Copper alloy cutting fluid composition and preparation method thereof

A cutting fluid and composition technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of cutting fluid blue, green, lack of copper ions, etc., to maintain pH value, enhance binding force, excellent slow release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

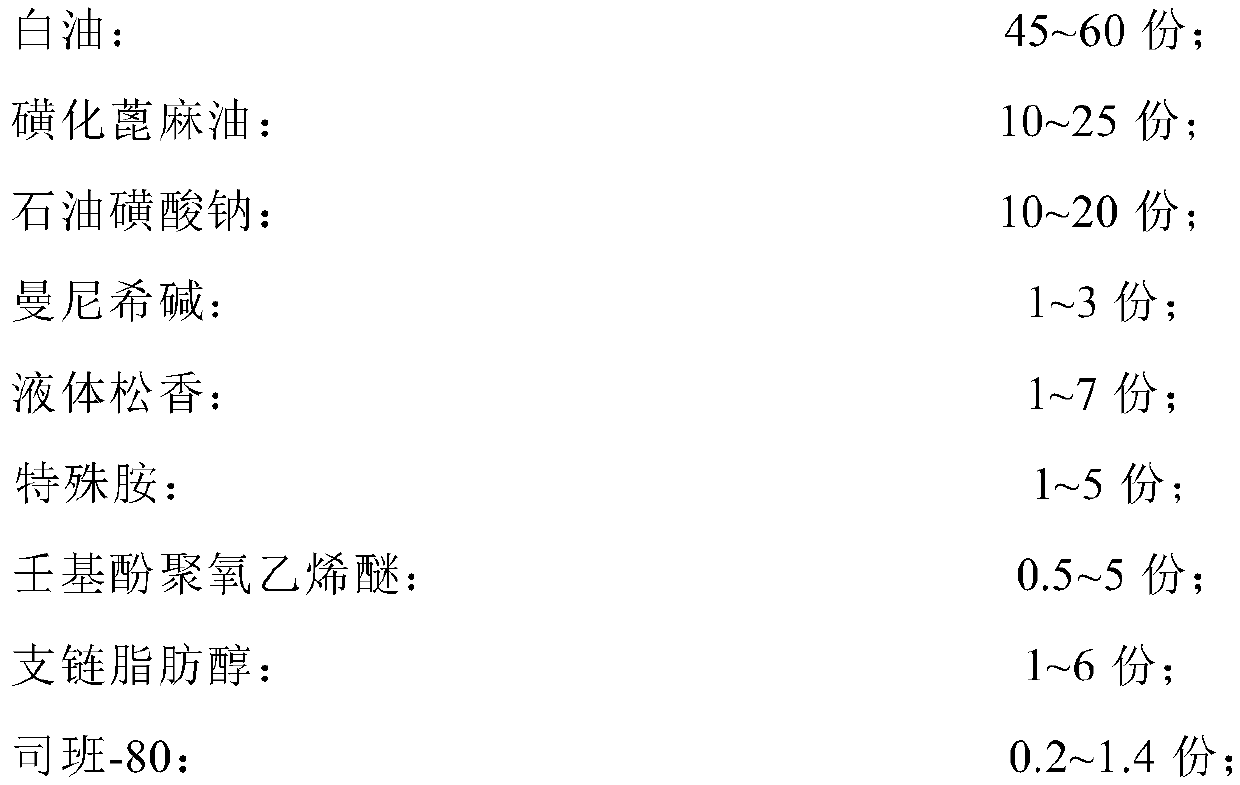

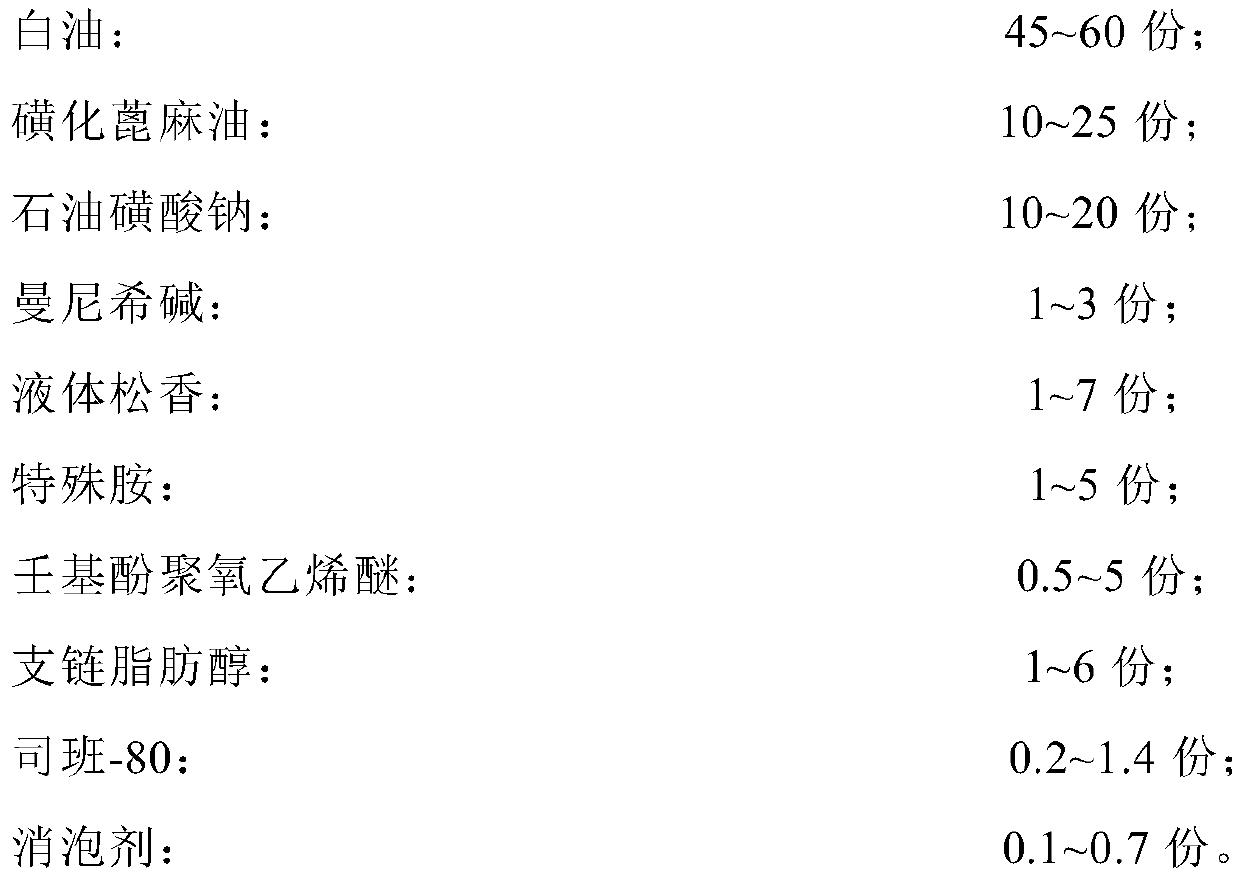

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment provides a kind of preparation method of Mannich base, comprises the steps:

[0032] After mixing benzotriazole, 40wt% formaldehyde aqueous solution and diethylamine according to the mass ratio of 4:3:2, after reacting at room temperature, the crude product was obtained by distillation;

[0033] The crude product and absolute ethanol were subjected to alcohol precipitation according to the volume ratio of 1:3, the collected precipitate was extracted with absolute ethanol, and dried to obtain the Mannich base, which was named diethylaminomethylbenzene Triazole.

Embodiment 2

[0035] The present embodiment provides a kind of preparation method of Mannich base, comprises the steps:

[0036] After mixing benzotriazole, 40wt% formaldehyde aqueous solution and dimethylamine according to the mass ratio of 4:3:2, after reacting at room temperature, the crude product was obtained by distillation;

[0037] The crude product and dehydrated ethanol are subjected to alcohol precipitation according to the volume ratio of 1:3, the collected precipitate is extracted with dehydrated ethanol, and the Mannich base is obtained by drying, which is named as dimethylaminomethylbenzene Triazole.

Embodiment 3

[0039] The present embodiment provides a kind of preparation method of Mannich base, comprises the steps:

[0040] After mixing benzotriazole, 40wt% formaldehyde aqueous solution and morpholine according to the mass ratio of 4:3:2, after reacting at room temperature, the crude product was obtained by distillation;

[0041] The crude product and dehydrated ethanol are subjected to alcohol precipitation according to the volume ratio of 1:3, the precipitate is collected and extracted with dehydrated ethanol, and dried to obtain the Mannich base, which is named as morpholine methylbenzene Azole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap