Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rust is an iron oxide, a usually red oxide formed by the redox reaction of iron and oxygen in the presence of water or air moisture. Several forms of rust are distinguishable both visually and by spectroscopy, and form under different circumstances. Rust consists of hydrated iron(III) oxides Fe₂O₃·nH₂O and iron(III) oxide-hydroxide (FeO(OH), Fe(OH)₃).

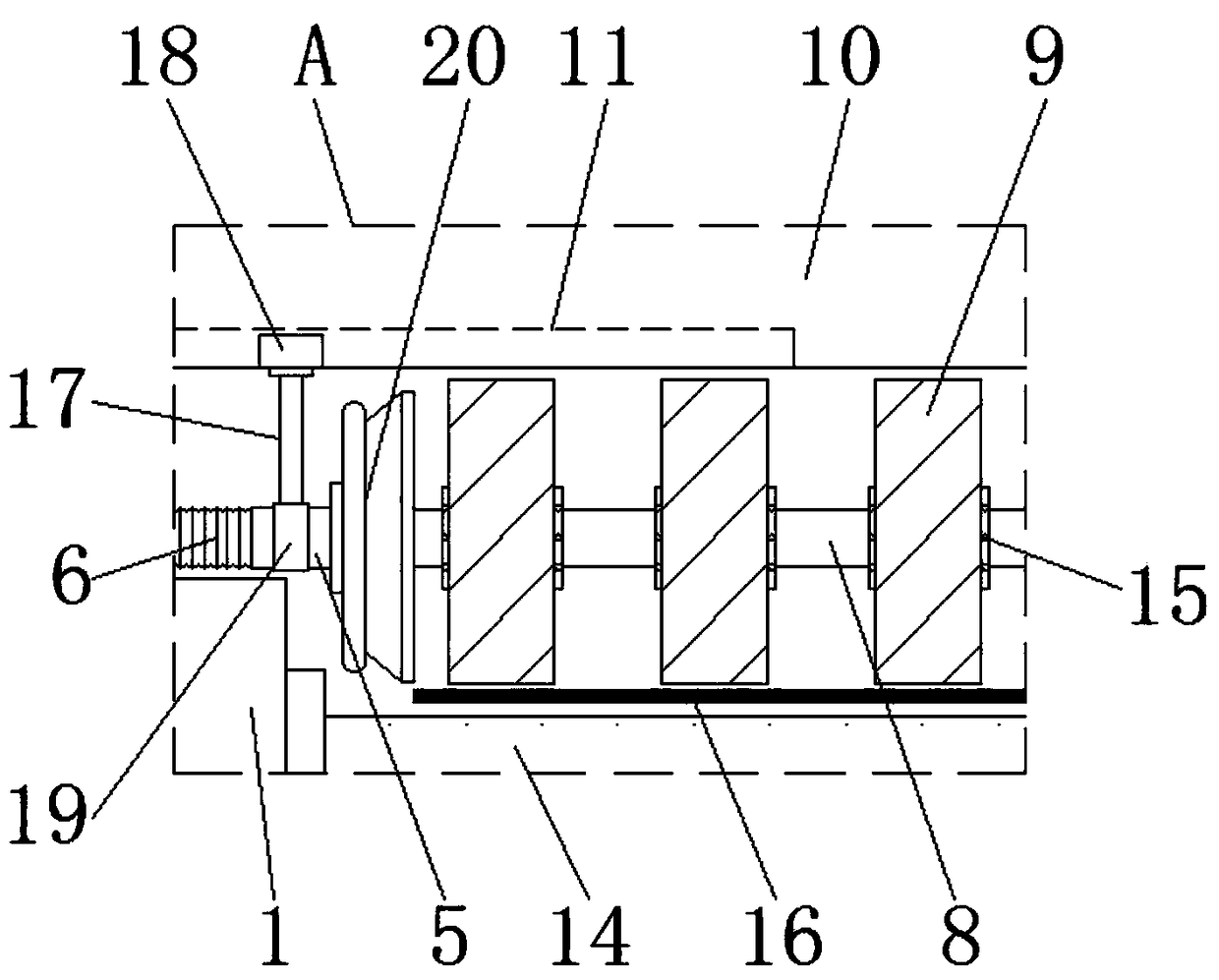

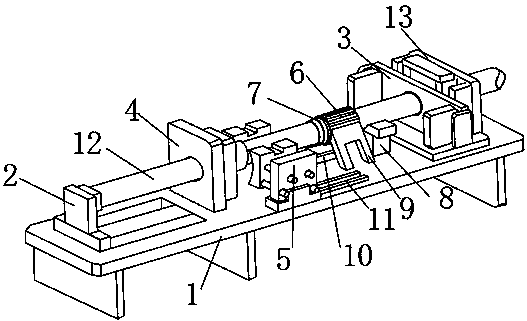

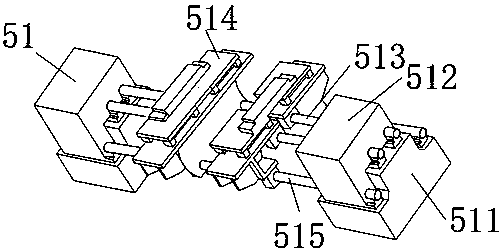

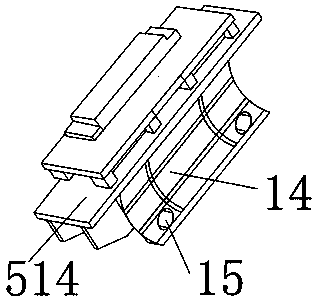

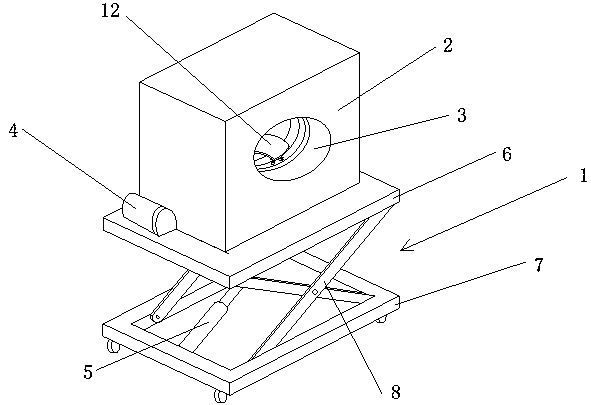

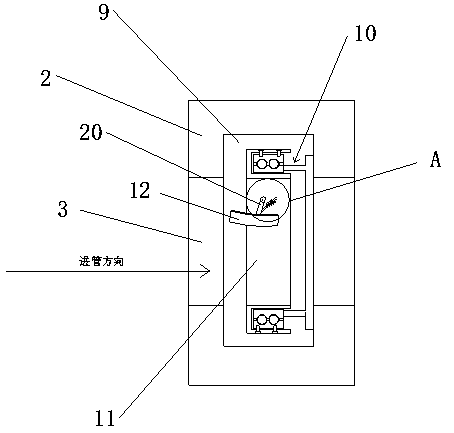

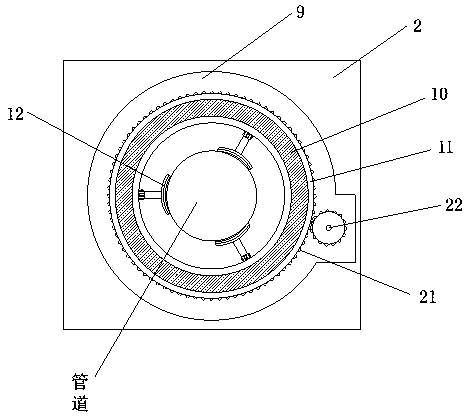

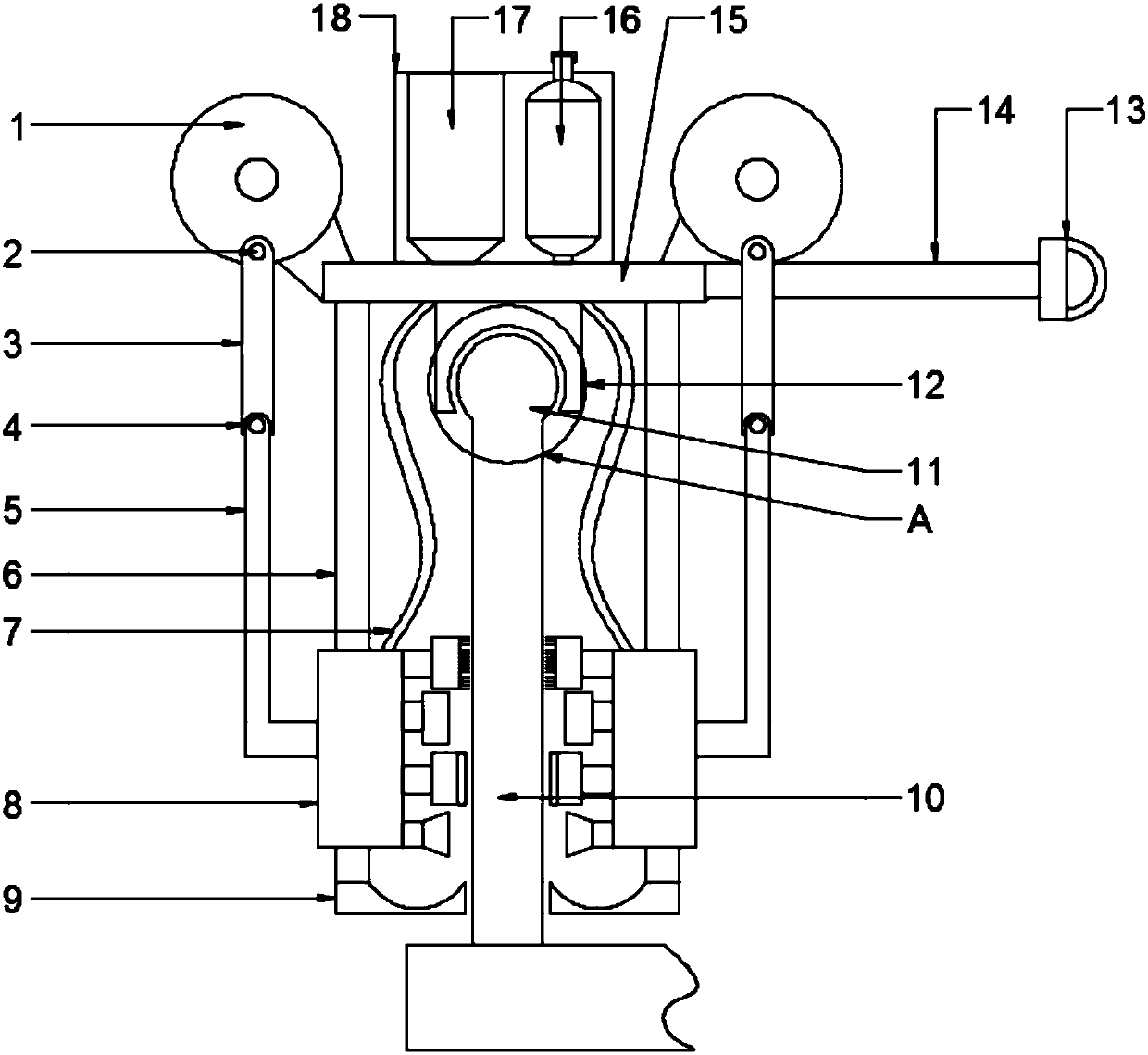

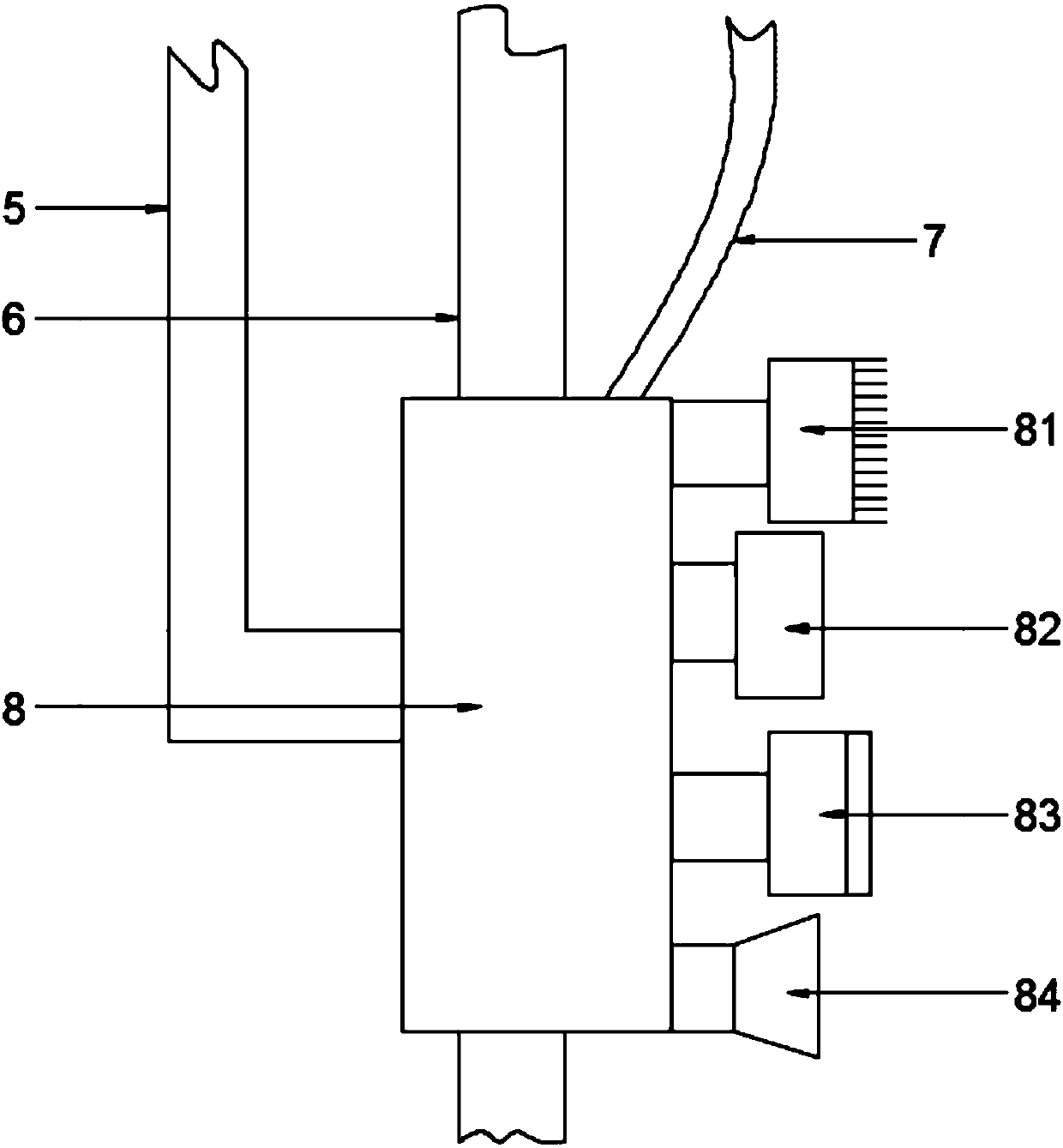

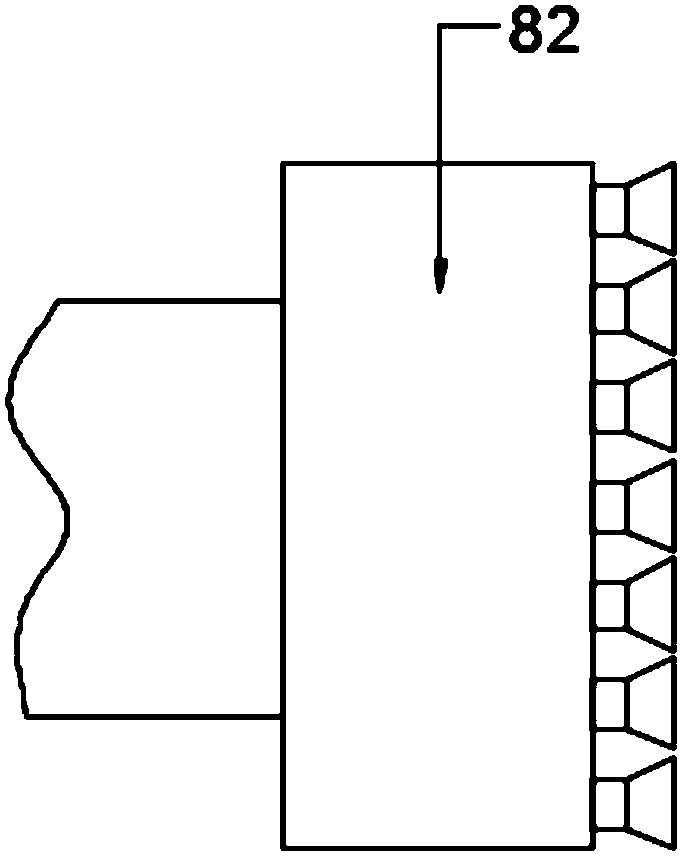

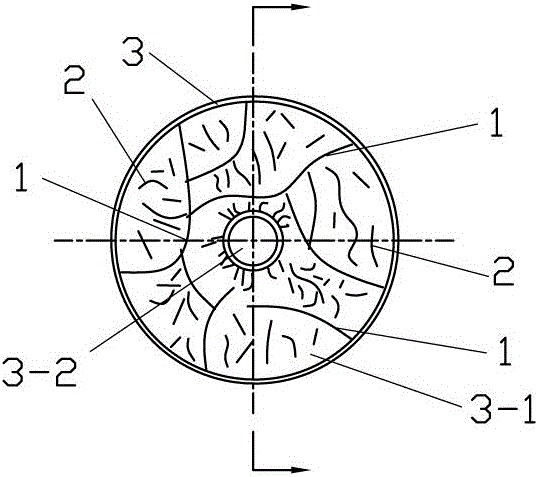

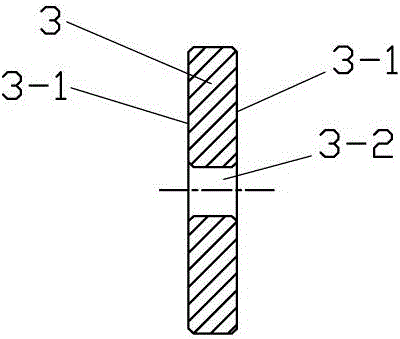

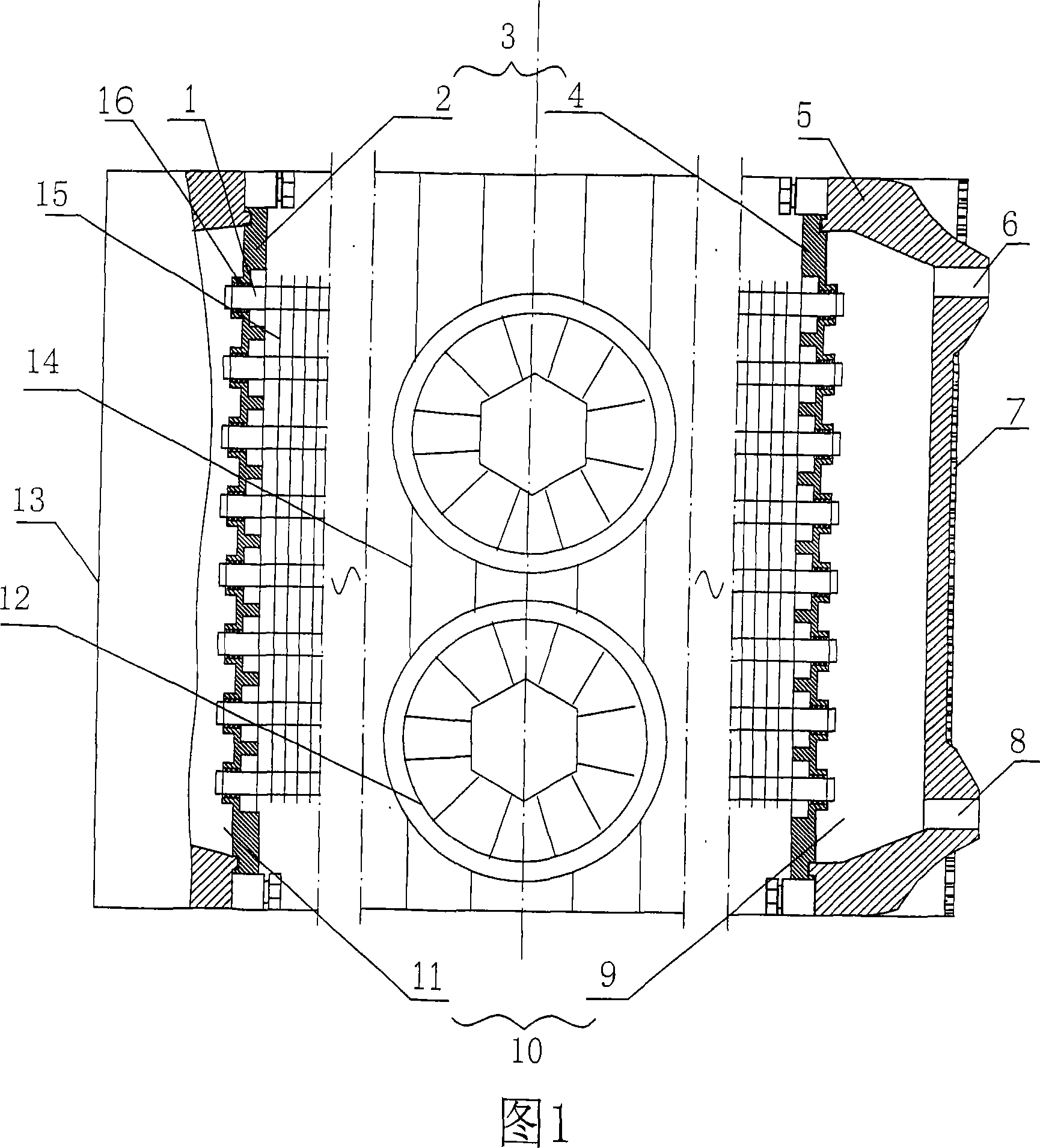

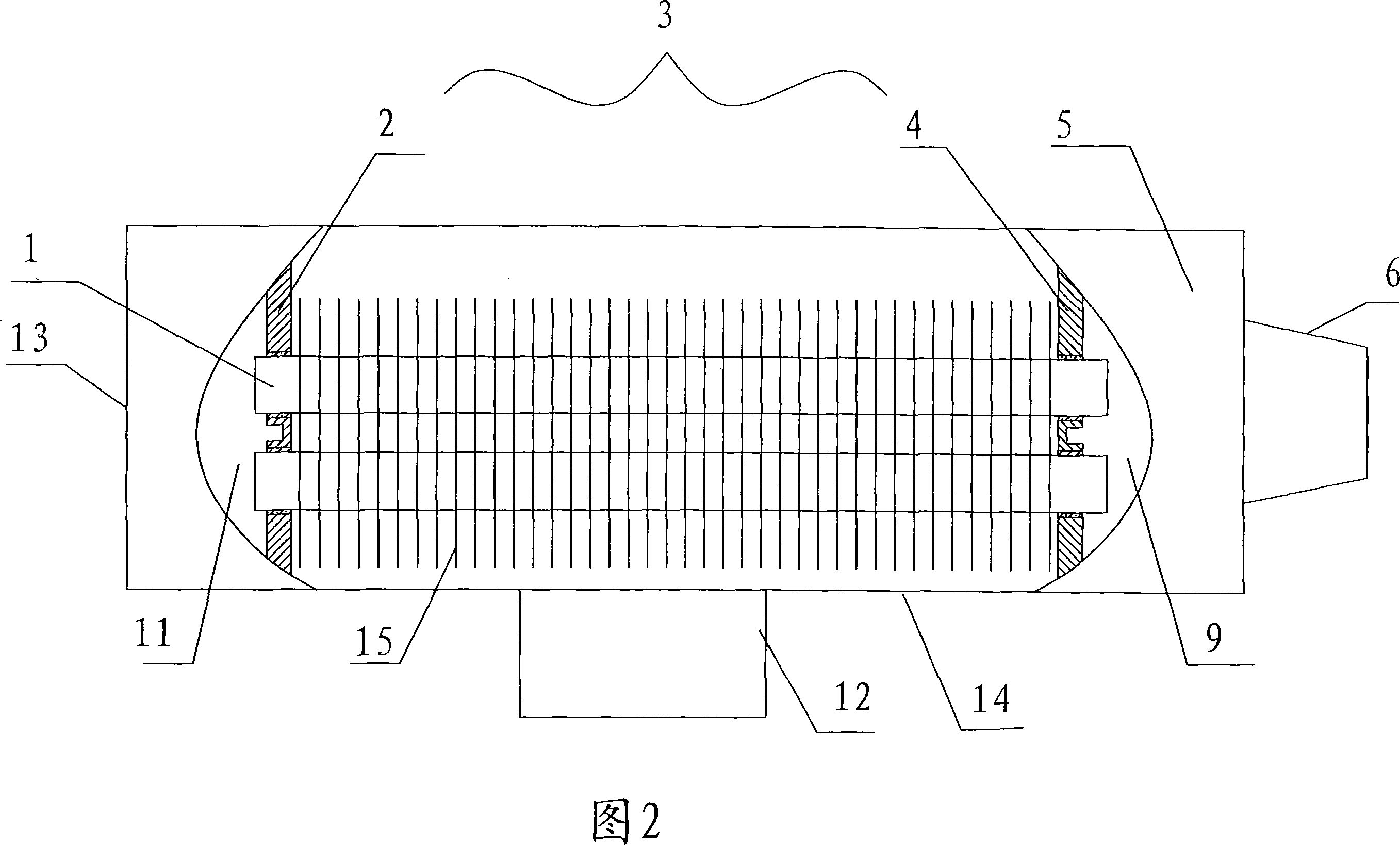

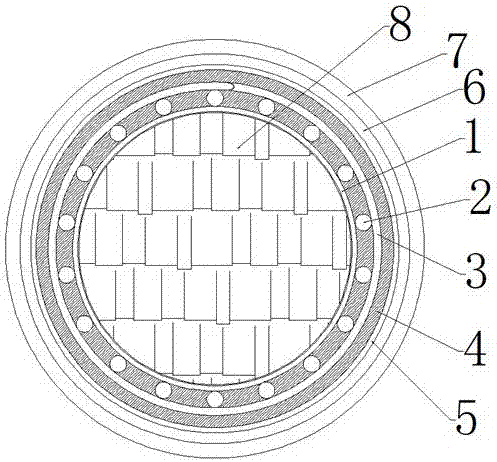

Device and method for magnetically grinding inner surfaces of large-diameter long and straight pipes

InactiveCN108857605ARealize finishingAchieve extrusionEdge grinding machinesPolishing machinesMotor drivePipe fitting

The invention relates to a device and a method for magnetically grinding the inner surfaces of large-diameter long and straight pipes. The device comprises a bed, spindle motors, couplings, a magneticpole disc, a motor driving slide rail device and a hoisting device. Two ends of each pipe fitting can be sealed by pipe fitting plugs and are fixed by the aid of four-jaw chucks, the four-jaw chuck at one end of each pipe fitting is connected with the corresponding spindle motor by the corresponding coupling, the four-jaw chuck at the other end of each pipe fitting is connected with a support seat by bearings, support seat slide rails are fixed onto the bed, and the support seats are slidably connected with the support seat slide rails by support seat sliders; the motor driving slide rail device is arranged at the bottom of the bed, and the magnetic pole disc is connected with the motor driving slide rail device by the hoisting device, can be lifted under the control of the hoisting device and can axially move along the pipe fittings under the control of the motor driving slide rail device. The device and the method have the advantages that finish machining can be carried out on the inner surfaces of the pipe fittings by the aid of magnetic grinding processes, and carbon deposits, oil stain and rust stain which are accumulated at grooves inside the pipe fittings can be effectivelyremoved by the aid of the device and the method.

Owner:UNIV OF SCI & TECH LIAONING

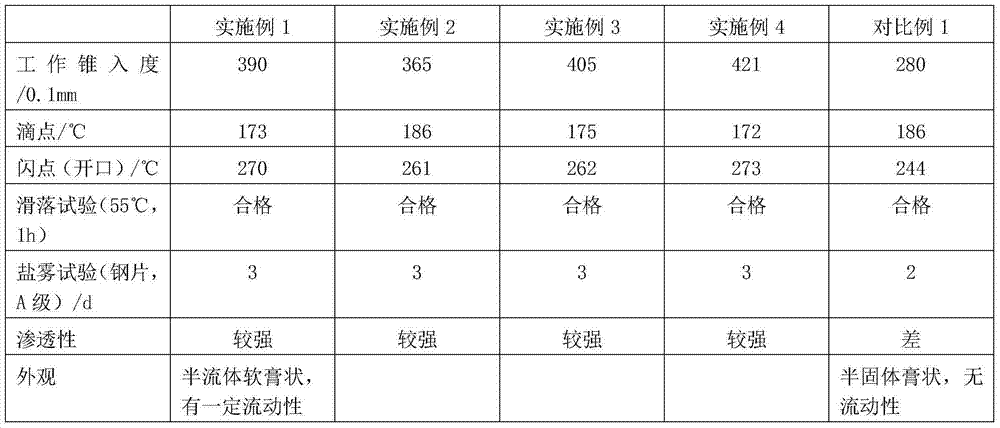

Lubricating grease composition for elevator wire ropes and preparation method thereof

ActiveCN103484218AImprove adhesionImprove permeabilityLubricant compositionMicrocrystalline waxOleic Acid Triglyceride

Owner:WUJIANG JUNDA ELEVATOR PARTS

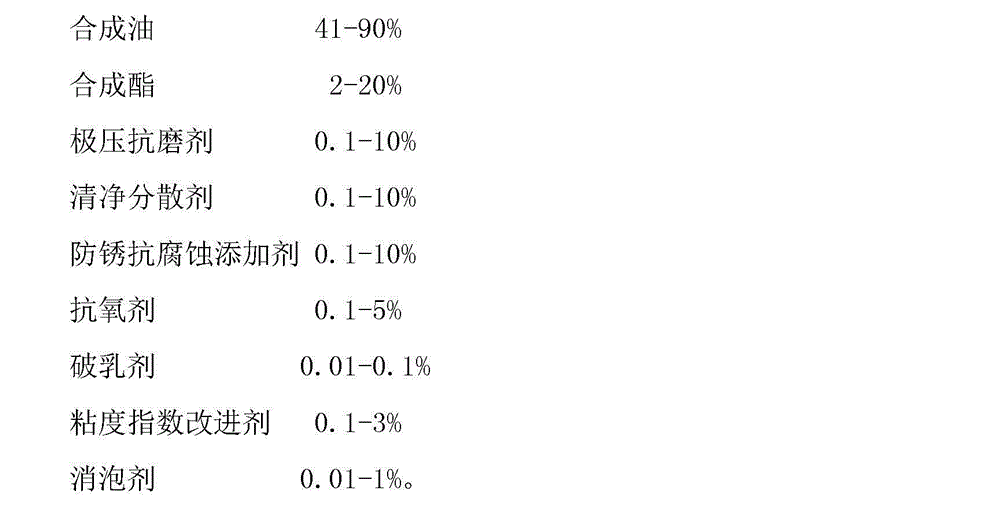

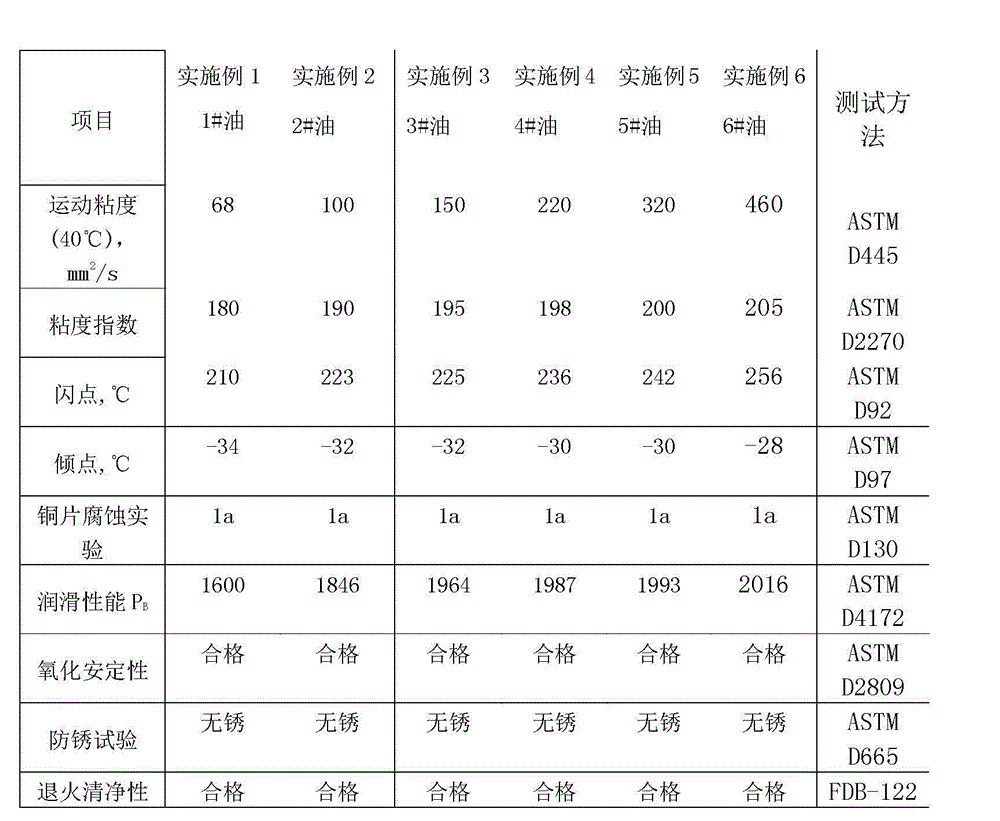

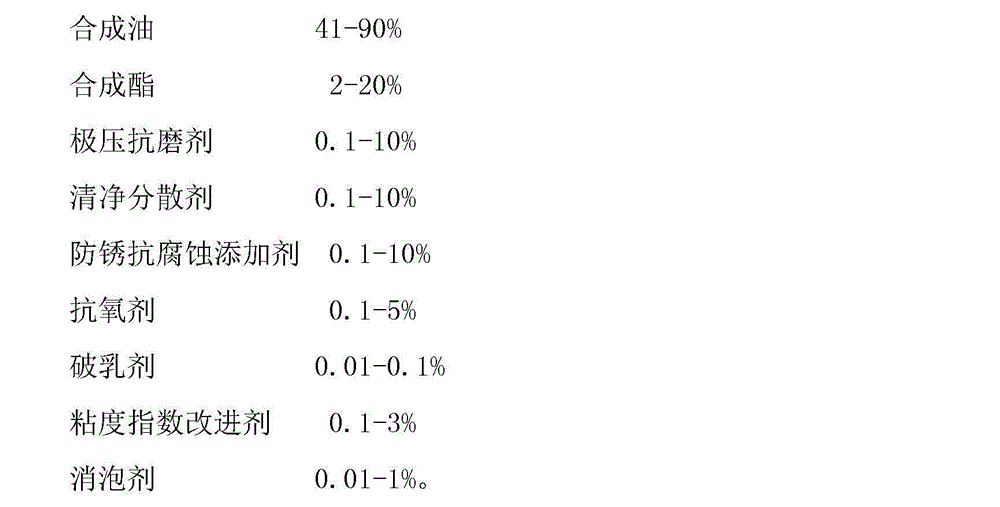

Totally synthetic non-staining bearing oil

InactiveCN102719305AReduce the temperatureImprove surface qualityLubricant compositionAntioxidantEngineering

Owner:上海福岛新材料科技有限公司

Flash rust-proof acrylic roof waterproof coating and preparation method thereof

InactiveCN109796825AAnti-rust and waterproof effect lasts for a long timeImprove UV protection effectAnti-corrosive paintsCelluloseUltraviolet

The invention relates to the field of water proofing of metal roofs and particularly discloses a flash rust-proof acrylic roof waterproof coating which is prepared from, by weight, the following raw materials: 30-50 parts of an acrylic emulsion, 25-60 parts of antirust slurry, 1-5 parts of a plasticizer, 0.3-5 parts of a dispersing agent, 0.1-1 part of a defoaming agent, 0.1-1 part of a base material wetting agent, 0.1-2 parts of an anti-flash rust additive, 1-4 parts of a film forming assistant, 3-10 parts of water, 0.01-0.5 part of cellulose ether, 0.1-0.5 part of a bactericide, 0.01-0.5 part of a coupling agent and 0.01-0.5 part of a pH adjusting agent. The flash rust-proof waterproof effect of the roof waterproof coating with a flash rust-proof function is longer lasting than that of acommon metal roof waterproof coating, the anti-ultraviolet effect is good, and the service life of a base material is prolonged. The waterproof coating has high elongation rate, good elasticity, strong base layer deformation resistance, the capability of shielding cracks, water proofing and breathability.

Owner:KESHUN WATERPROOF TECH CO LTD

Rapid cultivation method for Chinese rose landscape modelling

InactiveCN107318497AIncrease coverageShort training periodGrowth substratesCulture mediaMain branchLateral angle

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI

Strong anti-corrosion treatment technique for surface of carbon steel valve

ActiveCN105772370AImprove anti-corrosion performanceEasy to usePretreated surfacesSpecial surfacesEpoxyCross cut

Owner:浙江标盛阀门制造有限公司

Electrochemical pretreatment method of cathode for electrolytic extraction of metal gallium

ActiveCN102268714ANo corrosionReduced induction periodAnodisationPhotography auxillary processesPretreatment methodElectrolysis

Belonging to the technical field of electrolytic extraction of metal gallium, the invention provides an electrochemical pretreatment method of a cathode for electrolytic extraction of metal gallium. The method comprises the processes of: subjecting the cathode for electrolytic extraction of gallium to an oil and rust removal treatment; in an acidic, neutral or alkaline electrolyte, carrying out an electrochemical pretreatment to the cathode for gallium electrolytic extraction as an anode, with the cathode made of but not limited to stainless steel, and maintaining the pretreatment at a temperature of 15-40DEG C for 3min-2h, with an anodic current density of 0.01-0.2A / cm<2>. The electrode subjected to an electrochemical pretreatment has a smoother microscopic surface and a uniform surface current distribution. And as the surface of the electrode undergoing the electrochemical pretreatment exposes a partial crystal lattice structure, so the bonding force of electrodeposited gallium and the electrode surface becomes stronger, and the return dissolubility of the electrodeposited gallium in an alkaline condition can be reduced. Thus, continuous metal gallium layers are more likely to be electrodeposited and the induction time of electrodeposition can be shortened. The electrochemical pretreatment method of an electrode in the invention has the advantages of simple process, easy operation and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Steel structure shot blasting and rust removing method

Owner:SHANXI WUJIAN GRP CO LTD

Steel plate machining rust removal device capable of collecting waste scraps conveniently

InactiveCN108687634AEasy to collectAvoid random flyingGrinding carriagesGrinding drivesFixed frameArchitectural engineering

Owner:芜湖良匠机械制造有限公司

Tubular steel frame dust-removal device

InactiveCN107745319AGuaranteed derusting effectNo shakingGrinding carriagesGrinding machinesEngineeringSteel frame

Owner:四川大黄河建设工程有限公司

Automatic grinding device for short steel bars

InactiveCN109227288APrevent slidingPrevent rotationGrinding drivesGrinding feed controlArchitectural engineeringRebar

The invention discloses an automatic grinding device for short steel bars. The automatic grinding device comprises a base, wherein the left side of the upper portion of the base is provided with a positioning assembly, a sliding assembly is arranged under the positioning assembly, the positioning assembly is slidingly connected with the base through the sliding assembly, the right side of the upper portion of the base is provided with a grinding assembly, and the outer side of the base is provided with a central control module. The problem is solved that after steel bars are placed for a period of time, certain rust unavoidably exists on the surfaces, so steel bar grinding is needed, a worker needs to hole one end of each steel bar in the grinding process and then pull out the steel bar from the other end after the steel bar penetrates through the grinding device, the method needs manual control, unthorough surface grinding is possible if steel bar pulling is too quick, excessive grinding is also possible if the steel bar pulling is slower, the steel bar pulling is very strenuous, and large body burden is brought to the operator.

Owner:RUIXIONG METAL PROD (WUHU CO LTD

Steel pipe rust removal device

PendingCN108789101AAdjust effective lengthChange spacingGrinding carriagesGrinding drivesArchitectural engineeringDrive motor

Owner:HAIYAN HUITONG INTELLIGENT FURNITURE CO LTD

Chromium-ion-free zinc-nickel alloy automatic electroplating process

InactiveCN106637315AGood lookingMeet environmental protection requirementsElectrochemical responseNickel alloy

The invention discloses a chromium-ion-free zinc-nickel alloy automatic electroplating process. The chromium-ion-free zinc-nickel alloy automatic electroplating process comprises the following steps: pretreatment: removing oil stain and rust on the surface of a rubber-metal composite part or a metal part to be plated in such modes as pickling, electrolytic degreasing, and high-temperature degreasing; electroplating: utilizing electrochemical reaction to enable two metal ions (zinc and nickel) to be co-deposited on the metal surface to form a plating; confining: enabling a confining liquid to infiltrate the gap of the plating to form an organic or inorganic protective layer on the surface of the plating, wherein the confining temperature is 50-80 S, and the temperature of the confining liquid is 40-50 DEG C; blow-drying; drying; and packaging. By adoption of the chromium-ion-free zinc-nickel alloy automatic electroplating process, as the surface of the electroplating does not contain chromium ions, the requirement for environmental protection is satisfied; after electroplating, passivation is not needed, the anti-corrosion performance is good, long-time use can be realized, and the chromium-ion-free zinc-nickel alloy automatic electroplating process can guarantee favorable appearance of the plating; as passivation is not needed, the operation is simple, additional treatment is not required and the production efficiency is high; and the obtained plating has no red rust under neutral salt spray for 1,000 h.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Rust removal maintenance device for bridge guardrails

ActiveCN107584425AGood rust removal and maintenance effectImprove efficiencySpraying apparatusAbrasive machine appurtenancesBristleEngineering

Owner:盐城华航交通设施有限公司

Fuel oil additive mixture

Owner:黄慧娟

Production process of environment-friendly water-based anti-corrosion coating

InactiveCN104449091AImprove anti-corrosion performanceGood resistance to nitro paintAnti-corrosive paintsWater basedWater resistant

Owner:QINGDAO SHOUSHENG IND

Fingerprint preventing paint used on head of golf club and processing technology of fingerprint preventing paint

InactiveCN104403500ADeep colorImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyEngineering

Owner:DONGGUAN NISON VACUUM TECH

Magnetic powder sensitivity test device and test method

InactiveCN106525854AThe test method is accurateAccurate measurementMaterial analysis by optical meansSensitivity testQuenching

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Heating heat radiator

InactiveCN101101136AReduce maintenance costsReduce weightLighting and heating apparatusSpace heating and ventilation detailsEngineering plasticEngineering

Owner:李艳妍

Portable type steel bar telegraph pole

InactiveCN107191052AImprove mechanical propertiesPlay an insulating roleTowersYarnMoisture resistance

Owner:HEFEI HAIYIN TOWER

Lubricating liquid for food transporting equipment and preparation method of lubricating liquid

InactiveCN106167731ADifficult to volatileHigh specific heat capacityLubricant compositionPhosphateWater soluble chitosan

The invention relates to the field of lubricating liquid, in particular to lubricating liquid for food transporting equipment. The lubricating liquid is prepared from the following raw materials in parts by weight: 2-3 parts of water-soluble chitosan, 2-3 parts of triethanolamine citrate, 0.5-1 part of polyvinylpyrrolidone, 10-14 parts of mint extract, 8-14 parts of carboxylic acid, 2-4 parts of polyalkylene glycol, 3-5 parts of sodium octadecyl polyoxyethylene ether phosphate, 0.3-0.5 part of medical rust, 2-3 parts of a silicone defoamer, 1-2 parts of ethoxylated pentaerythritol tetra (methyl) acrylate, 1-2 parts of ethylparaben, 4-8 parts of sedoheptulose 7-phosphoric acid, and 20-26 parts of simethicone. The lubricating liquid disclosed by the invention is free from toxins, difficult to volatilize, and high in specific heat capacity, has certain heat-conducting properties for heat produced by equipment abrasion, has certain attraction capacity on bacteria and pests, has excellent capacity of killing the bacteria and the pests, has quite significant antirust capacity, and does not have crystal deposition, and the kinematic viscosity of the lubricating liquid is 10-20% higher than that of general lubricating liquid.

Owner:BENGBU ZHONGZHENG INDAL

Electrostatic spraying slushing oil

InactiveCN104611109AImprove adhesionImprove thermal stabilityLubricant compositionPolyesterPhosphate

The invention discloses electrostatic spraying slushing oil. The electrostatic spraying slushing oil is composed of the following raw materials in parts by weight: 0.4-1 part of p-nitrophenyl phosphate sodium, 60-70 parts of #25 transformer oil, 1-2 parts of polyisobutene, 3-5 parts of microcrystalline wax, 2-3 parts of hosho oil, 2-4 parts of phthalate polyester, 4-6 parts of petroleum sodium sulfonate, 2-3 parts of fumed silica, 1-3 parts of triethanolamine oleic soap, 1-2 parts of diphenyl silandiol, 0.5-1 part of monopotassium phosphate, 0.4-1 part of inositol hexaphosphoric acid, 0.3-0.5 part of zinc acetylacetonate, 2-3 parts of oleic acid and 3-5 parts of wear resistant machine oil. A molecular directional adsorption film can be formed on the surface of the metal by adding the wear resistant machine oil into the slushing oil, so that the friction can be reduced; the modified terpene resin has a good cohesive property and strong thermal stability so that the compatibility between the materials can be promoted and the adhesive force of the film can be enhanced; the zinc dihydrogen phosphate is used as a common metal surfactant which has a good rust removal preservative effect; the rare earth lanthanum ion and the OH<-> generated on the surface of the metal material during the oxygen absorption corrosion process can generate an insoluble complex which can slow down the corrosion of the electrode reaction and has a good slow-release effect.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

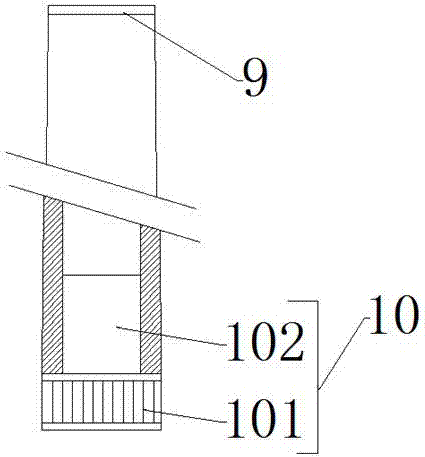

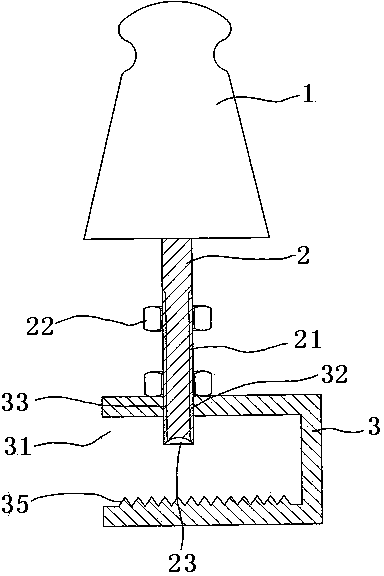

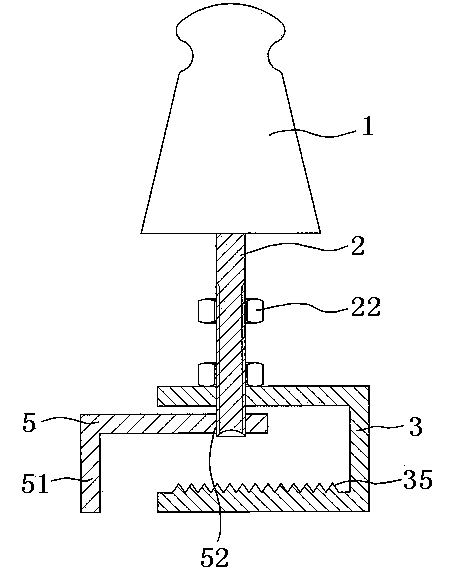

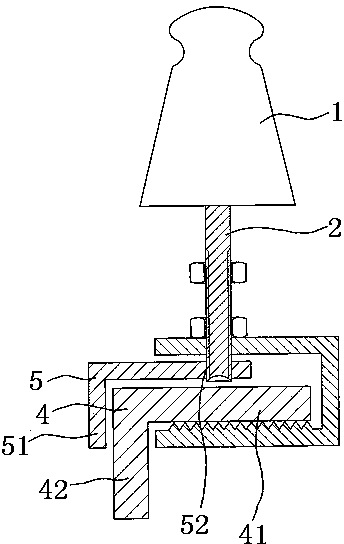

Low-voltage insulated straight bottle capable of being replaced rapidly and replacement method thereof

ActiveCN104269805AContact stabilityPrevent slidingOverhead installationApparatus for overhead lines/cablesLow voltageFixed frame

Owner:国网河北深州市供电有限责任公司

Anti-rust lubricating aqueous copper drawing fluid and preparation method thereof

InactiveCN104293458AImprove anti-corrosion effectQuality assuranceLubricant compositionCopper wireLubrication

Owner:ANHUI TATSU PRECISION ALLOY

Making method of high-corrosion-resistance air conditioner support

InactiveCN107702238AThe problem of shortened useful lifeAvoid shortened service lifeLighting and heating apparatusAnti-corrosive paintsRustHeat treating

Owner:成都毅诚机电工程有限公司

Rust steel simulation method based on surface random roughness

PendingCN114757074ADesign optimisation/simulationComplex mathematical operationsRough surfaceRandom roughness

The invention discloses a numerical method for simulating rusted steel based on surface random roughness, which specifically comprises the following steps: taking the rusted steel surface as a two-dimensional / three-dimensional random rough surface, and obtaining the corrosion rate of the steel according to an actual measurement or empirical formula. The arithmetic mean height, the root mean square height and the maximum height of the rusted steel surface corresponding to the corrosion rate are obtained through a morphology scanning or formula calculation mode, a one-dimensional / two-dimensional random rough surface is simulated and generated through a Monte Carlo method, and finally the distance from the lowest point of the rusted surface to other surfaces is calculated according to the corrosion rate. And combining the obtained rough surface with other planes to generate steel corrosion models under different corrosion degrees.

Owner:TIANJIN UNIV

Breeding method of high-resistance black millet variety

InactiveCN106665335AImprove qualityReduce usagePlant genotype modificationHigh resistanceDisease resistant

Owner:FUJIAN AGRI & FORESTRY UNIV

High speed railway without clear ballasts

The invention relates to a high speed railway without clear ballasts. The railway comprises steel rails, railway rectifying boards, rust and wearing resistant layers, reinforced concrete bars, ballast layers, ballast limiting boards, electric facilities, isolation belts and a foundation. The railway is characterized in that the steel railway rectifying boards are arranged below the steel rails. The relationship between the railway and motor trains is comprehensively considered, the high speed railway is scientifically classified, and through the railway rectifying and the corresponding appropriate reinforcement, the resistance reduction and energy saving can be achieved, so that the high speed railway without clear ballasts is very practical and low in price, and can be widely applied to construction and speed-up reconstruction of railways.

Owner:严宏生

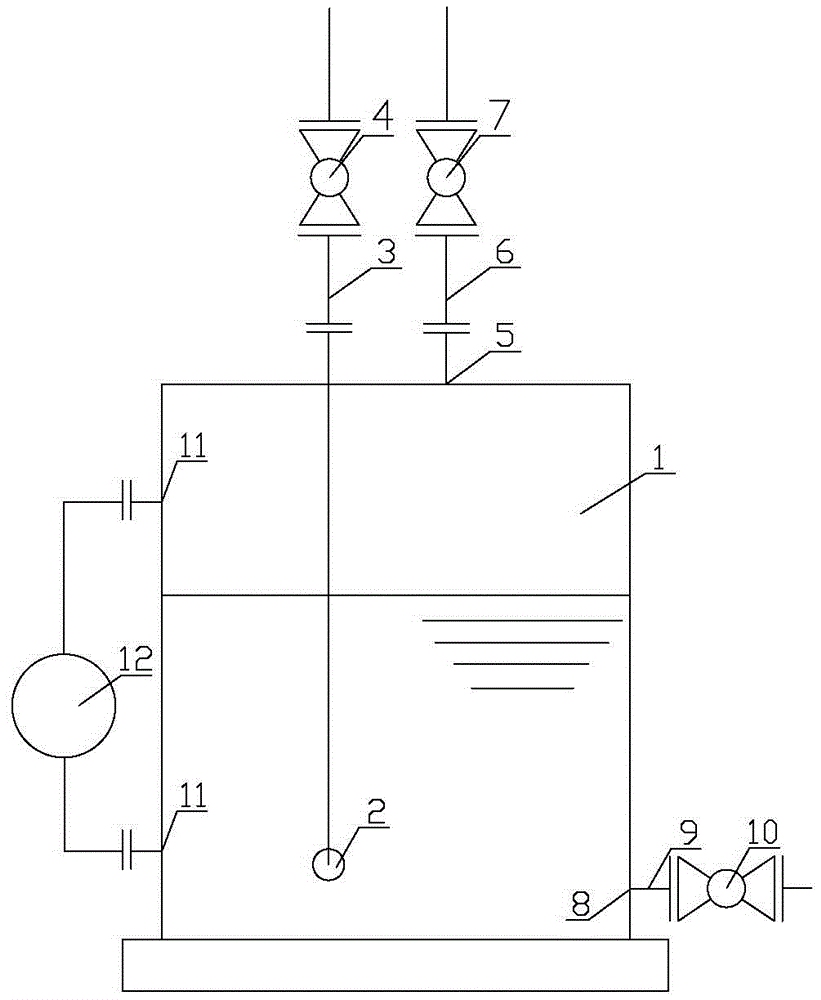

Device for filtering iron impurities of carbon steel pipeline

ActiveCN105413325AAvoid compromising the quality of high purity acidCompact and reasonable structureProcess control/regulationGas treatmentPhysical chemistryEnvironmental engineering

Owner:XINJIANG ZHONGTAI CHEM CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap