Free from cleaning soldering flux without halogen and rosin in use for solder without lead

A lead-free solder, halogen-free technology, used in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problem of incompatibility of no-clean welding process, and achieve superior soldering performance and high electrical insulation. , strong wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

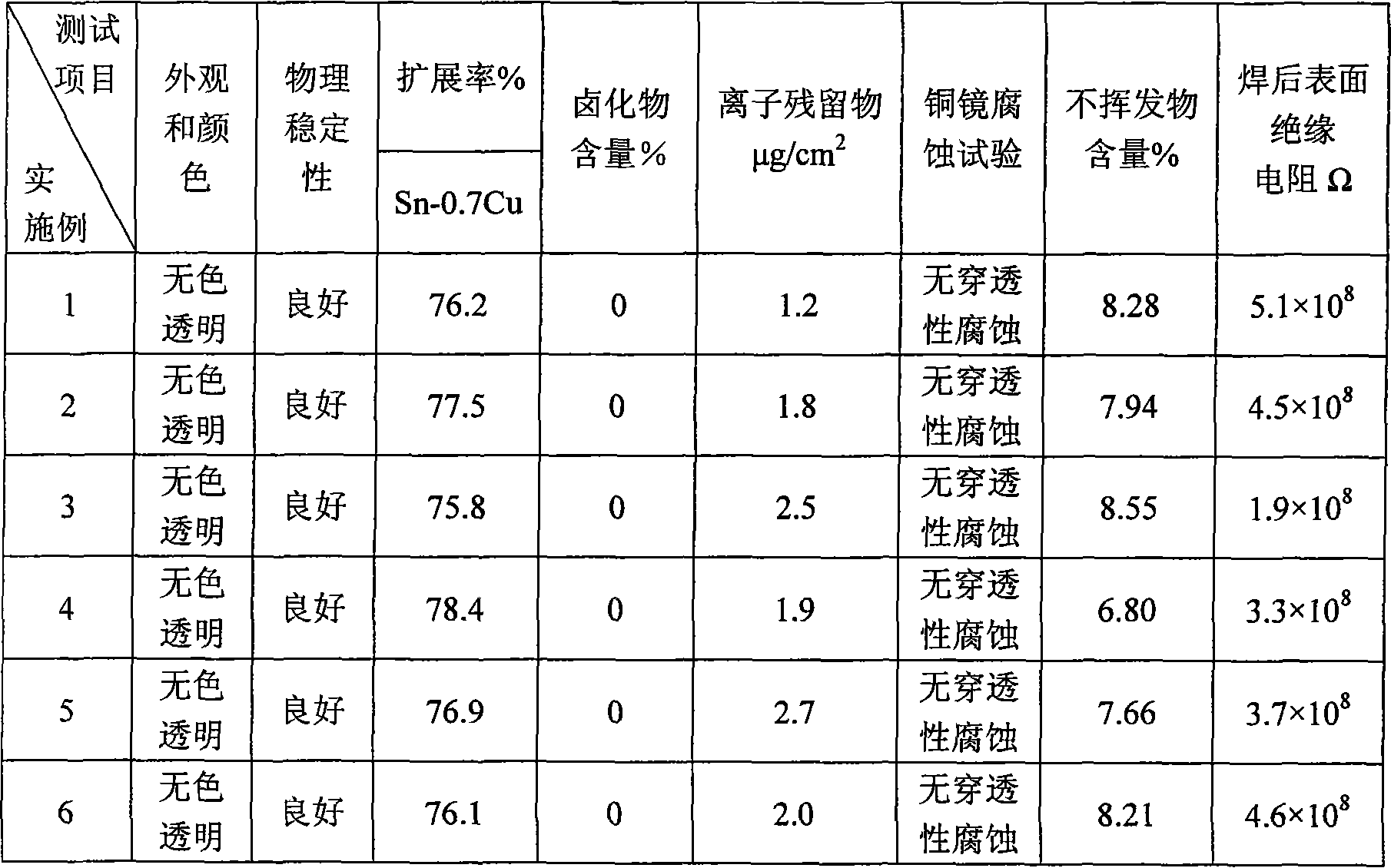

Examples

Embodiment 1

[0029] Succinic acid 2.0

[0030] Glutaric acid 0.6

[0031] Salicylic acid 1.2

[0032] Tartaric acid 0.1

[0033] Citric acid 0.8

[0034] OP emulsifier 0.1

[0035] Glycerol 16.0

[0036] Ethylene glycol monobutyl ether 12.0

[0037] PEG-400 0.5

[0038] Benzotriazole 0.1

[0039] Deionized water 57.6

[0040] Preparation method:

[0041] Add co-solvent and part of deionized water into the reaction kettle with agitator first, add film-forming agent under stirring, add the remaining amount of deionized water, activator and surfactant after dissolving, then add corrosion inhibitor, stir until The solid matter is completely dissolved, the materials are mixed evenly, and the filtrate is retained after static filtration to obtain the flux of the present invention.

Embodiment 2

[0043] Salicylic acid 1.5

[0044] Succinic acid 1.5

[0045] Adipic acid 0.2

[0046] Tartaric acid 0.2

[0047] Lactic acid 1.0

[0048] TX-10 0.2

[0049] Glycerol 18.0

[0050] Diethylene glycol 4.0

[0051] Ethylene glycol monobutyl ether 15.0

[0052] PEG-600 0.5

[0053] Benzotriazole 0.1

[0054] Deionized water 57.8

[0055] The preparation and use methods are the same as in Example 1.

Embodiment 3

[0057] DL-malic acid 1.8

[0058] Tartaric acid 0.2

[0059] Citric acid 0.5

[0060] Lactic acid 0.5

[0061] OP emulsifier 0.3

[0062] Glycerol 18.0

[0063] Diethylene glycol ether 15.0

[0064] PEG-400 0.5

[0065] Triethylamine 0.1

[0066] Deionized water 63.1

[0067] The preparation and use methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap