Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Polyvinylpyrrolidone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinylpyrrolidone (PVP), also commonly called polyvidone or povidone, is a water-soluble polymer made from the monomer N-vinylpyrrolidone.

Efficient keyboard cleaning solution

InactiveCN104312761AQuick clean upProtect healthSurface-active detergent compositionsDetergent compounding agentsTriclosanGlycerol

An efficient keyboard cleaning solution is prepared from the following raw materials by weight: 5-11 parts of tannic acid, 4-8 parts of triclosan, 2-6 parts of licorice, 1-5 parts of borneol, 4-8 parts of Chinese violet, 3-9 parts of citric acid, 4-6 parts of glycerol, 5-9 parts of polyvinylpyrrolidone, 2-6 parts of triethanolamine oleate, 1-3 parts of gallnut, 2-7 parts of didecyl dimethyl ammonium chloride, 4-6 parts of sodium gluconate and 1-5 parts of decyl dimethyl ammonium chloride. The invention has the beneficial effect that the efficient keyboard cleaning solution can quickly clean the keyboard, also has certain sterilization effect for the protection of human health, and does not affect the normal use.

Owner:QINGDAO TORIX ELECTRONICS TECH

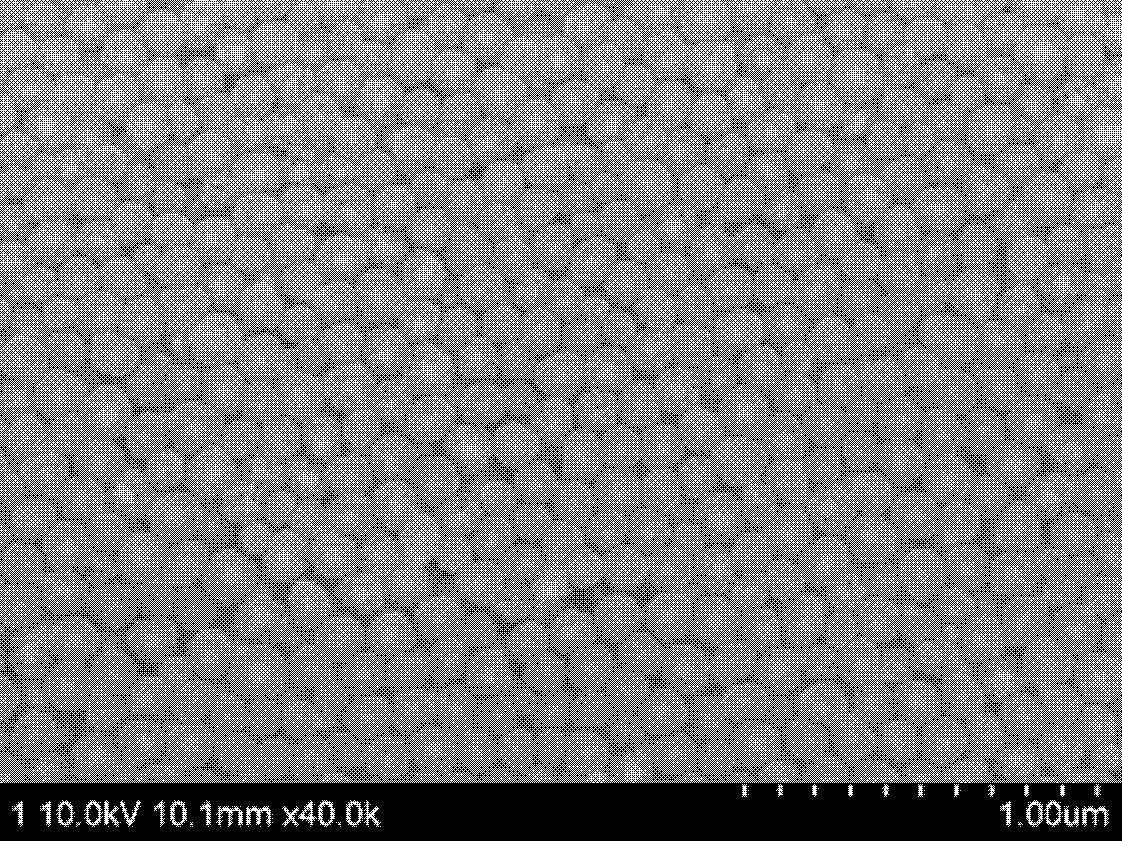

Method for preparing pure-phase monodisperse ZnS nanocrystalline by using diethylene glycol serving as solvent

InactiveCN102923759AGood dispersionSimple programmingZinc sulfidesNanotechnologyAlcoholRoom temperature

The invention discloses a method for preparing pure-phase monodisperse ZnS nanocrystalline by using diethylene glycol serving as a solvent. The method comprises steps of dissolving Zn (NO3)2.6H2O in the diethylene glycol, regarding the Zn (NO3)2.6H2O which is dissolved in the diethylene glycol as a zinc source precursor solution, dissolving thiacetamide and Polyvinylpyrrolidone (PVP) in the diethylene glycol, regarding the thiacetamide and the PVP which are dissolved in the diethylene glycol as a sulphur source precursor solution, pouring the sulphur source precursor solution into a flask with three necks which is provided with a condenser tube, feeding a nitrogen flow, heating, injecting the zinc source precursor solution of which the mol ratio of Zn and S is 1:1, conducting reflux for 10 minutes at the temperature from 180 DEG C to 200 DEG C, cooling to the room temperature by using water, cleaning centrifugally by using absolute ethyl alcohol, dispersing zinc oxide nanocrystalline in alcohol and sealing and storing the zinc oxide nanocrystalline. The zinc blende ZnS nanocrystalline which does not have any impure phases and is good in dispersibility is synthesized, the process is free from pollution, the device is simple, the preparation cost is low and the scale industrial production can be applied.

Owner:TIANJIN UNIV

Temperature-sensitive wall material as well as microcapsule preparation and preparation method thereof

InactiveCN111226922AMany types of drug loadingStabilize each otherBiocideAnimal repellantsPyrrolidinonesGlycerol

Owner:SUZHOU FENGBEI BIOTECH CO LTD

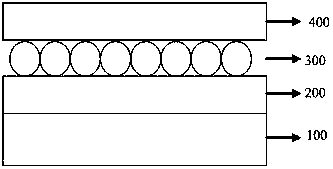

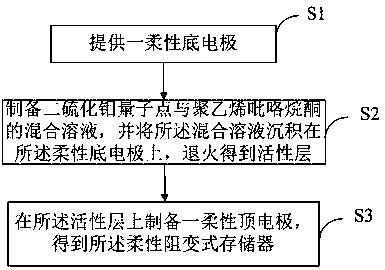

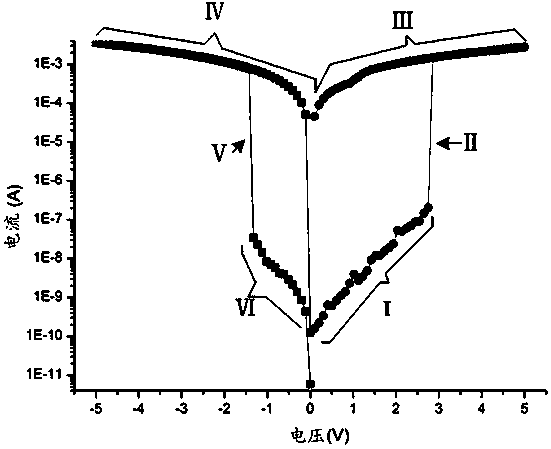

Flexible resistive random access memory and preparation method thereof

InactiveCN107863442AAddress mechanical propertiesFix stability issuesMaterial nanotechnologyElectrical apparatusStatic random-access memoryRandom access memory

Owner:SHENZHEN UNIV

Florfenicol/colistin sulfate soluble powder and preparation method thereof

ActiveCN103550755AImprove synergistic antibacterial effectEasy to usePowder deliveryOrganic active ingredientsPyrrolidinonesPolyvinylpyrrolidone

The invention discloses a florfenicol / colistin sulfate soluble powder which is composed of the following components in percentage by weight: 5-20% of florfenicol, 2-20% of colistin sulfate, 0.5-2% of borax, 5-30% of citric acid, 0.1-2% of potassium bicarbonate, 7.5-30% of polyvinylpyrrolidone, 1-5% of poloxamer 188 and the balance of anhydrous glucose. The invention also discloses a preparation method of the soluble powder, which comprises the following steps: dissolving the polyvinylpyrrolidone in anhydrous ethanol, adding the florfenicol, citric acid, borax, potassium bicarbonate and poloxamer 188, evenly mixing, recovering the ethanol, drying, pulverizing, adding the colistin sulfate and anhydrous glucose, and evenly mixing. The soluble powder ensures that the two reagents simultaneously enter the organism and better display the synergic antibacterial action; the method is simple and convenient to operate, and enhances the production efficiency; and the anhydrous ethanol is recovered, so the method protects the environment and is suitable for industrial production.

Owner:HENAN SOAR VETERINARY PHARMA

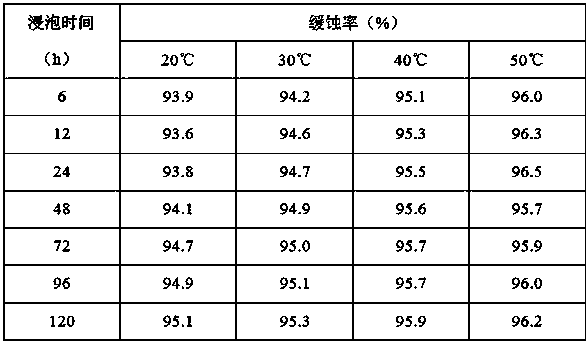

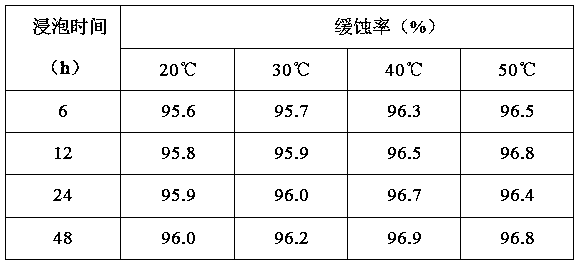

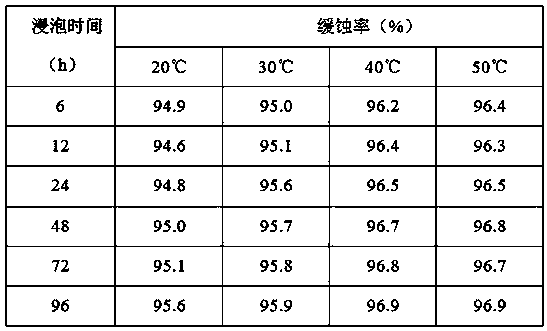

Camellia oleifera abel shell compound corrosion inhibitor and preparation method and application thereof

Owner:SOUTHWEST FORESTRY UNIVERSITY

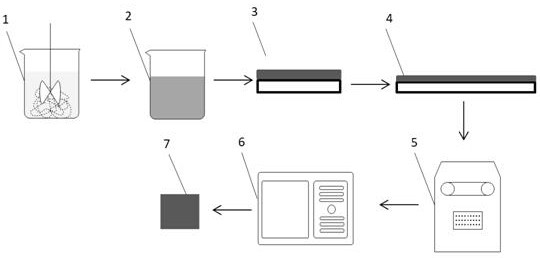

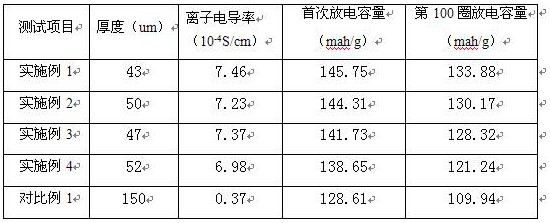

Continuous preparation method of an ultrathin ceramic chip solid composite electrolyte of lithium battery

InactiveCN112582684AGood effectThe preparation process is continuousFinal product manufactureElectrolyte accumulators manufactureGreen tapeComposite electrolyte

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Medical cotton swab capable of adhering to wound surface to promote healing

InactiveCN106730296AAddress inherent flawsReduce manufacturing costMedical applicatorsSwabsWound healingFiber

Owner:阜阳市汇康医疗器械有限公司

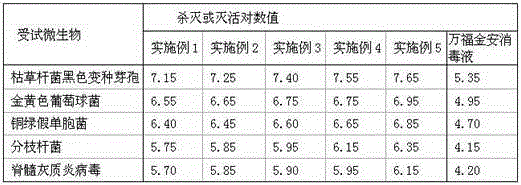

Flushing fluid for sterilizing and disinfecting medical instruments and preparation method

InactiveCN105638750AQuick killMeet the needs of sterilization and disinfectionBiocideDead animal preservationChinese waxBiology

Owner:史春艳

Preparation method of multi-phase catalyst for synthesizing dimethoxy bisphenol bimethyl carbonate

ActiveCN108816213AImprove conversion rateHigh selectivityPreparation from organic carbonatesMetal/metal-oxides/metal-hydroxide catalystsMethyl carbonateHigh pressure

The invention discloses a preparation method of a multi-phase catalyst for synthesizing dimethoxy bisphenol bimethyl carbonate. The preparation method comprises the following steps: (1) dissolving polyvinyl pyrrolidone into deionized water, and stirring for fully dissolving the polyvinyl pyrrolidone, thus obtaining a solution A; (2) adding a lithium source and a titanium source in the solution A one by one or at the same time, ultrasonically stirring for 30 to 60 minutes, and then stirring for 6 to 12 hours, thus obtaining a solution B, wherein a molar ratio of the lithium source to the titanium source is 1:1 to 1:10; (3) transferring the solution B into a high-pressure reaction kettle, putting the high-pressure reaction kettle at 150 to 180 DEG C, and reacting for 3 to 6 minutes with pressure; opening the high-temperature reaction kettle after cooling, evaporating a solvent, and drying obtained solid at 80 to 120 DEG C for 6 to 12 hours, thus obtaining white solid; (4) roasting the white solid in a muffle furnace of which the temperature is 300 to 600 DEG C for 2 to 6 hours, thus obtaining the multi-phase catalyst. A Ti / Li bimetal catalyst is prepared for the first time, and the Ti / Li bimetal catalyst is used in transesterification reaction of bisphenol A and dimethyl carbonate for the first time, so that the conversion rate of the bisphenol A is increased, the selectivity oftransesterification is increased, and alkylated products are reduced.

Owner:TIANJIN POLYTECHNIC UNIV

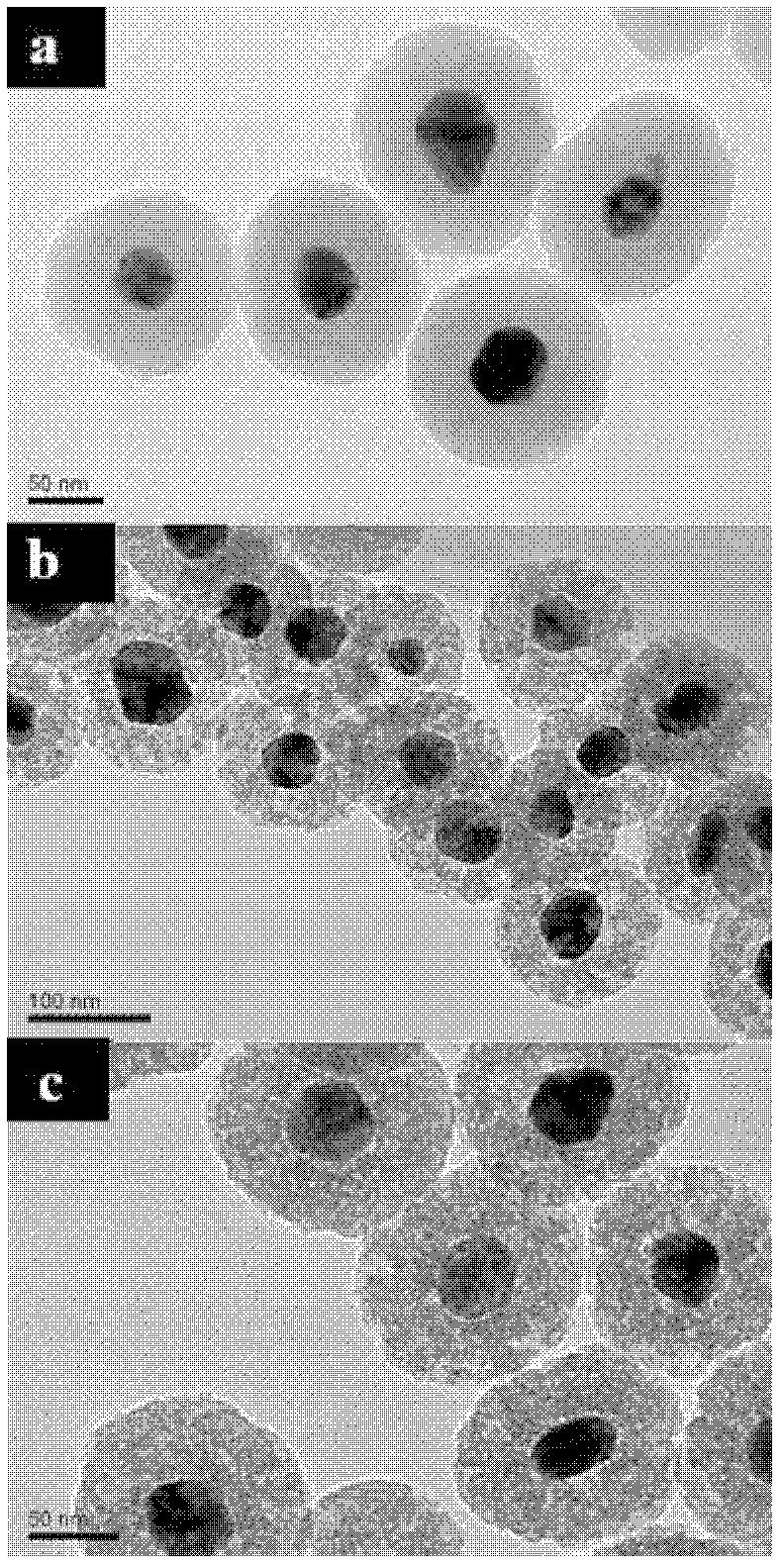

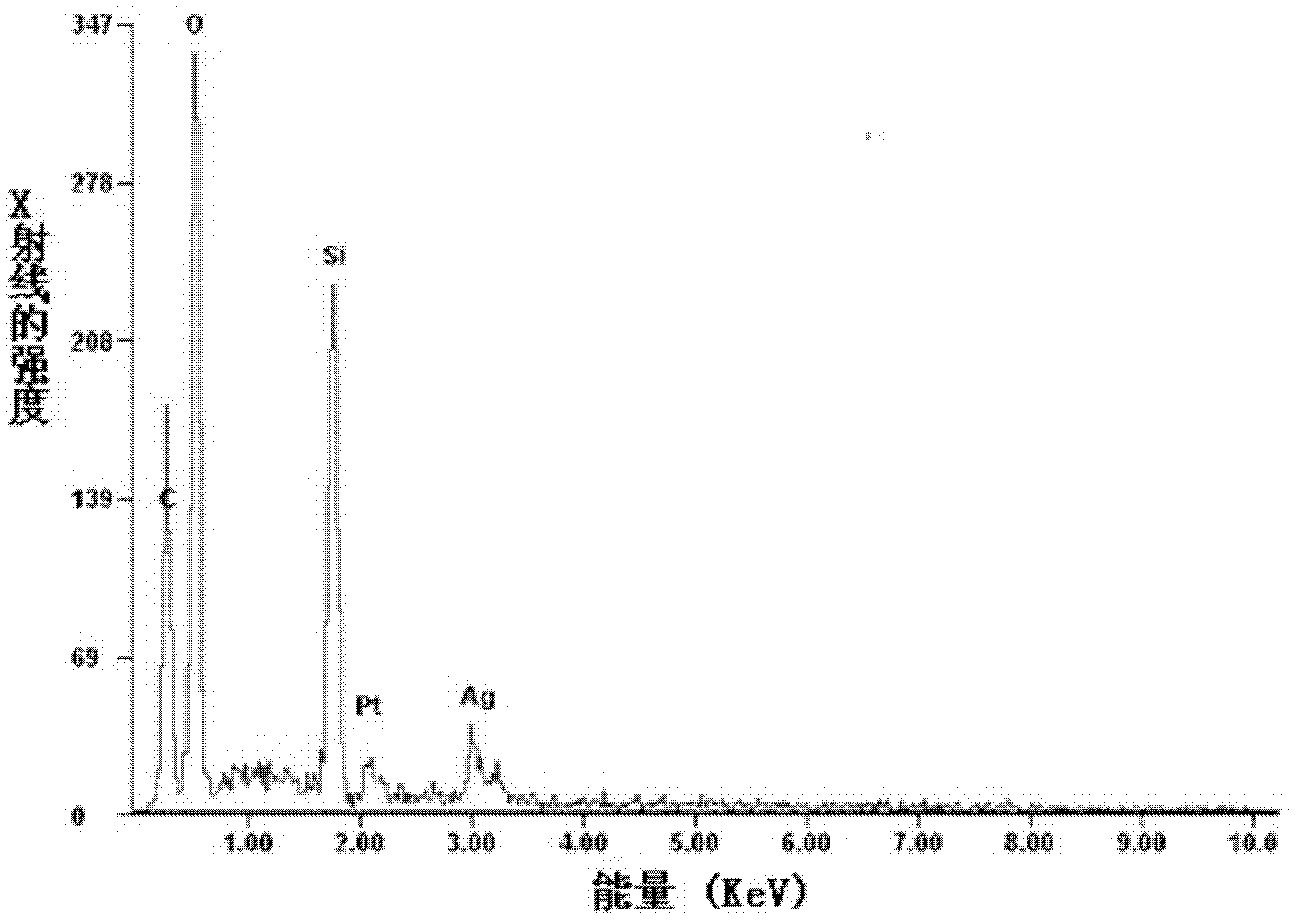

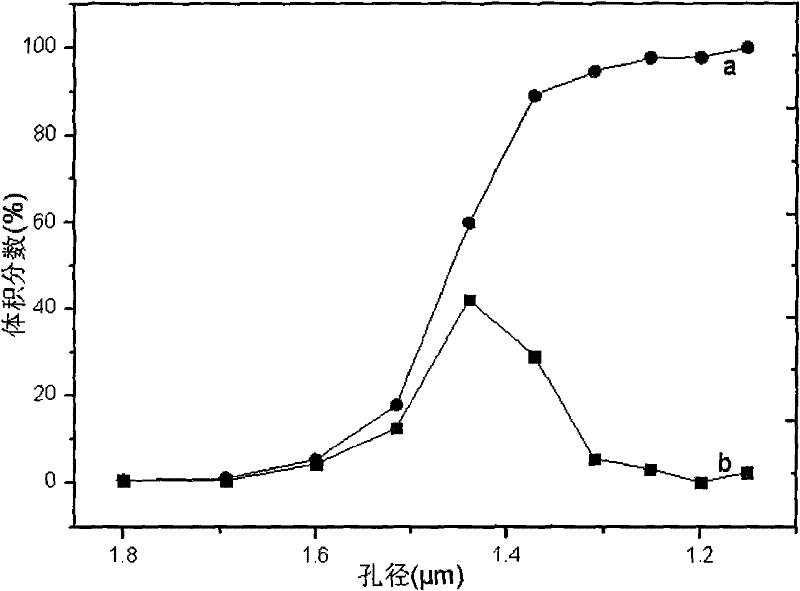

Silica-coated silver core composite particles and their preparation method and use

InactiveCN102660160BSimple production processEasy to operateInorganic pigment treatmentSilicon dioxideUltrasonic dispersion

Owner:ZHEJIANG SCI-TECH UNIV

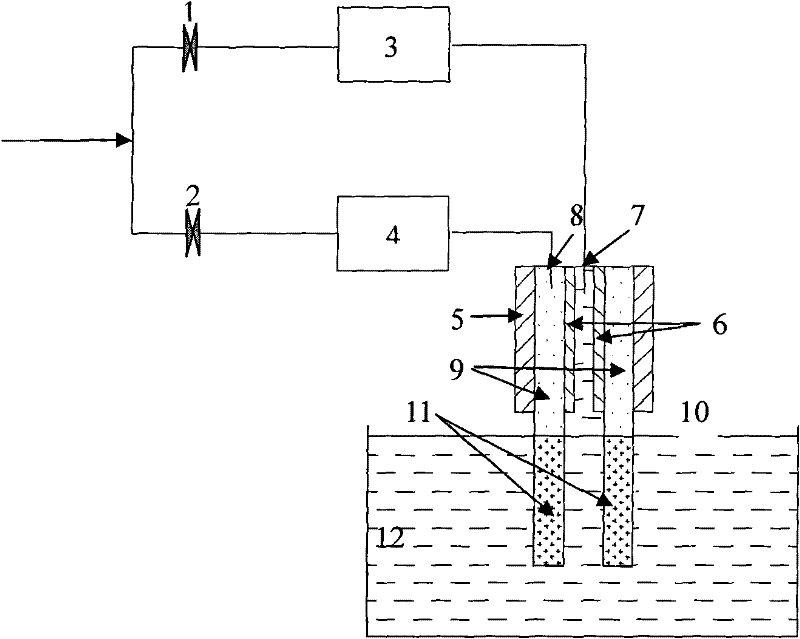

Metal-ceramic composite fibrous membrane tube and preparation method thereof

Owner:UNIV OF SCI & TECH OF CHINA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap