Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

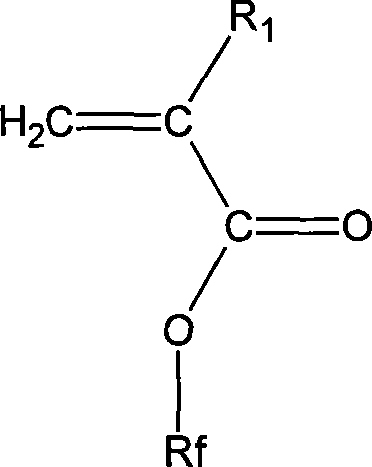

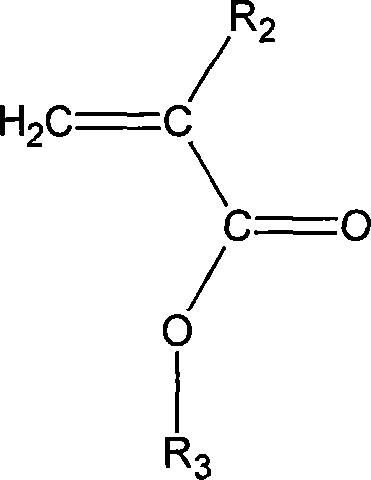

Acrylates (IUPAC: prop-2-enoates) are the salts, esters, and conjugate bases of acrylic acid and its derivatives. The acrylate ion is the anion CH₂=CHCOO⁻. Often acrylate refers to esters of acrylic acid, the most common member being methyl acrylate. Acrylates contain vinyl groups directly attached to the carbonyl carbon. These monomers are of interest because they are bifunctional: the vinyl group is susceptible to polymerization and the carboxylate group carries myriad functionality. Modified acrylates are also numerous, include methacrylates (CH₂=C(CH₃)CO₂R) and cyanoacrylates (CH₂=C(CN)CO₂R).

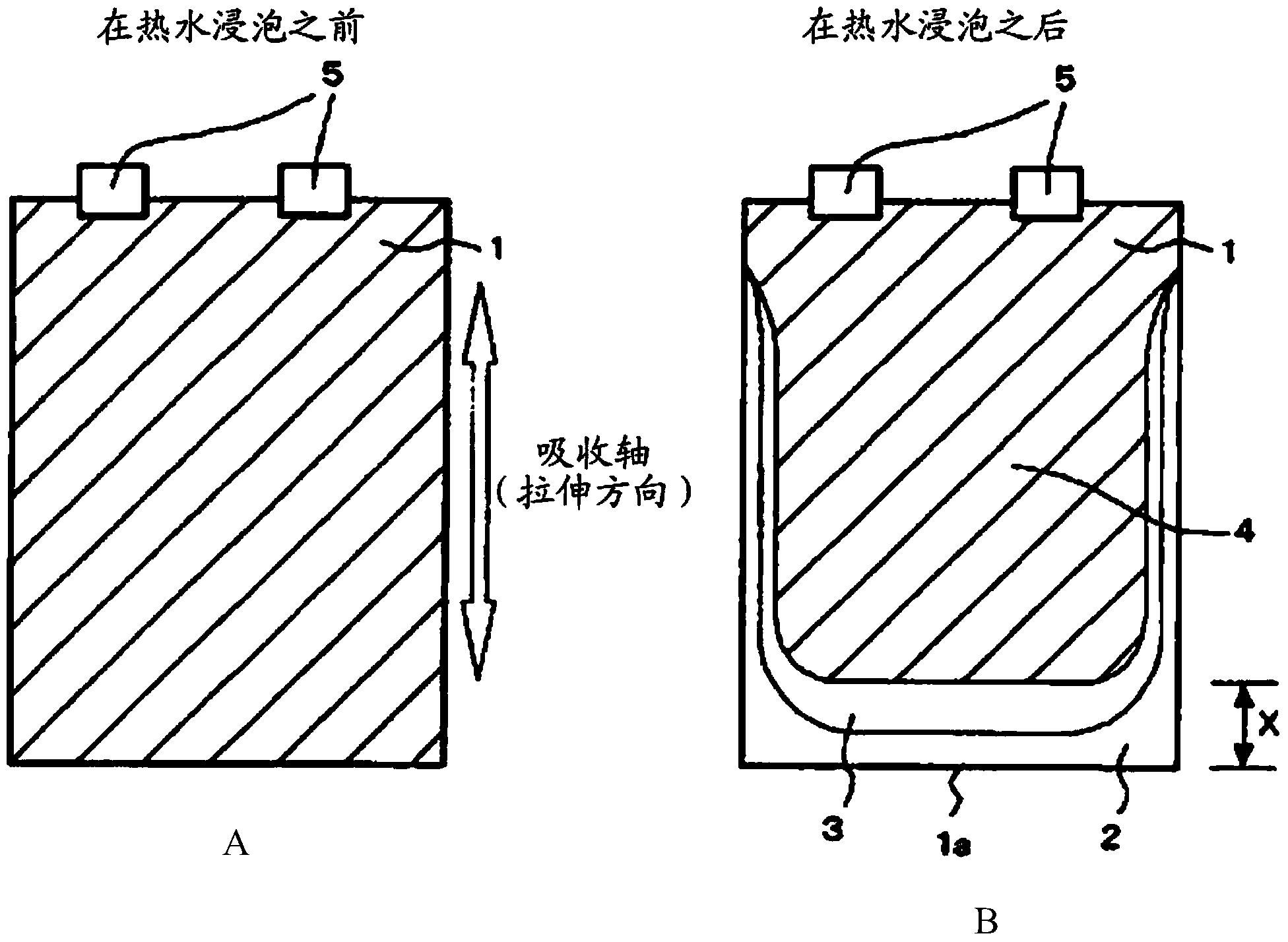

Irradiated biaxially oriented film

InactiveUS6869686B1Wrappers shrinkageShrinkage connectionsDeceneVinyl chloride

Owner:BEMIS COMPANY INC

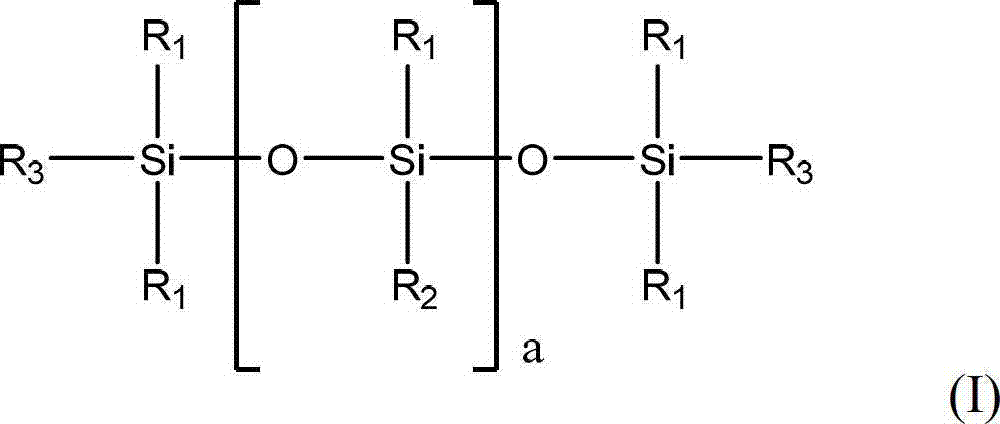

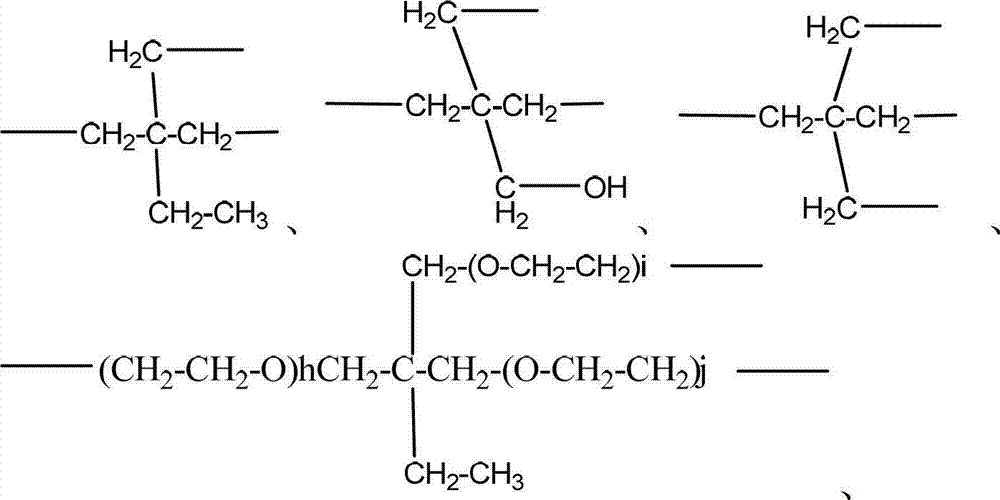

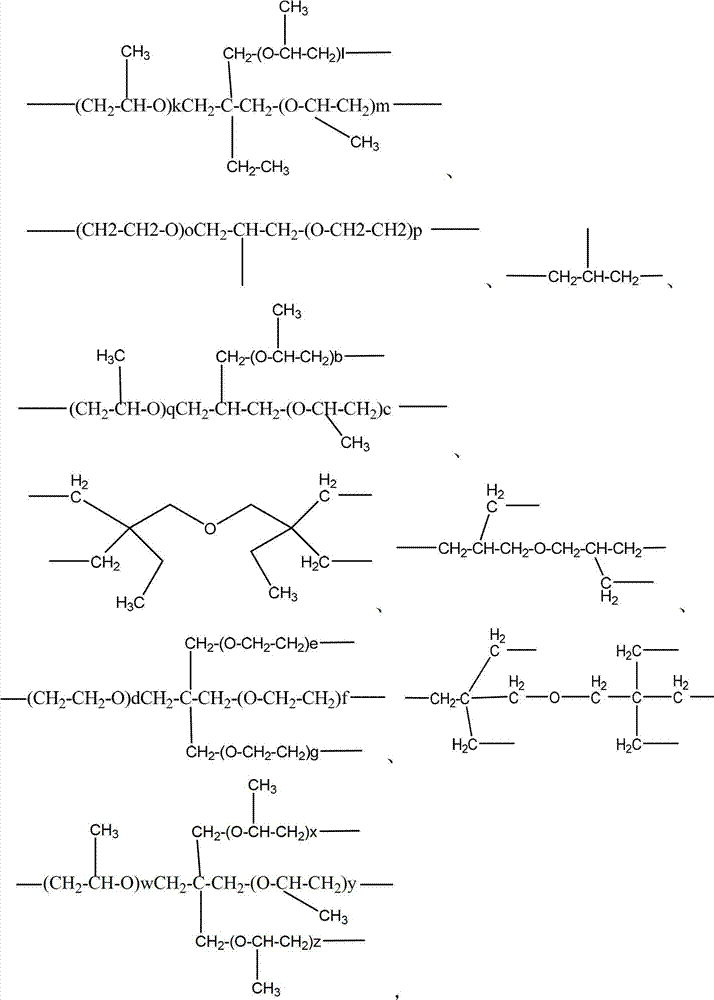

Use and composition of polysiloxane with modified acrylate radicals

ActiveCN102924993AImprove stain resistanceAntifouling/underwater paintsPaints with biocidesOligomerPolymer science

Owner:ETERNAL CHINA INVESTMENT

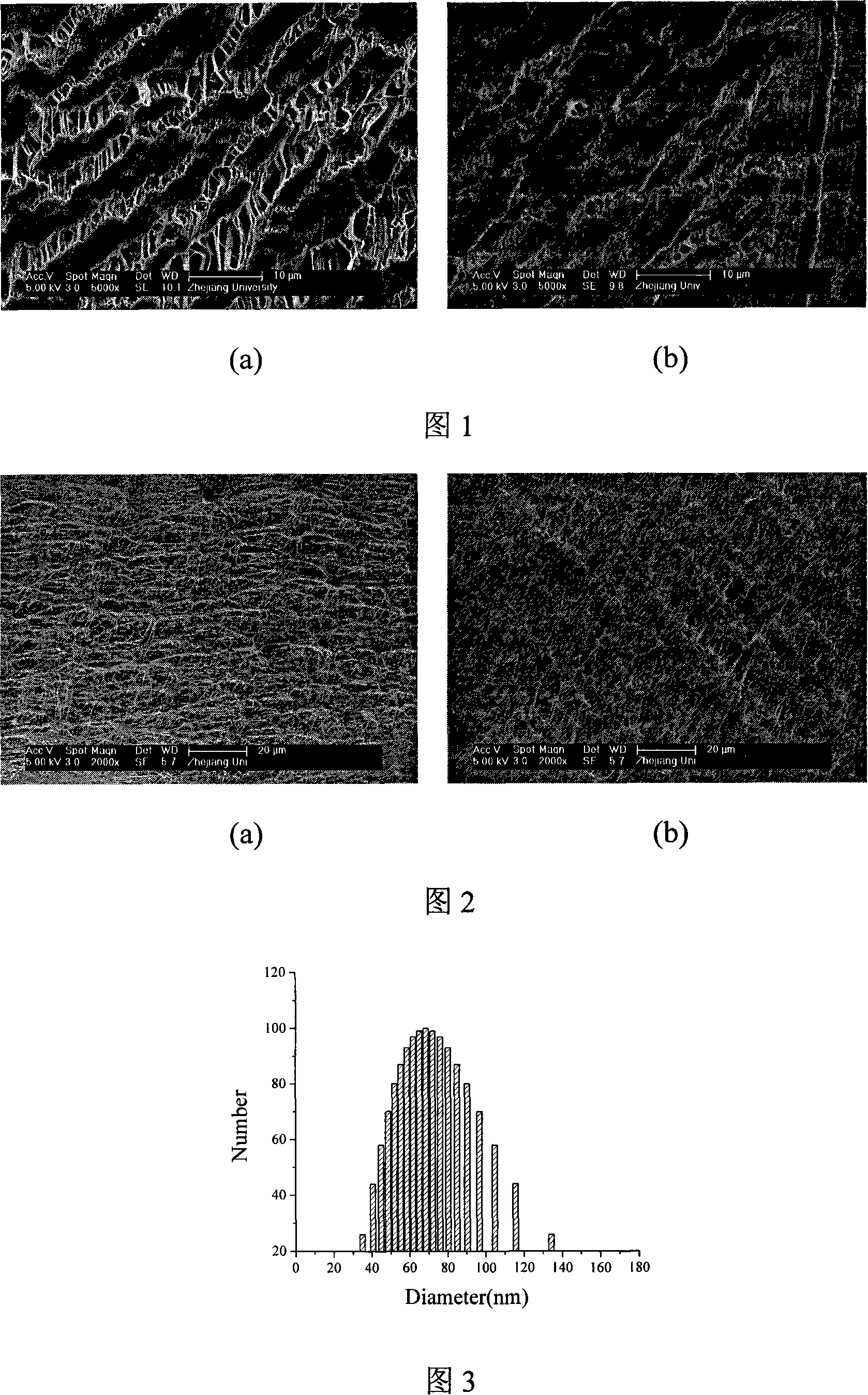

Method of amphipathic nature fluorine-contained copolymer modifying surface of polytetrafluoroethylene porous membrane

InactiveCN101108313AImprove anti-pollution performanceImprove hydrophilic abilitySemi-permeable membranesFiberTetrafluoroethylene

Owner:ZHEJIANG UNIV

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

Multi-purpose strippable acrylate adhesive microporous material and preparation method thereof

ActiveCN102925084AEasy to peelIncrease elasticityFilm/foil adhesivesEster polymer adhesivesPolymer scienceFoaming agent

Owner:HARBIN INST OF TECH

High-toughness high temperature-resistant modified PVC pipe

InactiveCN105440481AImprove toughnessImprove high temperature resistanceAcrylonitrileMaterials science

The invention discloses a high-toughness high temperature-resistant modified PVC pipe. The high-toughness high temperature-resistant modified PVC pipe comprises the following raw materials by weight: 80 to 120 parts of PVC resin, 30 to 60 parts of chlorinated polyethylene, 40 to 80 parts of liquid butadiene-acrylonitrile rubber, 10 to 30 parts of polyurethane elastomer, 2 to 8 parts of modified nanometer calcium carbonate, 1 to 5 parts of kaolin, 2 to 6 parts of fly ash, 4 to 8 parts of glass beads, 4 to 8 parts of glass fiber, 1 to 6 parts of titanium dioxide, 3 to 9 parts of PE wax, 2 to 5 parts of methyl methacrylate, 4 to 8 parts of acrylate, 1 to 5 parts of a heatproof modifier and 2 to 6 parts of a coupling agent. The PVC pipe provided by the invention has excellent toughness and high temperature resistance.

Owner:NINGGUO CITY GAOXIN PIPE CO LTD

Photo-cured acrylate-layered double hydroxide nano composite material and preparation method thereof

InactiveCN101555304AImprove efficiencyFast curingPigment treatment with non-polymer organic compoundsIon exchangeUltraviolet lights

Owner:广州市番禺广信丝印材料有限公司 +1

Modified polyurethane acrylic resin and preparation method thereof

InactiveCN107353865ANot yellowingGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesive

The invention discloses a modified polyurethane acrylic resin, which is prepared by polymerization among hydroxyl acrylate, diisocyanate, alkylated 4,4'-dicyclohexanol, and polyester / polyether glycol. The invention provides a method of preparing the modified polyurethane acrylic resin at the same time. The provided modified polyurethane acrylic resin does not contain active functional group such as phenyl ring, amino group, or the like, so the modified polyurethane acrylic resin will not become yellow even if the modified polyurethane acrylic resin is irradiated by light, and the weatherability is good. The resin can be applied to an adhesive, and has a good waterproof performance, good anti-falling performance, good drug resistant property, and excellent thermal stability.

Owner:SHENZHEN BAILICHU GLUE IND CO LTD

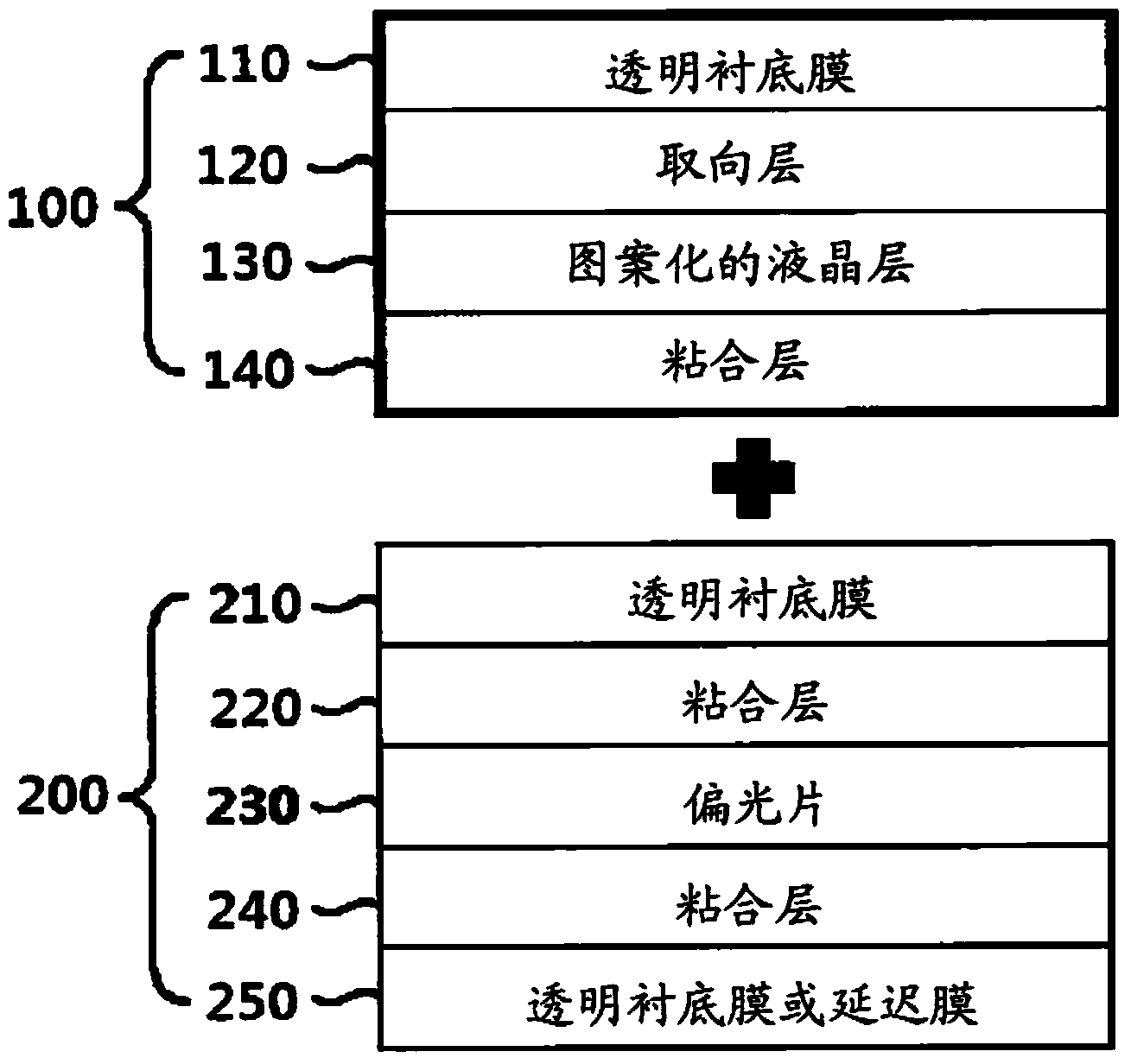

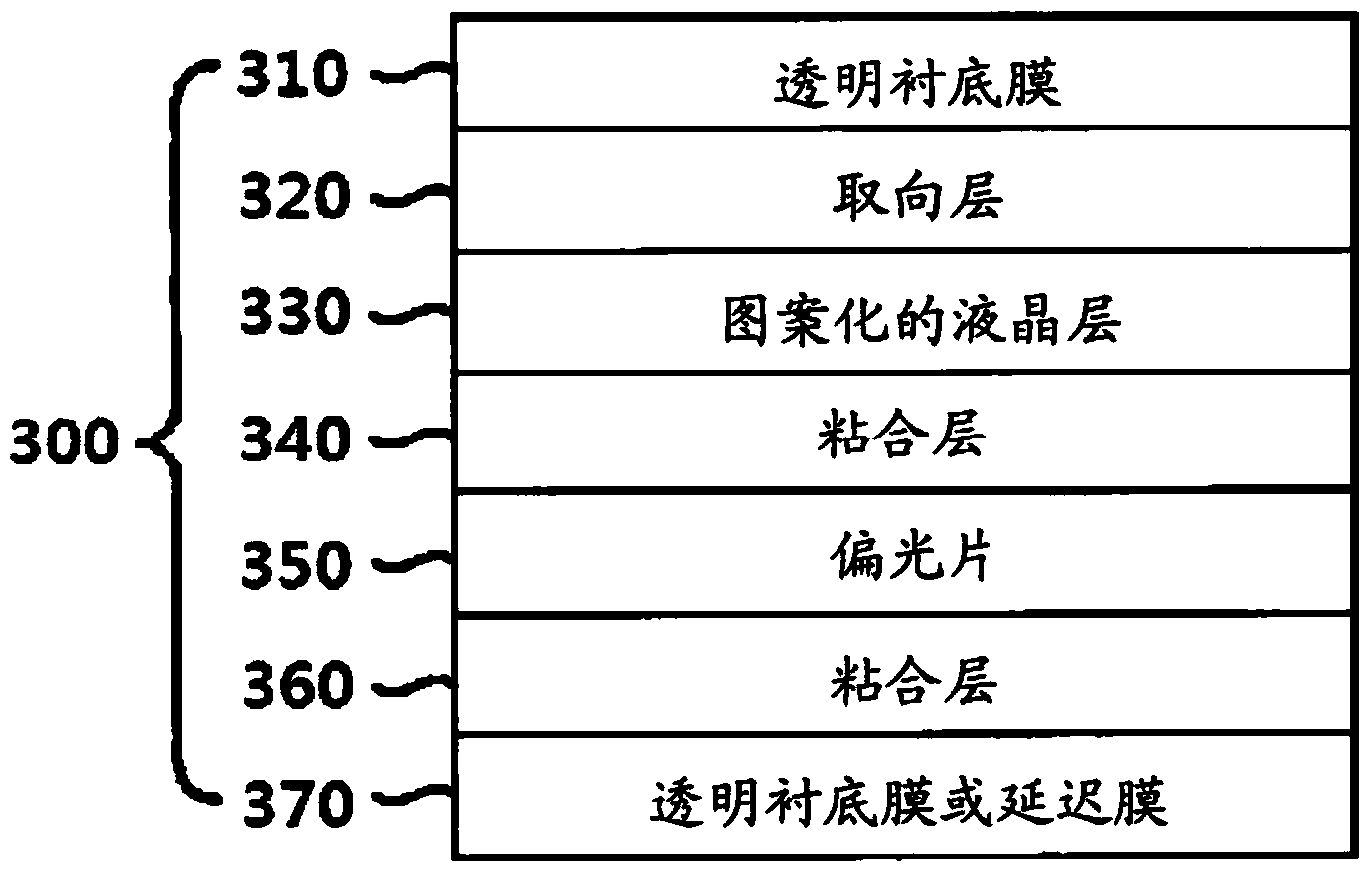

Polarizing plate and image display device having same

InactiveCN103998957AReduce scrap rateReduce manufacturing costPolarising elementsNon-linear opticsPhase differenceDisplay device

Owner:DONGWOO FINE CHEM CO LTD

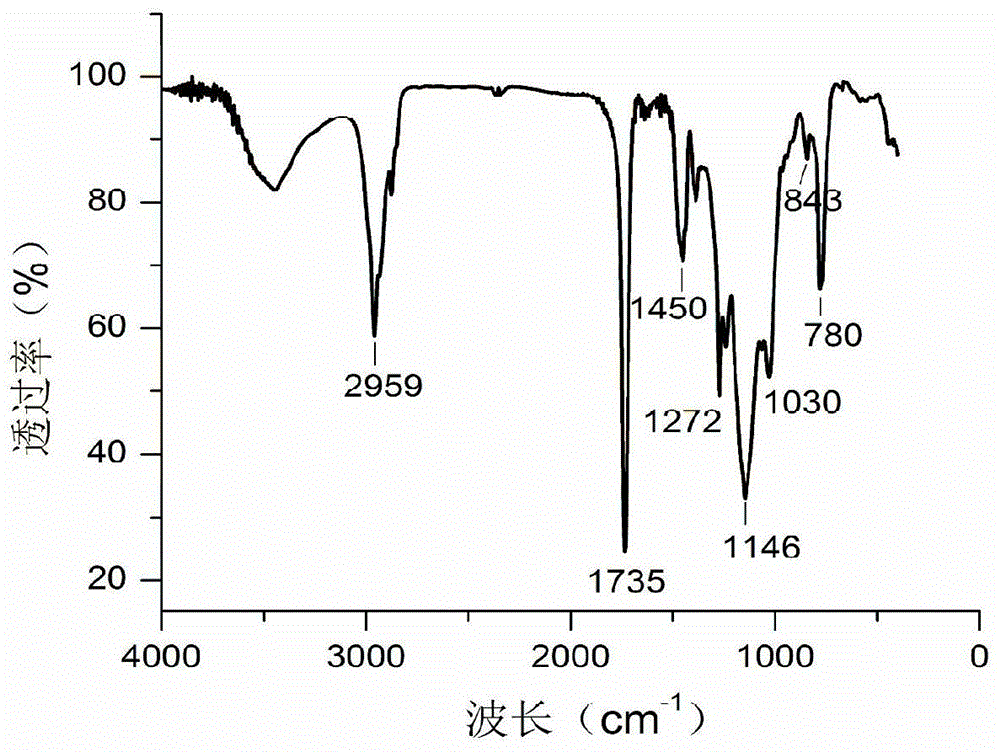

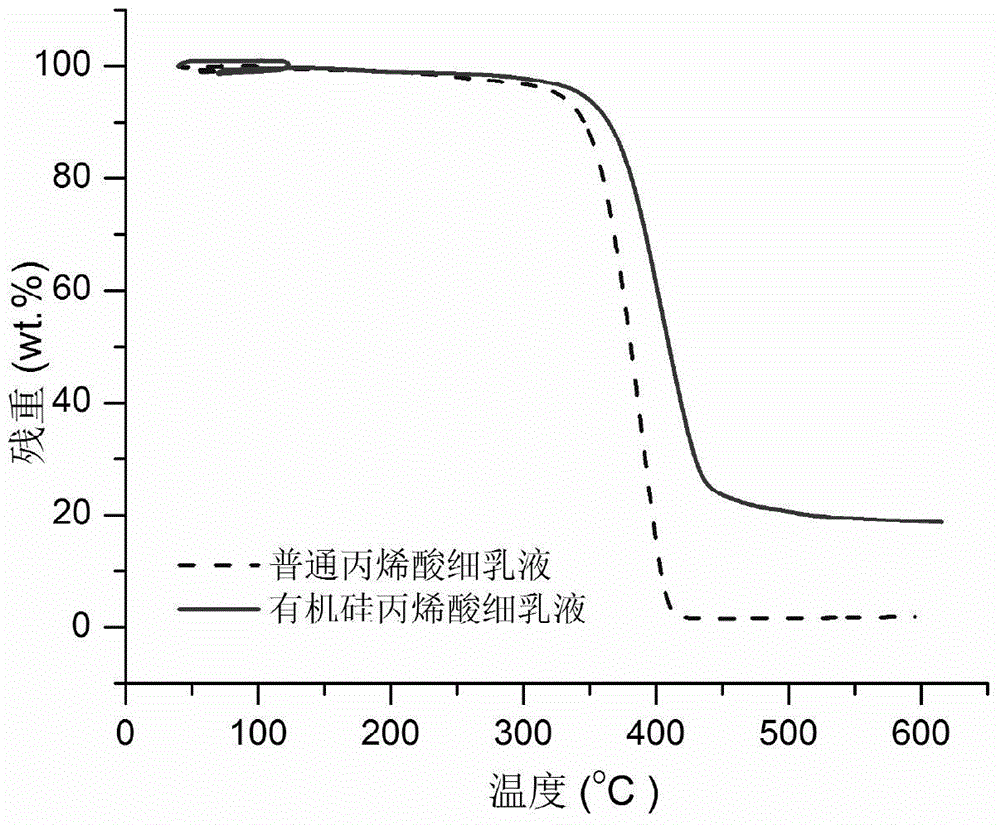

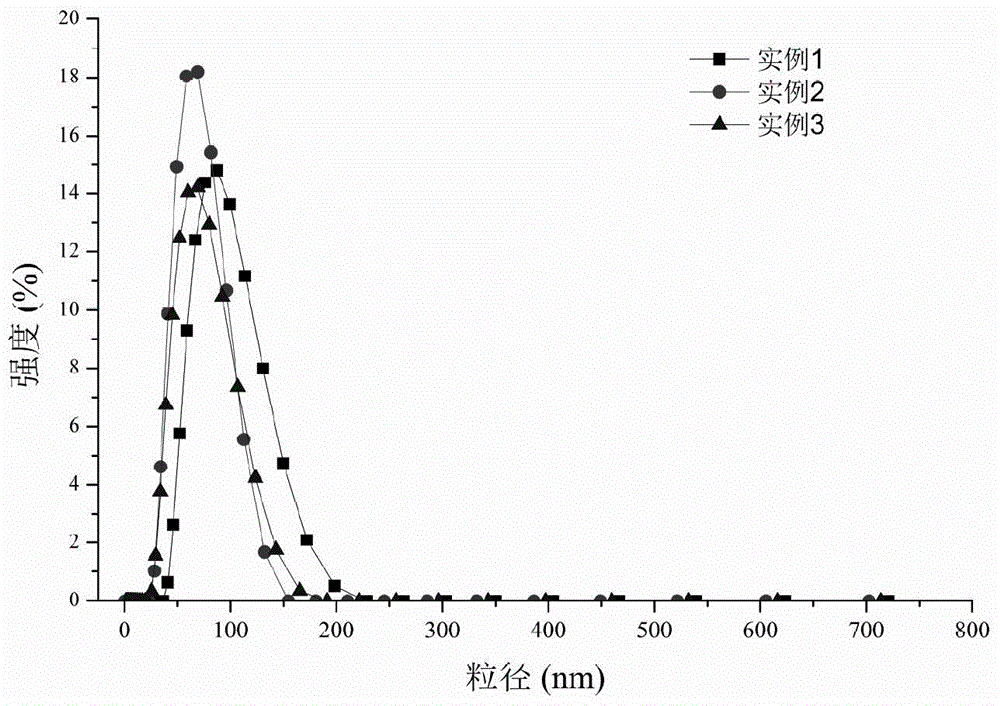

Preparation method for silicone-acrylic miniemulsion

Owner:ZHEJIANG UNIV

Acrylate damping coating and preparation method thereof

The invention discloses an acrylate damping coating and a preparation method thereof. The acrylate damping coating comprises, by weight, 20-35 parts of water, 1-3 parts of an aqueous disperser, 10-18 parts of calcium carbonate, 20-35 parts of talcum powder, 7-11 parts of a fire retardant, 0.5-2 parts of an aqueous antifoaming agent, 50-110 parts of a propionate emulsion, 0.1-1.5 parts of a thickener, 0.1-3.3 parts of a damping pigment filler and 0.5-1.8 parts of a film forming assistant. The propionate emulsion is adopted in the preparation process of the acrylate damping coating, so the damping performance of the coating in high and low temperature state is improved, and the coating also has the advantages of good noise reduction effect, non-toxicity, no peculiar smell, hard film, good gloss retention, good durability and good pollution resistance.

Owner:郭小曼

Weather-resistant impact-resistant waterproof plugging material with stable quality and its preparation method

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Decomposable environmentally-friendly heat-insulation packaging bag

Owner:桐城市人和包装有限公司

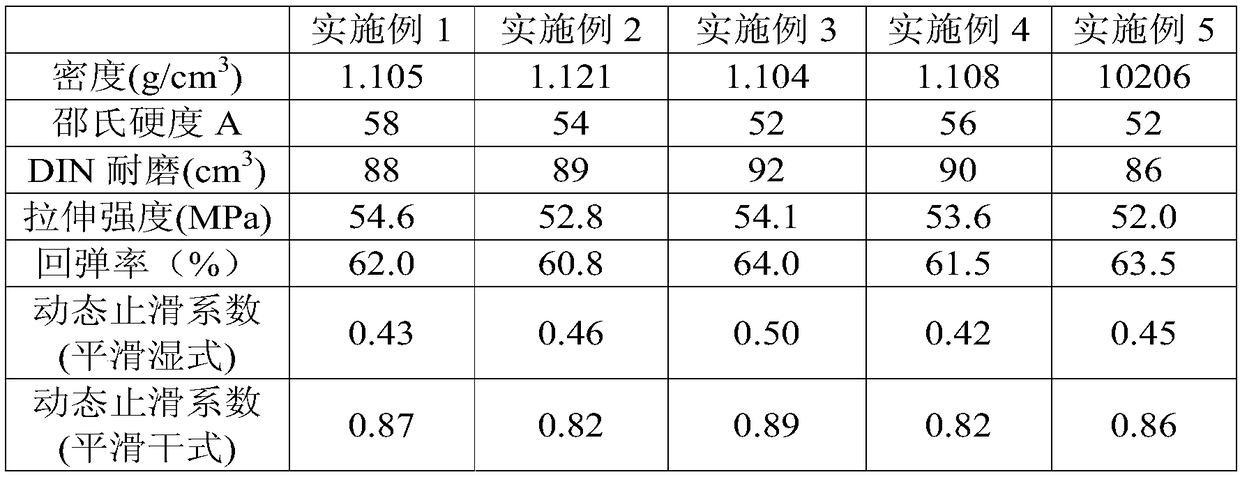

Fireproof anti-abrasion rubber shoe sole material and preparation method thereof

InactiveCN109354817AImprove wear resistanceGood mechanical propertiesSolesPolymer scienceMechanical property

Owner:JINJIANG XINQIMEI SHOES MATERIAL DEV

Novel acrylic pressure-sensitive adhesive

ActiveCN108192019AWide range of bondingGood adhesionNon-macromolecular adhesive additivesAmide/imide polymer adhesivesFiberPolyester

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

High-rigidity and high-toughness resin material for clothing buttons

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

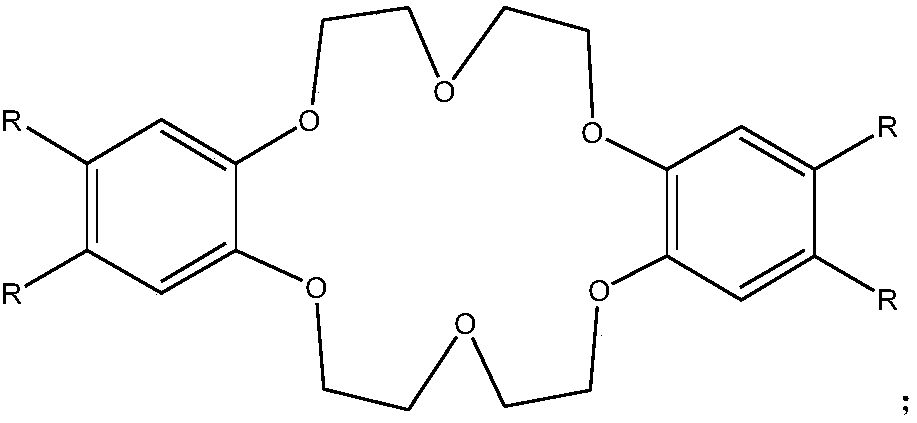

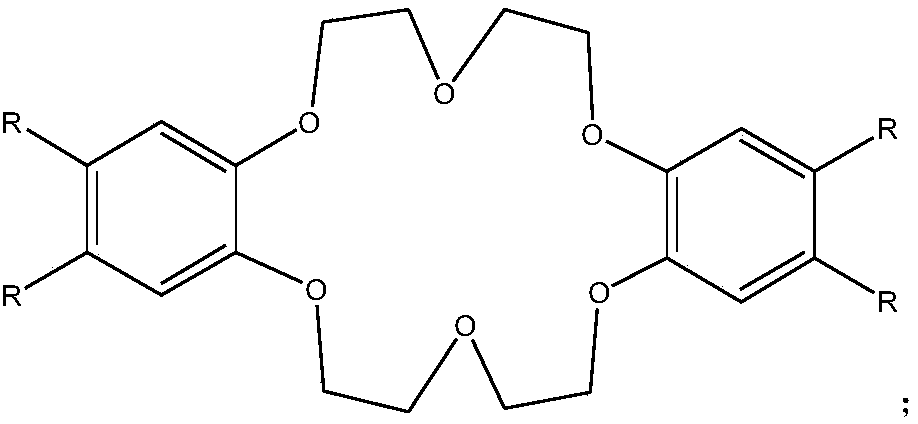

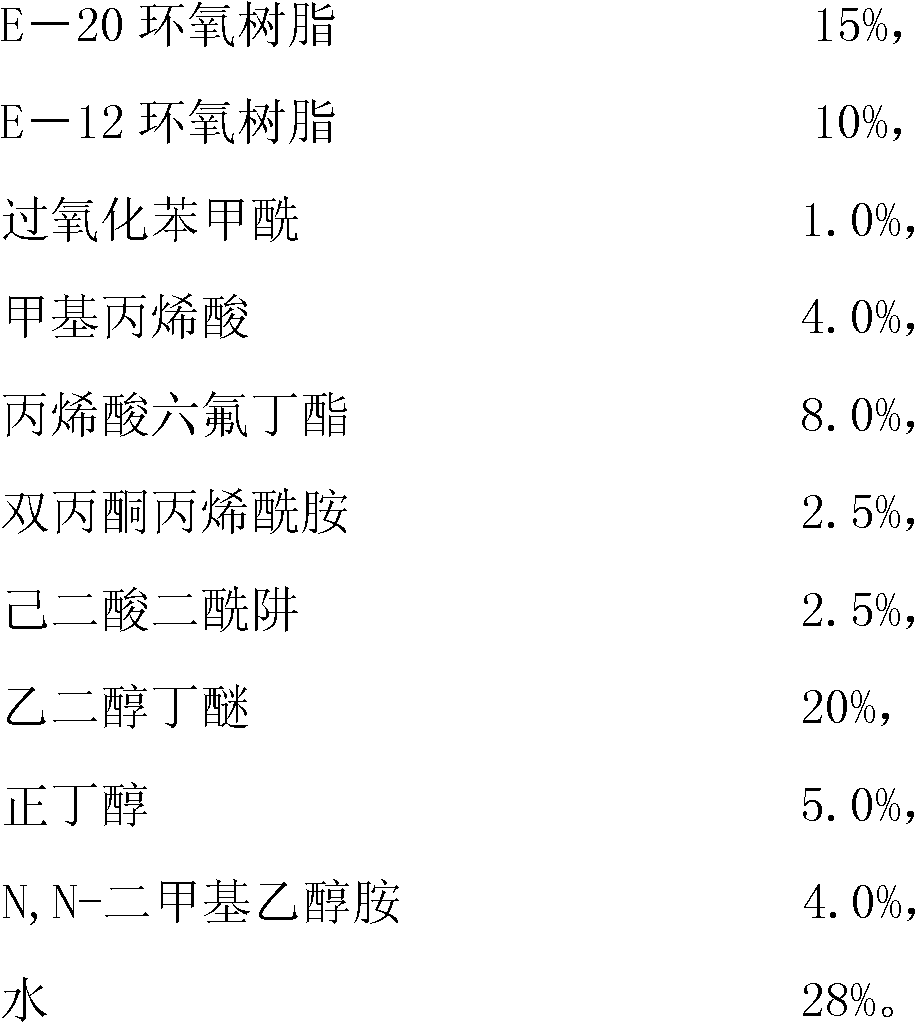

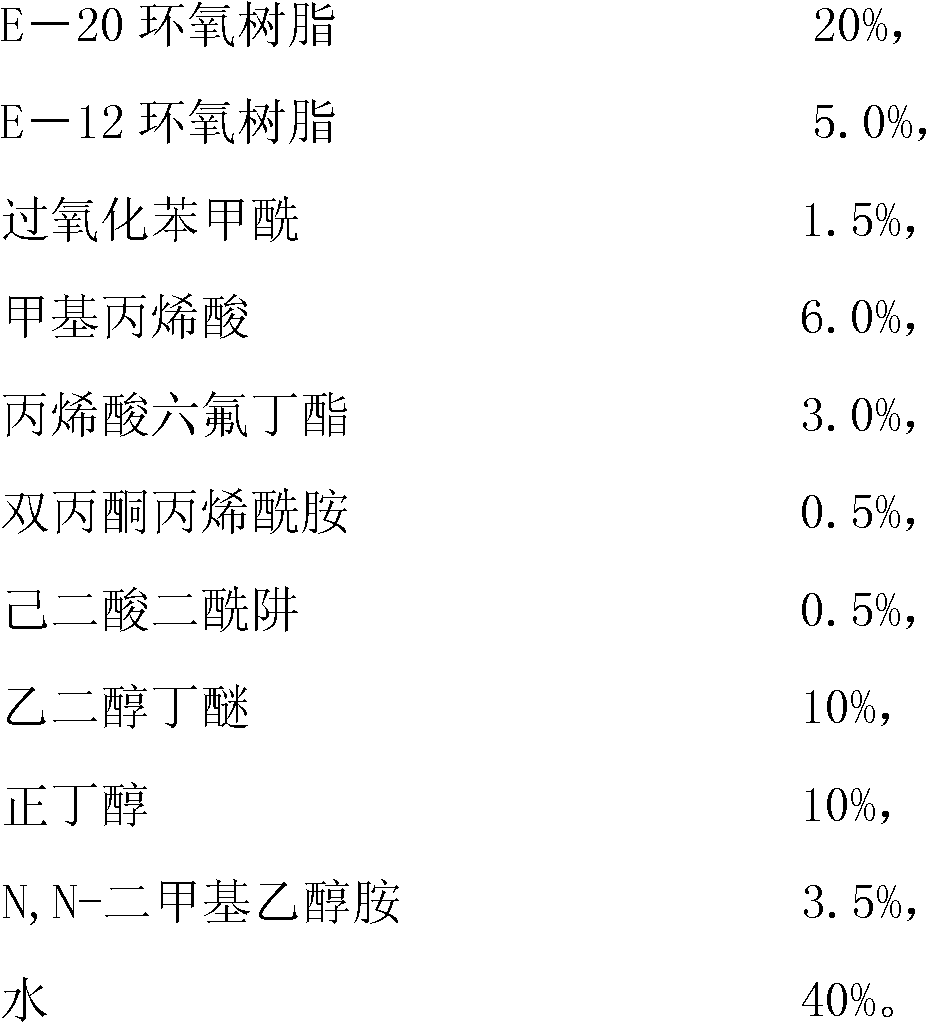

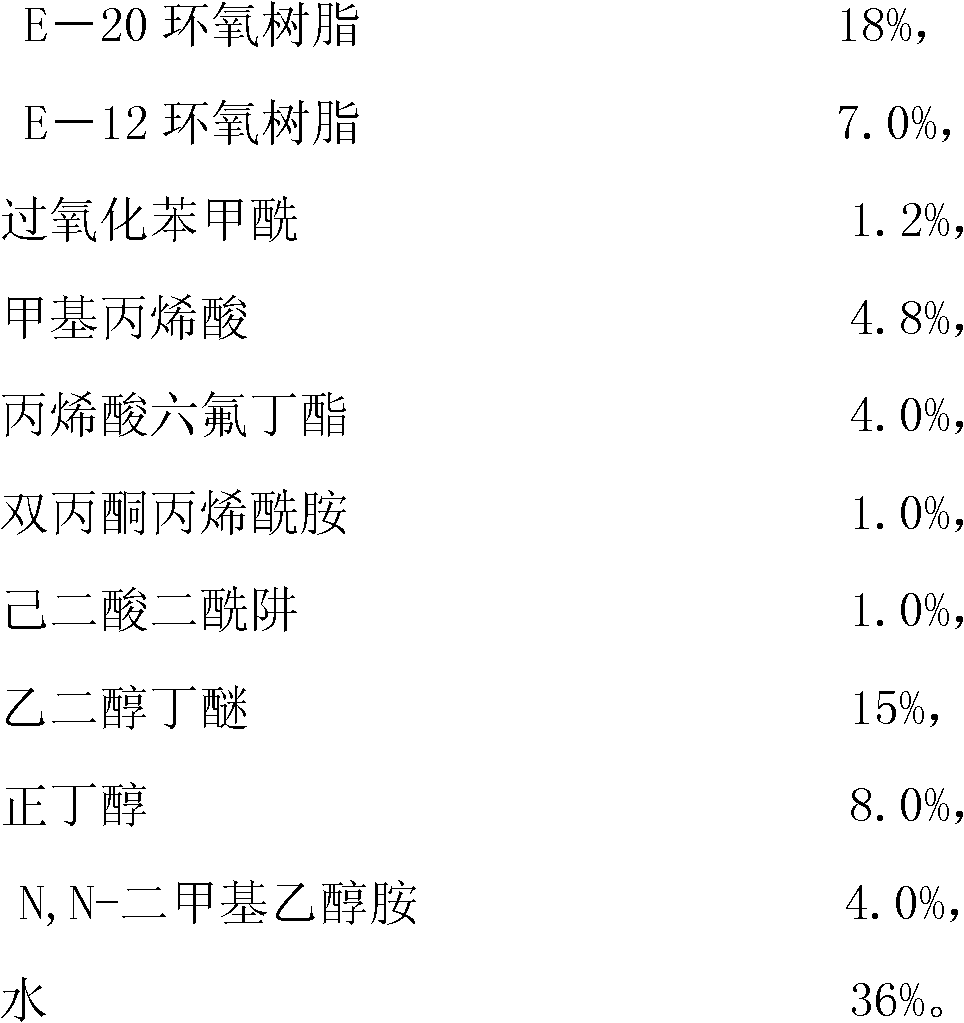

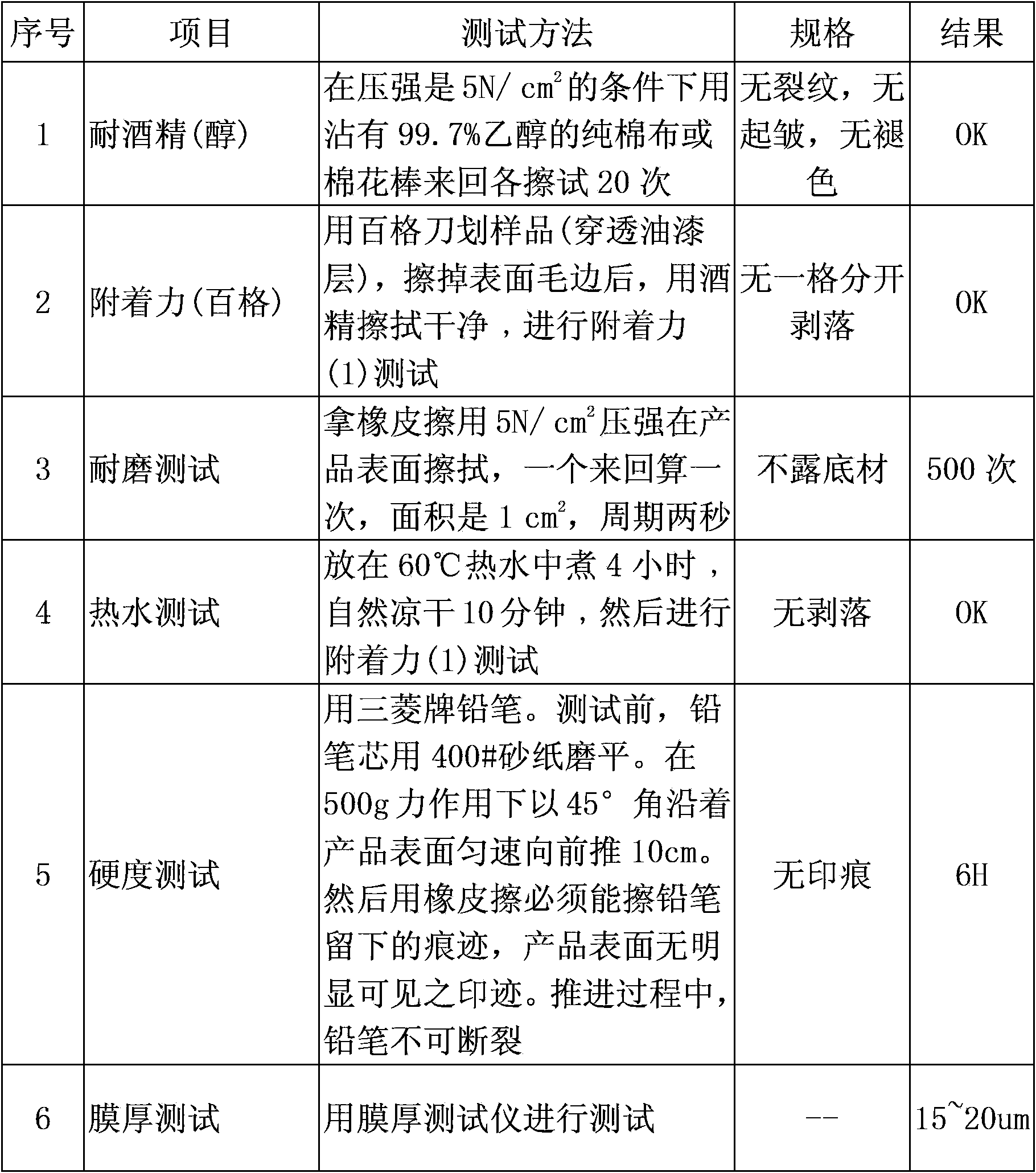

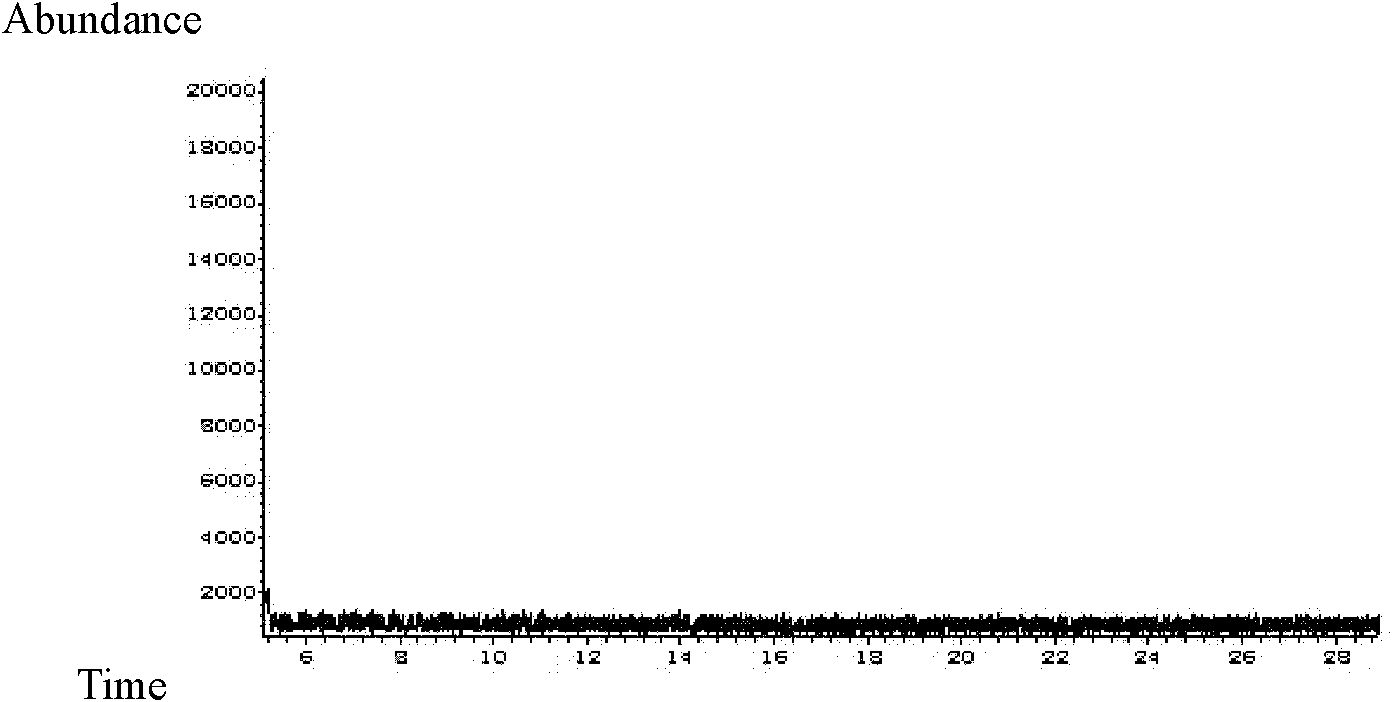

Epoxy emulsion cured at room temperature with high aquosity and weather resistance as well as preparation method of epoxy emulsion

InactiveCN102604047AGood film formingGood physical and mechanical propertiesCoatingsEpoxyBenzoyl peroxide

Owner:JIANGSU UNIV OF SCI & TECH

Impact-resistant composite insulating material and preparing method thereof

The invention discloses an impact-resistant composite insulating material and a preparing method thereof. The insulating material is prepared from 4-10 parts of polyimide resin, 3-6 parts of glass fibers, 5-12 parts of bisphenol-S epoxy resin, 5-15 parts of polycarbonate, 4-8 parts of dodecyl acrylate, 3-7 parts of dodecanol polyethenoxy ether, 2-5 parts of ethylene bis-oleamide, 3-6 parts of styrylphenol polyoxyethylene ether, 4-10 parts of phenolic epoxy vinyl ester resin and 2-5 parts of polyvinyl cinnamate. The preparing method includes the following steps that 1, the components are thrown into a high-speed mixer to be mixed; 2, the insulating material mixture mixed evenly is taken out of the high-speed mixer and extruded through a double-screw extruder; 3, the material extruded in the step 2 is granulated, and the impact-resistant composite insulating material is obtained after the granulated material is cooled to normal temperature.

Owner:SUZHOU YIXINYUAN PHOTOELECTRIC TECH

Novel powder metallurgical gear

InactiveCN106041095AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersALUMINUM STEARATES

Owner:黄宇

UV (ultraviolet)-highly-clear curtaining finish

Owner:JIANGSU HIMONIA TECH

Near infrared blocking membrane and preparation method thereof

ActiveCN104327757AReduce light transmittanceGood light transmissionNon-macromolecular adhesive additivesFilm/foil adhesivesInfraredFilm coating

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Aluminium powder paint, spraying method of aluminium powder paint and product sprayed by the method

InactiveCN103834247AHigh hardnessImprove alcohol resistancePretreated surfacesCoatingsSurface stressButyl acetate

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Seal primer added polymer with formaldehyde catching function and preparation method of polymer

InactiveCN104311737ASignificant and durable capture and removal capabilitiesClosed influencePolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterOrganic solvent

The invention discloses a seal primer added polymer with a formaldehyde catching function. The seal primer comprises acrylamide, an acrylate soft monomer, an acrylate hard monomer, an acrylate long-chain monomer, an initiator and an organic solvent. The invention further discloses a preparation method of the seal primer added polymer with the formaldehyde catching function. Resin prepared by adopting the seal primer added polymer with the formaldehyde catching function and the preparation method thereof has good compatibility with existing wooden ware primers (nitro wooden ware primer, polyester two-component wooden ware primer, acrylic emulsion type wooden ware primer, epoxy two-component wooden ware primer and the like); according to the formaldehyde content of a wooden ware base material, the polymer is added into the traditional wooden ware primer; and the wooden ware seal primer prepared by adding the polymer has obvious and lasting formaldehyde catching and clearing capability on the premise that obvious poor influence is not produced on the aspects of closure, adhesion, flexibility, polishing property and the like.

Owner:GUANGZHOU UNIVERSITY

High weatherability optical adhesive film and making process thereof

InactiveCN106928875AImprove adhesionGood weather resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesUV curingPolymer science

Owner:东莞市亚马电子有限公司

High-temperature-resistant special water-retaining admixture for concrete as well as preparation process and application of admixture

ActiveCN109867486AImprove water retentionGood and lasting water-locking effectCarboxylic acidTartrate

The invention discloses a high-temperature-resistant special water-retaining admixture for concrete as well as a preparation process and application of the admixture. The admixture comprises the following components: 1-5 parts of a sustained-release polycarboxylic acid, 5-20 parts of a comprehensive polycarboxylic acid, 1-10 parts of a retarder, 0.1-2 parts of a biomass glue, 0.1-5 parts of an airentraining agent, 0.1-5 parts of a defoaming agent, and 63.8-92.97 parts of water, wherein the sustained-release polycarboxylic acid is composed of isopentenyl polyoxyethylene ether, water, acrylic acid, hydroxyethyl acrylate, sodium methallyl sulfonate and ammonium persulfate, and the comprehensive polycarboxylic acid is composed of isobutylene polyoxyethylene ether, water, acrylic acid, tartrate acrylate, ascorbic acid and mercaptopropionic acid. The water-retaining admixture provided by the invention has a better water-retaining effect, and the preparation process provided by the inventionmakes the obtained admixture less prone to overpolymerization; and according to the application of the water-retaining admixture, the concrete can maintain a better water lock effect for a long timein a high-temperature environment in summer, so that the phenomenon of blocking of a pumping pipe when the concrete is pumped is not easy to cause.

Owner:HANGZHOU JIANSHE NEW MATERIALS CO LTD

Anti-cracking epoxy ceramic paint and preparation method thereof

InactiveCN108864898AHigh hardnessImprove mechanical propertiesFireproof paintsAnti-corrosive paintsWater resistantDodecylbenzene

The invention provides anti-cracking epoxy ceramic paint, which is prepared from the following raw materials in parts by weight: diatomite, silicon carbide powder, corn starch, coconut oil acid diethanolamide, aluminum oxide, C12 alcohol ester, triphenyl phosphate, diethylene glycol monobutyl ether, expanded vermiculite, nanometer silicon dioxide, barium sulfate, styrene-acrylate emulsion, tri(dodecyl benzene sulfonyl) titanium isopropoxide, carbon fiber, epoxy resin E-44, diluents 660A, triglycidyl p-aminophenol, bisoxaldihydrazone, water glass, hydroxypropyl methyl cellulose and a proper amount of deionized water. The prepared epoxy ceramic paint has excellent characteristics that the coating is compact and smooth, and is firm as ceramics; the bonding is firm; the thickness is uniform; the water-resistant, anti-corrosion and electric insulation performance is excellent, and the like.

Owner:黄春梅

Production process of environment-friendly water-based anti-corrosion coating

InactiveCN104449091AImprove anti-corrosion performanceGood resistance to nitro paintAnti-corrosive paintsWater basedWater resistant

Owner:QINGDAO SHOUSHENG IND

Lubricating liquid for food transporting equipment and preparation method of lubricating liquid

InactiveCN106167731ADifficult to volatileHigh specific heat capacityLubricant compositionPhosphateWater soluble chitosan

The invention relates to the field of lubricating liquid, in particular to lubricating liquid for food transporting equipment. The lubricating liquid is prepared from the following raw materials in parts by weight: 2-3 parts of water-soluble chitosan, 2-3 parts of triethanolamine citrate, 0.5-1 part of polyvinylpyrrolidone, 10-14 parts of mint extract, 8-14 parts of carboxylic acid, 2-4 parts of polyalkylene glycol, 3-5 parts of sodium octadecyl polyoxyethylene ether phosphate, 0.3-0.5 part of medical rust, 2-3 parts of a silicone defoamer, 1-2 parts of ethoxylated pentaerythritol tetra (methyl) acrylate, 1-2 parts of ethylparaben, 4-8 parts of sedoheptulose 7-phosphoric acid, and 20-26 parts of simethicone. The lubricating liquid disclosed by the invention is free from toxins, difficult to volatilize, and high in specific heat capacity, has certain heat-conducting properties for heat produced by equipment abrasion, has certain attraction capacity on bacteria and pests, has excellent capacity of killing the bacteria and the pests, has quite significant antirust capacity, and does not have crystal deposition, and the kinematic viscosity of the lubricating liquid is 10-20% higher than that of general lubricating liquid.

Owner:BENGBU ZHONGZHENG INDAL

Stirring and extracting bar for polyacrylate compound nanocarbon fiber coating and its preparation method

InactiveCN102366719AAvoid competitive adsorptionHigh enrichment factorIon-exchange process apparatusOther chemical processesCarbon fibersAdsorption effect

Owner:TIANJIN CHUNFA BIO TECH GRP

Preparation method of cleaning agent for cleaning and drying loading arm steering joint

InactiveCN105462716AImprove processing efficiencyReasonable formula designOrganic non-surface-active detergent compositionsEmulsionEngineering

The invention relates to the technical field of loading arm cleaning and maintenance and particularly relates to a preparation method of a cleaning agent for cleaning and drying a loading arm steering joint. The method comprises the following steps: adding 15 parts of acetone, 5 parts of acrylate emulsion and 25 parts of water into a container, and stirring for 5 minutes; slowly adding 5 parts of citric acid and stirring at the same time, and after the addition, stirring for 5 minutes; slowly adding 5 parts of ethyl ether and 15 parts of water and stirring at the same time, and after the addition, stirring for 5 minutes; slowly adding 0.5 part of rhamnoside and stirring at the same time, and after the addition, stirring for 10 minutes; and finally, quickly adding 10 parts of cyclohexane and 15 parts of water and stirring for 10 minutes. According to the preparation method of the cleaning agent provided by the invention, through gradual addition and different adding sequences, the dissolving property among the substances can be improved, and the possibility of particle aggregation can be avoided so as to remarkably improve the treatment efficiency of the cleaning agent.

Owner:WUHU JINYU PETROCHEM EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap