Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20 results about "Centrifugal pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits.

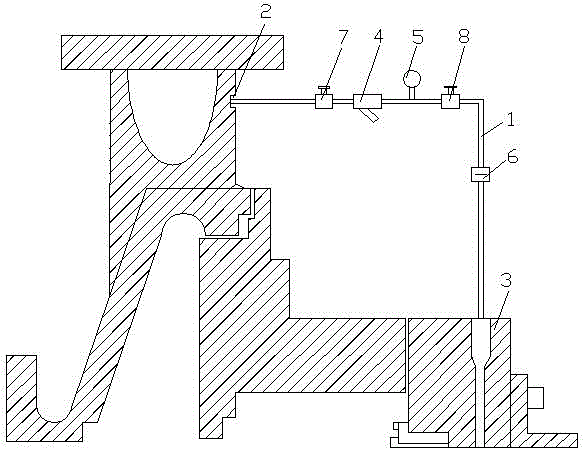

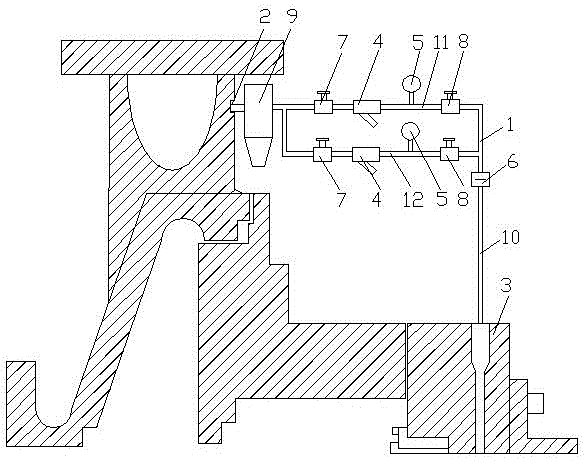

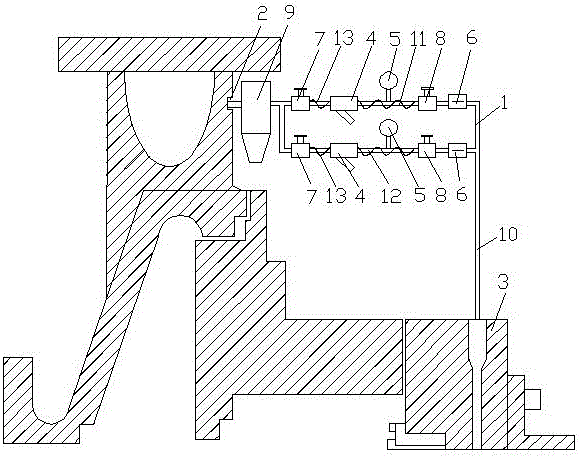

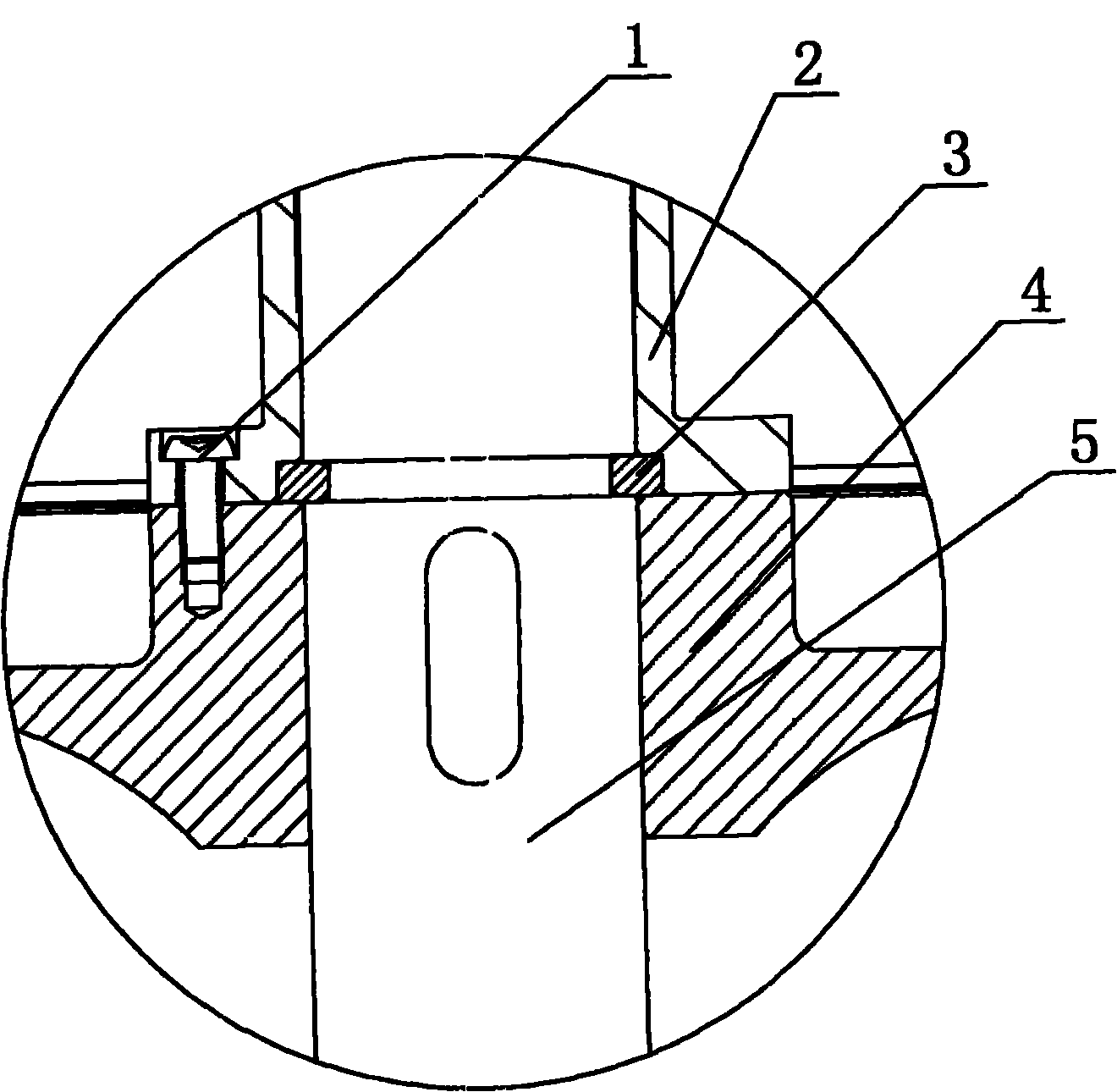

Flushing device for mechanical seal of centrifugal pump

Owner:CHINA PETROLEUM & CHEM CORP +1

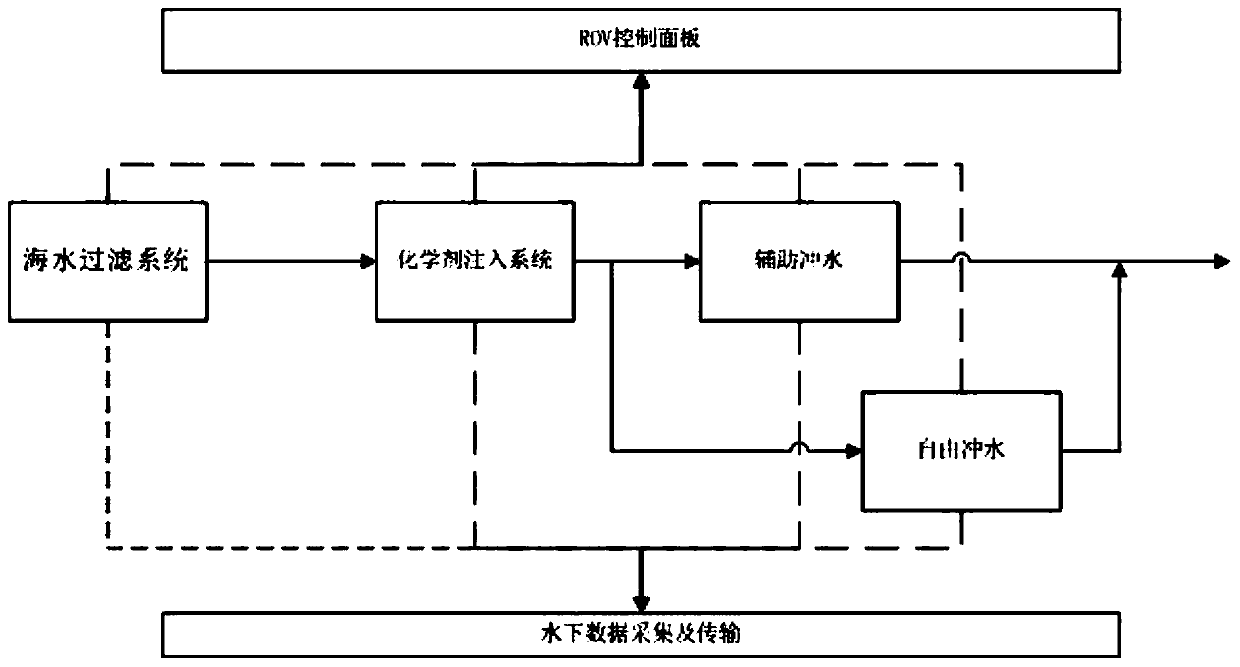

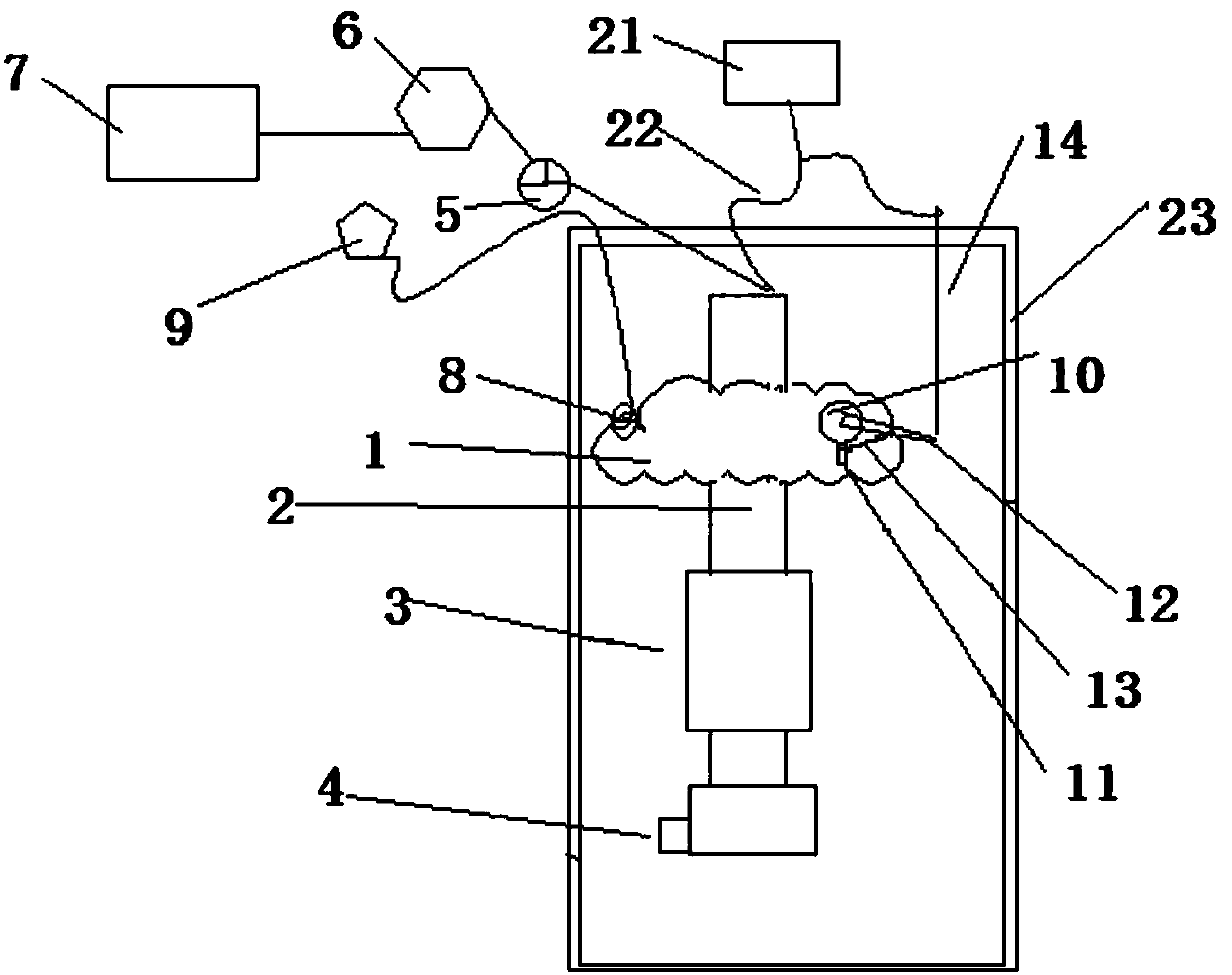

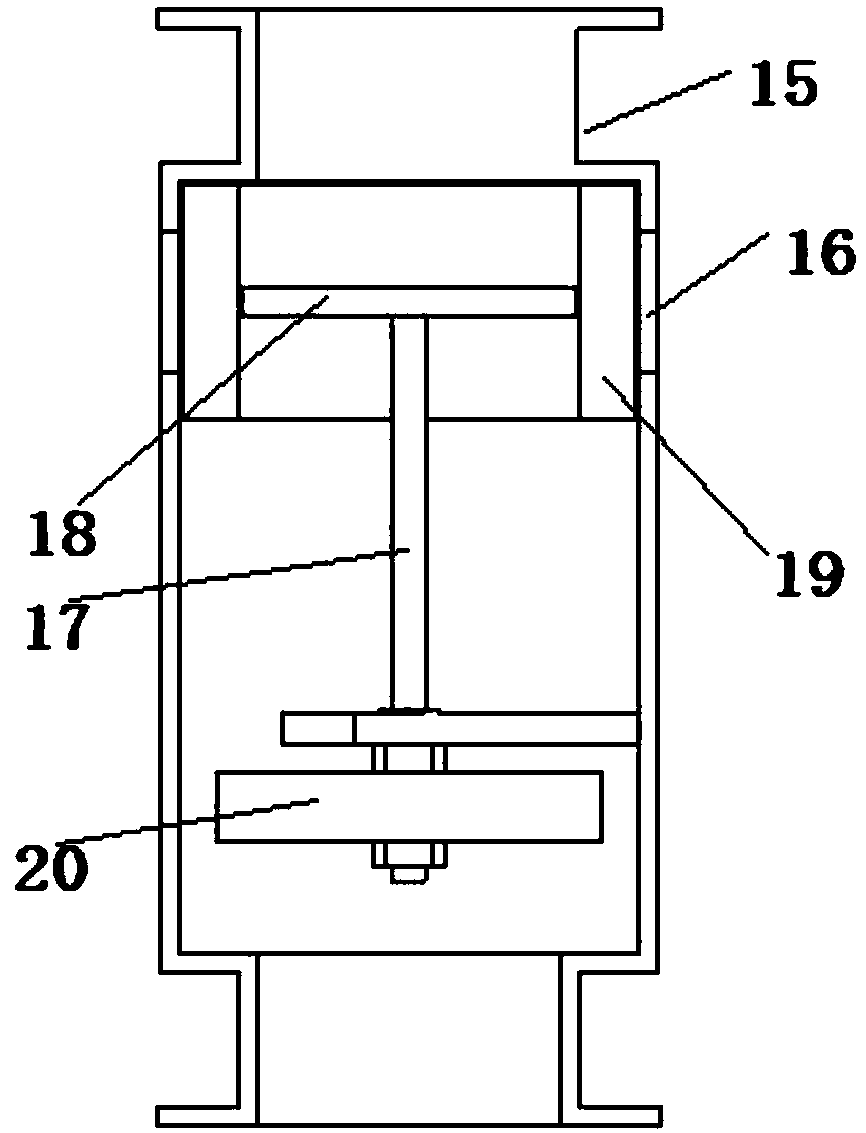

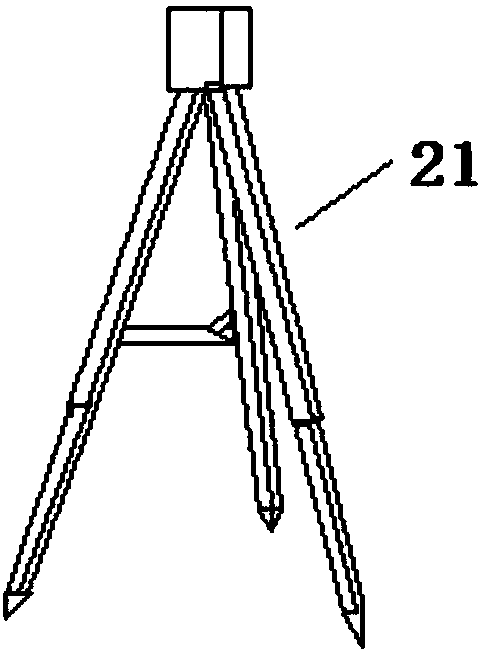

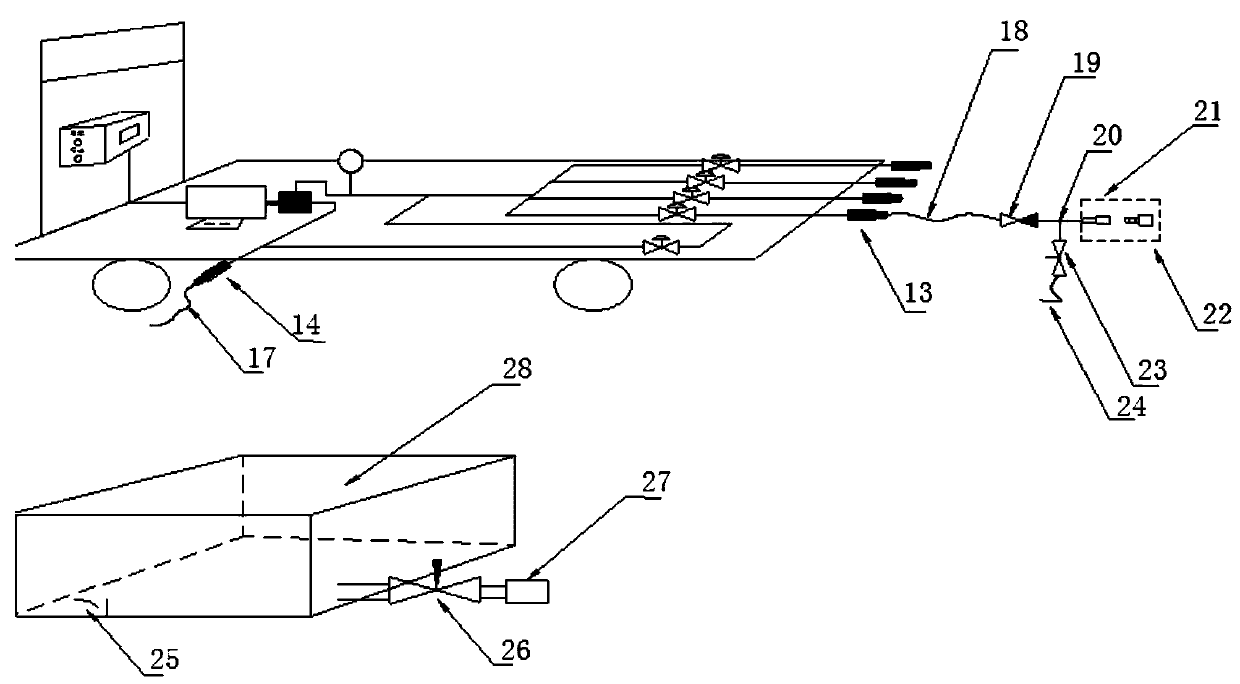

Device applicable to pipe washing work of deep sea oil and gas pipeline

InactiveCN110252750AOvercome stressOvercoming resistance along the wayHollow article cleaningPiggingPore water pressure

Owner:OFFSHORE OIL ENG +1

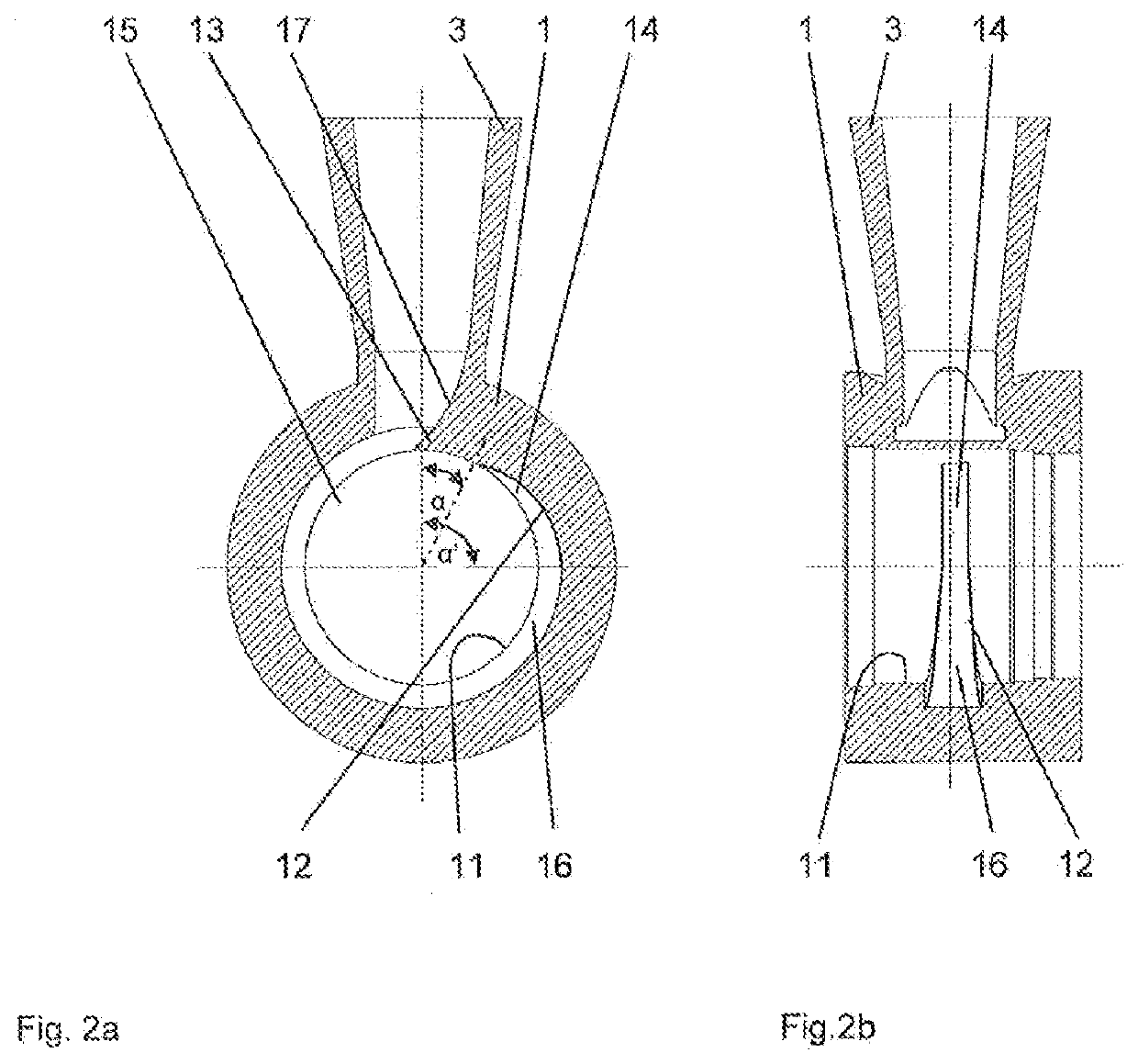

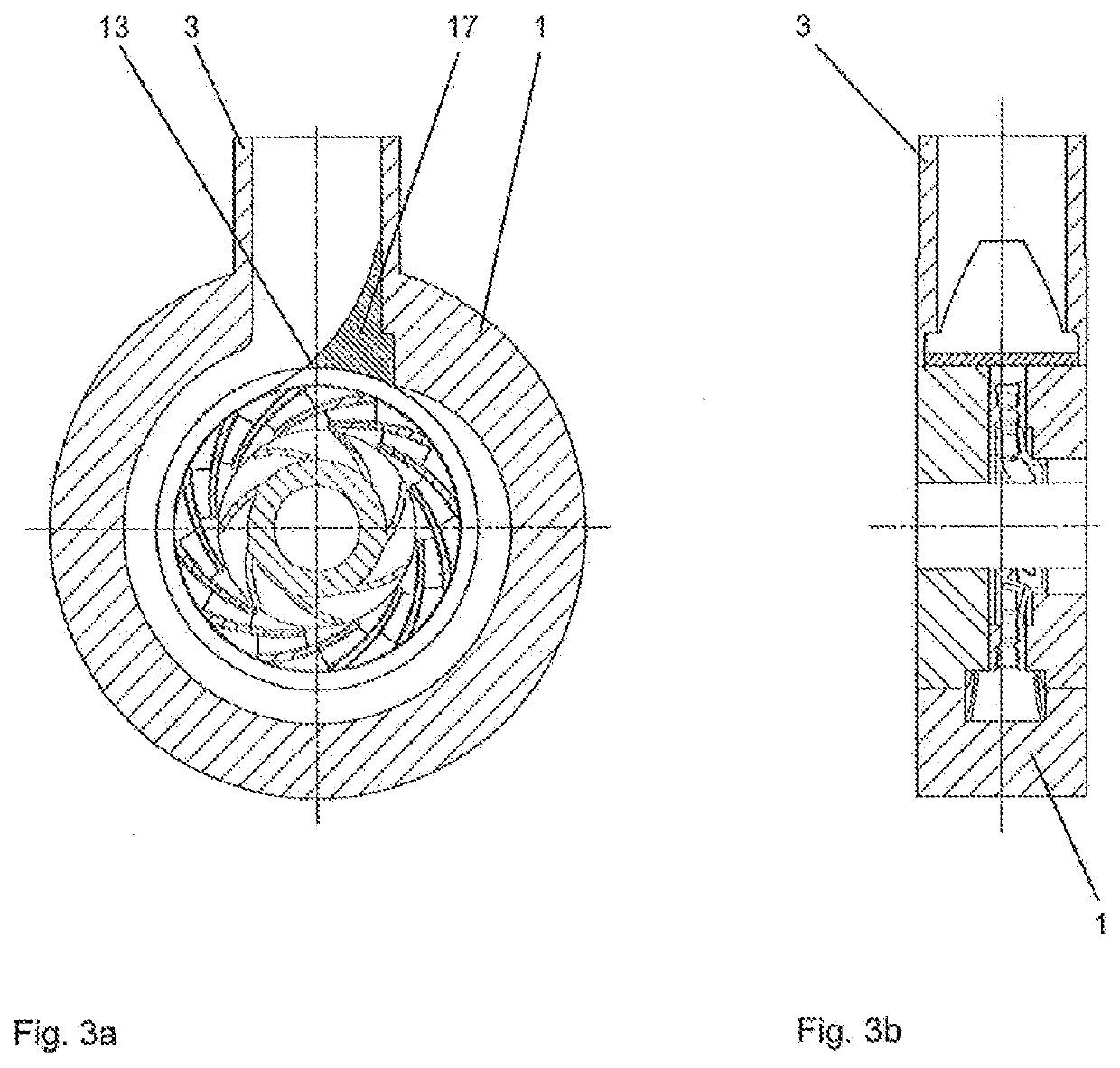

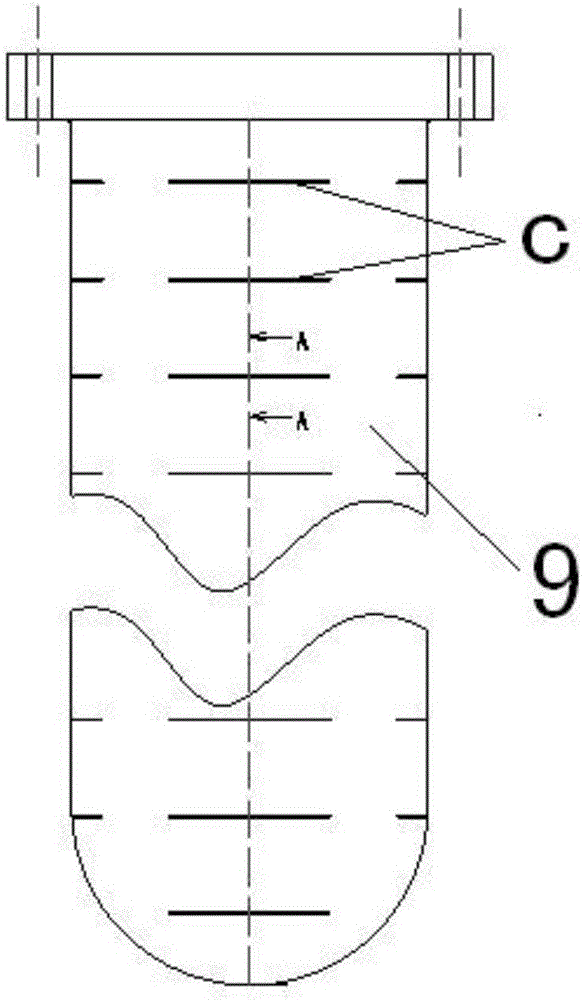

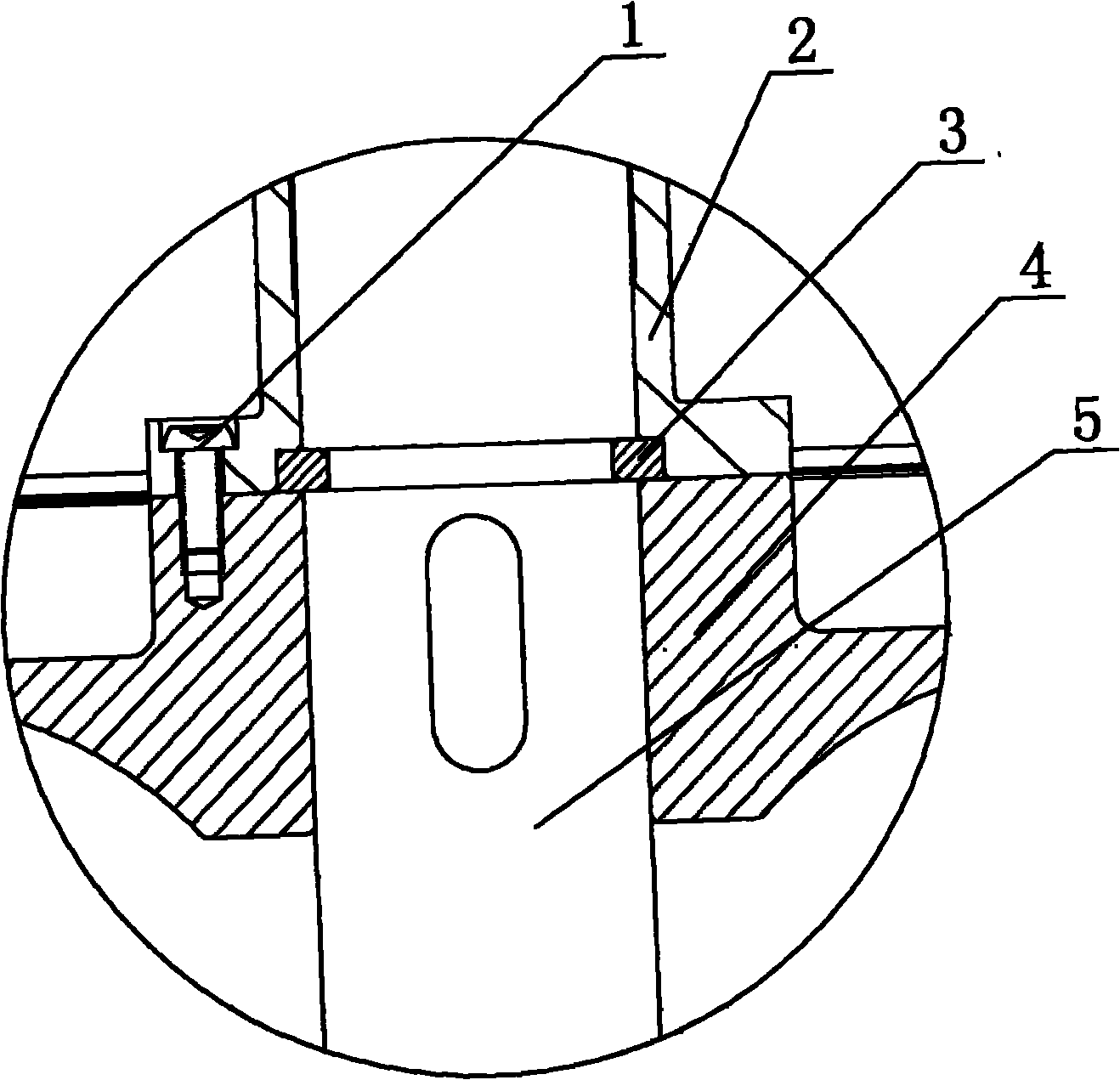

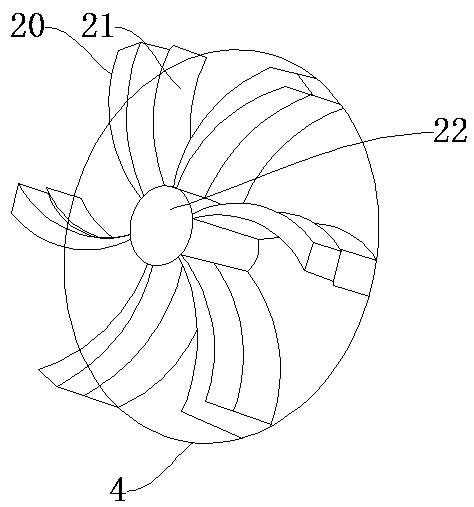

Lossless super-cavitation centrifugal pump impeller

ActiveCN106337835APrecise design methodReduce friction lossPump componentsPumpsCavitationSolid particle

The invention relates to a lossless super-cavitation centrifugal pump impeller. The impeller is mainly composed of blades (1), an impeller front cover plate (2) and an impeller rear cover plate (3) and mainly characterized in that geometric structures of the super-cavitation blade pump blades (1) are modified, and according to the requirements of different design conditions, single short super-cavitation blades or combined blades combining the super-cavitation blades and non-overloading blades are adopted; and geometric shapes of blade inlets are modified to simultaneously meet the super-cavitation requirement and the requirement of allowing larger solid particles to pass through the impeller without a plunger, the blades in the impeller are prevented from being abraded by the large solid particles in the operating process, the frictional resistance to the blades in the operating process can be effectively reduced, the working efficiency of a super-cavitation pump is improved, and the service life of the super-cavitation pump is prolonged.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH

Fixed depth treatment device for seepage well filling material layer blockage suspensions and method thereof

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

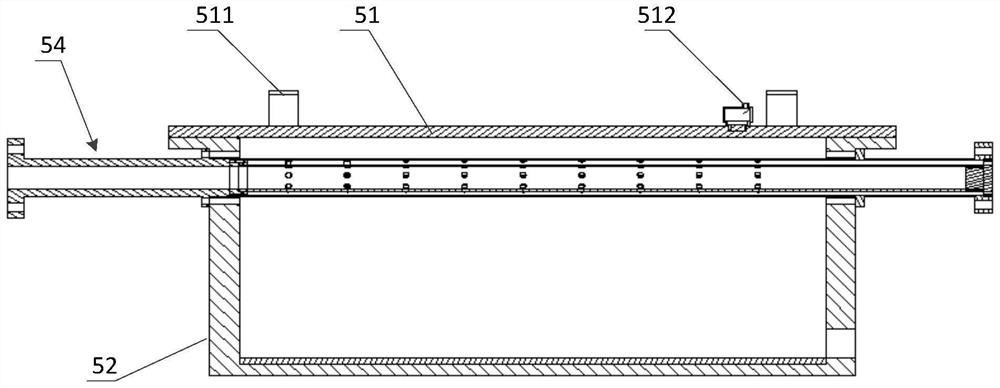

Cutting edge passivation device for magneto-rheological diamond cutter

InactiveCN112975599AHigh passivation precisionHigh removal rateOther manufacturing equipments/toolsGrinding work supportsEngineeringMechanical engineering

The invention belongs to the field of cutter passivation, and particularly relates to a cutting edge passivation device for a magneto-rheological diamond cutter. The cutting edge passivation device comprises a bottom plate, a supporting plate, a side plate and a rotating plate, wherein the side plate is perpendicular to the bottom plate, the rotating plate and the supporting plate are sequentially arranged on the side plate from top to bottom, the supporting plate is parallel to the bottom plate, a grinding fluid basin is arranged on the supporting plate, a centrifugal pump is installed on the side portion of the grinding fluid basin, an electromagnet is arranged on the bottom plate and located on the lower portion of the grinding fluid basin, the rotating plate is perpendicularly installed on the side plate, the rotating plate is turnable, a clamping mechanism for fixing a cutter is arranged on the rotating plate, and a cutter is inserted into the grinding fluid basin. According to the cutting edge passivation device, the passivation efficiency and effect can be improved, the passivation cost is reduced, and the designated position of the cutting edge of the cutter is passivated.

Owner:YANCHENG INST OF TECH

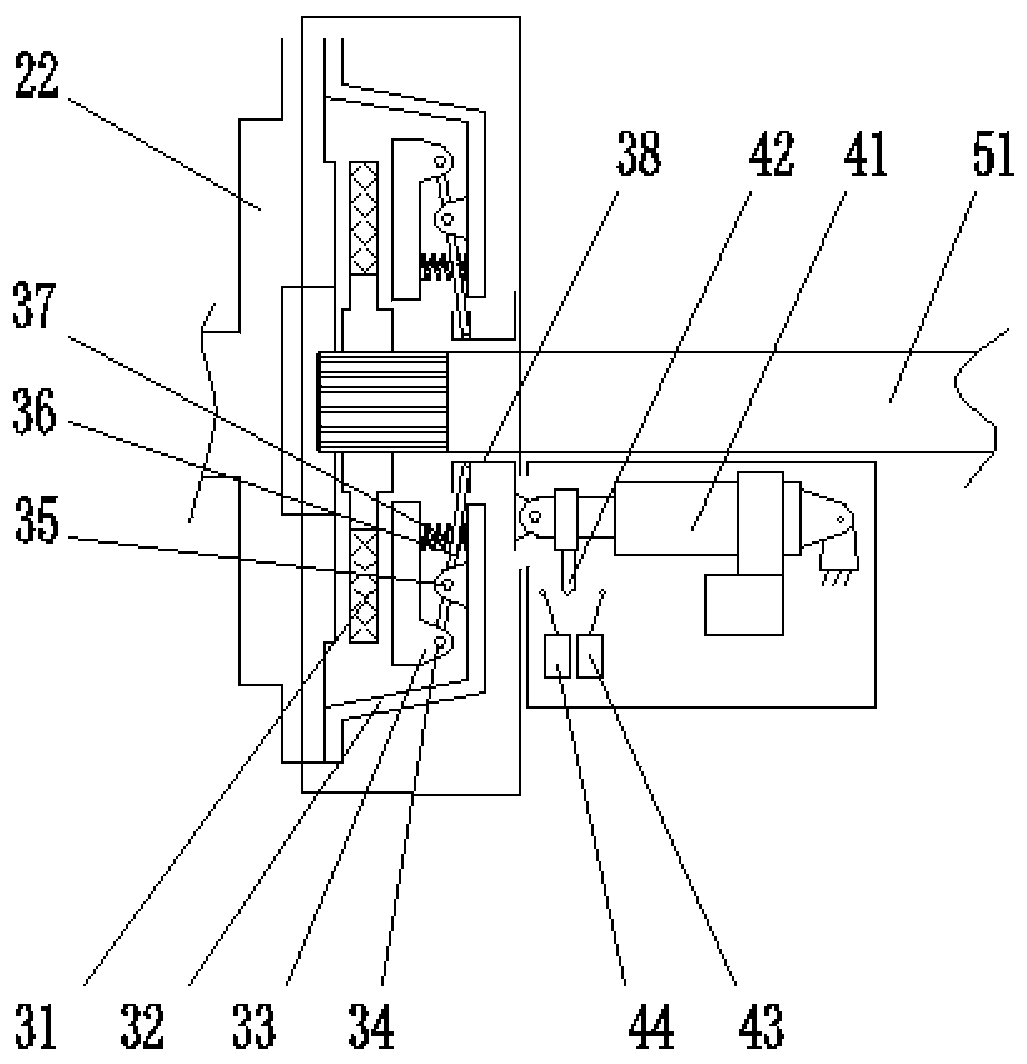

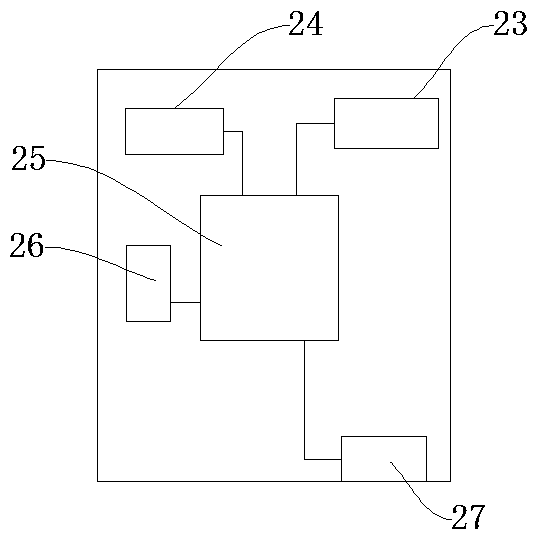

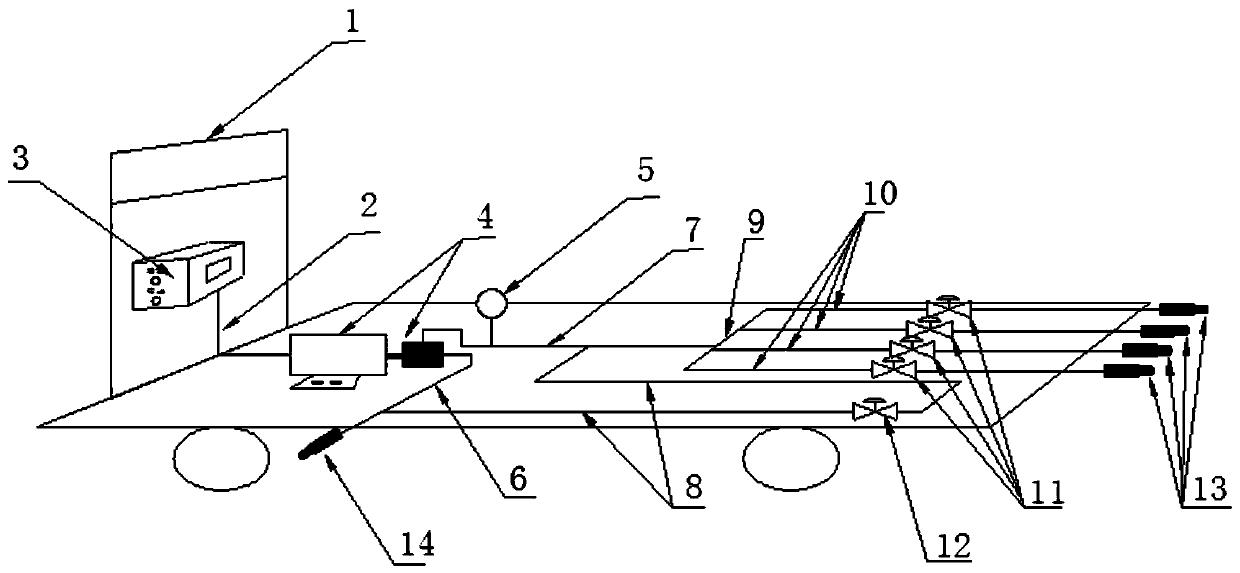

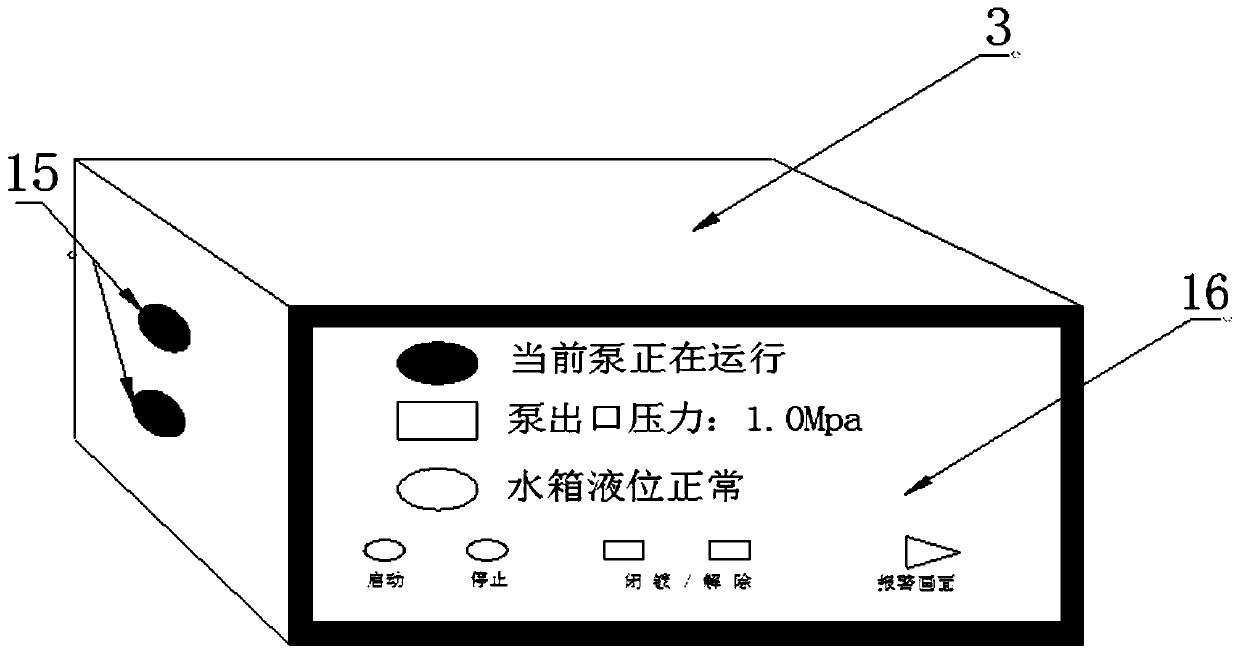

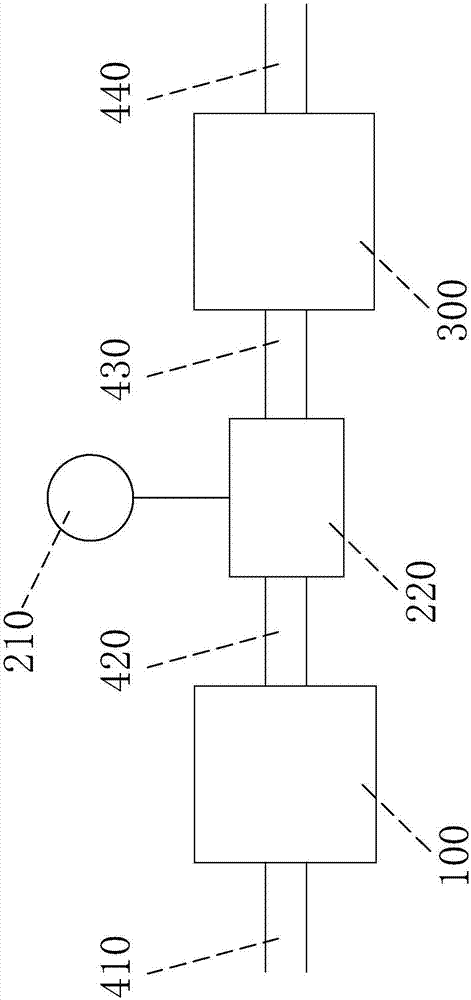

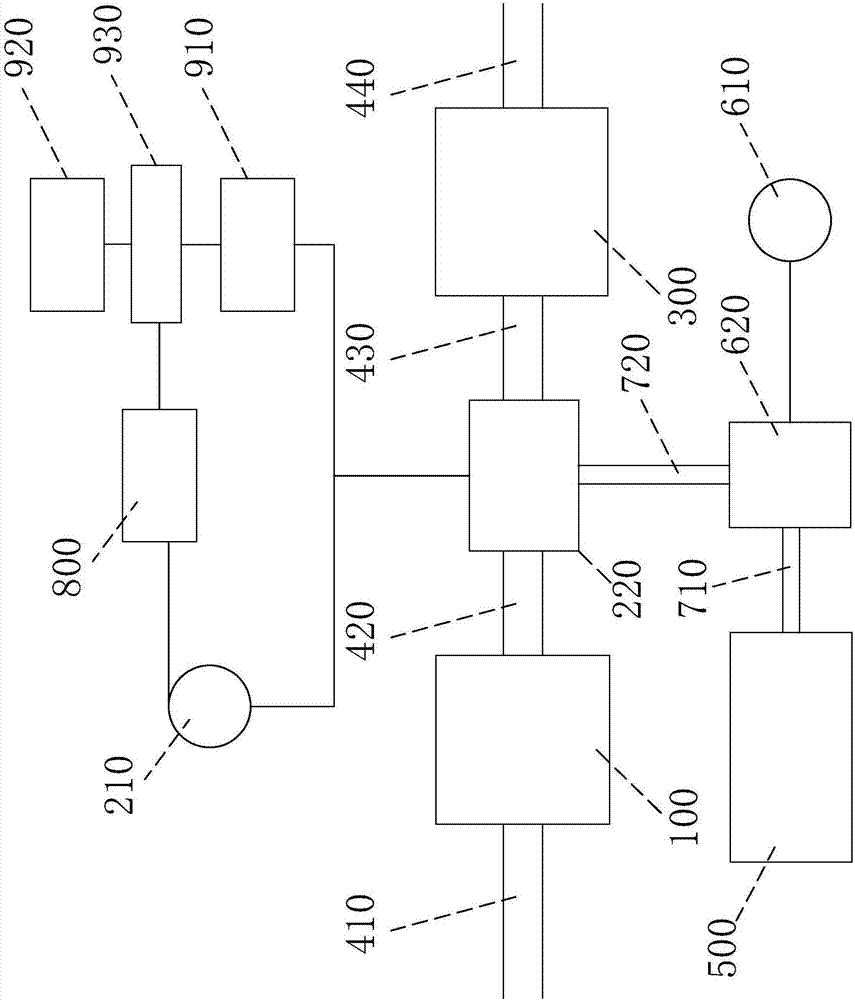

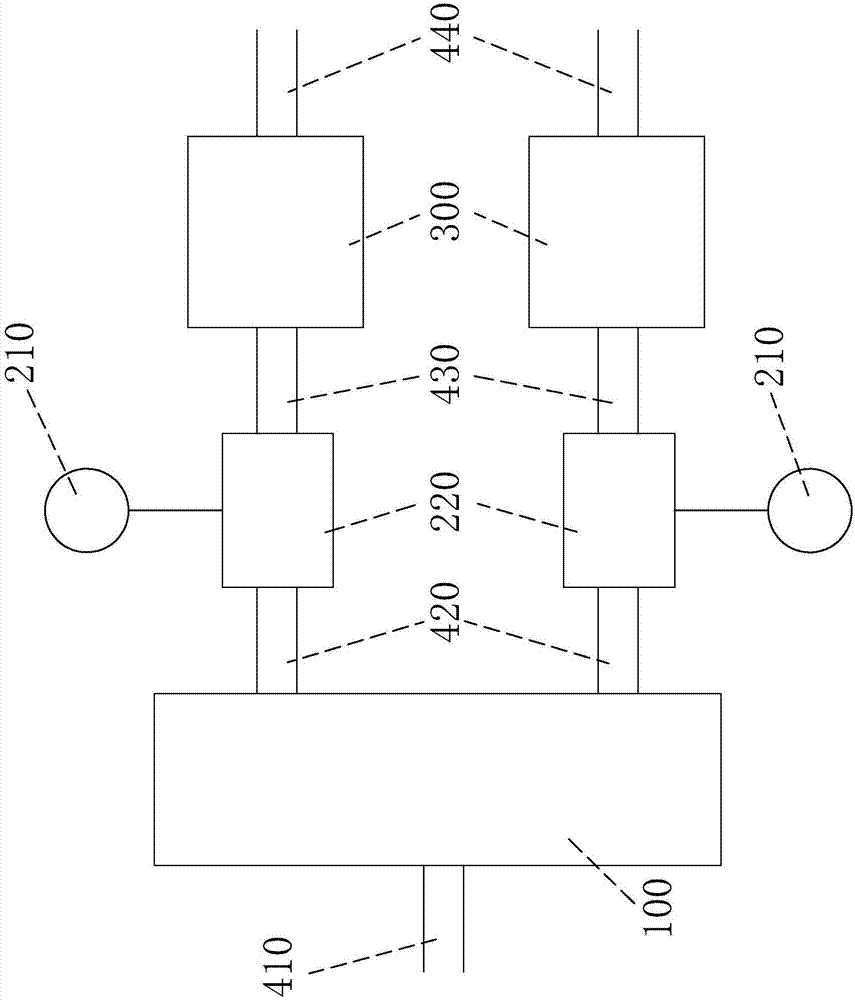

Diesel-engine-driven self-priming pump and control protection method

PendingCN110219807ARealize automatic exhaustAvoid damageMagnetically actuated clutchesFriction clutchesElectricityWater source

Owner:哈尔滨庆功林泵业股份有限公司

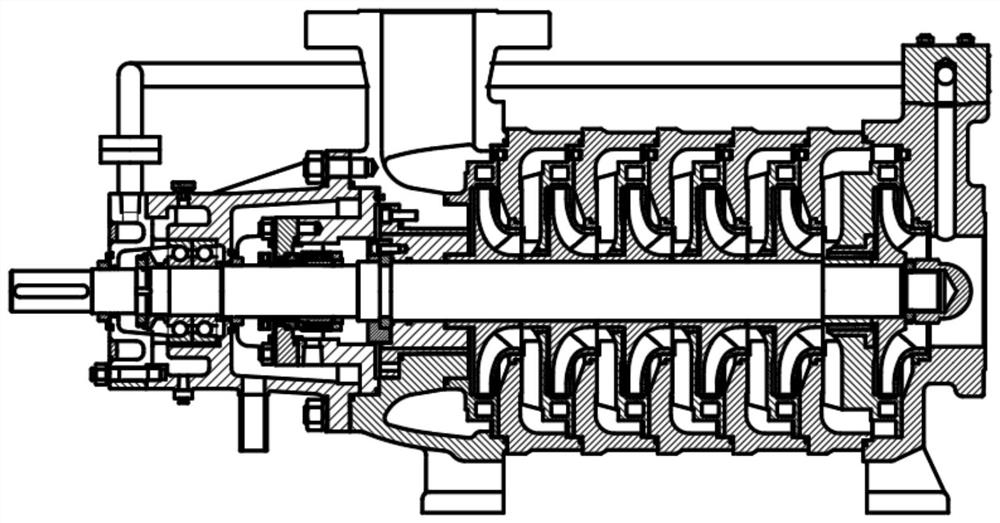

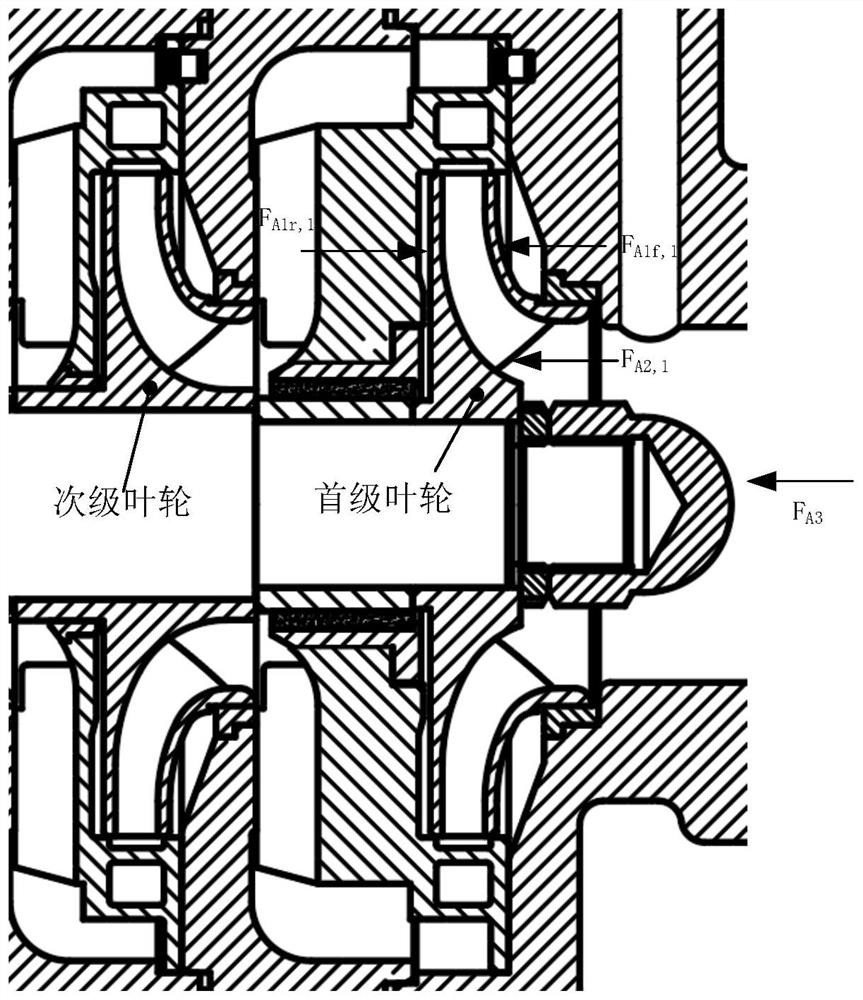

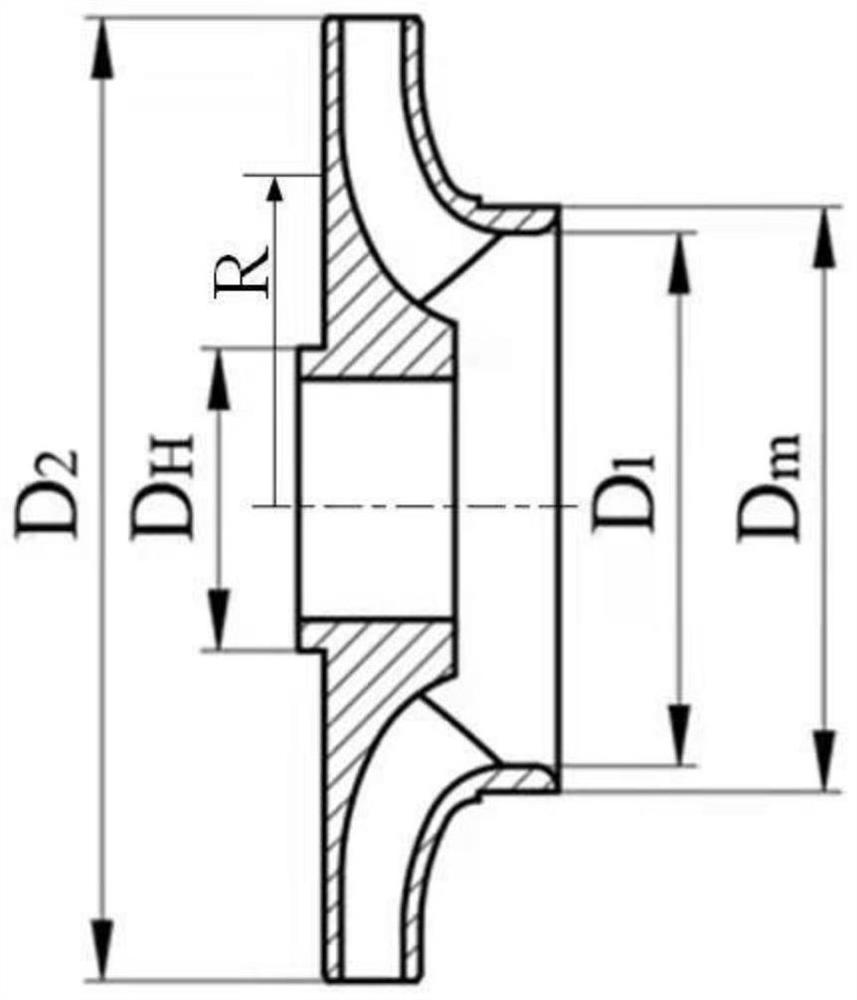

Multi-stage centrifugal pump axial force calculation method considering wear ring leakage

ActiveCN114329828AAccurate calculationEasy to calculateGeometric CADDesign optimisation/simulationEngineeringAxial force

Owner:SHANDONG SHUANGLUN

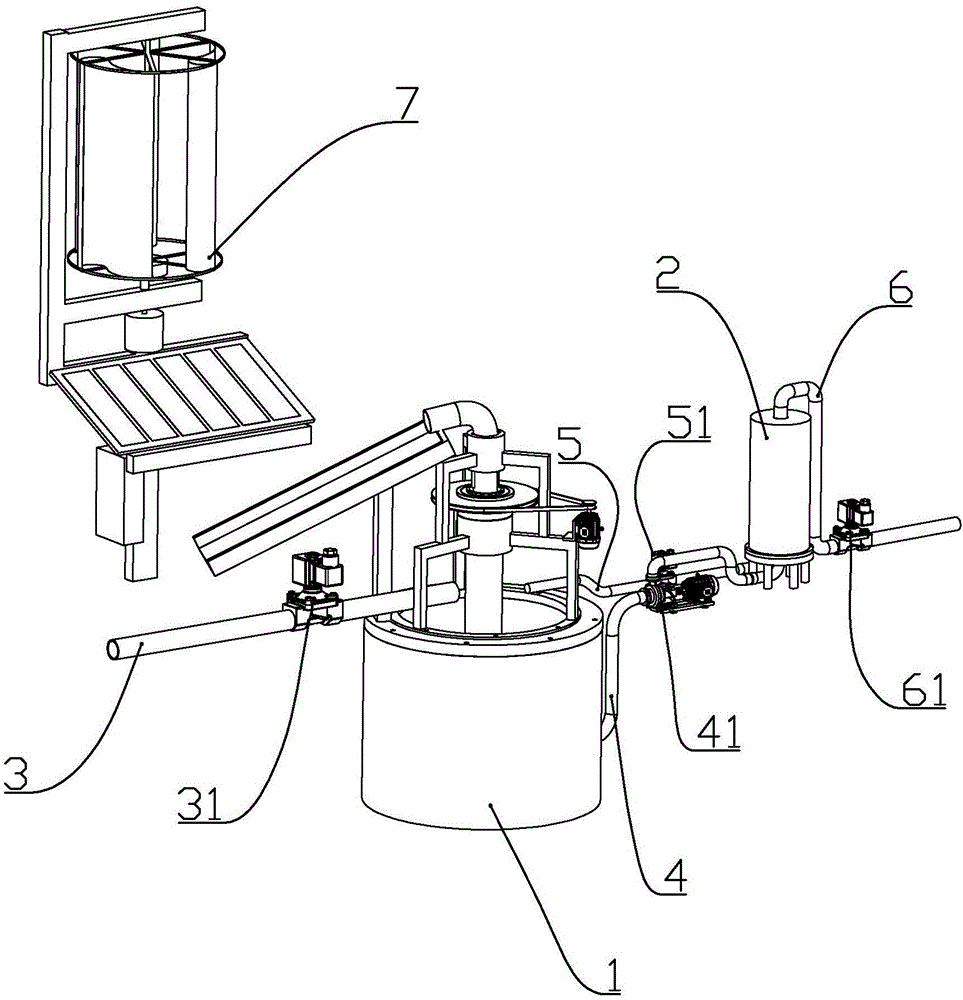

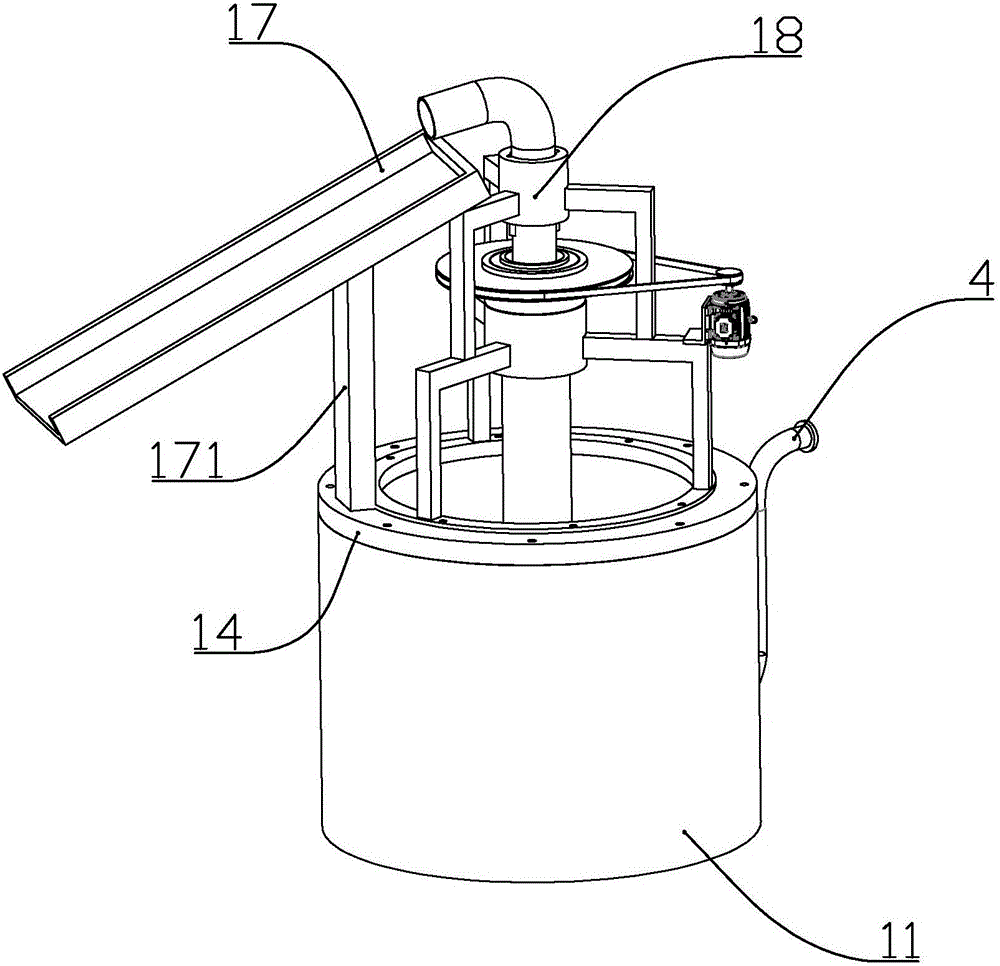

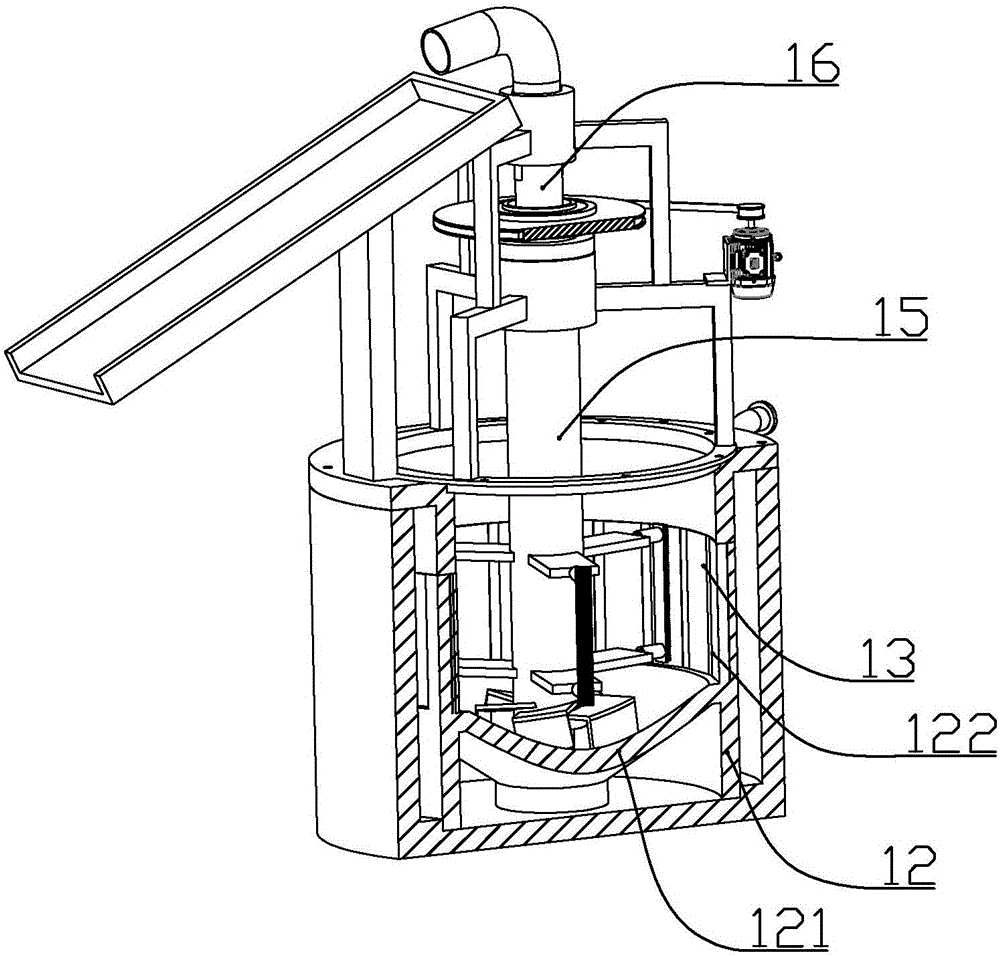

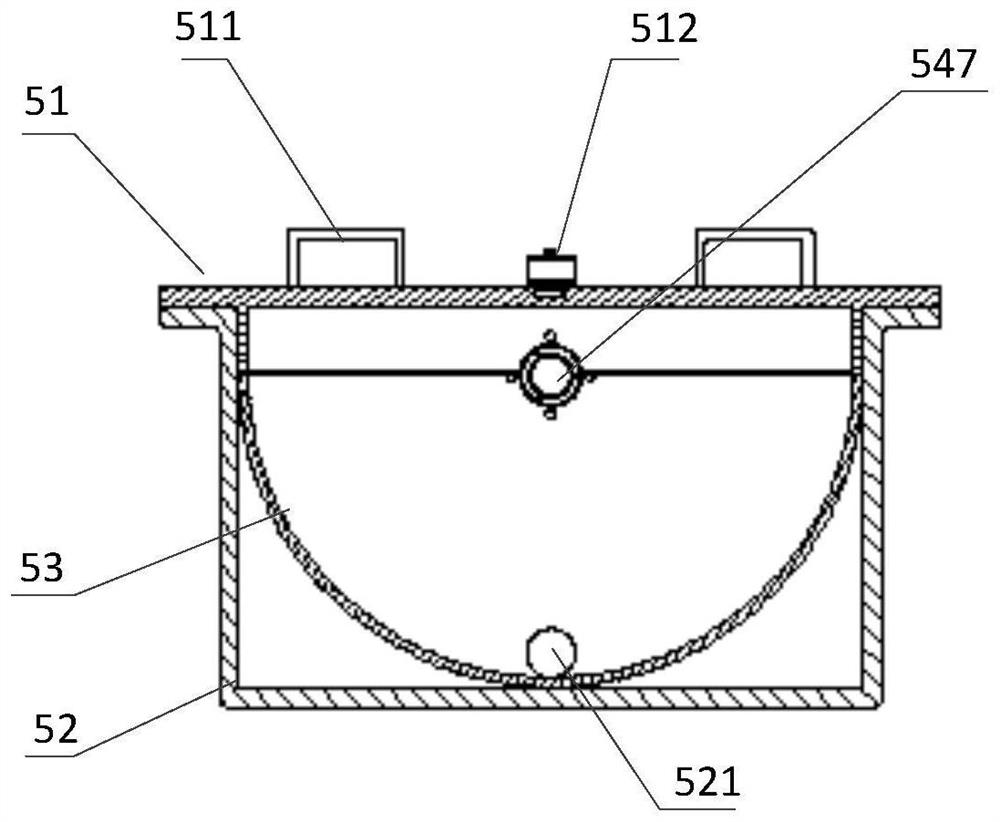

Sewage filtration system

The invention discloses a sewage filtration system which comprises a primary filter and a secondary filter. The primary filter comprises a primary water tank, a transfer pipe, a sludge discharge assembly and a sludge discharge tank; scrubbing plates are formed on the outer wall of the lower portion of the transfer pipe; scrubbing heads are formed on the scrubbing plates; a secondary water outlet pipe is arranged at the upper end of the secondary filter, and a water inlet pipe and a drainage pipe are arranged at the lower end of the secondary filter; when the system works, a water inlet solenoid valve and a centrifugal pump are switched on, the water after the primary filtration flows into the secondary filter from a primary filtration pipe, a solenoid valve is switched on, the water after secondary filtration is drained from the secondary water outlet pipe, and the water after secondary filtration flows into the primary water tank through a sewage pipe again for primary filtration; due to the fact that power generation equipment is arranged, the sewage filtration system can be used in an area free of power grid coverage, and energy consumption and environmental protection are achieved.

Owner:娄菊叶

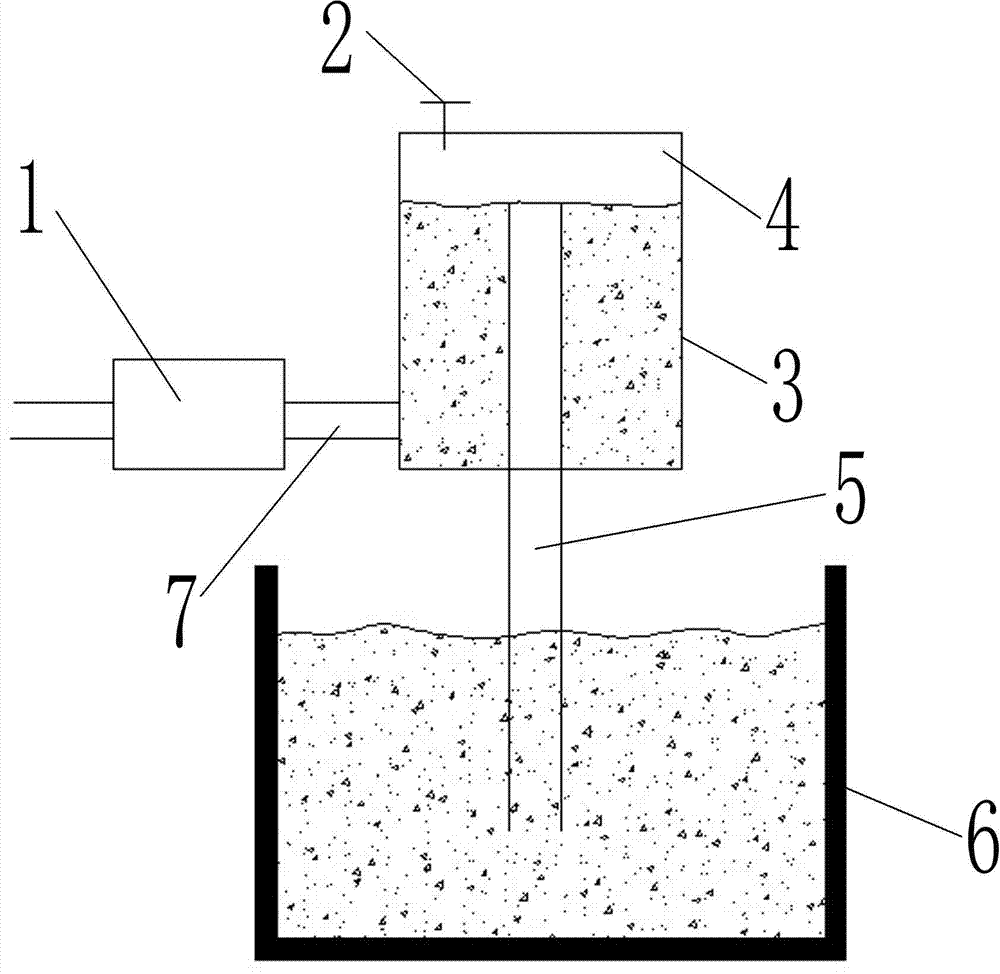

Treatment device and method for spent fuel assembly

ActiveCN113289968ANuclear energy generationRecycling and recovery technologiesProcess engineeringWater soluble

The invention relates to a treatment device and method for a spent fuel assembly. The treatment device for the spent fuel assembly comprises a cleaning tank provided with an injection port, wherein the injection port is used for injecting flushing fluid to a preset height, and the flushing fluid comprises organic water-soluble substances; a heater mounted on the cleaning tank and used for heating the flushing fluid in the cleaning tank; a first pipeline, a second pipeline and a third pipeline which are sequentially in communication, wherein one end of the first pipeline communicates with one end close to the bottom of the cleaning tank, and one end of the third pipeline communicates with one end close to the top of the cleaning tank; and a centrifugal pump arranged on one of the pipelines, wherein the centrifugal pump is used for driving the heated flushing fluid to flow in a loop formed by the first pipeline, the second pipeline, the third pipeline and the cleaning tank, so that the lead-bismuth coolant on the spent fuel assembly soaked in the flushing fluid is stripped by the flowing flushing fluid. The treatment device for the spent fuel assembly can ensure the storage safety of the spent fuel assembly in a storage water tank.

Owner:LINGDONG NUCLEAR POWER +3

Equipment and method for guaranteeing decolorizing efficiency in process of extracting salt from coking desulfurization waste solution

InactiveCN105776400AWater/sewage treatment apparatusWater/sewage treatment by sorptionCentrifugal pumpActivated carbon

Owner:北京新佰奥科技有限公司

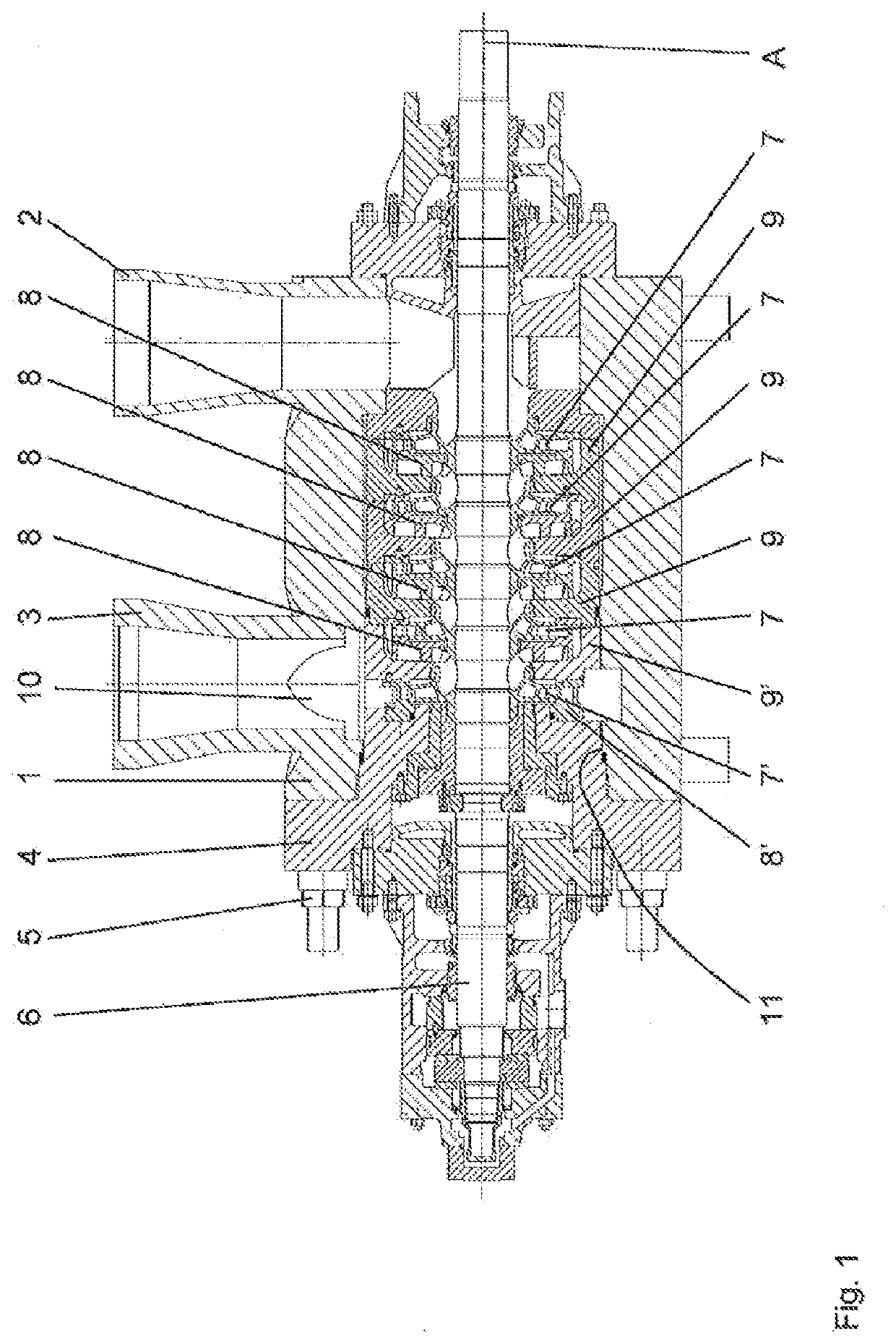

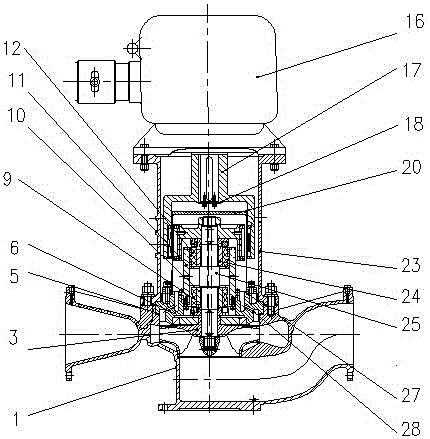

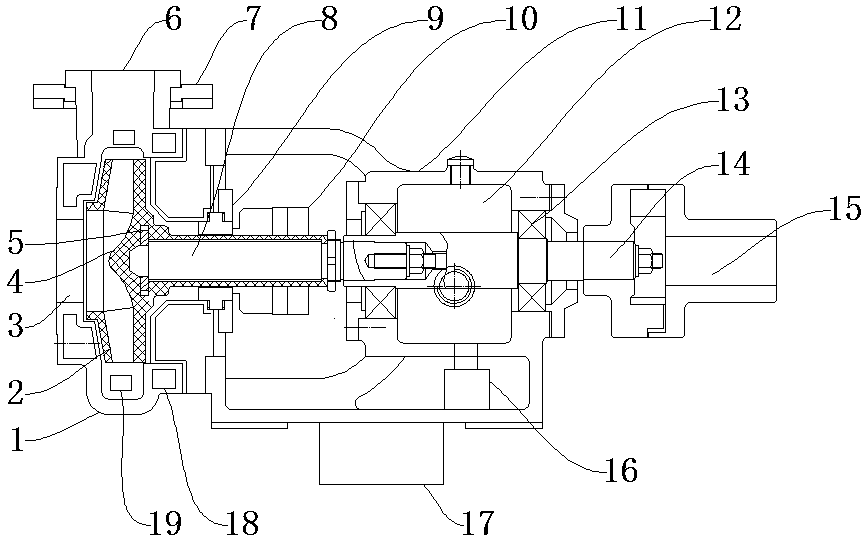

Magnetically driven pipeline type centrifugal pump

InactiveCN106122036ANo leak functionImprove general performanceSpecific fluid pumpsPump componentsThrust bearingEngineering

Owner:CHANGJIANG PUMP & VALVE MFG JINGJIANG

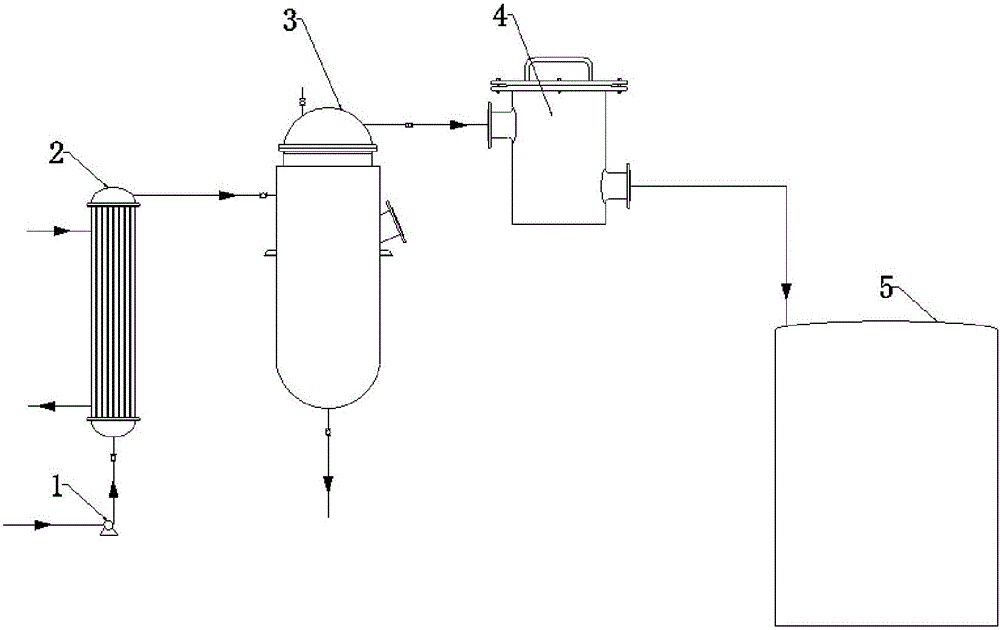

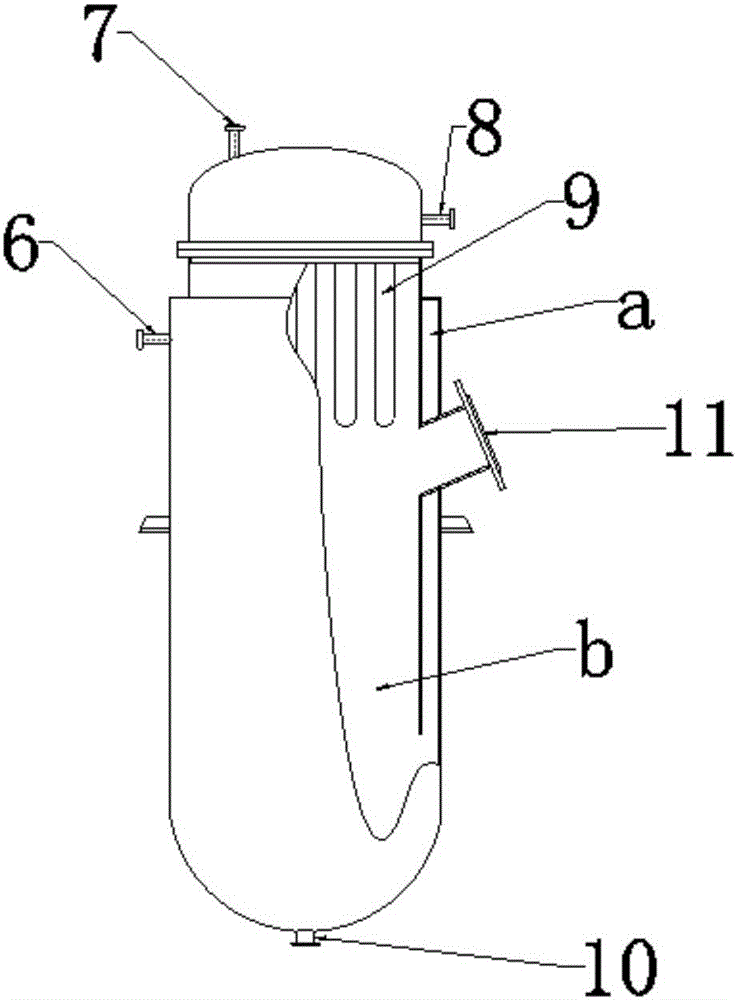

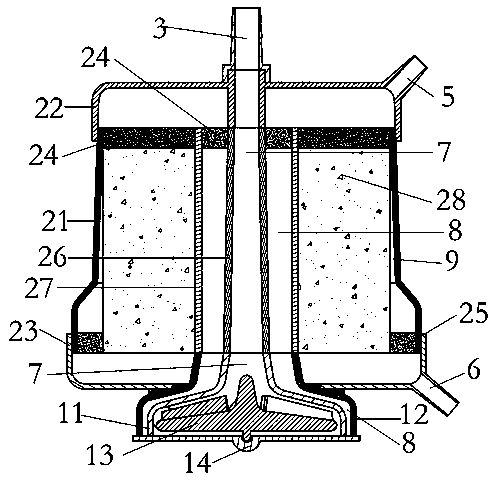

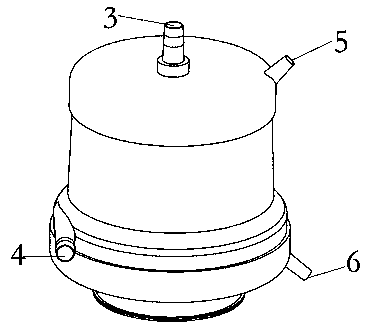

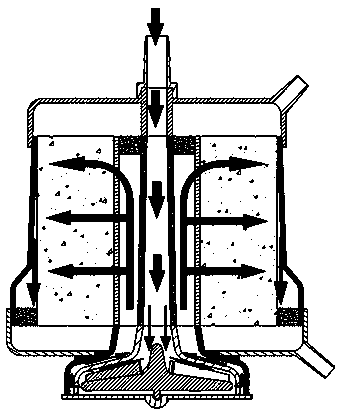

A membrane oxygenator with an integrated centrifugal pump

PendingCN109224164AOther blood circulation devicesBlood pumpsCentrifugal pumpMembrane oxygenators

Owner:江苏美思康医疗科技有限公司

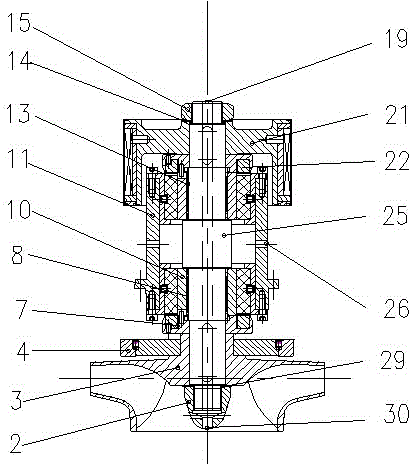

Vertical centrifugal pump impeller positioning device

Owner:SHUANGLUN GRP CO LTD SHANDONG

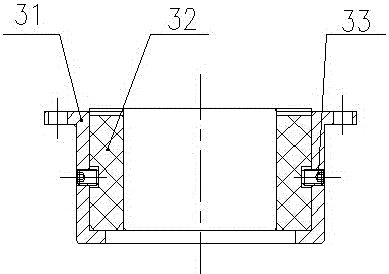

Centrifugal pump with variable impeller width

InactiveCN108999788AAdjustable widthEasy to usePump componentsPump controlDrive shaftCentrifugal pump

Owner:徐雪兰

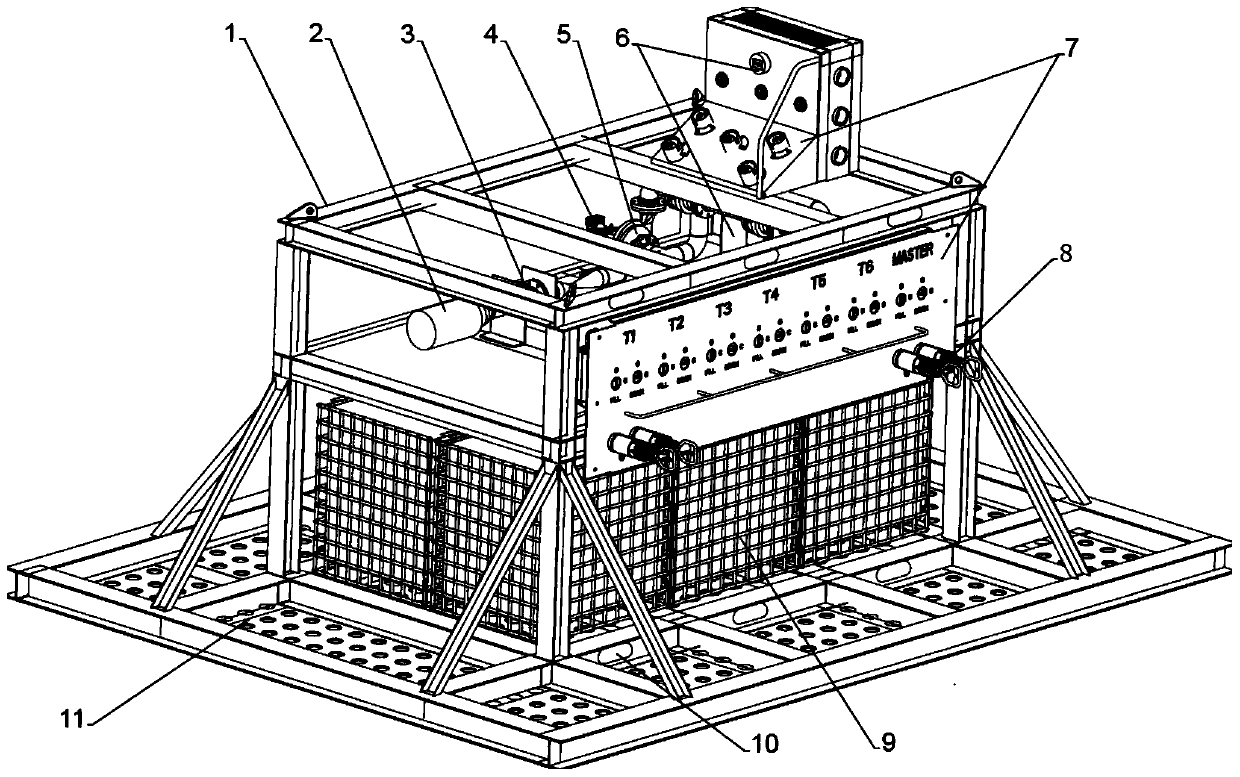

Hotspot backwash device for instrument pipes of main pipelines of nuclear power stations

Owner:JIANGSU NUCLEAR POWER CORP

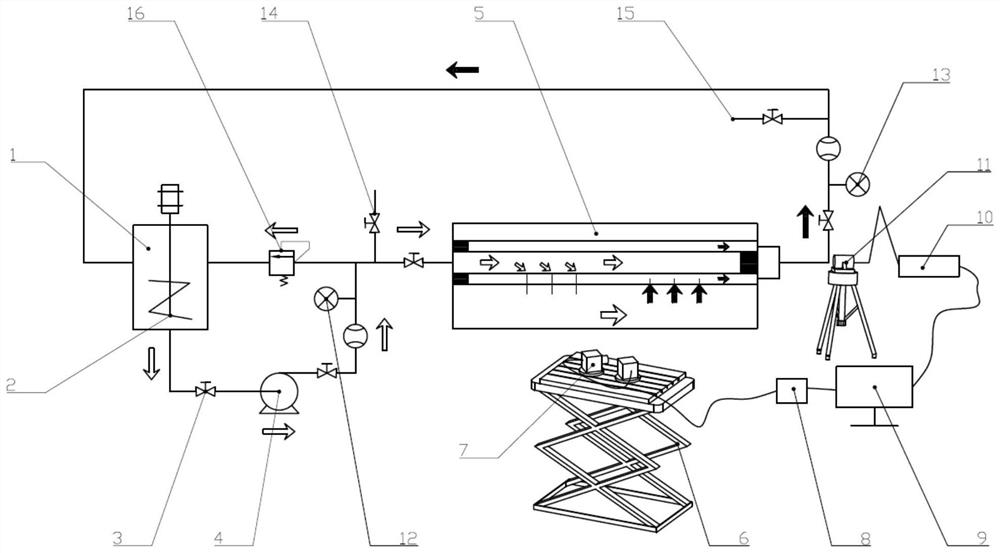

Solid-state fluidization mining jet flow recovery flow field detection experiment device and experiment method

PendingCN114166469AHydrodynamic testingCentrifugal pumpJet flow

Owner:SOUTHWEST PETROLEUM UNIV

Acid pump vacuum suction apparatus

InactiveCN103498798APrevent damage to pump sealsPriming pumpNon-positive displacement fluid enginesPulp and paper industryCentrifugal force

Owner:JINAN LUXECOTE FERTILIZER

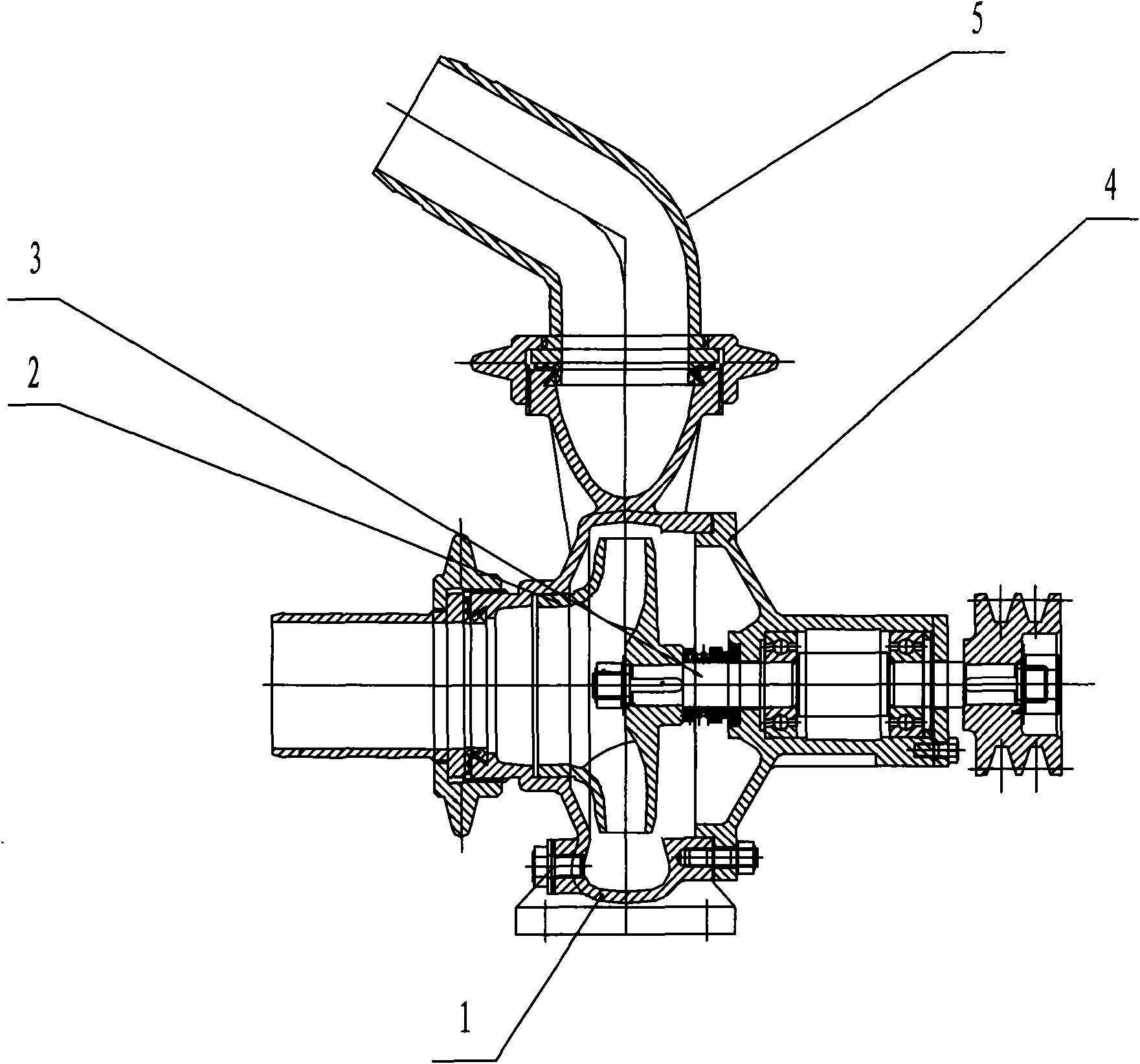

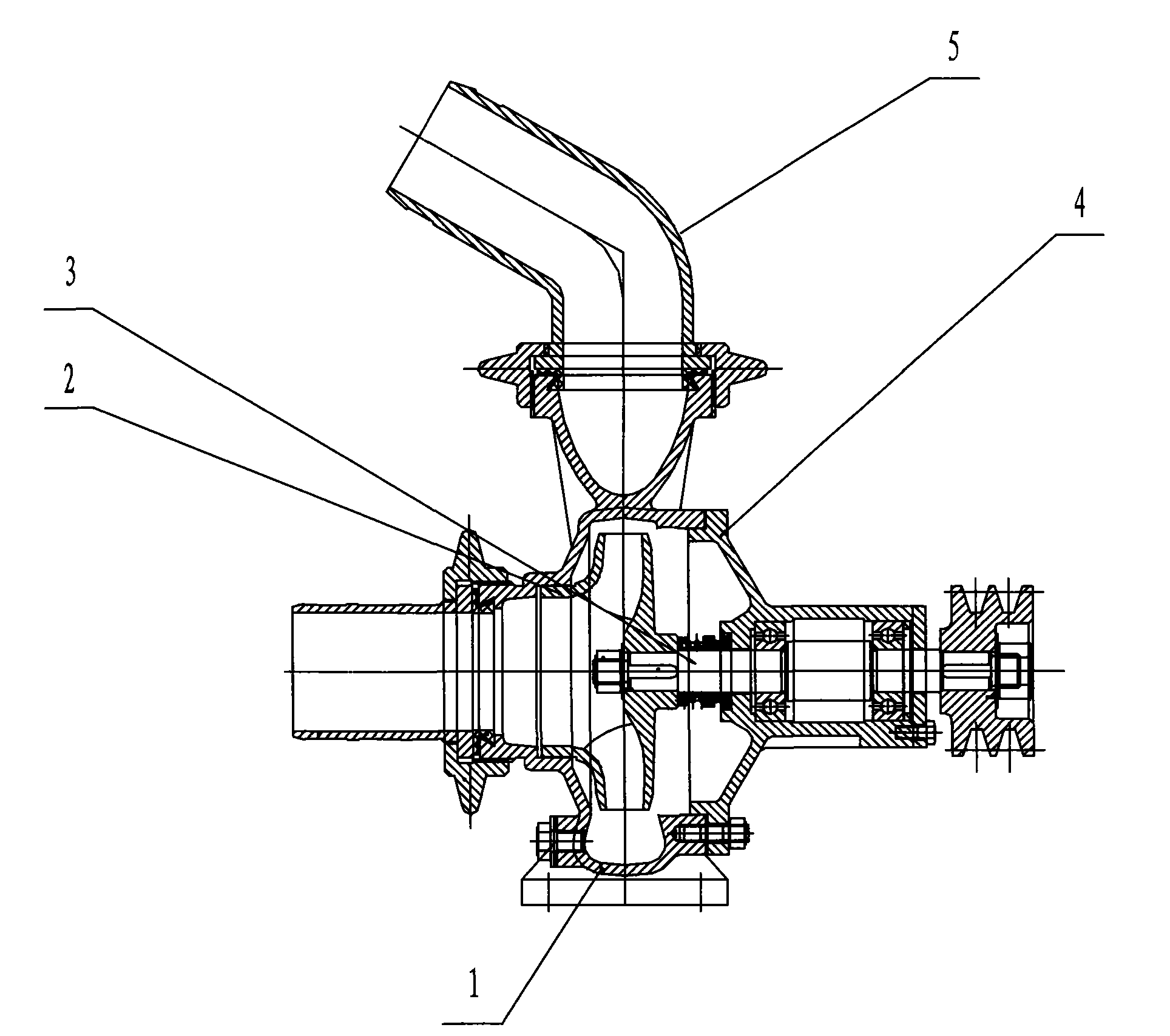

Universal water outlet of centrifugal pump

InactiveCN102434494AReduce consumption factorImprove efficiencyPump componentsPumpsPipingCentrifugal pump

The invention discloses a universal water outlet of a centrifugal pump. The universal water outlet comprises a water outlet, wherein the water outlet is arranged in a pump body of the centrifugal pump, a bearing is arranged on the pump body and connected with a shaft, the shaft is connected with an impeller, and the water outlet is the universal water outlet capable of rotating for 360 DEG. The water outlet of the centrifugal pump, disclosed by the invention, can rotate for 360 DEG, the function of ensuring that a water pump is shriveled and smooth in any direction is achieved, consumption factors of delivery lift and suction life are reduced, and high efficiency is really realized.

Owner:杨高怀

Grinding system for calcium carbonate

InactiveCN107952574AImprove transmission efficiencyReduce noise and pressure fluctuationsGrain treatmentsCentrifugal pumpPlunger pump

The invention discloses a grinding system for calcium carbonate, comprising a storage container, a hydraulic plunger pump, a plunger pump motor, a stirring grinder, a material input pipeline, a first communication pipeline, a second communication pipeline and a material output pipeline; One end of the material input pipeline is connected to a storage container, the storage container communicates with the hydraulic plunger pump through a first communication pipeline, and the hydraulic plunger pump communicates with the agitating grinder through a second communication pipeline , the stirring grinder is also connected to one end of the material output pipeline, and the hydraulic plunger pump is also connected to the plunger pump motor. The invention adopts a hydraulic plunger pump to replace the traditional centrifugal pump, screw pump or rotor pump, improves the transmission efficiency of calcium carbonate materials, reduces the noise and pressure fluctuation during system operation, and makes the system run more stably and reliably.

Owner:ENPING YANYI NEW MATERIALS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap