Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Membrane bioreactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Membrane bioreactor (MBR) is the combination of a membrane process like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. It is now widely used for municipal and industrial wastewater treatment.

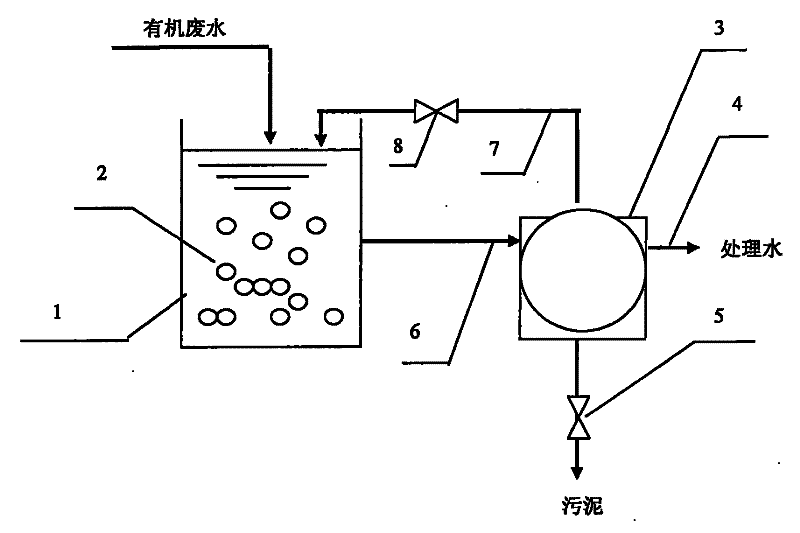

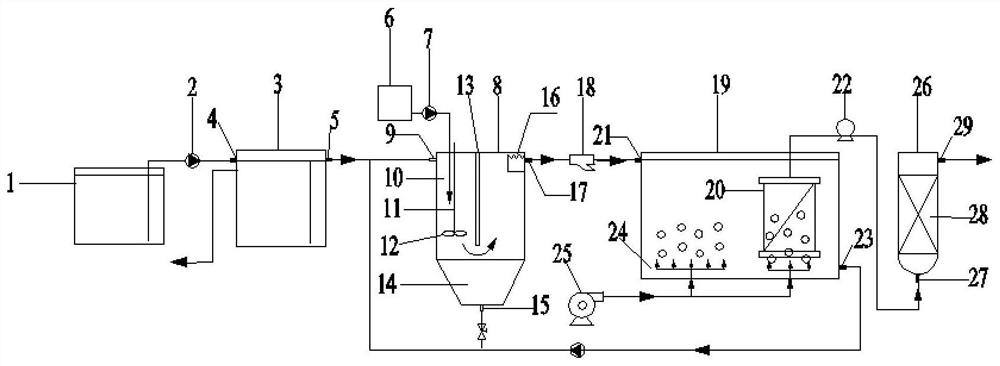

Magnetic bioreaction separation device for treating organic wastewater

InactiveCN101746883ANotable featuresSignificant positive effectWater contaminantsWater/sewage treatment bu osmosis/dialysisHigh concentrationRare earth

Owner:四川环美能科技有限公司

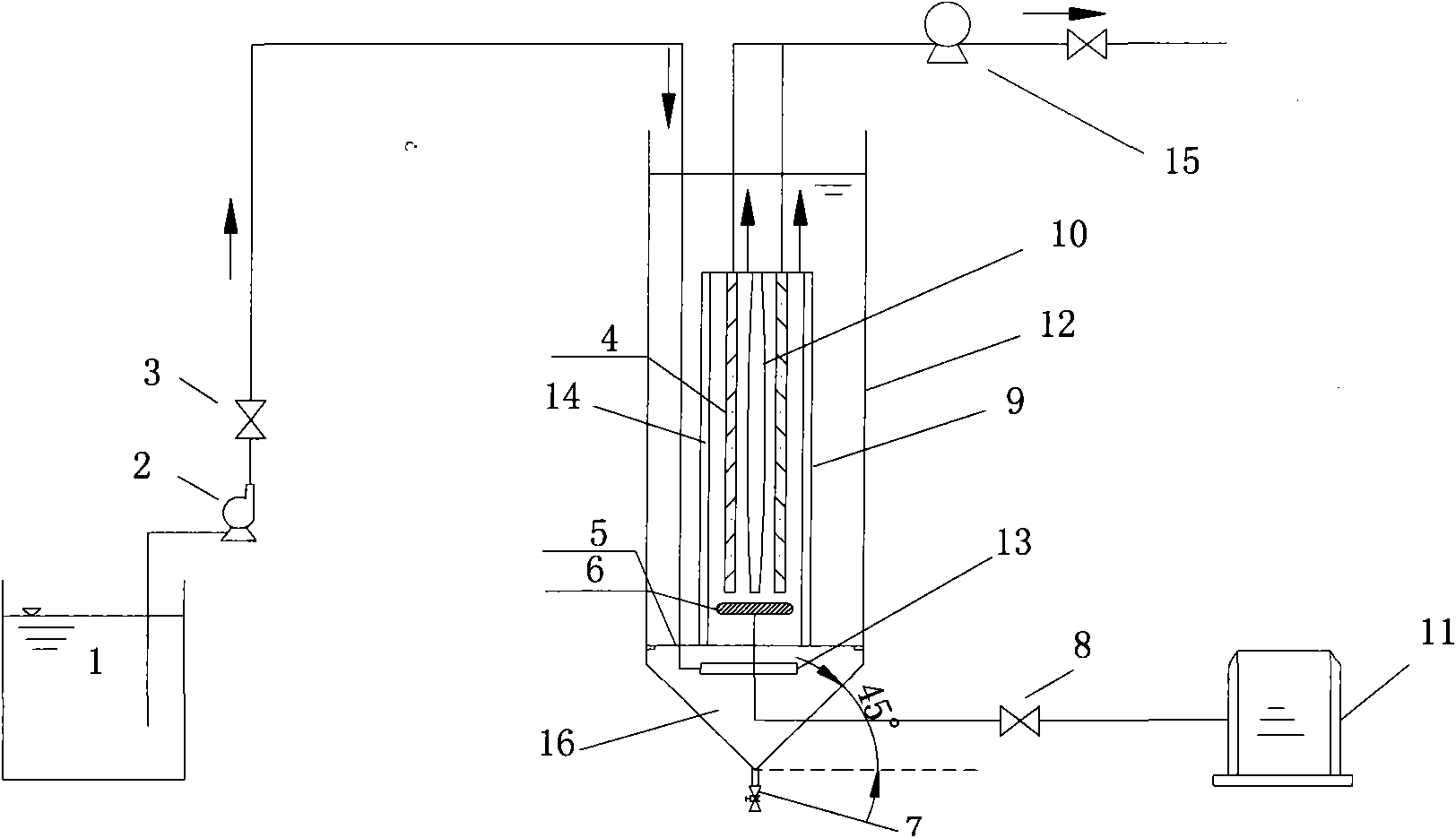

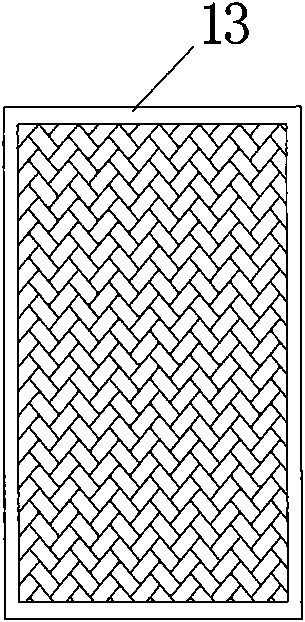

Refuse leachate ammonia nitrogen handling arrangement

InactiveCN101549904AHigh removal rateStrong removal rateSustainable biological treatmentBiological water/sewage treatmentMembrane bioreactorEnvironmental engineering

Owner:XIAMEN UNIV

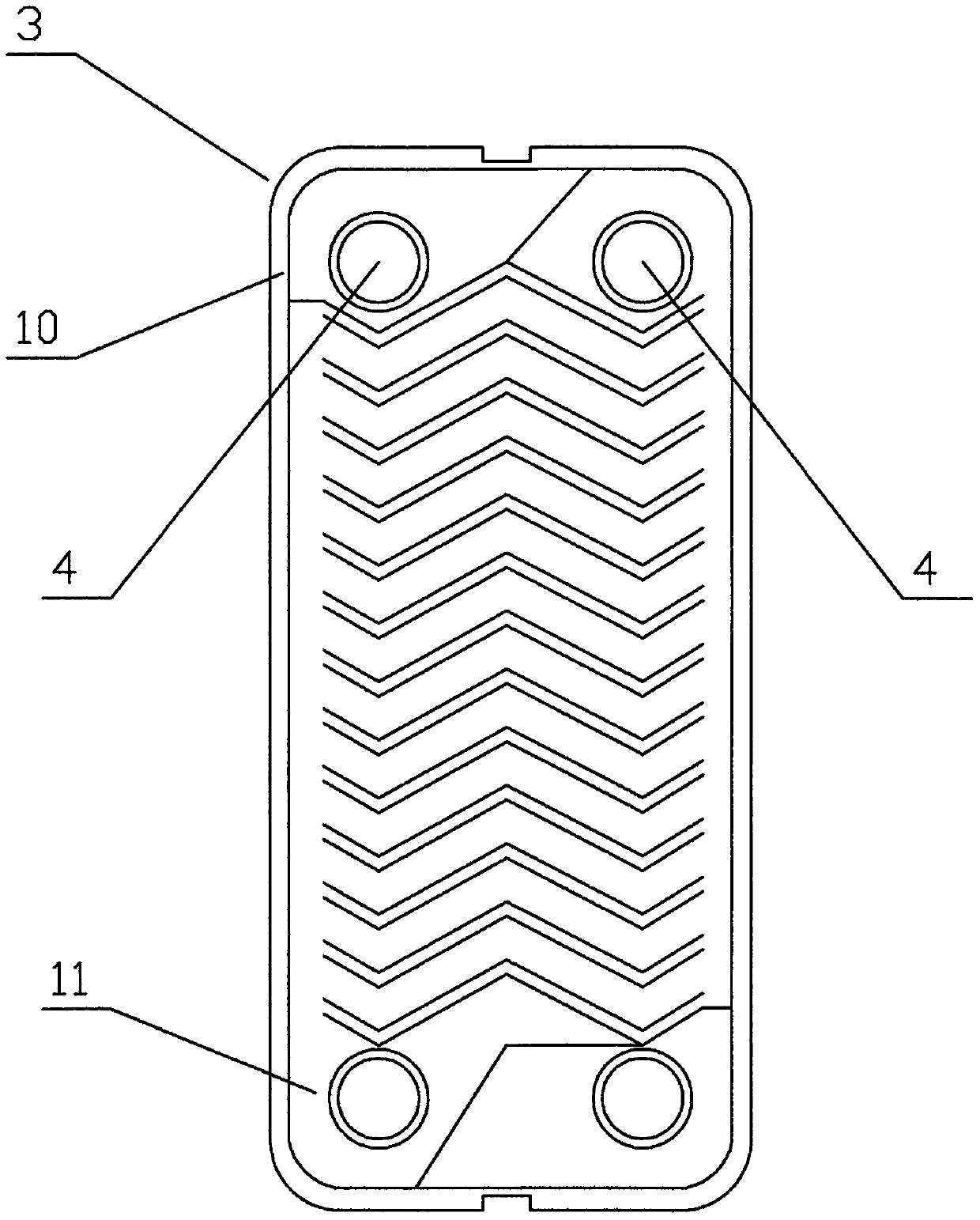

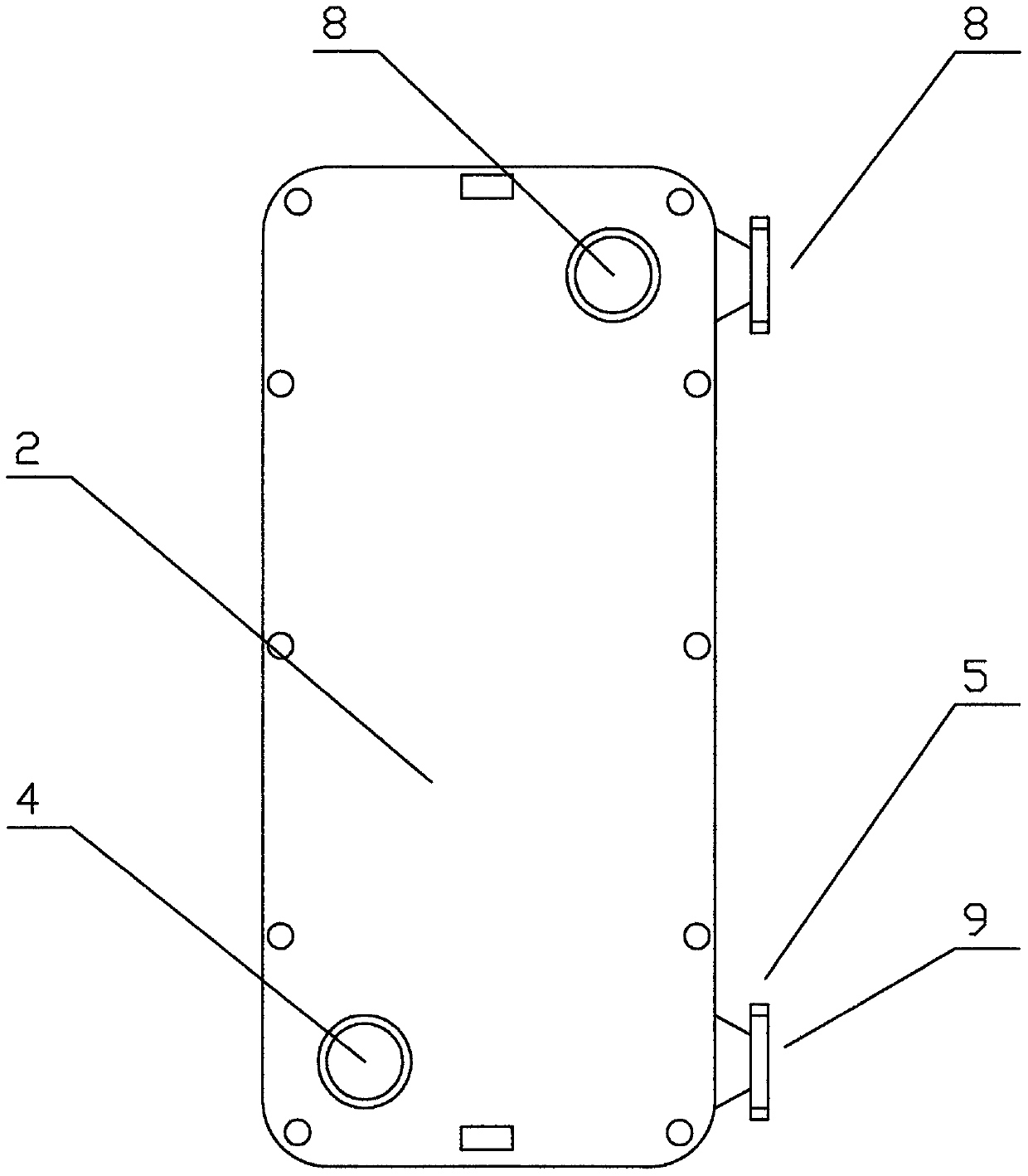

Pate heat exchanger for triple-effect heat energy reusing

InactiveCN111089501AAchieve recyclingIncrease temperatureHeat exchanger casingsLaminated elementsPlate heat exchangerReverse osmosis

Owner:石亮

Biochemical treatment method and device for benzo (a) pyrene in coking wastewater

PendingCN114426369AMembrane pore size is smallIncrease concentrationWater treatment parameter controlFatty/oily/floating substances removal devicesActivated sludgeCoking wastewater

Owner:CHINA PETROLEUM & CHEM CORP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap