Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Passivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Passivation, in physical chemistry and engineering, refers to a material becoming "passive," that is, less affected or corroded by the environment of future use. Passivation involves creation of an outer layer of shield material that is applied as a microcoating, created by chemical reaction with the base material, or allowed to build from spontaneous oxidation in the air. As a technique, passivation is the use of a light coat of a protective material, such as metal oxide, to create a shell against corrosion. Passivation can occur only in certain conditions, and is used in microelectronics to enhance silicon. The technique of passivation strengthens and preserves the appearance of metallics. In electrochemical treatment of water, passivation reduces the effectiveness of the treatment by increasing the circuit resistance, and active measures are typically used to overcome this effect, the most common being polarity reversal, which results in limited rejection of the fouling layer. Other proprietary systems to avoid electrode passivation, several discussed below, are the subject of ongoing research and development.

Semiconductor integrated circuit device

ActiveUS20120241969A1Improve reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A semiconductor integrated circuit device includes: a rectangular shaped semiconductor substrate; a metal wiring layer formed on or over the semiconductor substrate; and a passivation layer covering the metal wiring layer. A corner non-wiring region where no portion of the metal wiring layer is formed is disposed in a corner of the semiconductor substrate. A slit is formed in a portion of the metal wiring layer which is close to the corner of the semiconductor substrate. The passivation layer includes a first passivation layer which is formed on the metal wiring layer and a second passivation layer which is formed on the first passivation layer. The first passivation layer is formed of a material that is softer than a material of the second passivation layer.

Owner:ROHM CO LTD

Middle frame component and production method thereof

ActiveCN106714507APrevent or reduce corrosionIncrease contactDigital data processing detailsSubstation equipmentEngineeringMechanical engineering

Embodiments of the invention provide a middle frame component and a production method thereof. The middle frame component is a support component which is in an electronic product and is used for supporting components of the electronic product. The middle frame component comprises a middle frame base material body, a first metal layer and an insulation passivation layer, wherein the first metal layer is attached to a first area of the middle frame base material body; a heat conductivity coefficient of the first metal layer is greater than a heat conductivity coefficient of the middle frame base material body; the first area includes all or parts of external surfaces of the middle frame base material body; the first metal layer is used for conducting heat generated by at least one component which is contacted with or adjacent to the first metal layer to the whole first metal layer and the middle frame base material body; and the insulation passivation layer is attached to a surface of the first metal layer. In the embodiments of the invention, heat dissipation performance of the middle frame component can be increased.

Owner:HUAWEI TECH CO LTD

Process for fabricating an array of germanium-based diodes with low dark current

ActiveUS20200176503A1Improve fill factorLower average currentFinal product manufactureSolid-state devicesEngineeringPhotodiode

A process for fabricating an optoelectronic device including an array of germanium-based photodiodes including the following steps: producing a stack of semiconductor layers, made from germanium; producing trenches; depositing a passivation intrinsic semiconductor layer, made from silicon; annealing, ensuring, for each photodiode, an interdiffusion of the silicon of the passivation semiconductor layer and of the germanium of a semiconductor portion, thus forming a peripheral zone of the semiconductor portion, made from silicon-germanium.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

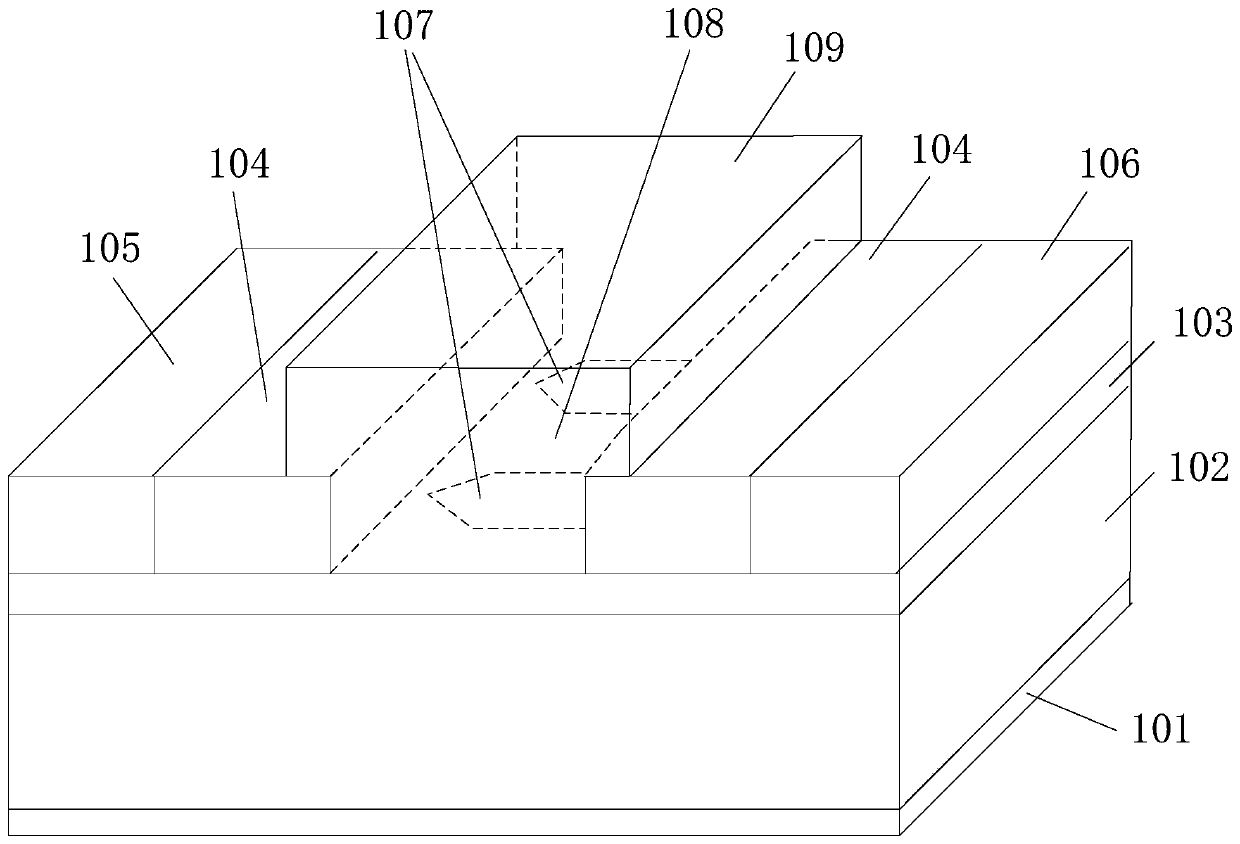

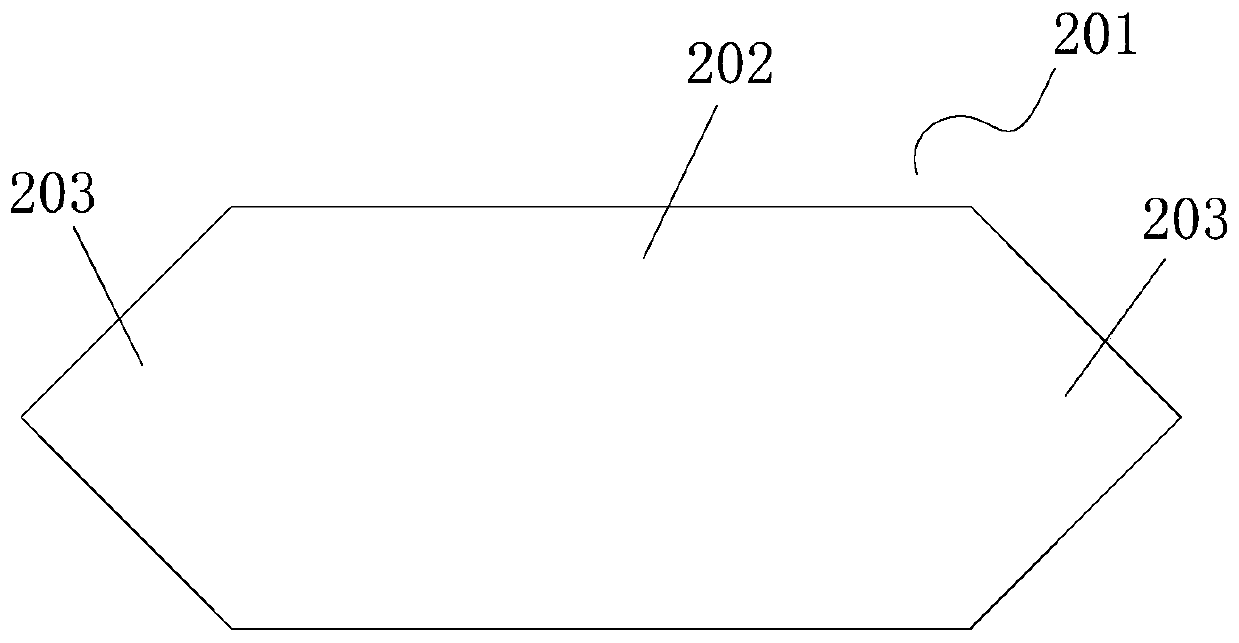

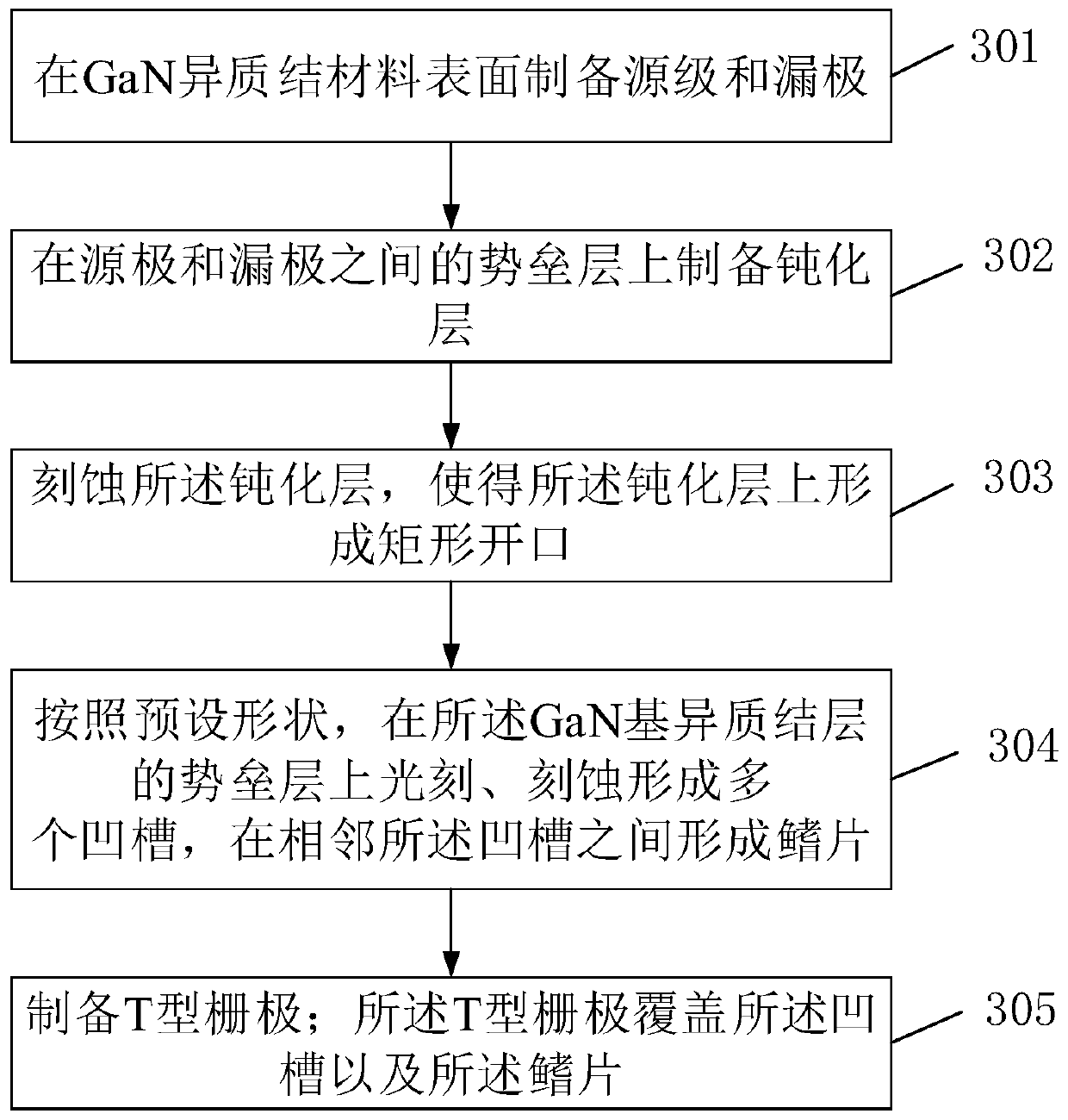

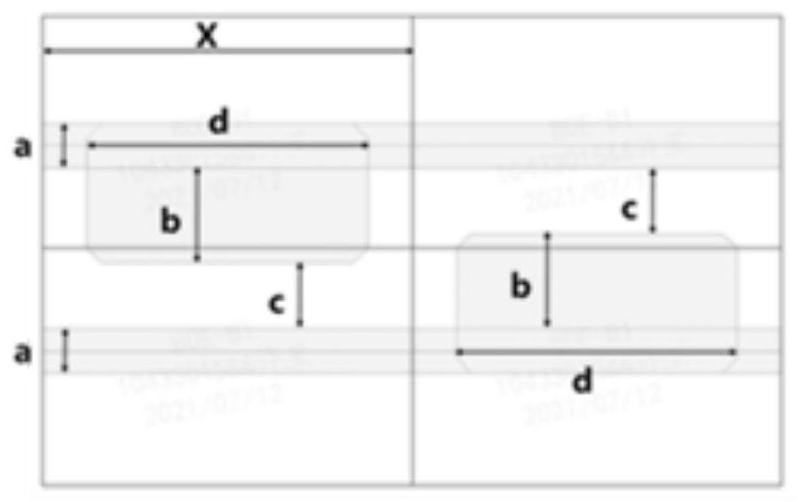

GaN-based fin field effect transistor device and manufacturing method thereof

InactiveCN110571265AUniform electric field distributionReduce electric field strengthSemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsField-effect transistor

The invention provides a GaN-based fin field effect transistor device and a manufacturing method thereof. The device comprises a substrate, a buffer layer, a barrier layer and a passivation layer which are arranged in sequence, wherein a source is arranged at one end of the barrier layer, and a drain is arranged at the other end of the barrier layer; the passivation layer is arranged on the barrier layer between the source and the drain; an opening is formed in the middle of the passivation layer; a plurality of grooves are formed in the barrier layer region corresponding to the opening; finsare arranged between the adjacent grooves; a T-shaped gate is arranged on the passivation layer, and the T-shaped gate covers the groove and the fins; the length of the groove is equal to that of thebottom of the T-shaped gate; the thickness of the fin is equal to the depth of the groove; and the width of the portion, away from the passivation layer, of the groove is larger than the width of theportion, close to the passivation layer, of the groove.

Owner:XIDIAN UNIV

Solar cell and preparation method thereof

PendingCN114447127AGood light trapping structure designUniform dense depositionSolid-state devicesSemiconductor/solid-state device manufacturingLight reflectionEngineering

The invention discloses a solar cell which comprises a substrate, the surface of the substrate is provided with a suede structure, and the substrate is provided with a carrier transport layer and a perovskite absorption layer which are arranged in a stacked mode. An interface passivation layer is arranged between the perovskite absorption layer and the carrier transmission layer, and the interface passivation layer and the suede structure are conformal. The invention also provides a preparation method of the solar cell. According to the solar cell provided by the invention, the interface passivation layer and the textured surface of the substrate are conformal, so that uniform and compact deposition of the interface passivation layer and the textured surface of the substrate is realized, ion migration is inhibited, and hysteresis of a positive scanning curve and a negative scanning curve of the cell is remarkably reduced; and meanwhile, the conformal structure of the interface passivation layer continues the good light trapping structure design of the substrate textured surface, the light reflection loss is reduced to the maximum extent, and the photo-generated current is remarkably improved.

Owner:LONGI SOLAR TECH (XIAN) CO LTD

Cutting edge passivation device for magneto-rheological diamond cutter

InactiveCN112975599AHigh passivation precisionHigh removal rateOther manufacturing equipments/toolsGrinding work supportsEngineeringMechanical engineering

The invention belongs to the field of cutter passivation, and particularly relates to a cutting edge passivation device for a magneto-rheological diamond cutter. The cutting edge passivation device comprises a bottom plate, a supporting plate, a side plate and a rotating plate, wherein the side plate is perpendicular to the bottom plate, the rotating plate and the supporting plate are sequentially arranged on the side plate from top to bottom, the supporting plate is parallel to the bottom plate, a grinding fluid basin is arranged on the supporting plate, a centrifugal pump is installed on the side portion of the grinding fluid basin, an electromagnet is arranged on the bottom plate and located on the lower portion of the grinding fluid basin, the rotating plate is perpendicularly installed on the side plate, the rotating plate is turnable, a clamping mechanism for fixing a cutter is arranged on the rotating plate, and a cutter is inserted into the grinding fluid basin. According to the cutting edge passivation device, the passivation efficiency and effect can be improved, the passivation cost is reduced, and the designated position of the cutting edge of the cutter is passivated.

Owner:YANCHENG INST OF TECH

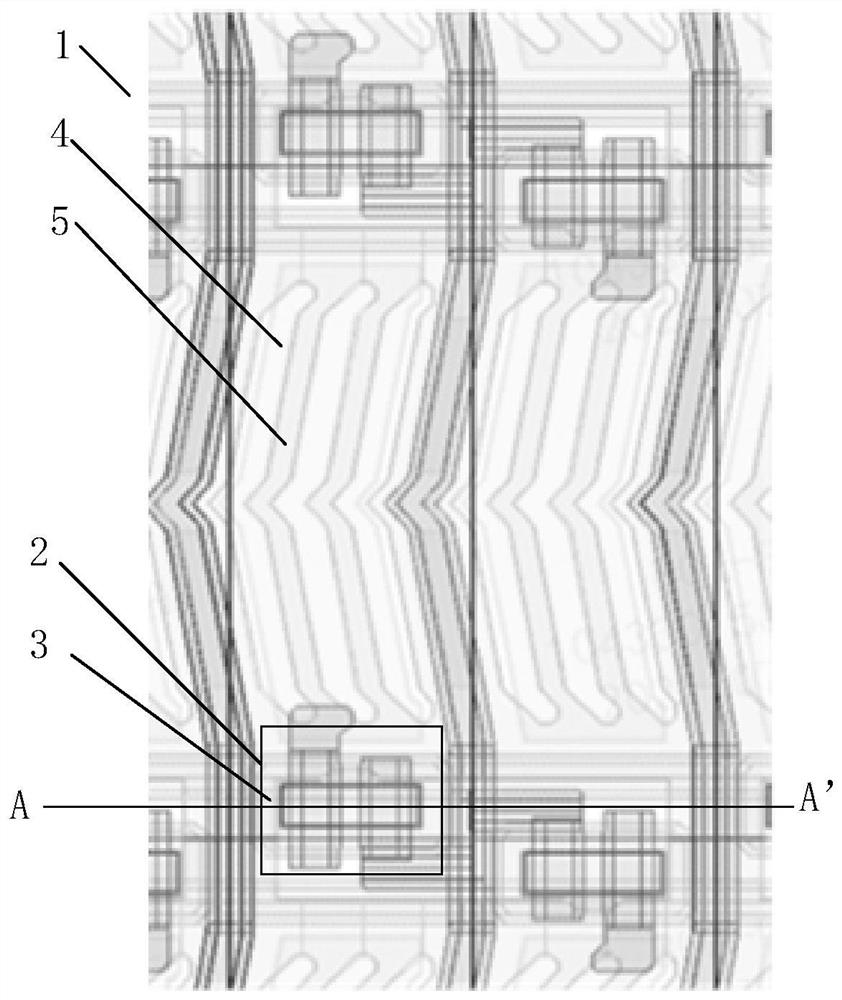

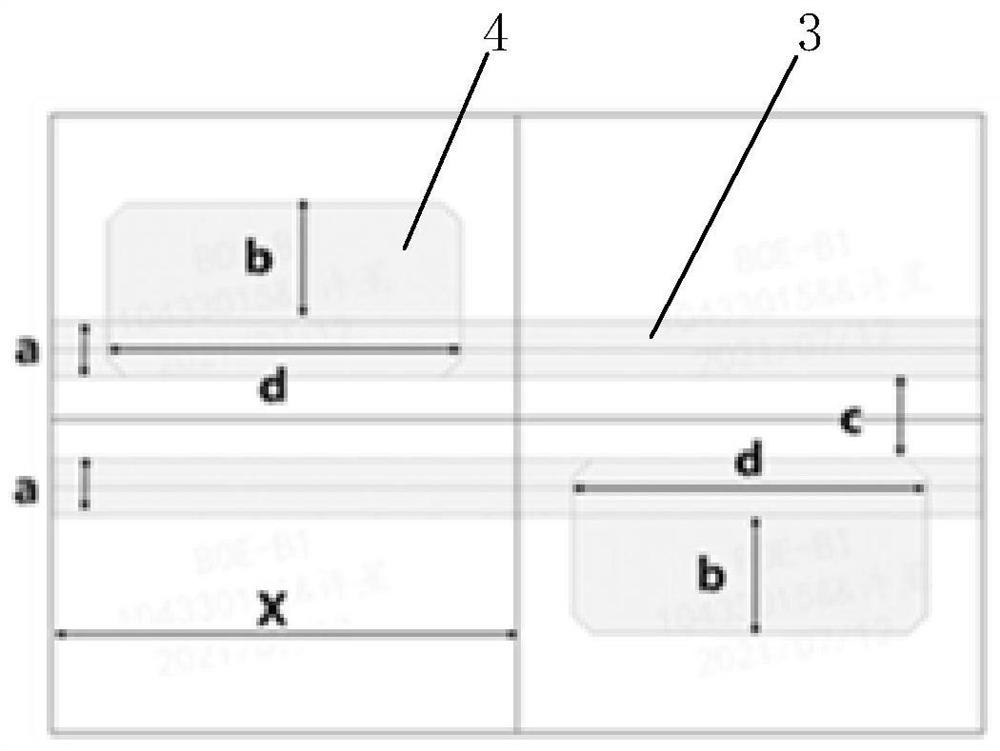

Display structure of double-gate driving equipment and display device

PendingCN113937110AAddress riskIncrease storage capacitySolid-state devicesIdentification meansCapacitanceDisplay device

Owner:BOE TECH GRP CO LTD +1

Surface passivation process of semiconductor material

PendingCN114005762AImprove insulation performanceImprove corrosion resistanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsSemiconductor chip

Owner:徐州领测半导体科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap