Silica-coated silver core composite particles and their preparation method and use

A composite particle, silica technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of pollution, poor product uniformity, etc., achieve great commercial value, slow release effect lasting, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

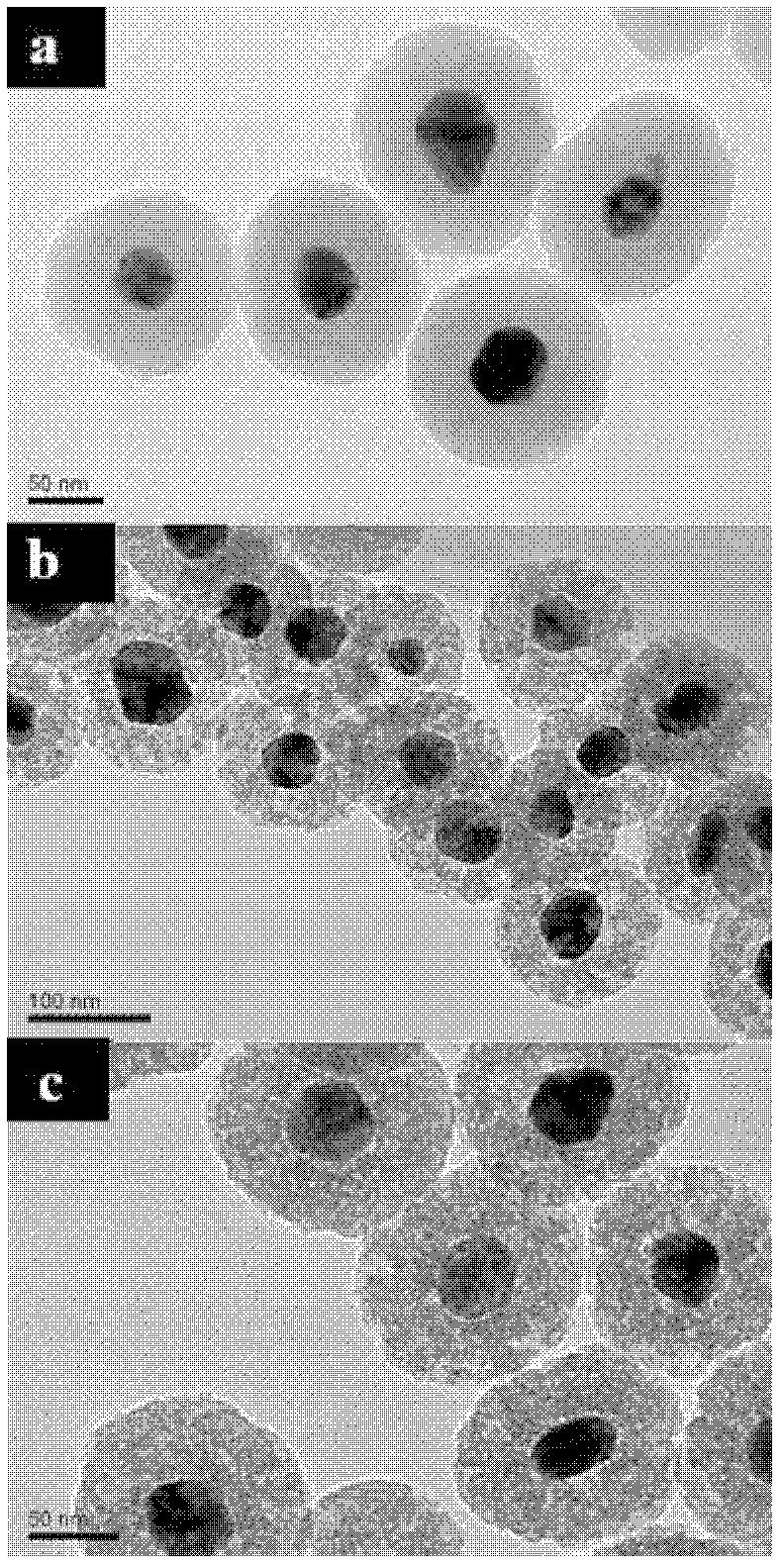

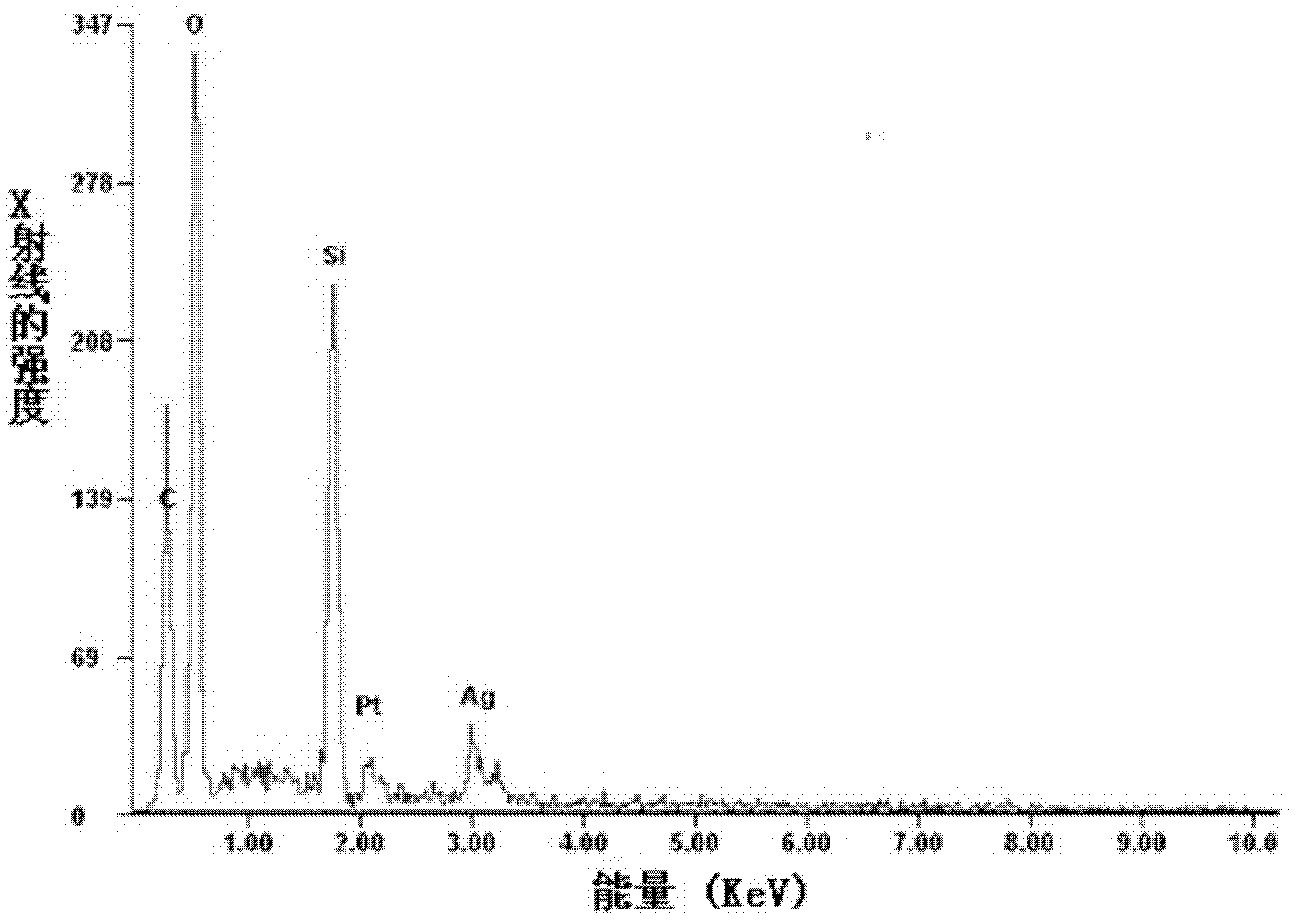

Image

Examples

Embodiment 1

[0052] 1) Pour 100ml of dehydrated ethanol with a density of 0.791g / ml into a 500ml large beaker that has been washed and dried in advance, add water to dilute to an aqueous ethanol solution containing 50% ethanol by mass, and mix the nitric acid with stirring Add 5.0ml of silver nitrate aqueous solution with a silver concentration of 0.10mol / L dropwise into an ethanol aqueous solution with a mass percentage of 50% ethanol to obtain a mixed solution, heat the mixed solution to 80°C, and then add polyvinylpyrrolidone after the temperature is stable Aqueous solution (containing 2g of polyvinylpyrrolidone, using polyvinylpyrrolidone of type K30 produced by BASF Company in Germany) 20mL, then dropwise added 5.0ml of aqueous sodium hydroxide solution with a sodium hydroxide concentration of 0.10mol / L, reacted at 80°C for 2h, After cooling down to 25°C, a solution containing silver nanoparticles is obtained;

[0053] 2) Under stirring conditions, add 5.0ml of ammoniacal liquor co

Embodiment 2

[0062] 1) Pour 100ml of dehydrated ethanol with a density of 0.791g / ml into a 500ml large beaker that has been washed and dried in advance, add water to dilute to an aqueous ethanol solution containing 40% ethanol by mass, and mix the nitric acid with stirring Add 5.0ml of silver nitrate aqueous solution with a silver concentration of 0.10mol / L dropwise into an ethanol aqueous solution with a mass percentage of 40% ethanol to obtain a mixed solution, heat the mixed solution to 80°C, and then add polyvinylpyrrolidone after the temperature is stable Aqueous solution (containing 2g of polyvinylpyrrolidone, using polyvinylpyrrolidone of type K30 produced by Germany BASF company) 20mL, then add dropwise 5.0ml of aqueous sodium hydroxide solution with a concentration of sodium hydroxide of 0.10mol / L, and react at 90°C for 1.5h , after cooling down to 25°C, a solution containing silver nanoparticles is obtained;

[0063] 2) Under the condition of stirring, add 5.0ml of ammonia wat

Embodiment 3

[0067] 1) Pour 100ml of dehydrated ethanol with a density of 0.791g / ml into a 500ml large beaker that has been washed and dried in advance, add water to dilute it to an aqueous ethanol solution containing 60% ethanol by mass, and mix the nitric acid with stirring Add 5.0ml of silver nitrate aqueous solution with a silver concentration of 0.10mol / L dropwise into an aqueous ethanol solution containing 60% ethanol by mass to obtain a mixed solution, heat the mixed solution to 70°C, and then add polyvinylpyrrolidone after the temperature is stable Aqueous solution (containing 2g of polyvinylpyrrolidone, using polyvinylpyrrolidone of type K30 produced by BASF, Germany) 20mL, then dropwise added 5.0ml of aqueous sodium hydroxide solution with a sodium hydroxide concentration of 0.10mol / L, reacted at 70°C for 3h, After cooling down to 25°C, a solution containing silver nanoparticles is obtained;

[0068] 2) Under stirring conditions, add 5.0ml of ammonia water containing 0.91g of

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap