Grinding system for calcium carbonate

A calcium carbonate and grinding machine technology, applied in the field of grinding systems, can solve problems such as unstable operation, large pressure fluctuations, and low efficiency, and achieve the effects of stable and reliable system operation, reduced noise and pressure fluctuations, and improved transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

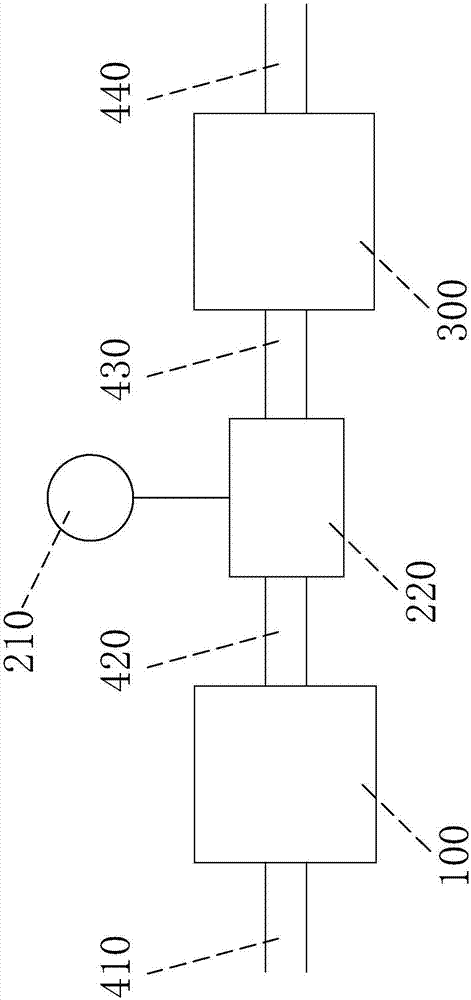

[0016] refer to figure 1 , a block diagram of the basic structure of a grinding system for calcium carbonate in the present invention, including a storage container 100, a hydraulic plunger pump 220, a plunger pump motor 210, an agitating grinder 300 and a pipeline, and the pipeline includes a material input pipeline 410 , a first communication pipeline 420, a second communication pipeline 430 and a material output pipeline 440; one end of the material input pipeline 410 is connected to the storage container 100, and the first communication pipeline passes between the storage container 100 and the hydraulic plunger pump 220 420 is communicated, and the hydraulic plunger pump 220 and the agitating grinder 300 are communicated through the second communication pipeline 430, and the agitating grinder 300 is also connected to one end of the material output pipeline 440, and the hydraulic plunger pump 220 Also connected to the plunger pump motor 210 .

[0017] During system operati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap