Sewage filtration system

A filtration system and sewage technology, applied in the direction of filtration and separation, membrane filter, fixed filter element filter, etc., can solve the problems of low working efficiency, small ceramic membrane module, and easy damage to the connection of the outlet pipe ceramic membrane module.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

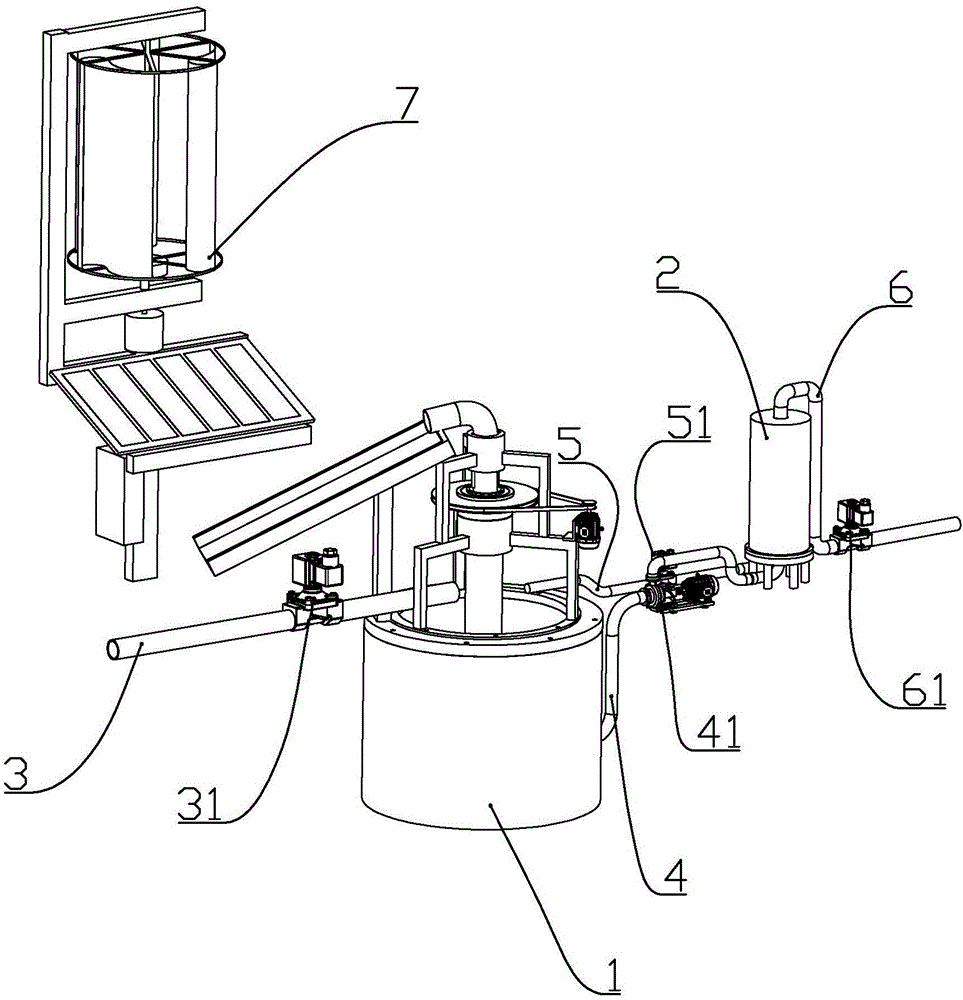

[0035] according to Figure 1 to Figure 14 As shown, a kind of sewage filtering system described in this embodiment includes a primary filter 1, a secondary filter 2, a water inlet pipe 3, a primary filter water pipe 4, and a sewage pipe 5, which are fixedly connected to the two The secondary water outlet pipe 6 on the primary filter, the power generation device 7 and the control box 73.

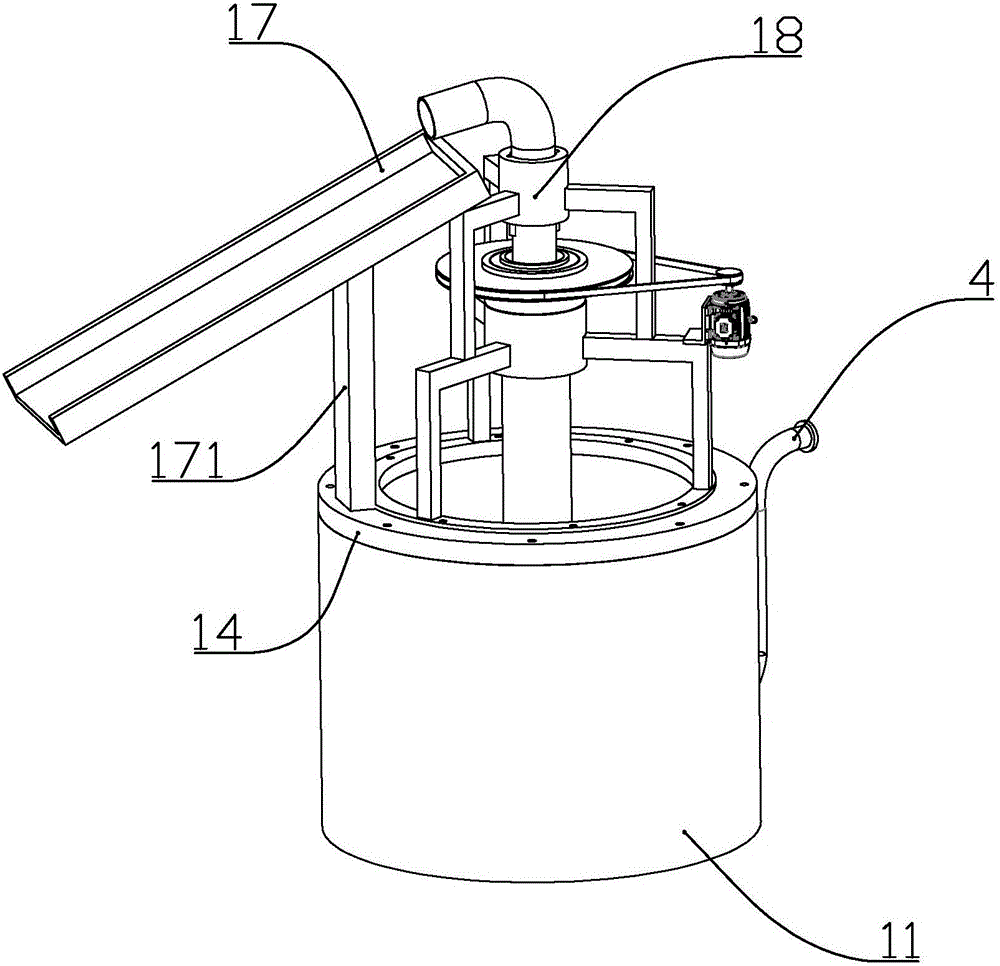

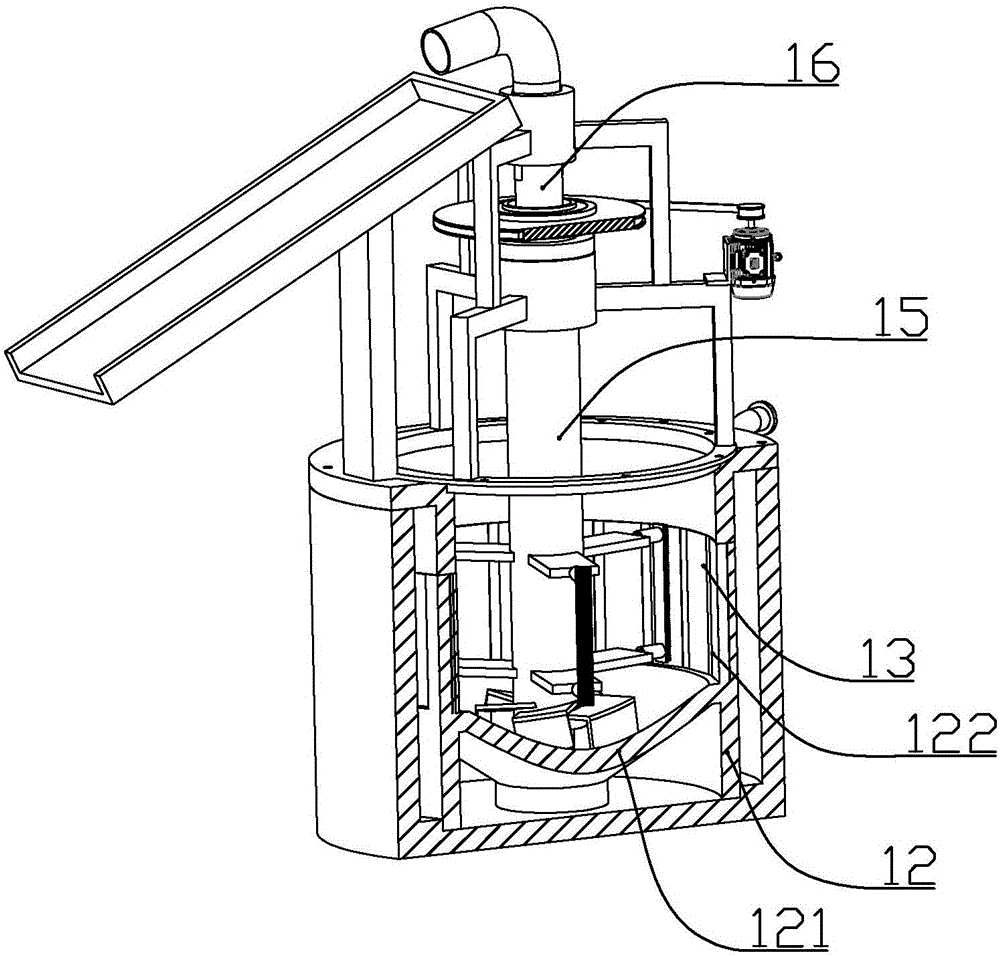

[0036] The first-stage filter includes a first-stage water tank 11, a lower filter seat 12 installed inside the first-stage water tank, an upper filter seat 14 fixedly connected to the upper end surface of the first-stage water tank, and longitudinally installed on the first-stage water tank. The drive pipe 15 in the middle of the water tank, the sludge discharge assembly 16, the sludge discharge tank 17, and the fixed bracket 18.

[0037] The first-s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap