a high-speed roller, shaping by a shaping roller, cutting edges, rolling and performing aging treatment to obtain a finished product. The production efficiency andthe product performance of the modified PET tangle film can be greatly improved.

Owner:ANHUI JIAMEI PACKAGING CO LTD

Antistatic foaming tipping paper printing ink

Owner:江苏卫星新材料股份有限公司

Foam concrete foaming agent

InactiveCN106007459AEvenly distributedDoes not significantly reduce strengthFoam concreteFatty alcohol

The invention discloses a foam concrete foaming agent, which comprises the following components in proportion by weight: 50-60 parts of hydrogen peroxide, 3-5 parts of hydrochloric acid, 2-3 parts of borax, 0.1-0.2 parts of rosin emulsion, fat Alcohol polyoxyethylene ether sodium sulfate 0.2-0.4 parts, magnesium sulfate 2-3 parts, water 28.4-42.7 parts, a total of 100 parts of each component. The invention has the advantages of strong foaming ability, uniform distribution of pores, small and consistent pore size, and does not significantly reduce the strength of the concrete under the premise of satisfying various properties of the foamed concrete.

Owner:JIANGSU MINGHE GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap