Biochemical treatment method and device for benzo (a) pyrene in coking wastewater

A technology for coking wastewater and biochemical treatment, applied in biological treatment devices, water/sewage treatment, water treatment parameter control, etc., can solve problems such as difficult to treat industrial wastewater, achieve good biological population diversity, good effluent quality, tolerance impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

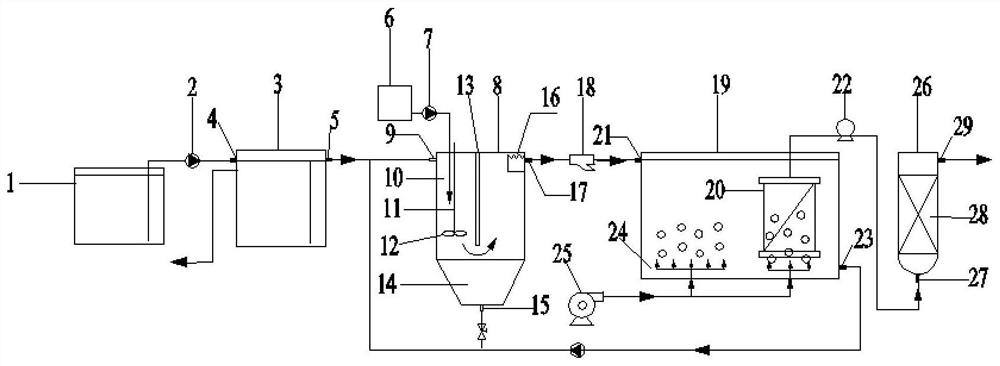

[0087] Example 1: In a refinery plant, the concentration of benzo(a)pyrene in the outlet of the coking device is 60 μg / L and the COD is 600 mg / L, in order to meet the requirement that the concentration of benzo(a)pyrene at the outlet of the device is less than 0.03 μg / L , using the biochemical process of the present invention for treatment, the final effluent concentration of benzo (a) pyrene is 0.03 μg / L, and the COD effluent concentration is 50 mg / L.

[0088] The process flow is:

[0089] (1) after the coking wastewater is homogenized in the homogenization tank 1, it is sent to the oil separator 3 by the homogenization tank lift pump 2, and the tar in the wastewater is separated and removed, and the scum is discharged;

[0090] (2) The effluent from the grease trap 3 is sent to the coagulation sedimentation tank 8, and is mixed with the coagulation agent under the action of the stirring paddle, and the flocculent precipitation is discharged from the mud discharge port

Embodiment 2

[0100] Example 2: In a refinery plant, the concentration of benzo(a)pyrene in the outlet of the coking device is 40 μg / L and the COD is 500 mg / L, in order to meet the requirement that the concentration of benzo(a)pyrene at the outlet of the device is less than 0.03 μg / L , using the biochemical process of the present invention for treatment, the final effluent concentration of benzo (a) pyrene is 0.03 μg / L, and the COD effluent concentration is 40 mg / L.

[0101] The process flow is:

[0102] (1) after the coking wastewater is homogenized in the homogenization tank 1, it is sent to the oil separator 3 by the homogenization tank lift pump 2, and the tar in the wastewater is separated and removed, and the scum is discharged;

[0103] (2) The effluent from the grease trap 3 is sent to the coagulation sedimentation tank 8, and is mixed with the coagulation agent under the action of the stirring paddle, and the flocculent precipitation is discharged from the mud discharge port

Embodiment 3

[0113] Example 3: Take a certain industrial wastewater with benzo(a)pyrene concentration of 60 μg / L and COD of 600 mg / L. The difference from Example 1 is that 22% of the activated sludge after the reaction is returned to the front section of the coagulation tank, the benzo(a)pyrene energy in the treated water is reduced from 60 μg / L to 0.02 μg / L, and the COD is reduced from 600 mg / L down to 40mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap