Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

27 results about "Front cover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

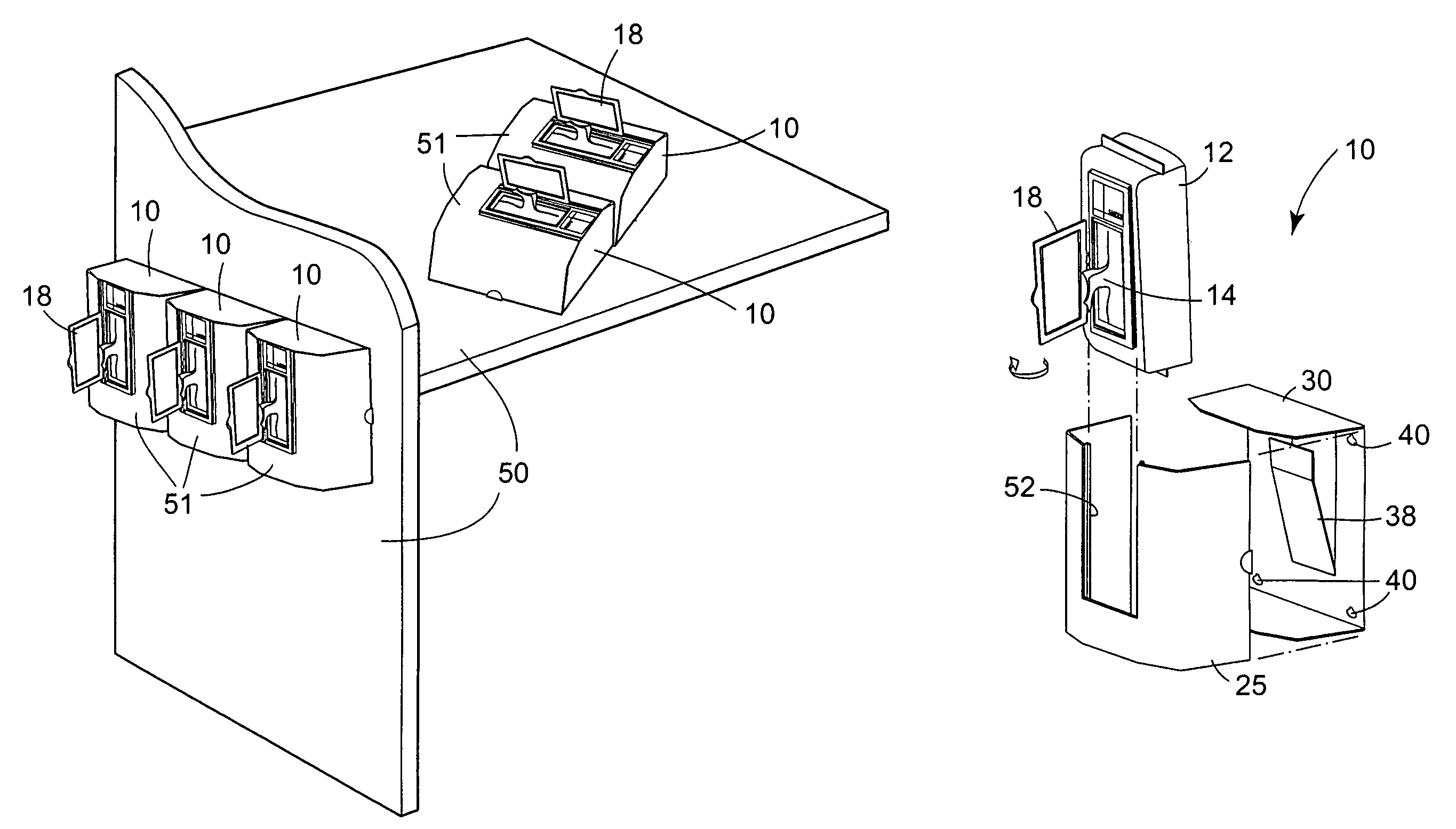

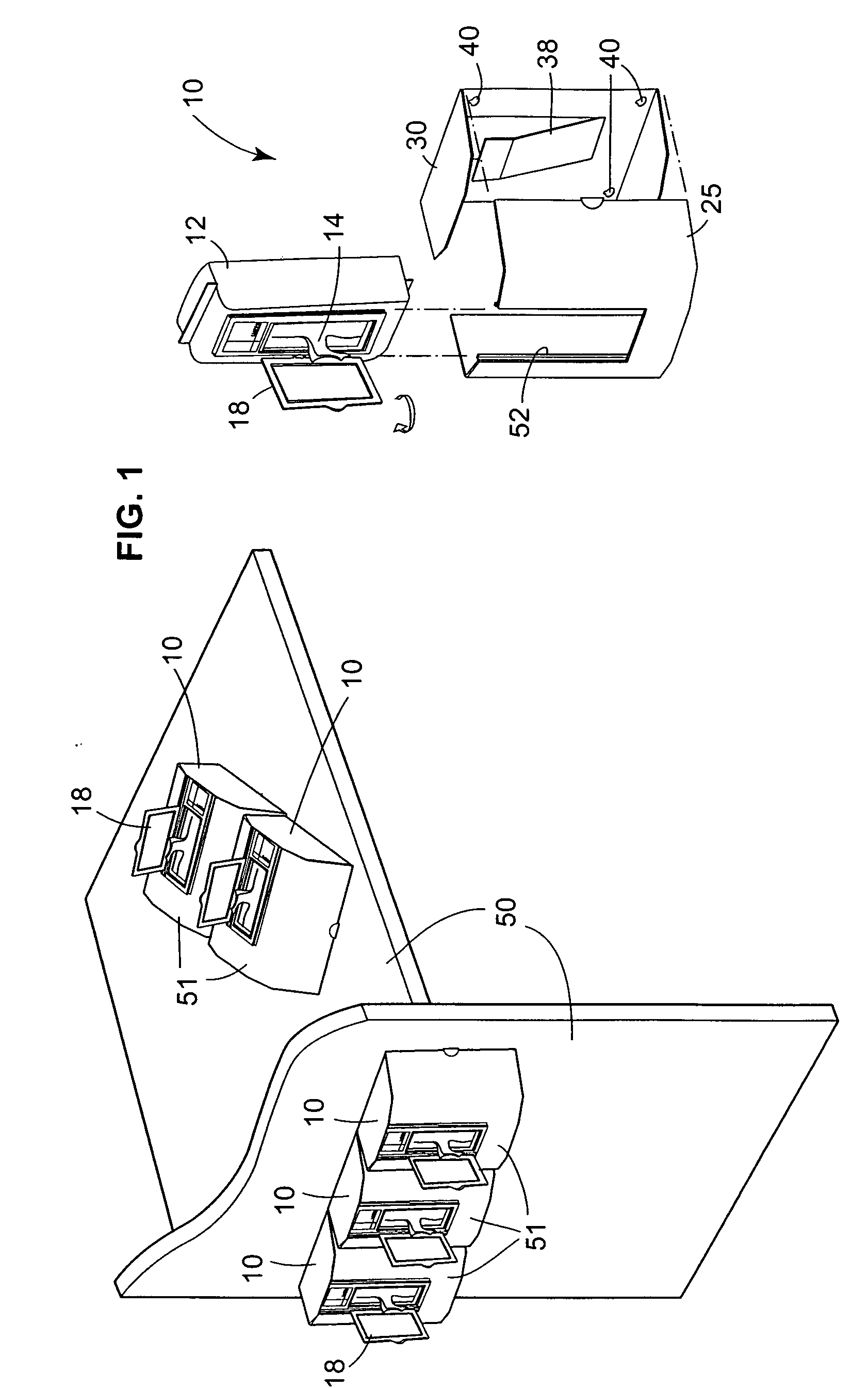

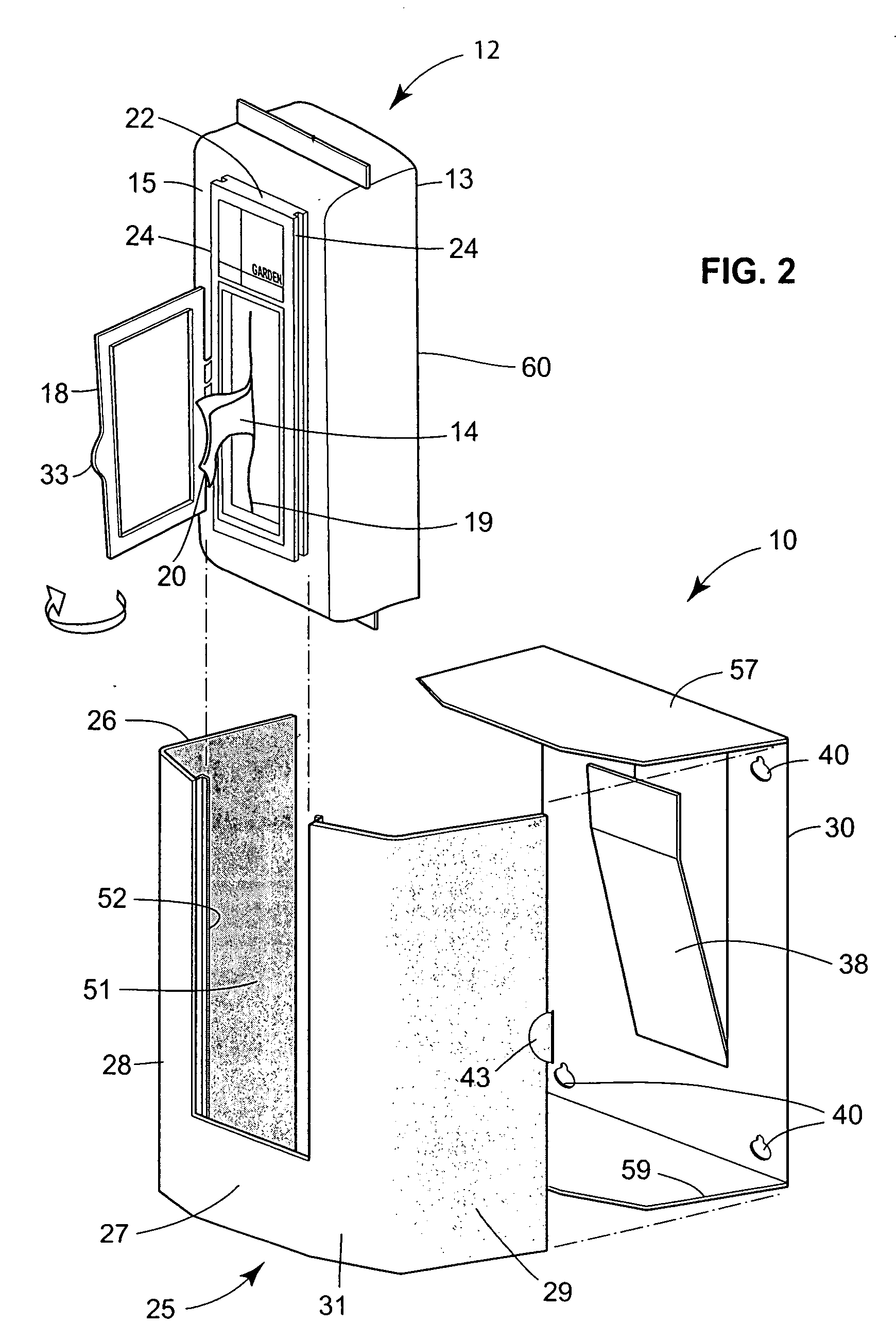

Apparatus, system and method for dispensing wipes

Owner:APG ASIA

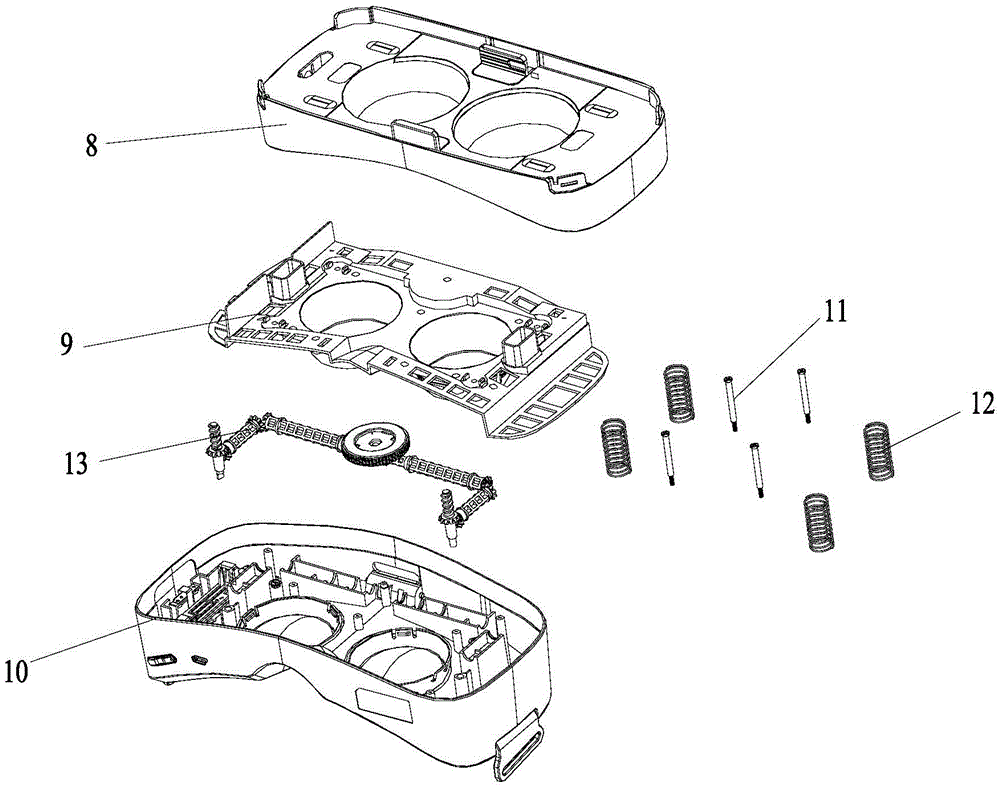

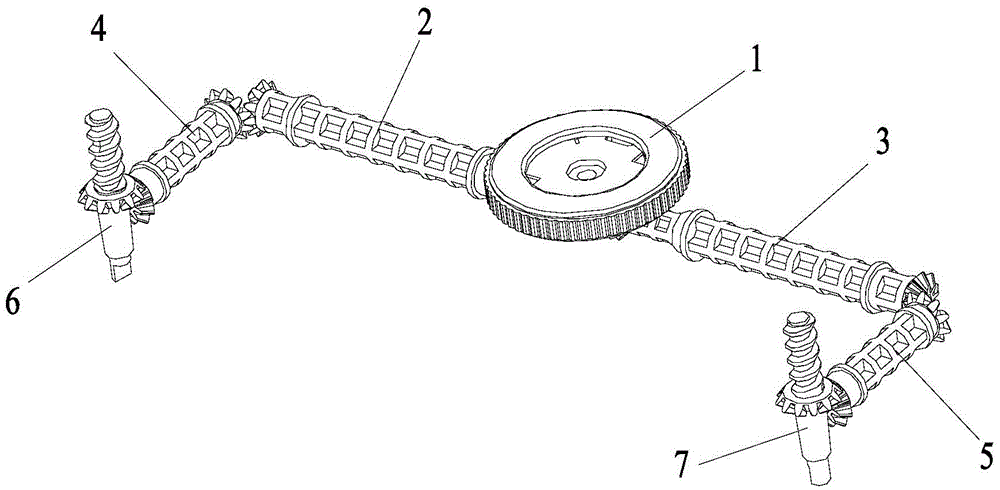

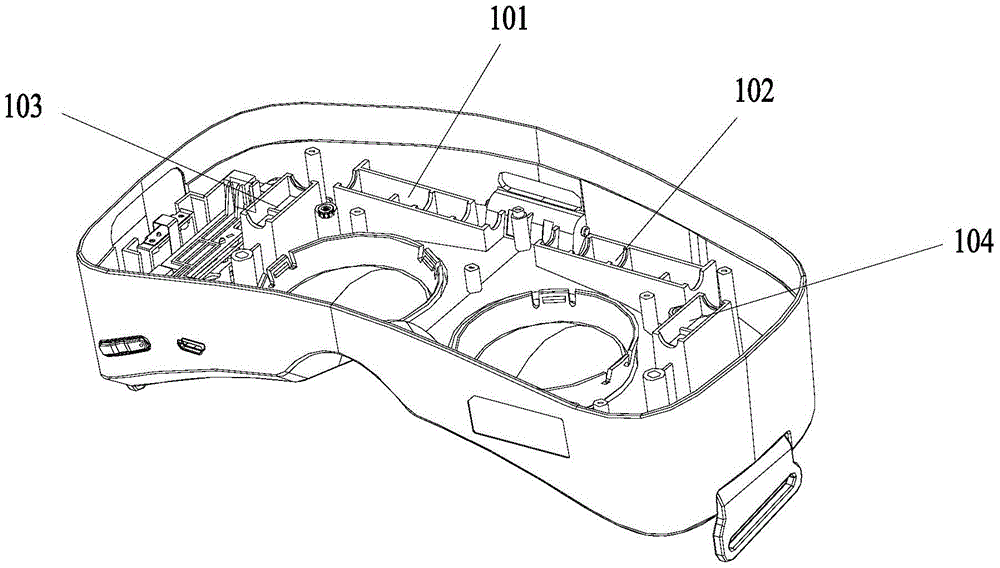

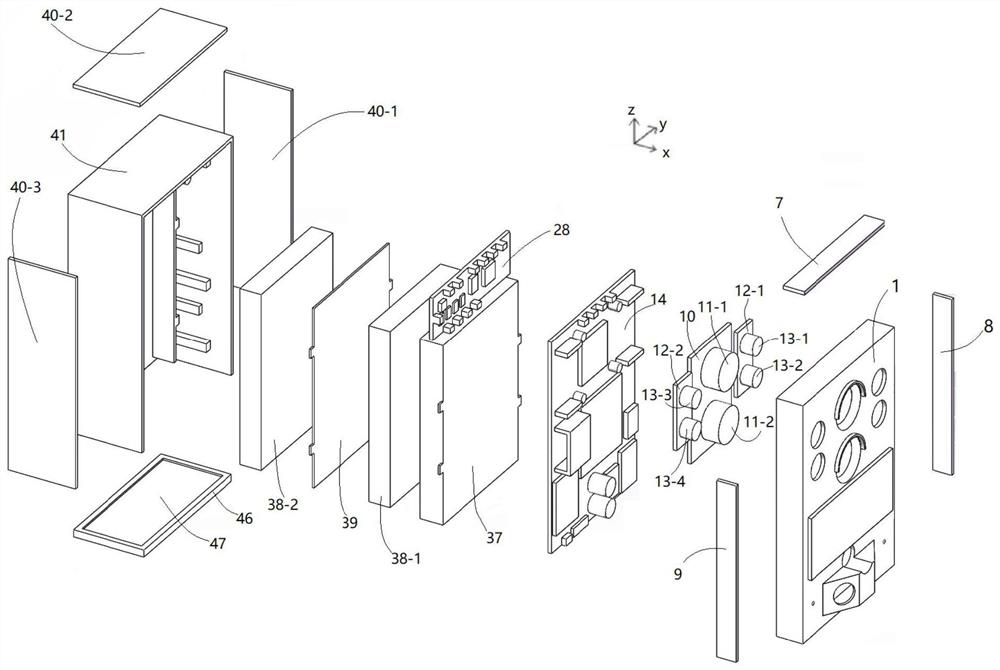

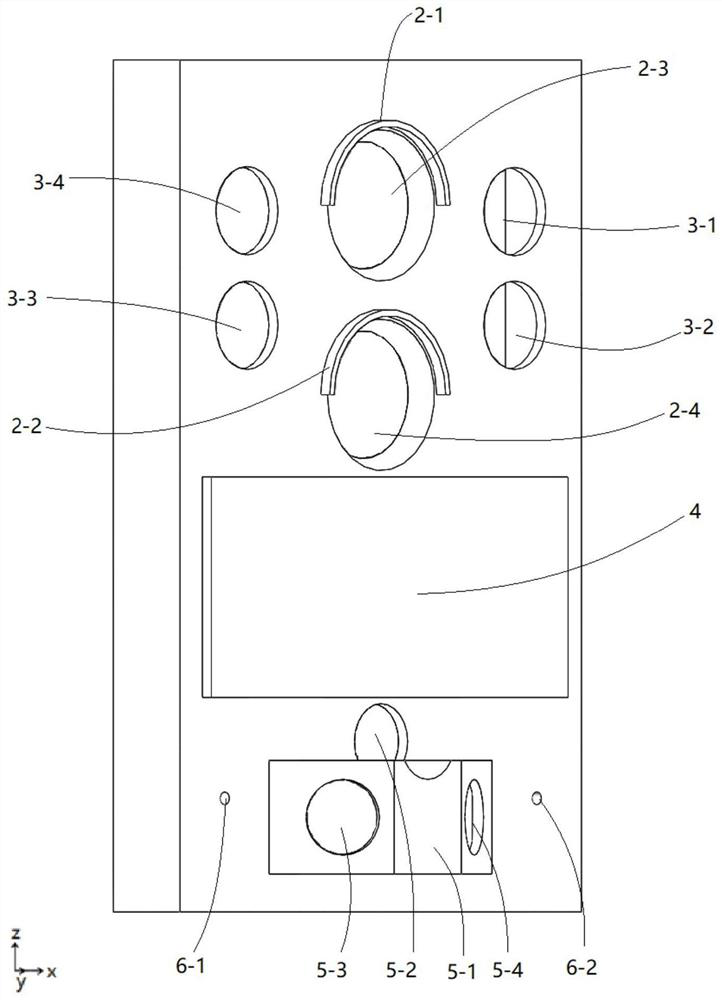

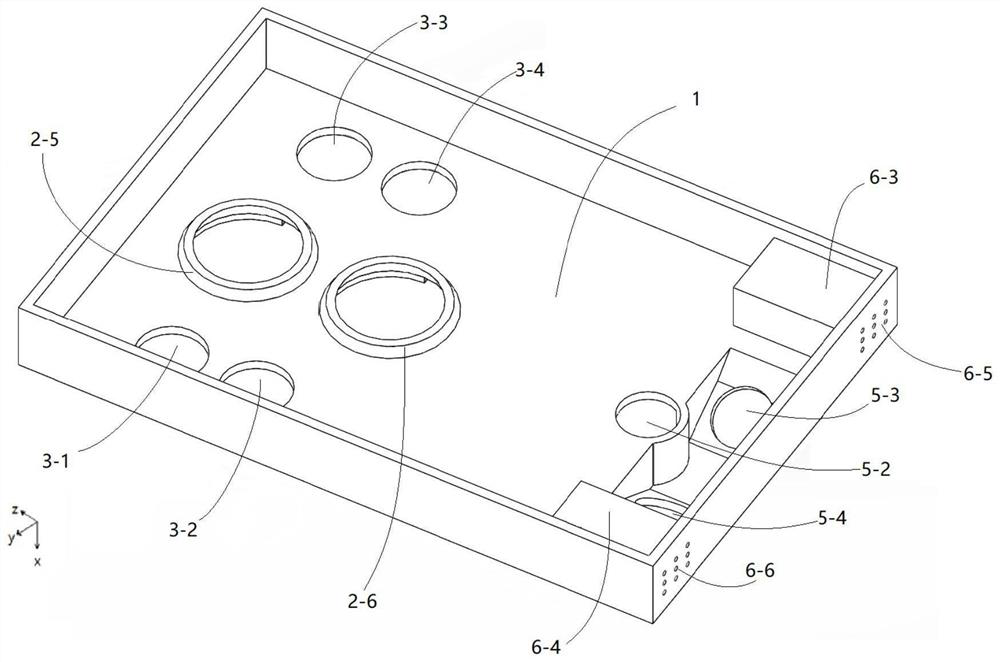

Focal length adjusting apparatus for VR device, and VR device

ActiveCN105425398ASimple internal structureImprove experienceOptical elementsAgricultural engineeringEngineering

Owner:SHENZHEN DLODLO NEW TECHNOLOGY CO LTD

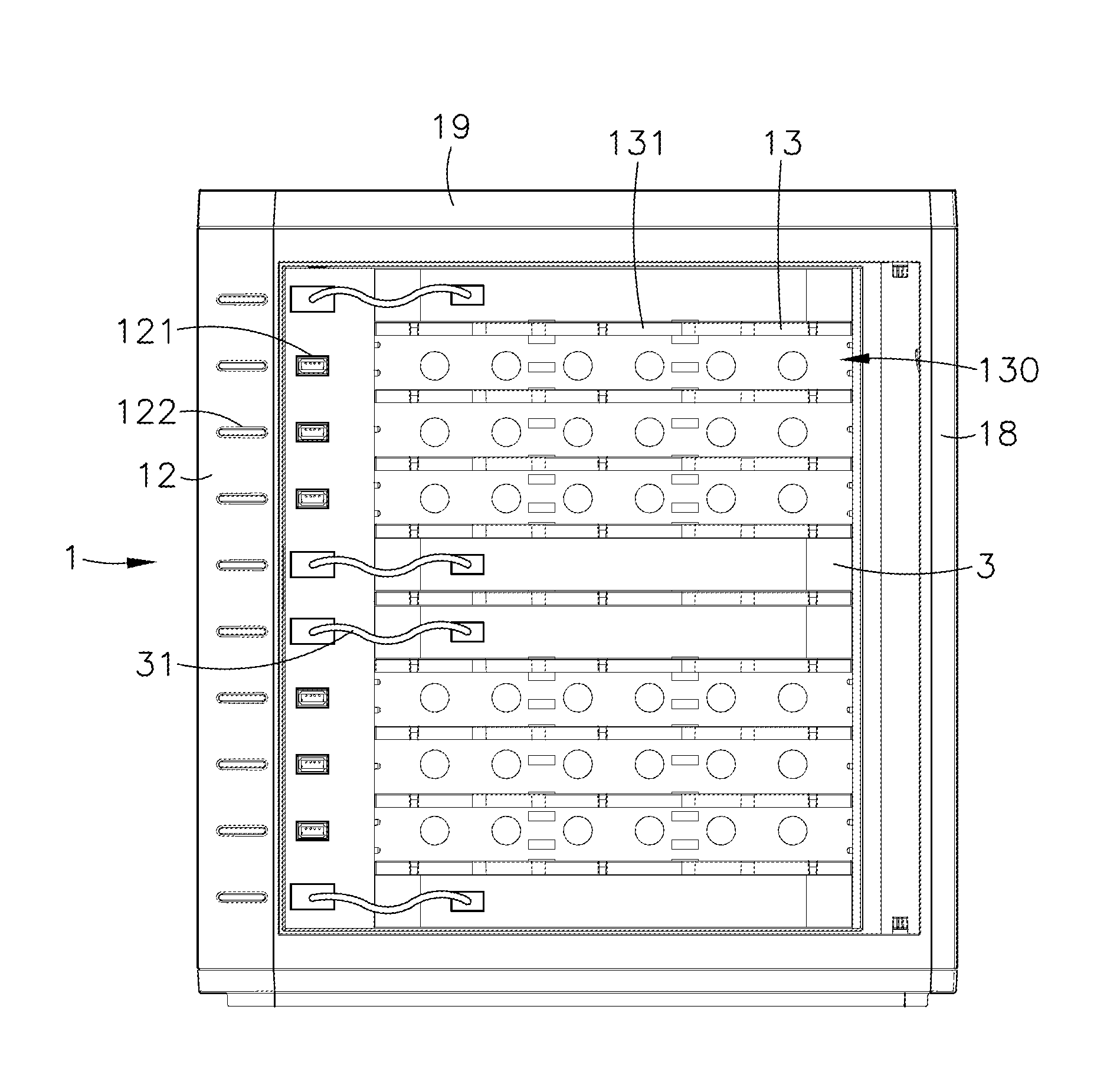

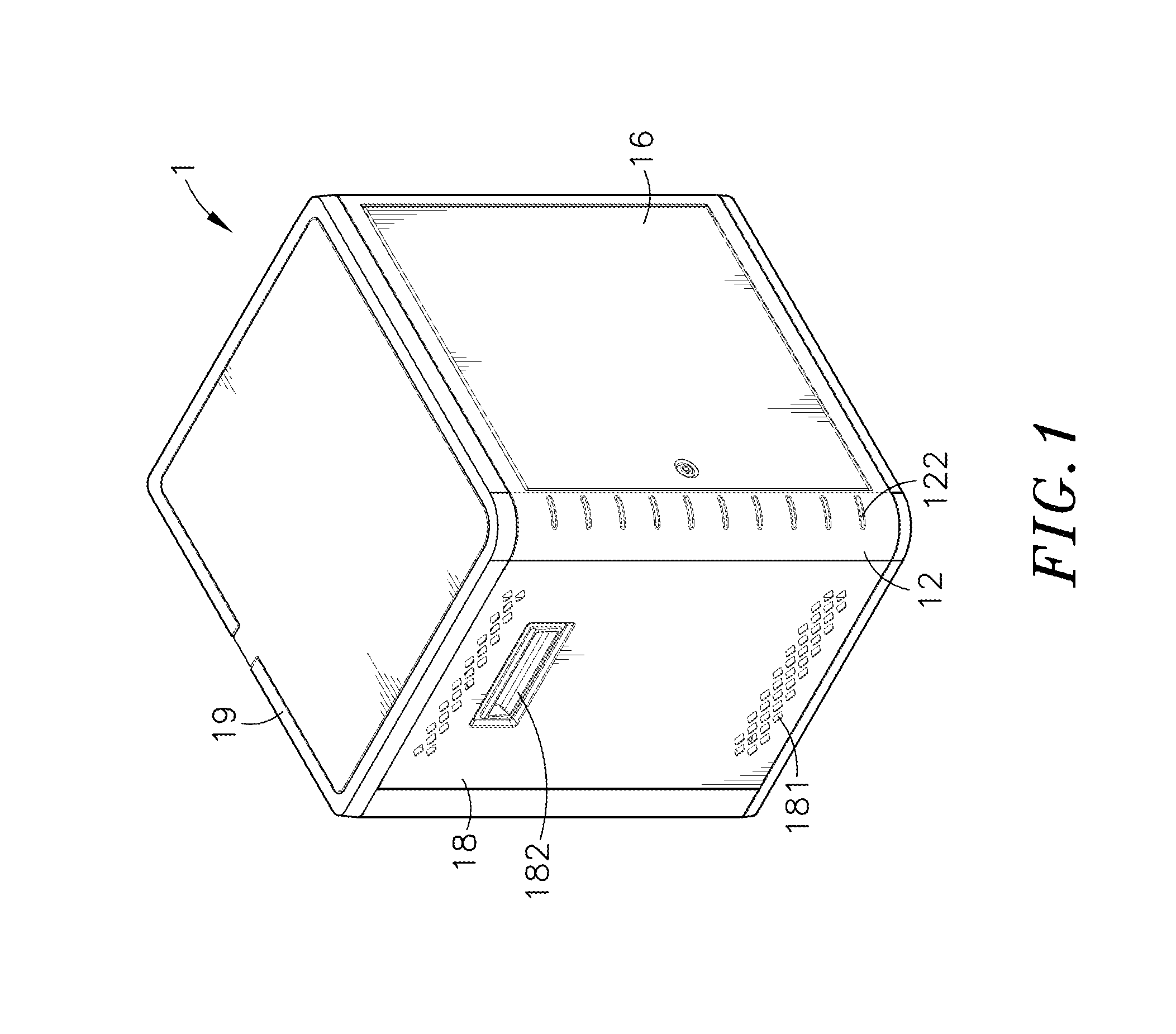

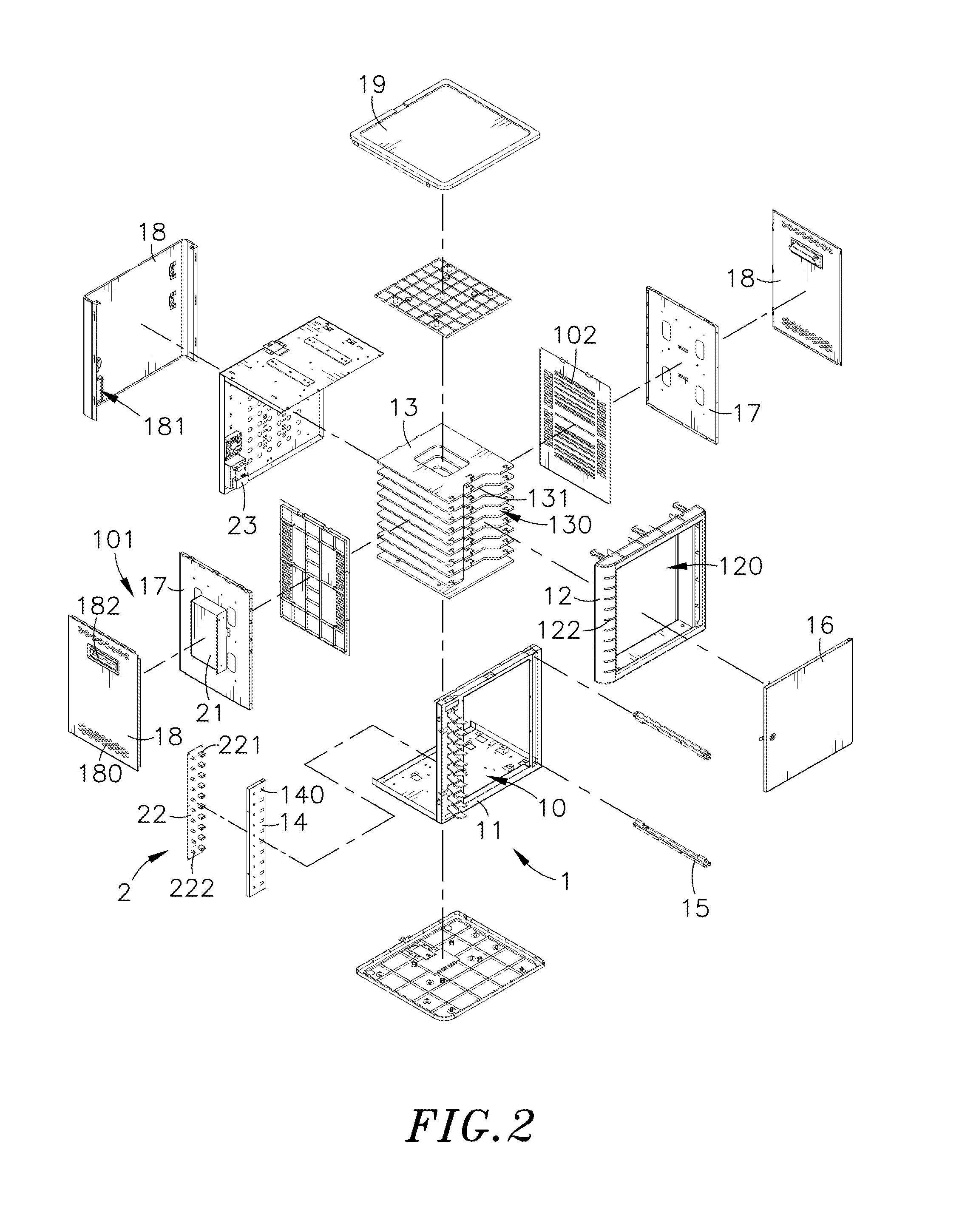

Desk storage device with power charging function

InactiveUS20150137738A1Circuit monitoring/indicationIndicating/monitoring circuitsElectricityControl system

Owner:CHUNG CHIAO HLDG

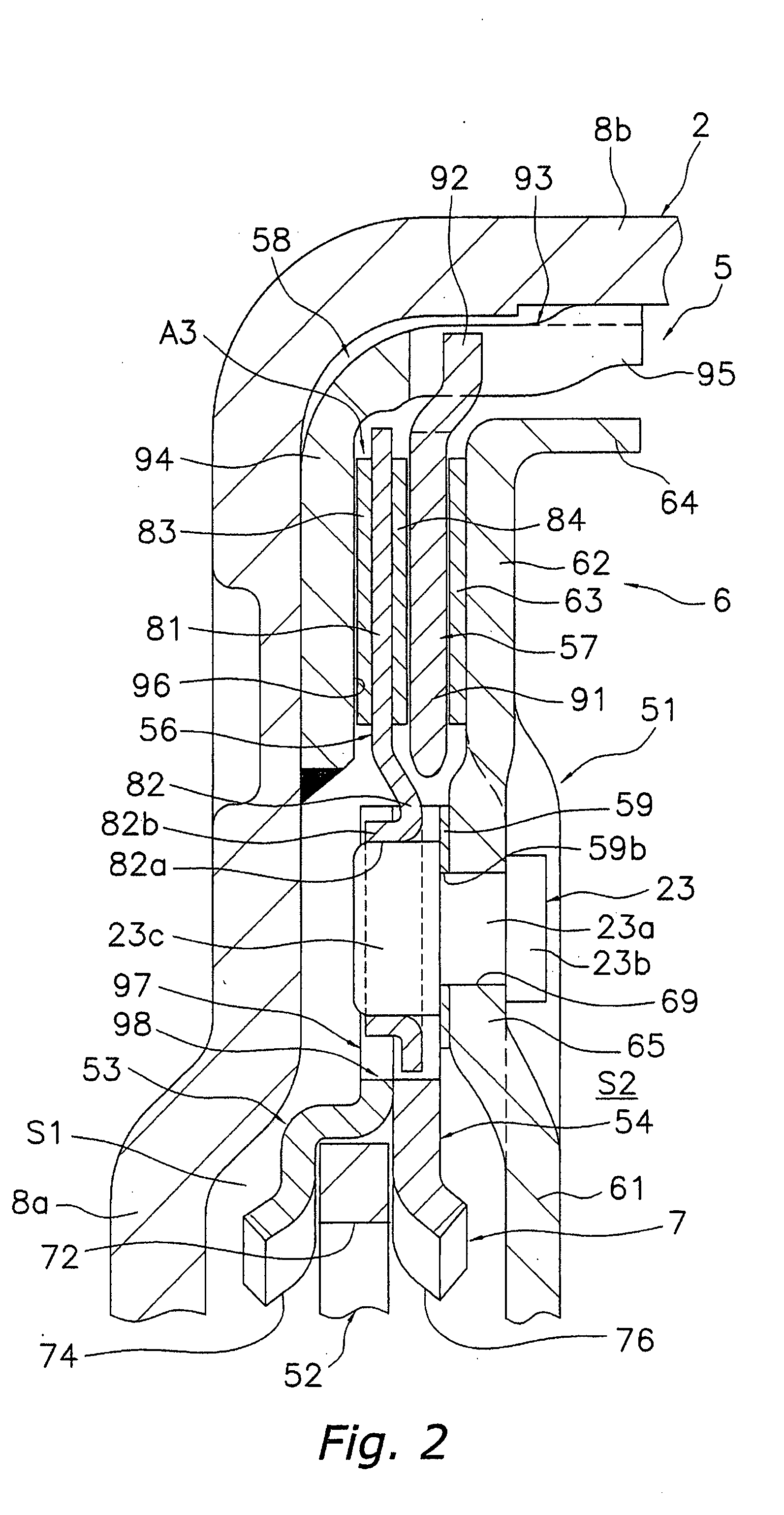

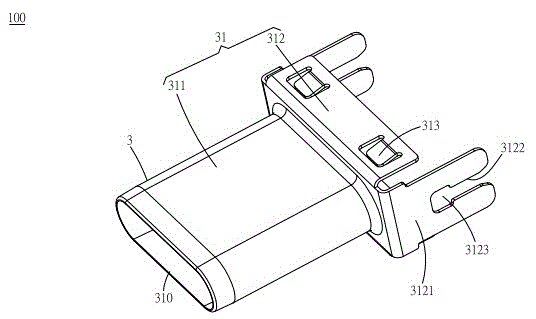

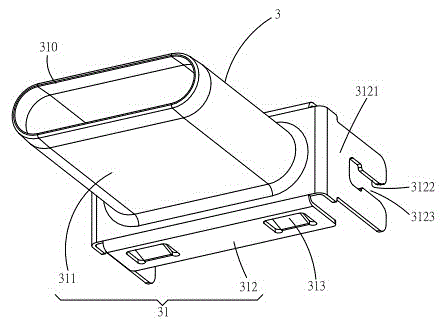

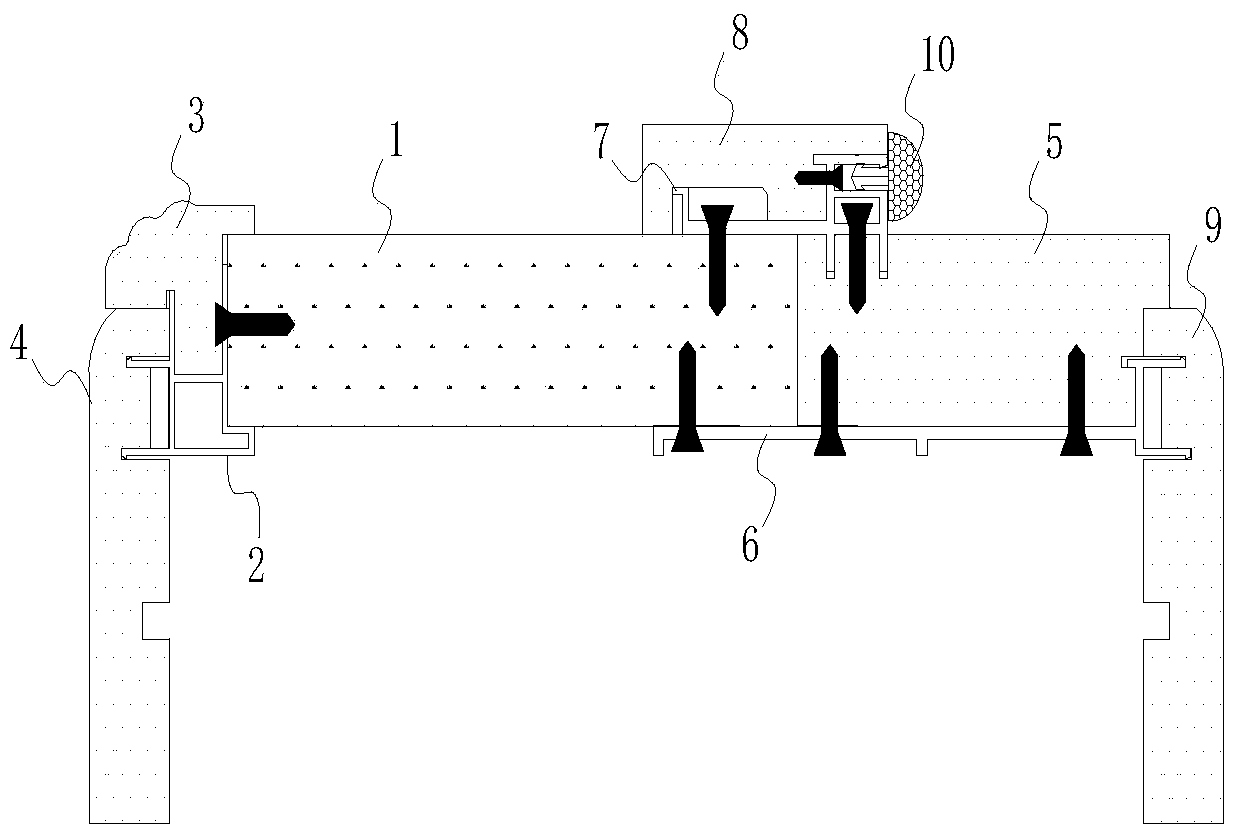

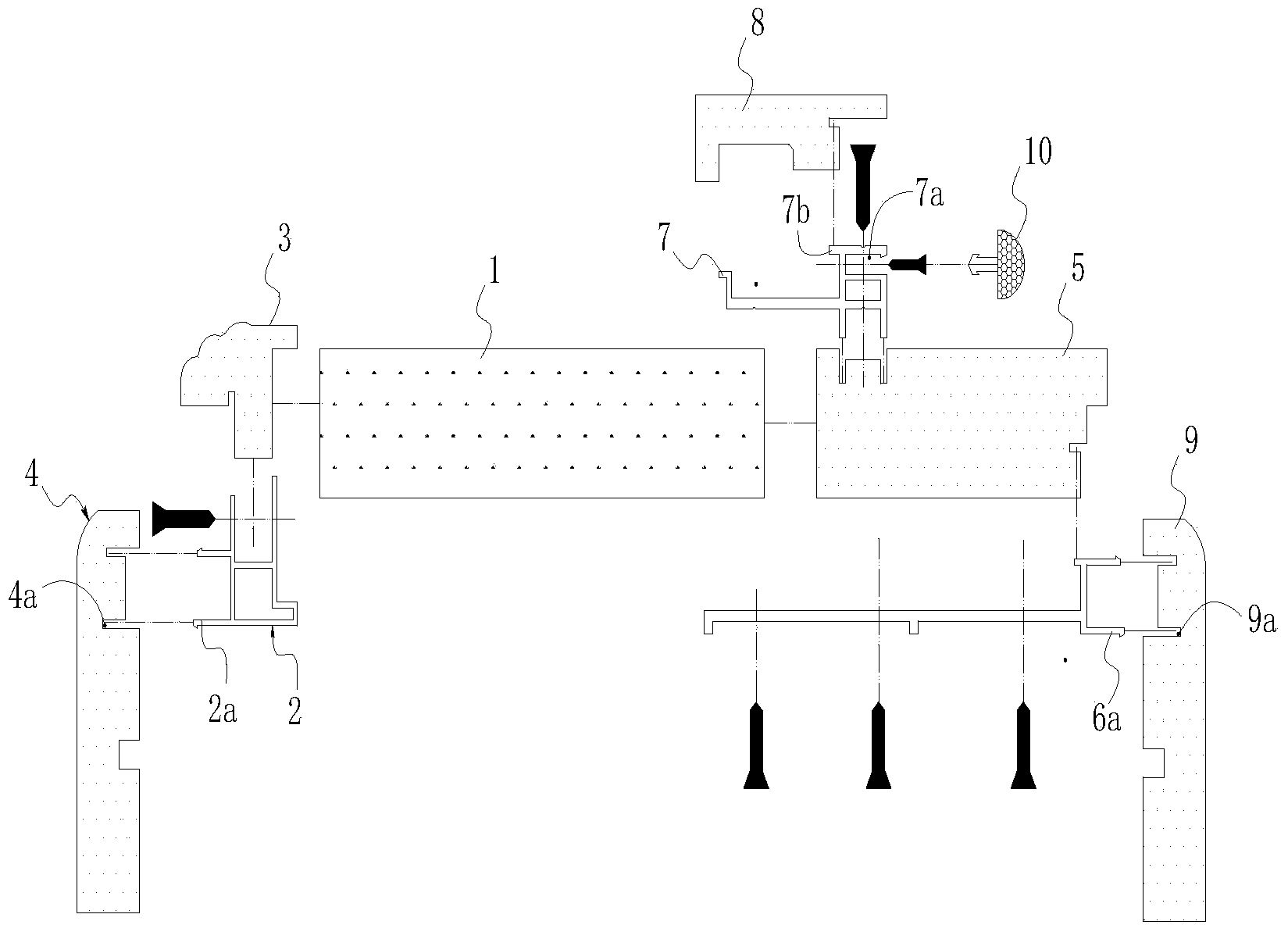

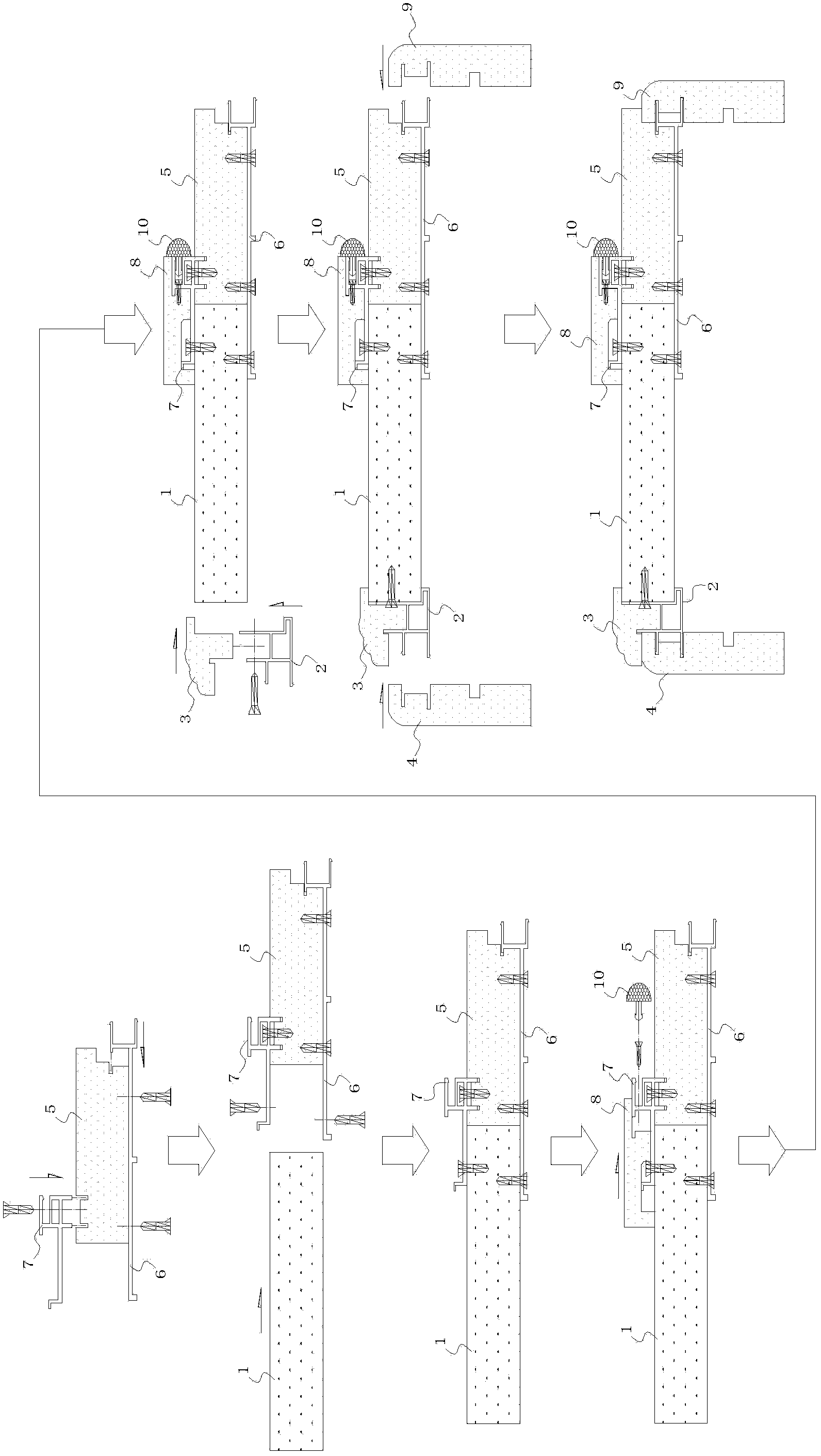

LGA socket connector with floating cover

InactiveUS20060121751A1Overcomes shortcomingCoupling contact membersComponent plug-in assemblagesElectrical connectorElectrical and Electronics engineering

Disclosed is an electrical connector assembly including an insulative housing (10) with a plurality of passageways (103) therethrough from a top mating interface (100). A plurality of terminals (20) is inserted into the passageways with upper connecting portions (202) thereof have projections overlapped. A floating cover (30) is movably mounted above the base, and defines at least one slot (305) extending in a row direction along which, from a top view, the whole upper connecting portions direct to. The slot is configured to allow for upper mating sections (2021) of the whole row of terminals to be simultaneously extended therethrough when the floating cover is pressed downwardly to engage with the base. Thus, no damage will bring to the terminals that have overlapped configuration.

Owner:HON HAI PRECISION IND CO LTD

Method for machining submerged pump impeller

The invention discloses a method for machining a submerged pump impeller. The method comprises the steps that firstly, a three jaw chuck clamps a large outer circle of the impeller, and rough turning is performed on an impeller opening ring, a plane A and a front cover board after calibration; secondly, surfacing adjusting is performed, the three jaw chuck clamps the opening ring, rough turning is performed on a plane B after calibration, drilling is performed, rough turning is performed on a rear cover board and a sealing surface, and rough turning is performed on the large outer circle; thirdly, rough turning is performed on the plane B, boring is performed, the rear end cover and the sealing surface undergo finish turning so as to meet the requirements of a drawing, and chamfering is performed; fourthly, turning is performed on a core rod, the impeller is sleeved in the core rod and screwed through a nut, finish turning is performed on the plane A (1), the overall length is controlled according to the requirements of the drawing, the opening ring and the front end cover (3) undergo turning so as to meet the requirements of the drawing, the large outer circle undergoes finish turning so as to meet the requirements of the drawing, and chamfering is performed; fifthly, checkout is performed; sixthly, a static equilibrium test is performed as the requirements; seventhly, a keyway is inserted; eighthly, checkout is performed; ninth, cleaning, burring, oiling and stockroom entering are performed. The method for machining the submerged pump impeller facilitates machining, ensures machining precision and improves production efficiency, and is suitable for machining of industrial pump impellers.

Owner:JIANGSU YAMEI PUMP IND GRP

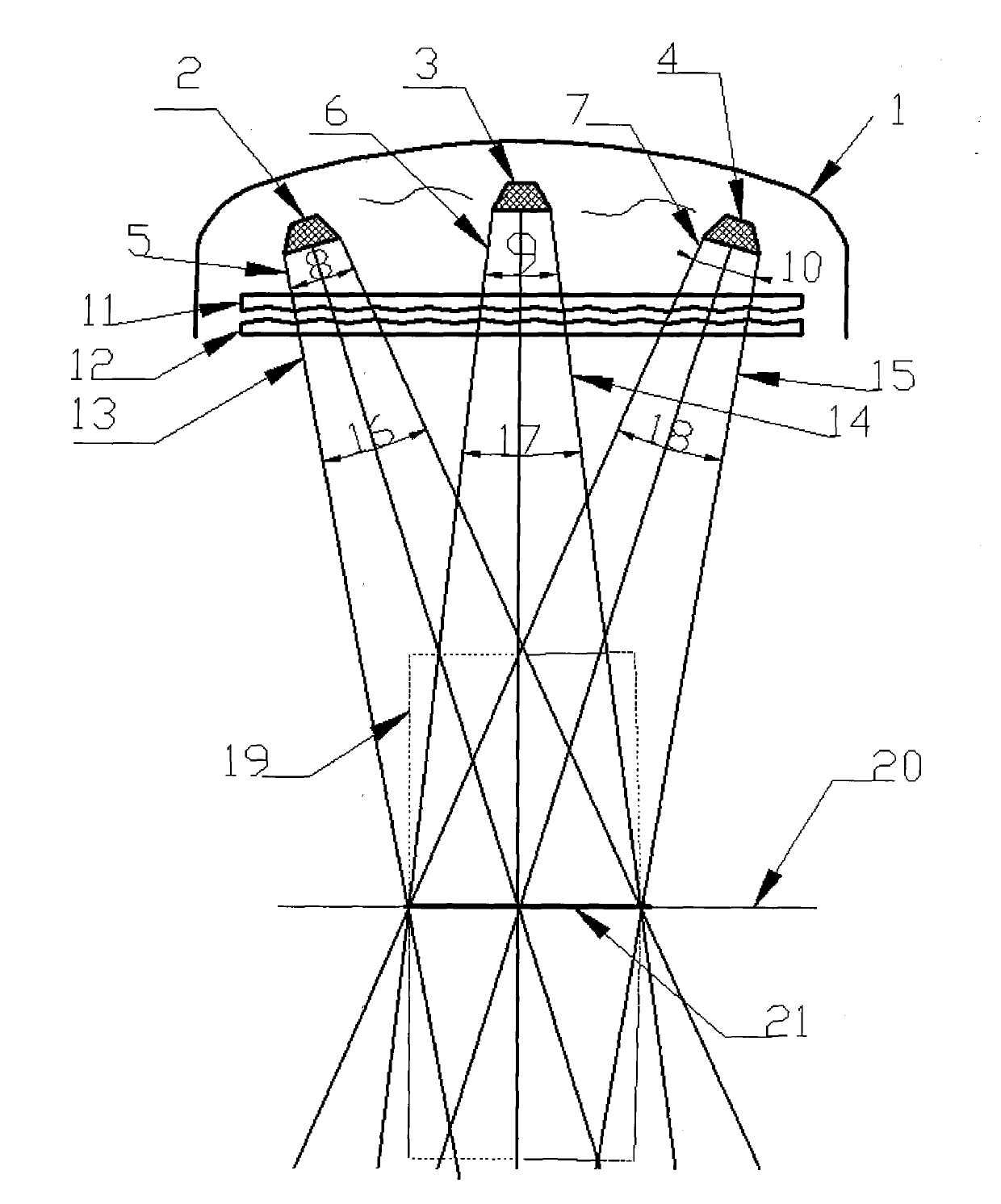

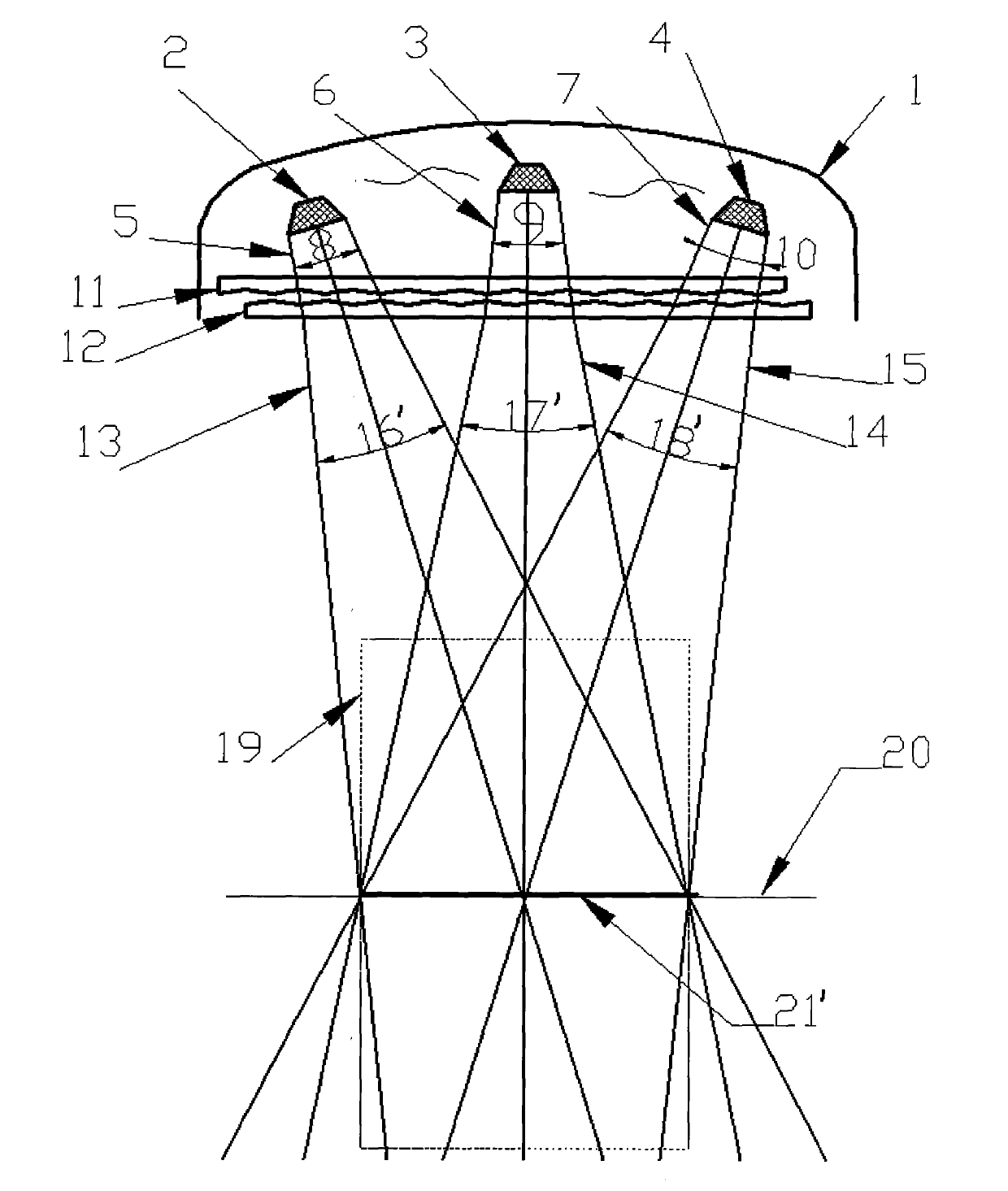

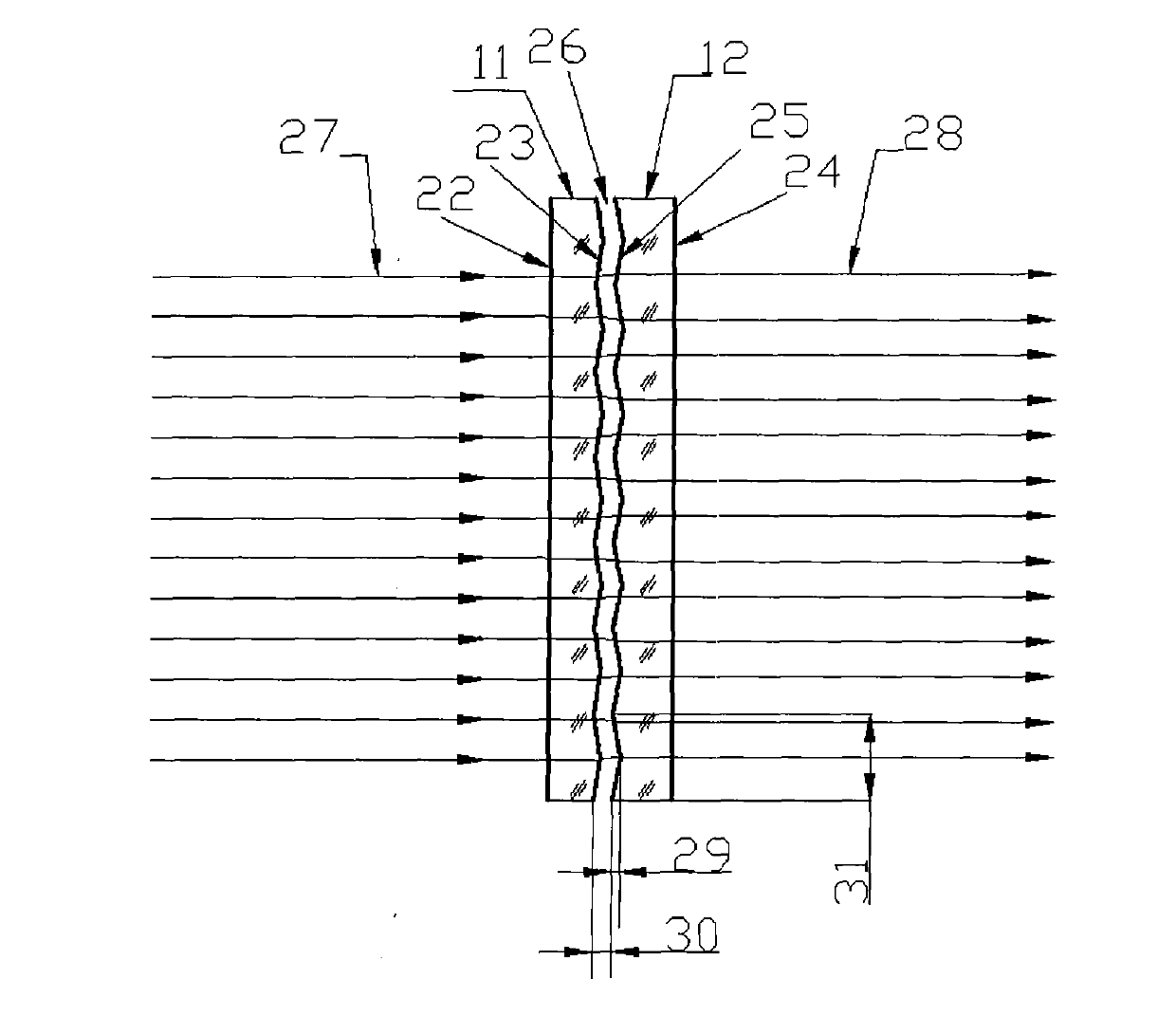

Operating lamp and its light transmission cover and light spot regulation method

ActiveCN102563397ASimple structureEasy to change the irradiation rangeTreatment roomsMedical lightingLight spotEngineering

Owner:NANJING MINDRAY BIO MEDICAL ELECTRONICS

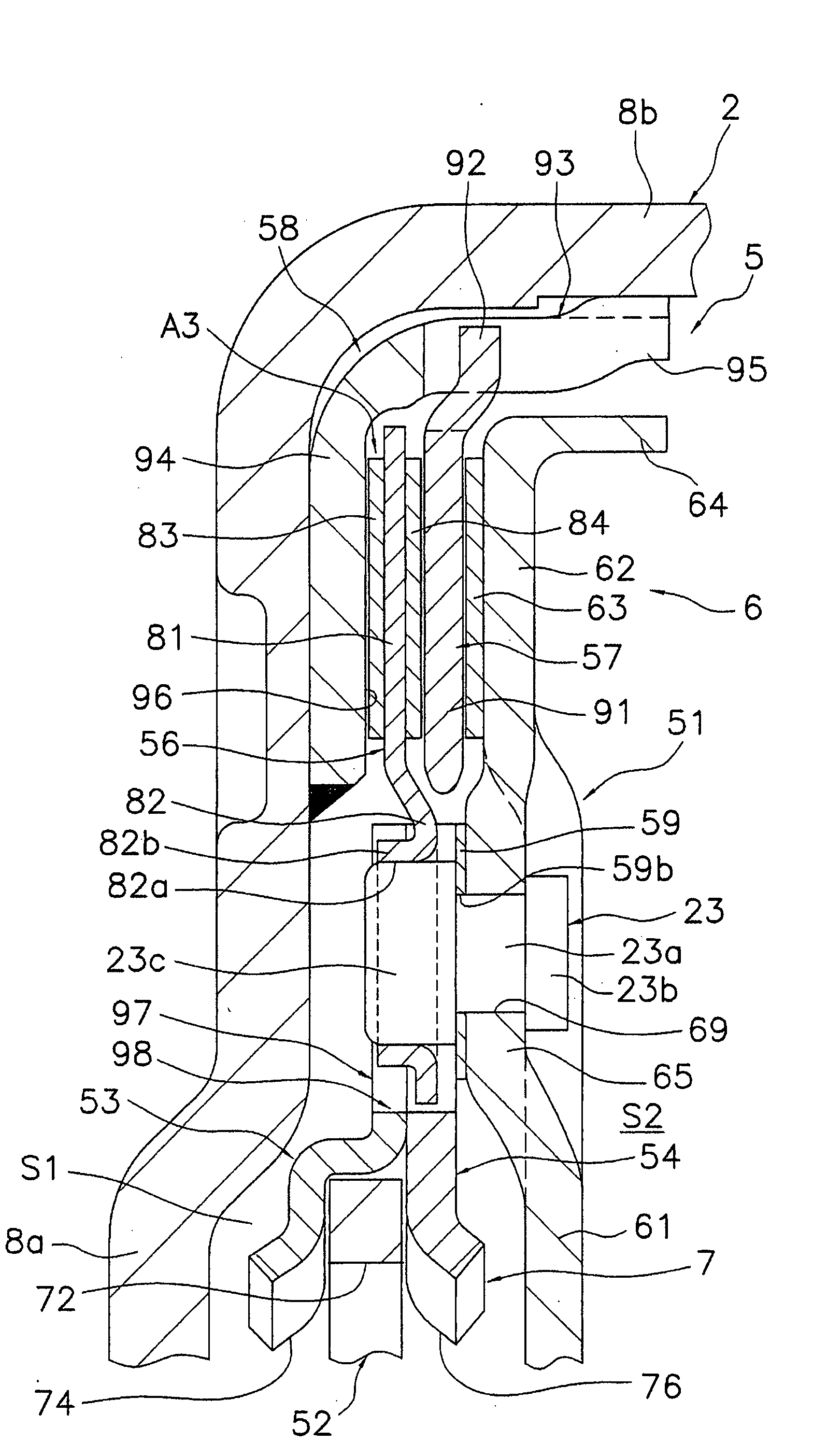

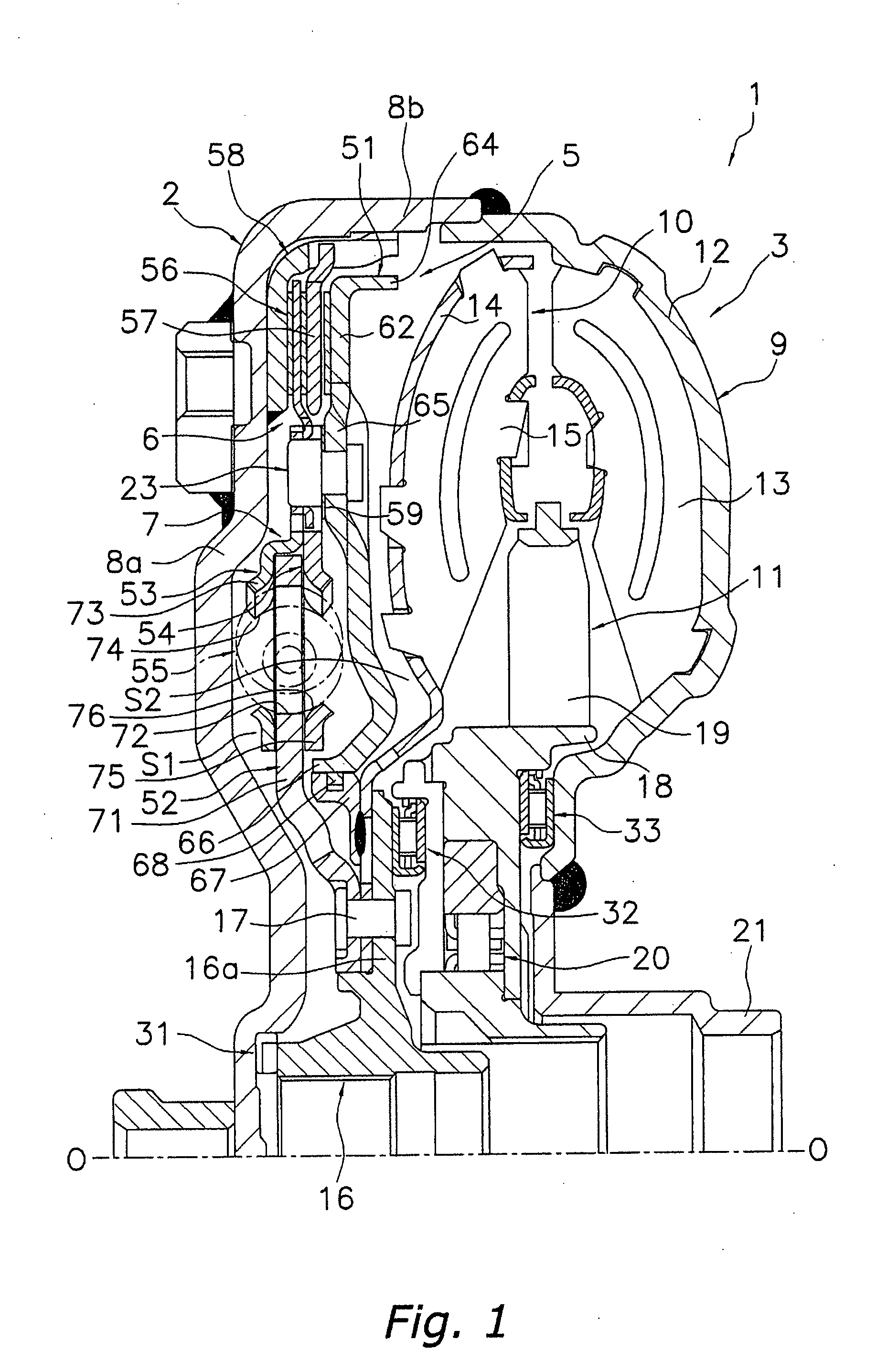

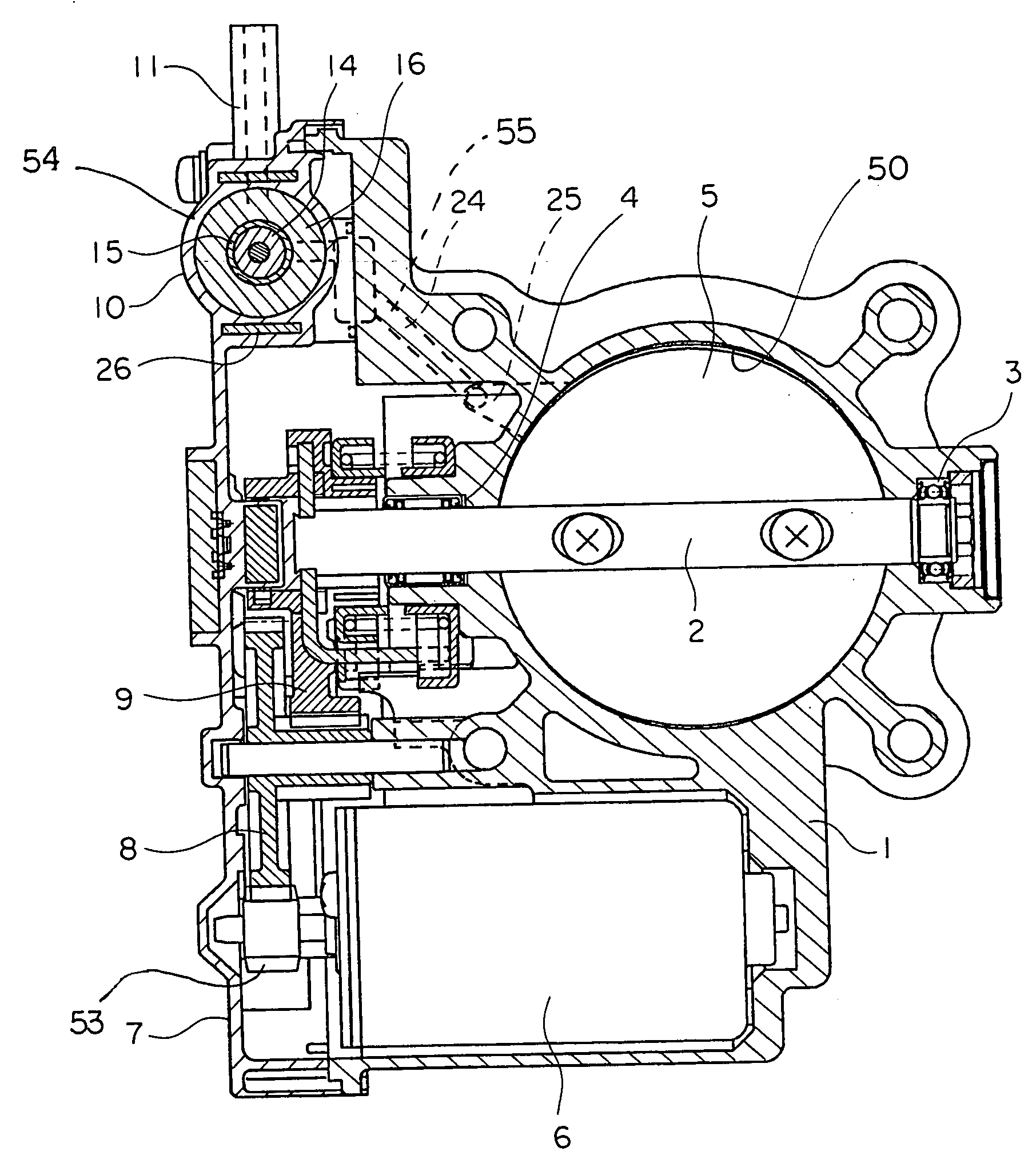

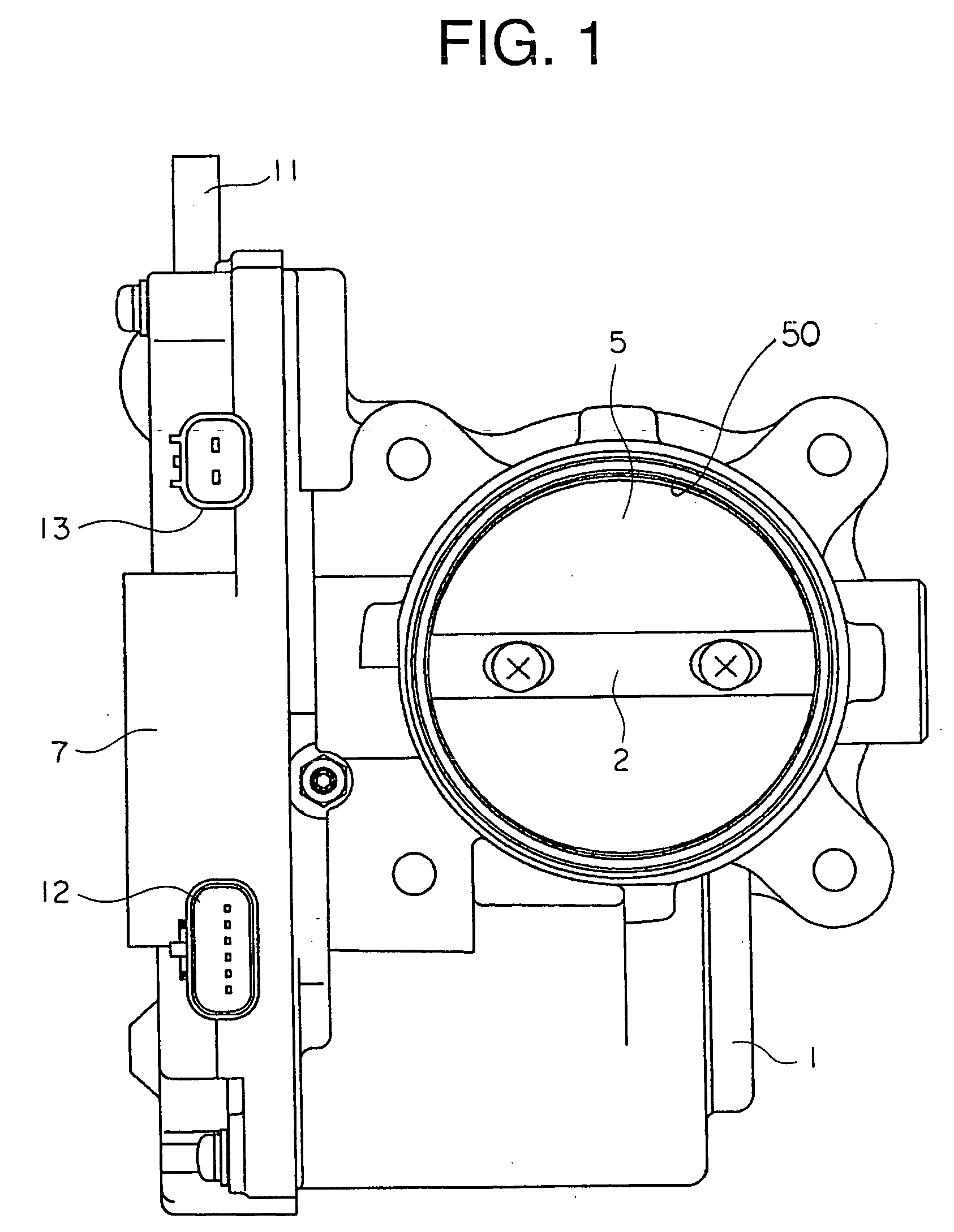

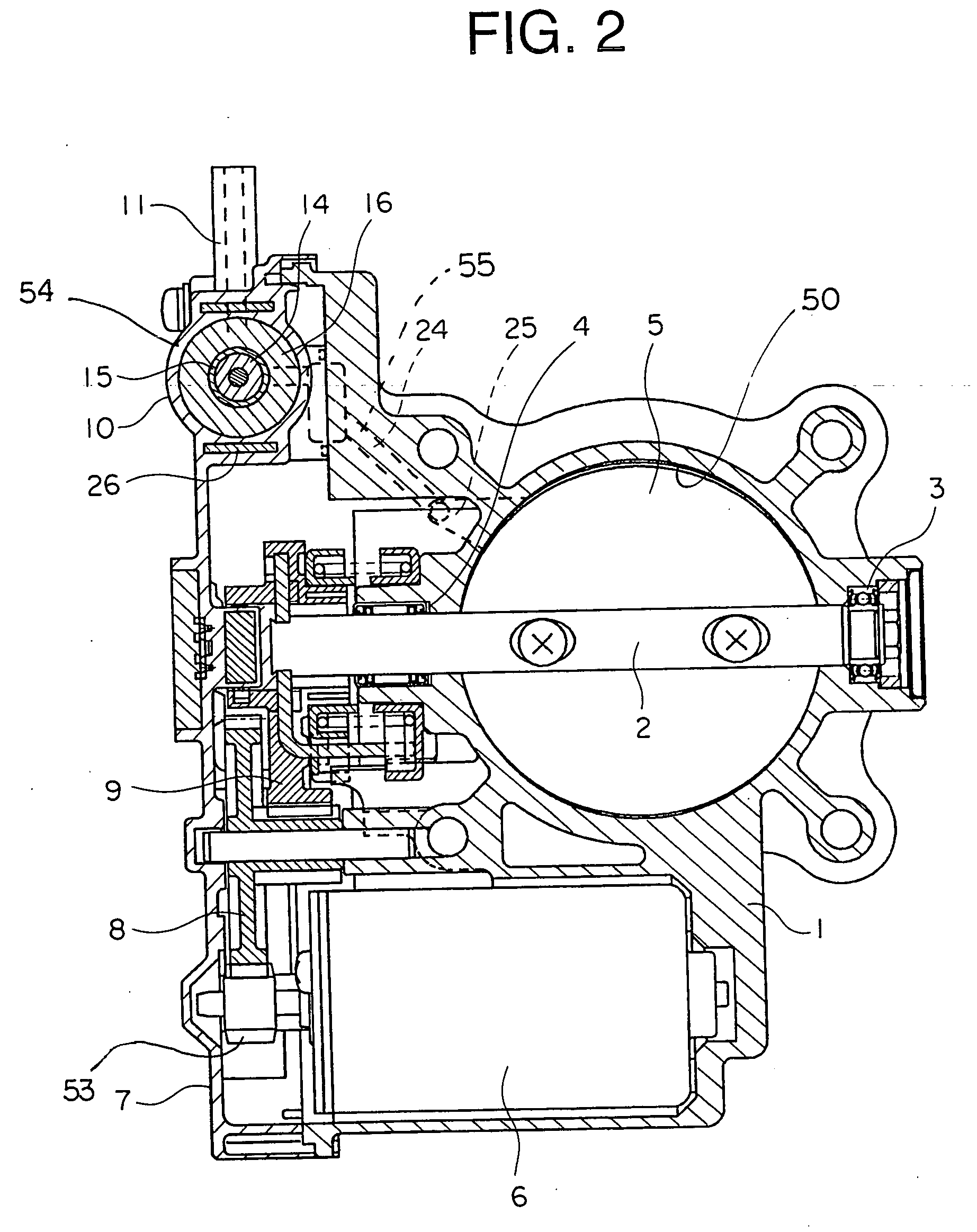

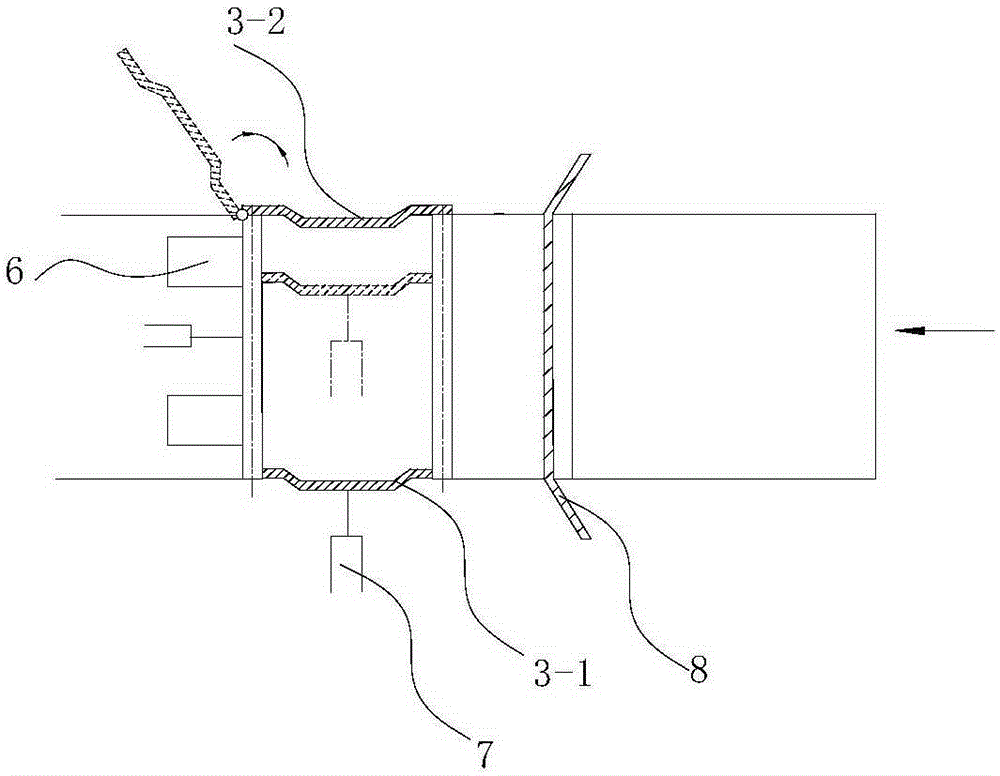

Engine intake control device

Owner:MITSUBISHI ELECTRIC CORP

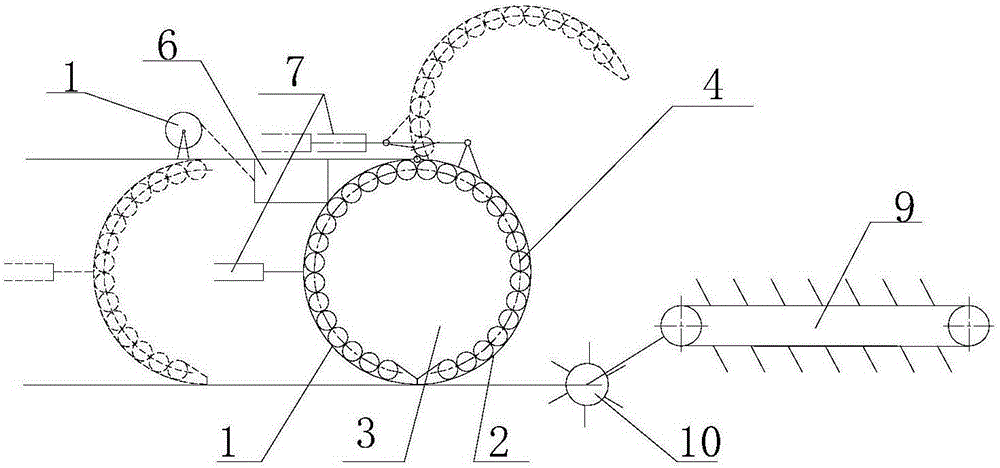

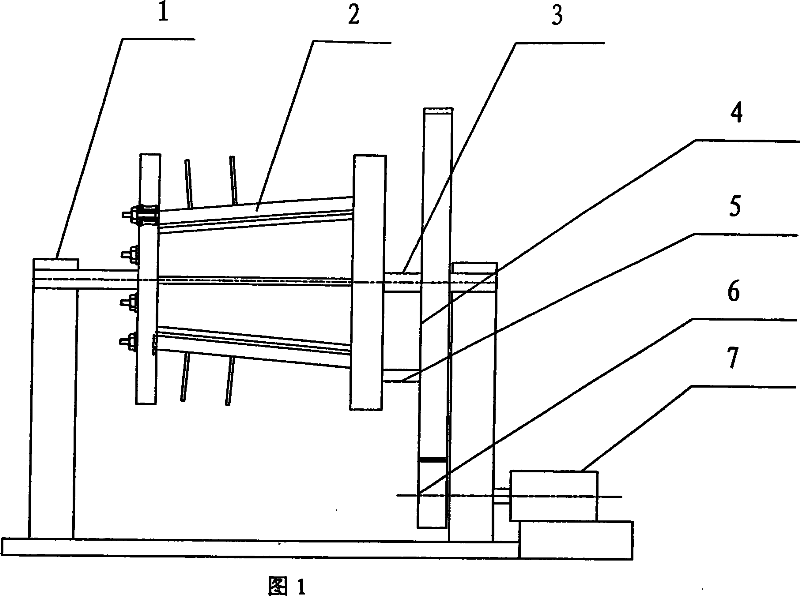

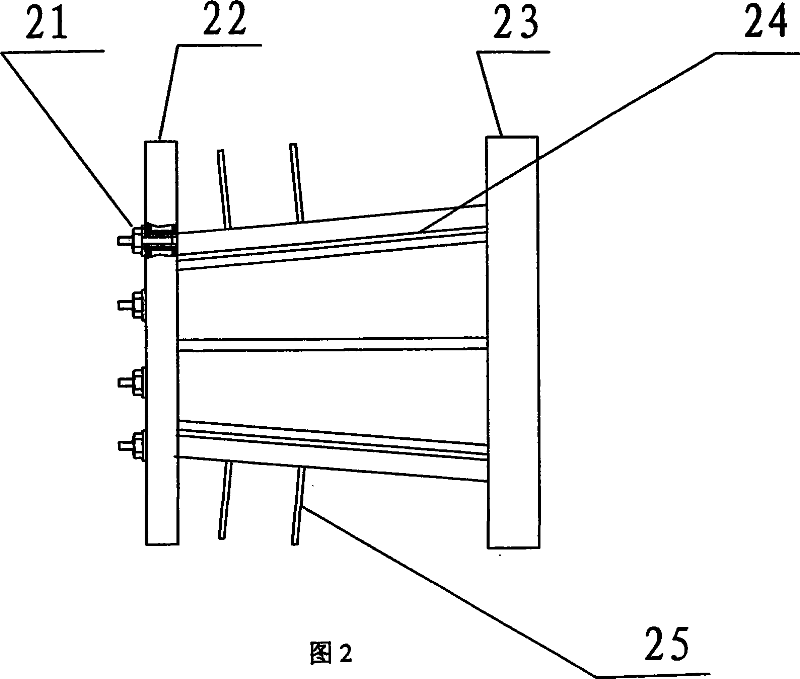

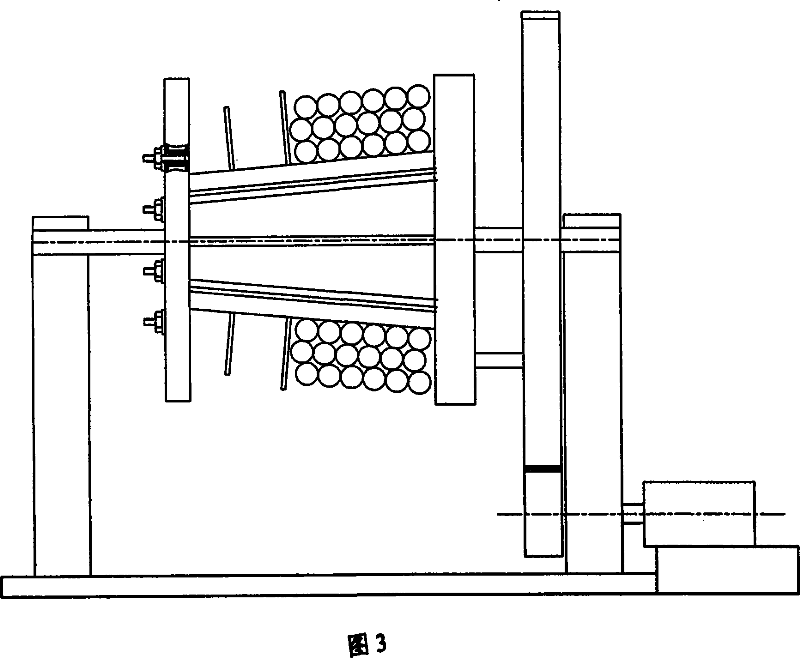

Bundling machine making cotton straw bundle used for processing high water content mud and novel dredger fill

ActiveCN105145010AEasy to feedTake advantage of strength and stiffnessBalingSoil preservationLeft halfReciprocating motion

Owner:冠县民富物业管理有限公司

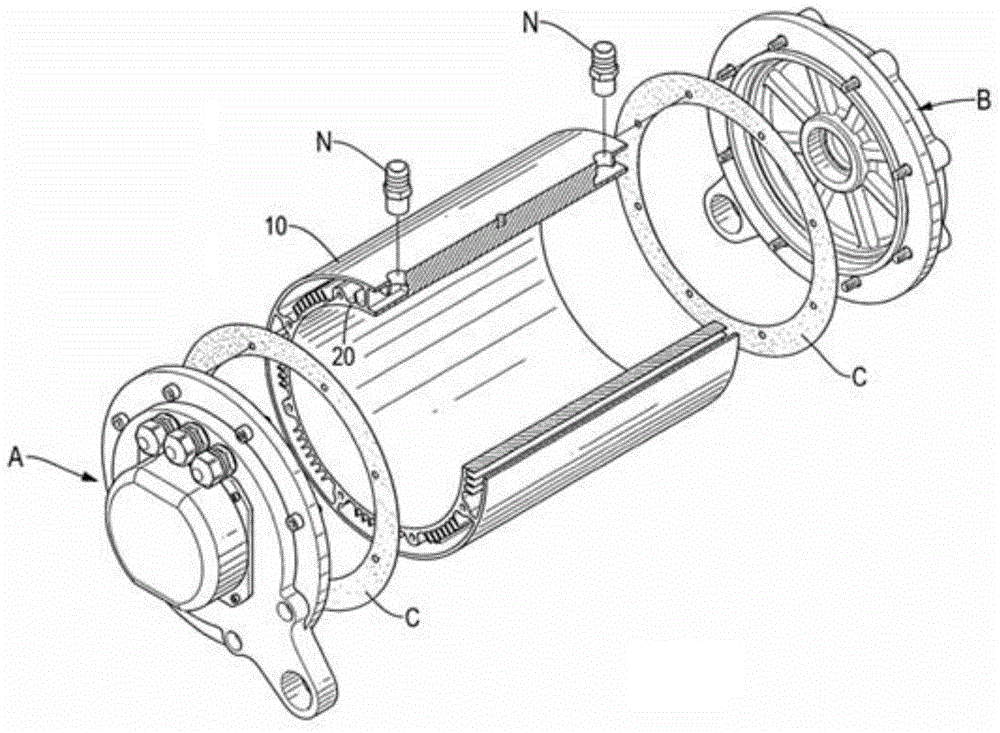

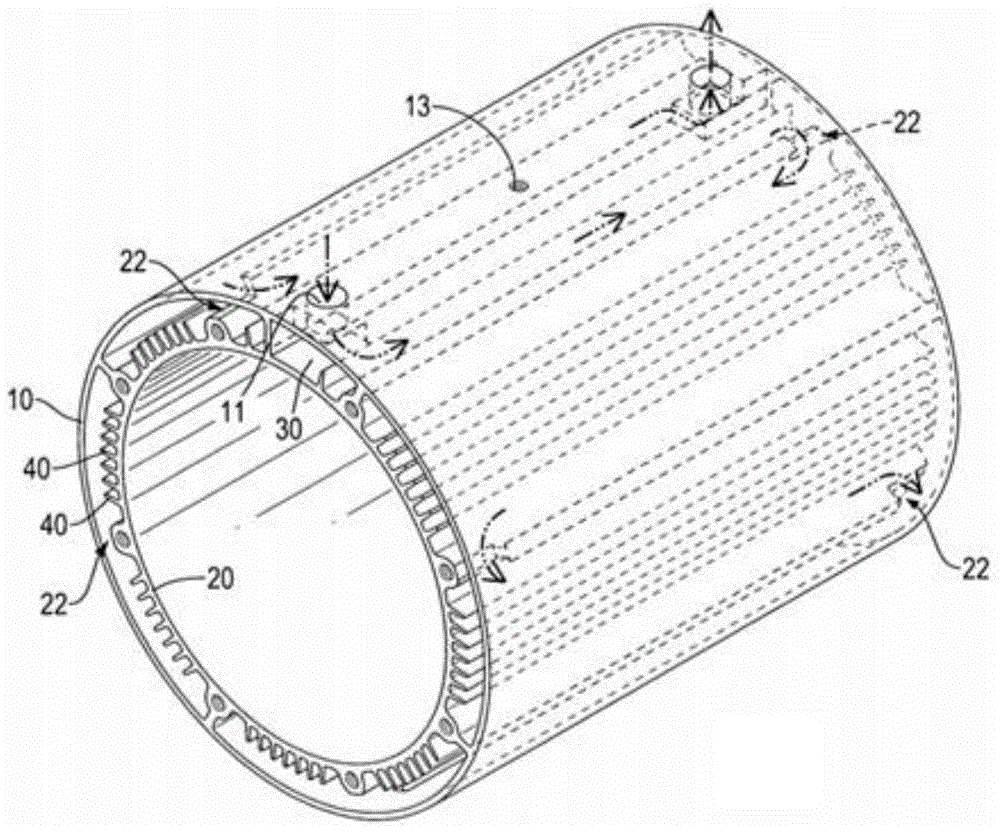

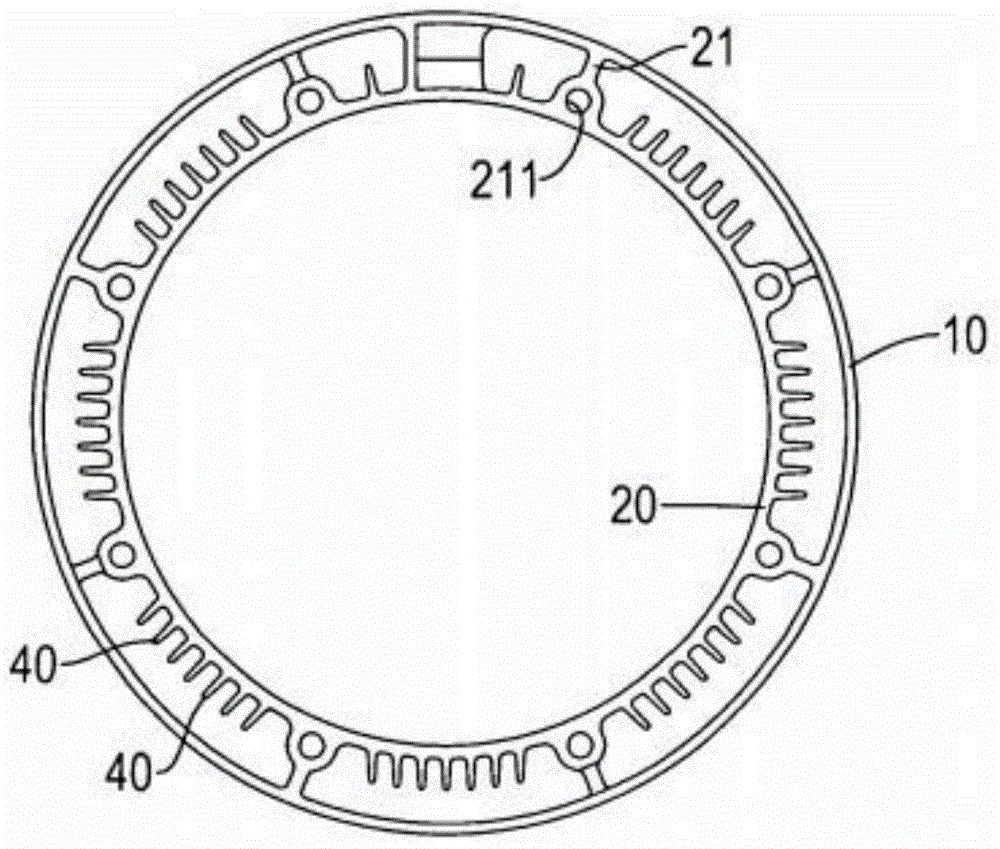

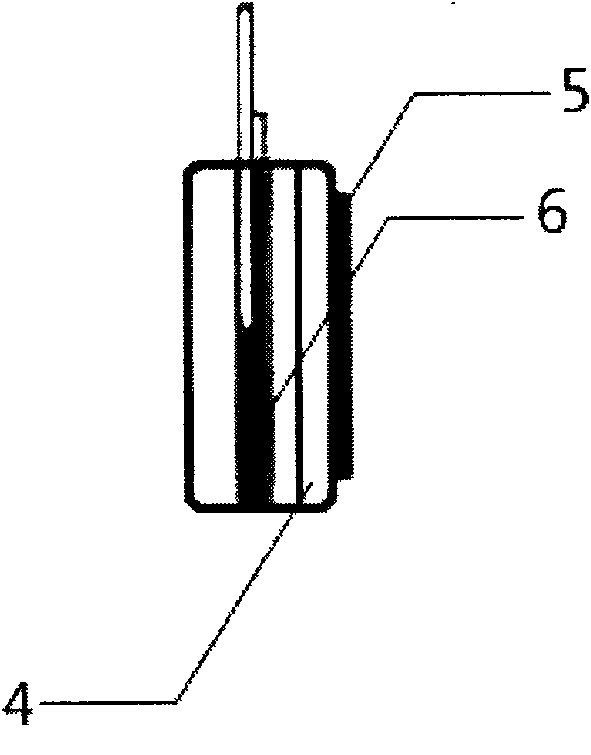

Liquid-cooled motor

InactiveCN104578518ASimple structureEasy to operateCooling/ventillation arrangementSupports/enclosures/casingsEngineeringFront cover

Owner:CHENGDU ZHONGYUANXIN ELECTRONICS TECH

Scrapbook having scented pages

InactiveUS20060202466A1High transparencyTough and long-lastingToysFiling appliancesPolymer thin filmsDiffusion barrier

A scrapbook, in which multiple fragrances associated with memorable events can be stored for extended periods of time, includes scented pages enclosed in perforated see-through protector sleeves, diffusion barrier sheets bound between adjacent pages having dissimilar fragrances, a diffusion barrier sheet bound between a front cover of the scrapbook and the first scented page, and a diffusion barrier sheet bound between a back cover of the scrapbook and the last scented page. The protector sleeves, which control the release of fragrance from paper sheets to which a fragrance has been applied, are fabricated from polymeric films, such as polypropylene, which have excellent resistance to oils and gases. Barrier sheets may be metalized for enhancement of diffusion barrier qualities. Fragrances may be applied to scrapbook paper by spraying, rolling, painting, stamping, printing or immersion.

Owner:HIRONAKA ROBIN S

Suspension bridge main cable rope retracting method

Owner:JIANGSU FASTEN STEEL CABLE CO LTD

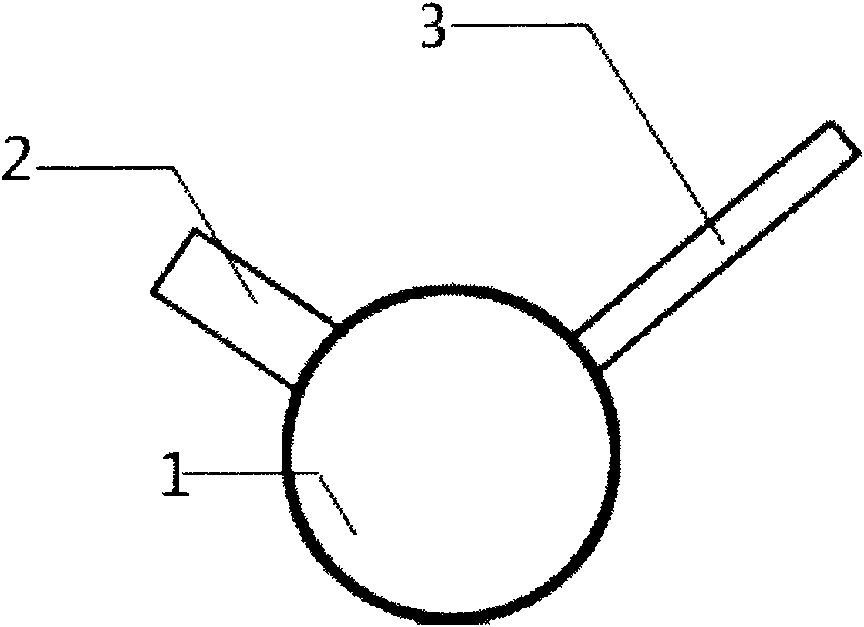

Lossless super-cavitation centrifugal pump impeller

ActiveCN106337835APrecise design methodReduce friction lossPump componentsPumpsCavitationSolid particle

The invention relates to a lossless super-cavitation centrifugal pump impeller. The impeller is mainly composed of blades (1), an impeller front cover plate (2) and an impeller rear cover plate (3) and mainly characterized in that geometric structures of the super-cavitation blade pump blades (1) are modified, and according to the requirements of different design conditions, single short super-cavitation blades or combined blades combining the super-cavitation blades and non-overloading blades are adopted; and geometric shapes of blade inlets are modified to simultaneously meet the super-cavitation requirement and the requirement of allowing larger solid particles to pass through the impeller without a plunger, the blades in the impeller are prevented from being abraded by the large solid particles in the operating process, the frictional resistance to the blades in the operating process can be effectively reduced, the working efficiency of a super-cavitation pump is improved, and the service life of the super-cavitation pump is prolonged.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH

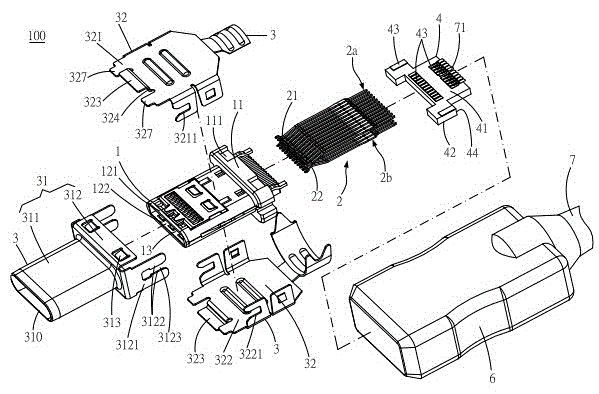

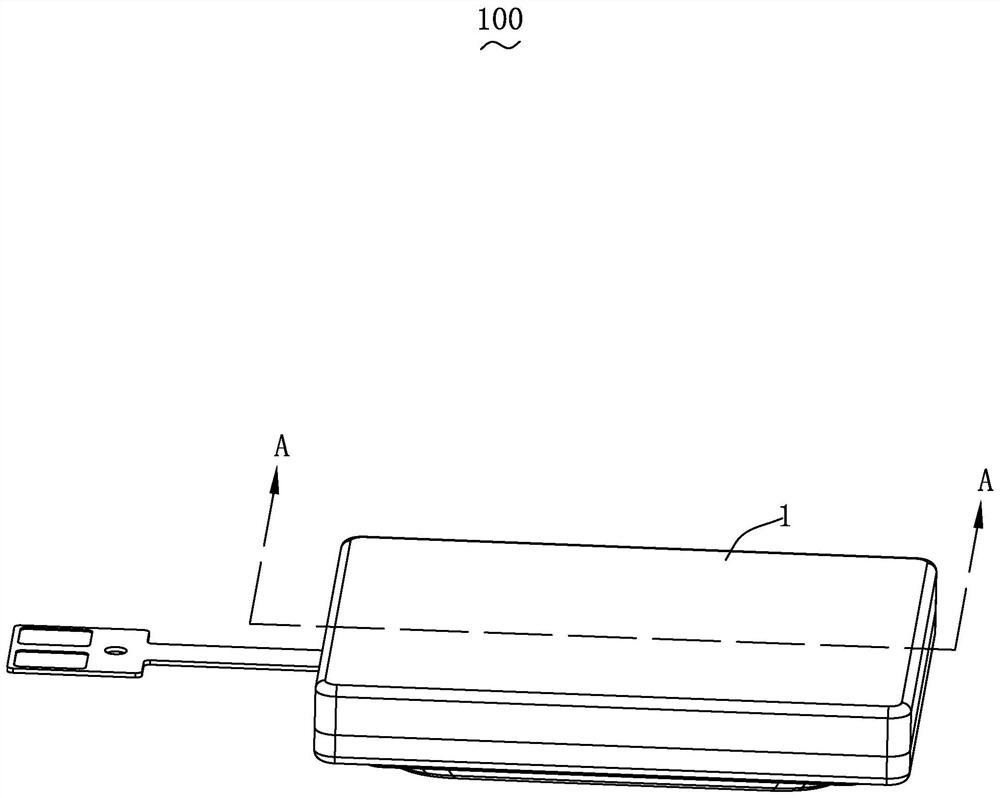

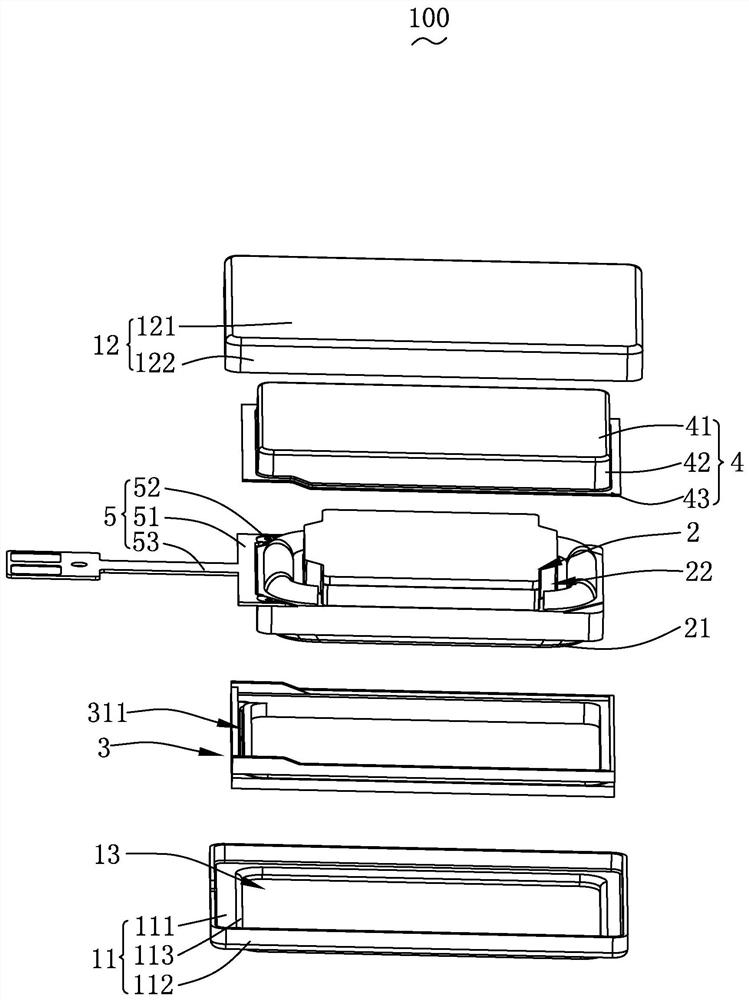

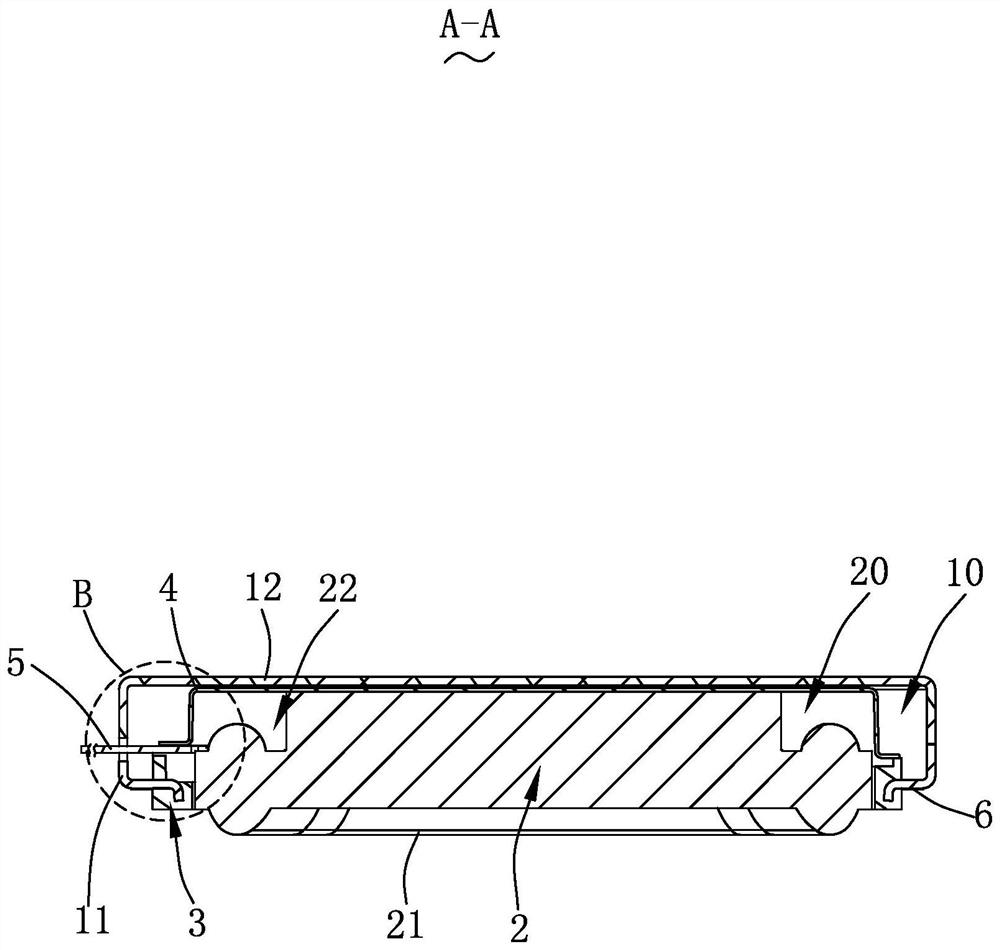

Plug electrical connector

ActiveCN105006698AImprove aestheticsHigh strengthCoupling protective earth/shielding arrangementsElectrical connectorFront cover

Owner:连展科技电子(昆山)有限公司

Multifunctional field infrared camera device

InactiveCN111711743AExtend battery lifeReduce use costTelevision system detailsBatteries circuit arrangementsEngineeringSolar battery

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

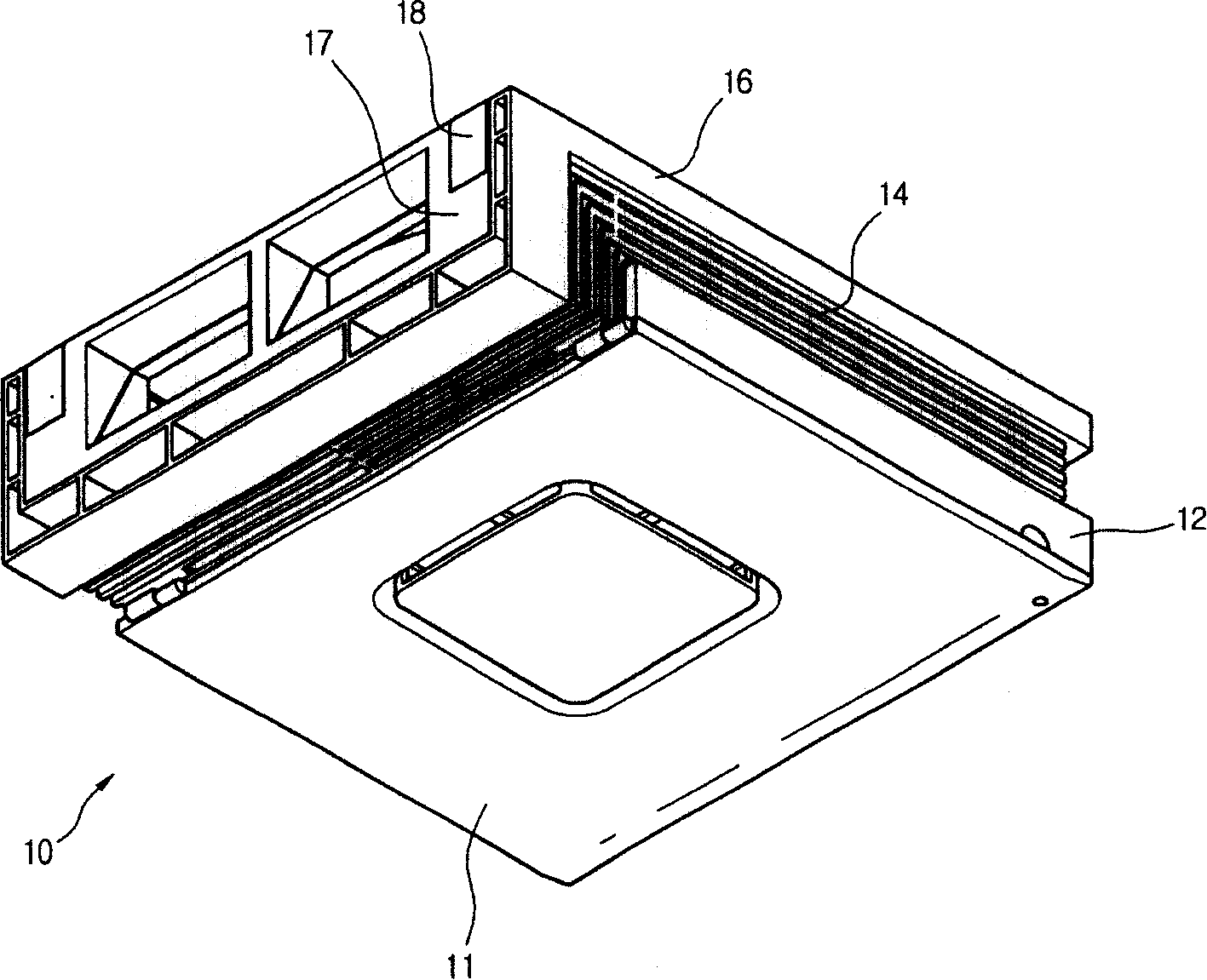

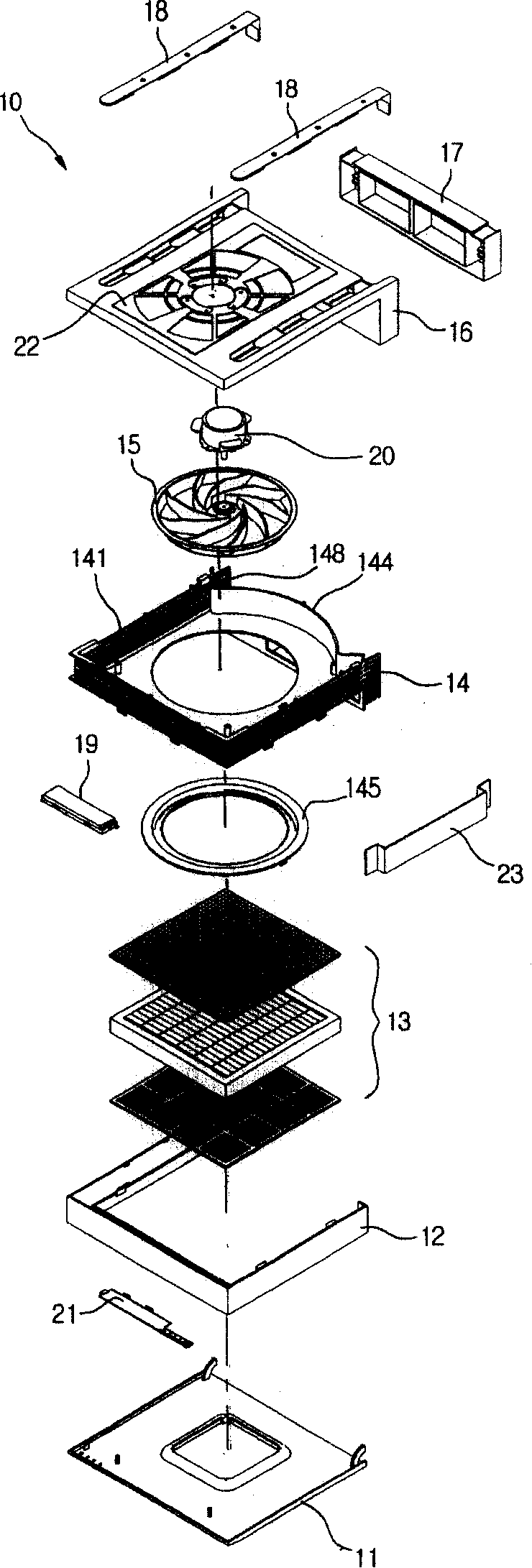

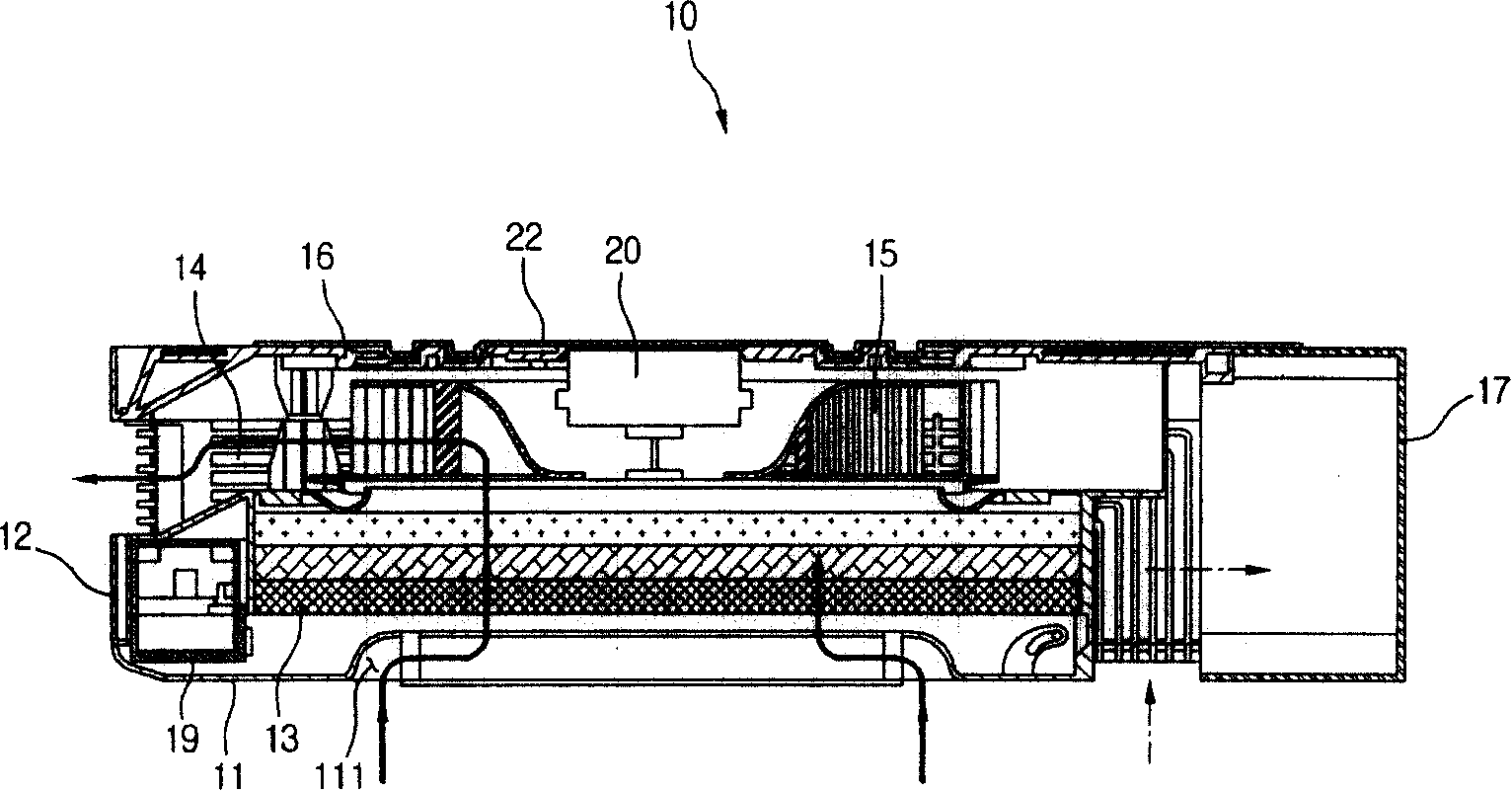

Aeration purifier

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Combined type door frame processed in standardized mode and combination method thereof

ActiveCN103410404AImprove installation qualityImprove carrying capacityWindow/door framesEngineeringFront cover

The invention discloses a combined type door frame processed in a standardized mode and a combination method of the combined type door frame. The structure of the combined type door frame processed in the standardized mode is convenient to assemble, beneficial to standardized processing, high in strength and long in service life. The combined type door frame processed in the standardized mode is characterized in that the combined type door frame processed in the standardized mode comprises a wooden main board, a front connecting piece is fixed to the front end portion of the wooden main board, a wooden trim strip and a wooden front cover board are respectively installed on the front connecting piece, a wooden opening stop board is arranged on the rear portion of the wooden main board, the inner side surface of the wooden main board and the inner side surface of the wooden opening stop board are fixedly connected through an inner connecting board, the outer side surface of the wooden main board and the outer side surface of the wooden opening stop board are fixedly connected through an outer connecting piece, a wooden decorative panel is fixed outside the outer connecting piece, and a wooden rear cover board is installed at the rear end of the wooden opening stop board. The combination method comprises the following steps that the opening stop board, the inner connecting board and the outer connecting piece are combined firstly, the wooden decorative panel is combined in sequence secondly, the wooden main board is combined thirdly, the front connecting piece and the wooden trim strip are combined fourthly, and the front cover board and the rear cover board are combined finally. The combined type door frame processed in the standardized mode and the combination method of the combined type door frame are applied to installation of a door of a building.

Owner:GUANGDONG SINPOLO DOOR IND

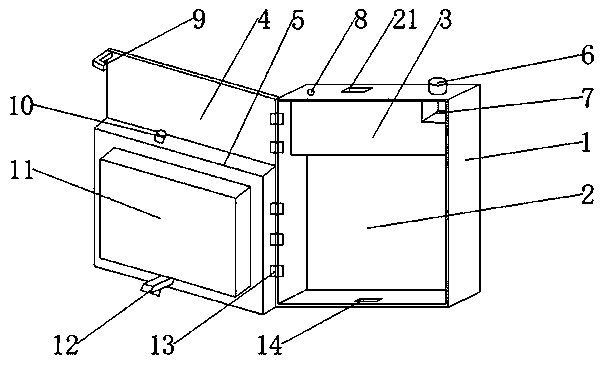

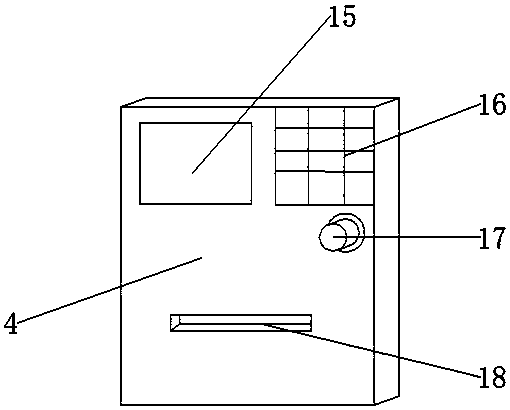

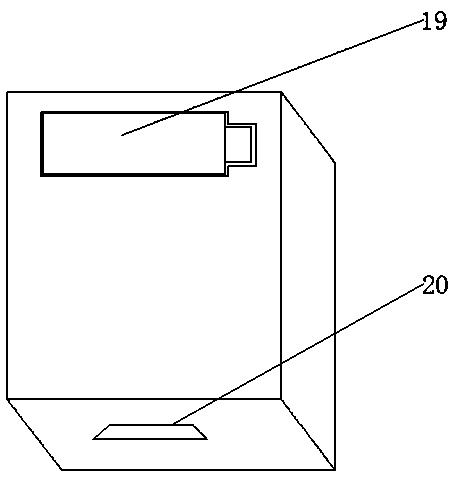

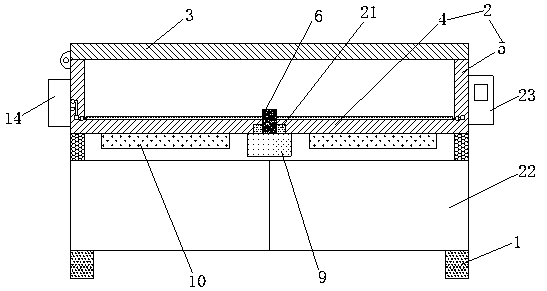

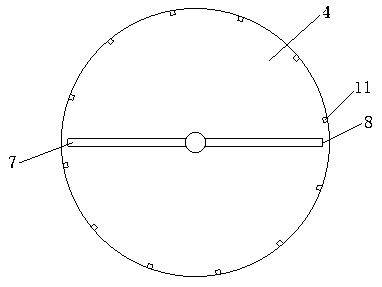

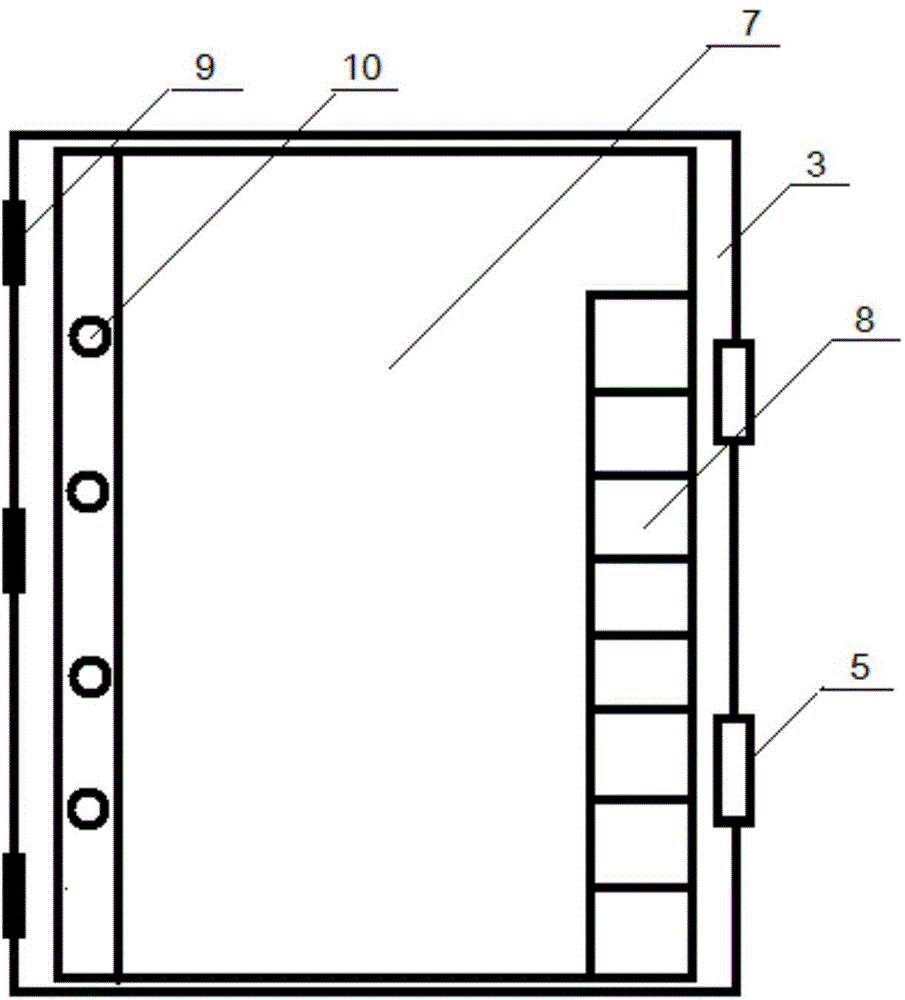

Electronic retrieval file box

InactiveCN107718928ASolve the problem that cannot be used at the same timePlay a double layer of protectionFiling appliancesInternal memoryPassword

Owner:陈红燕

Pot sticker cake processing machine

Owner:邹莉昕

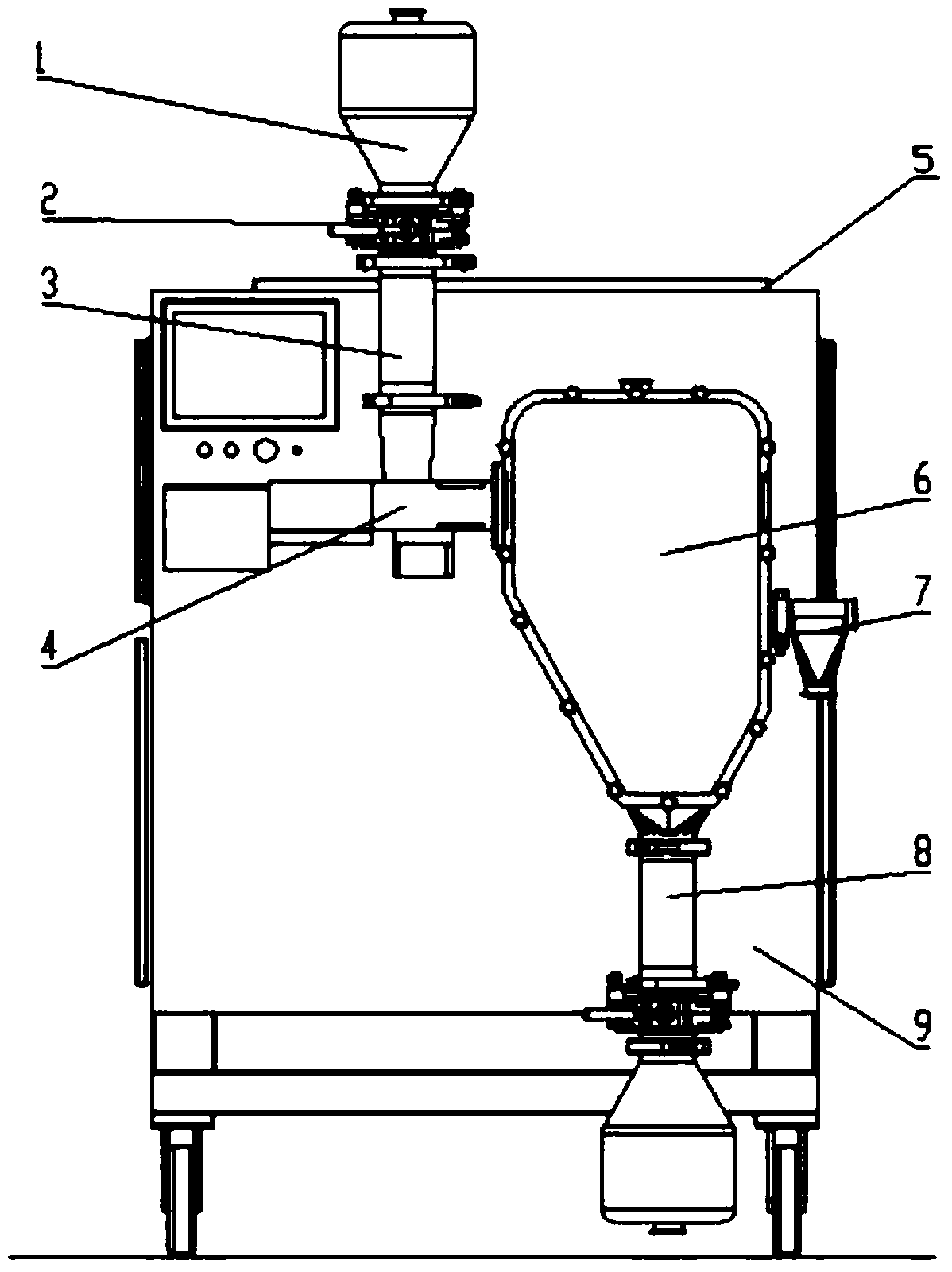

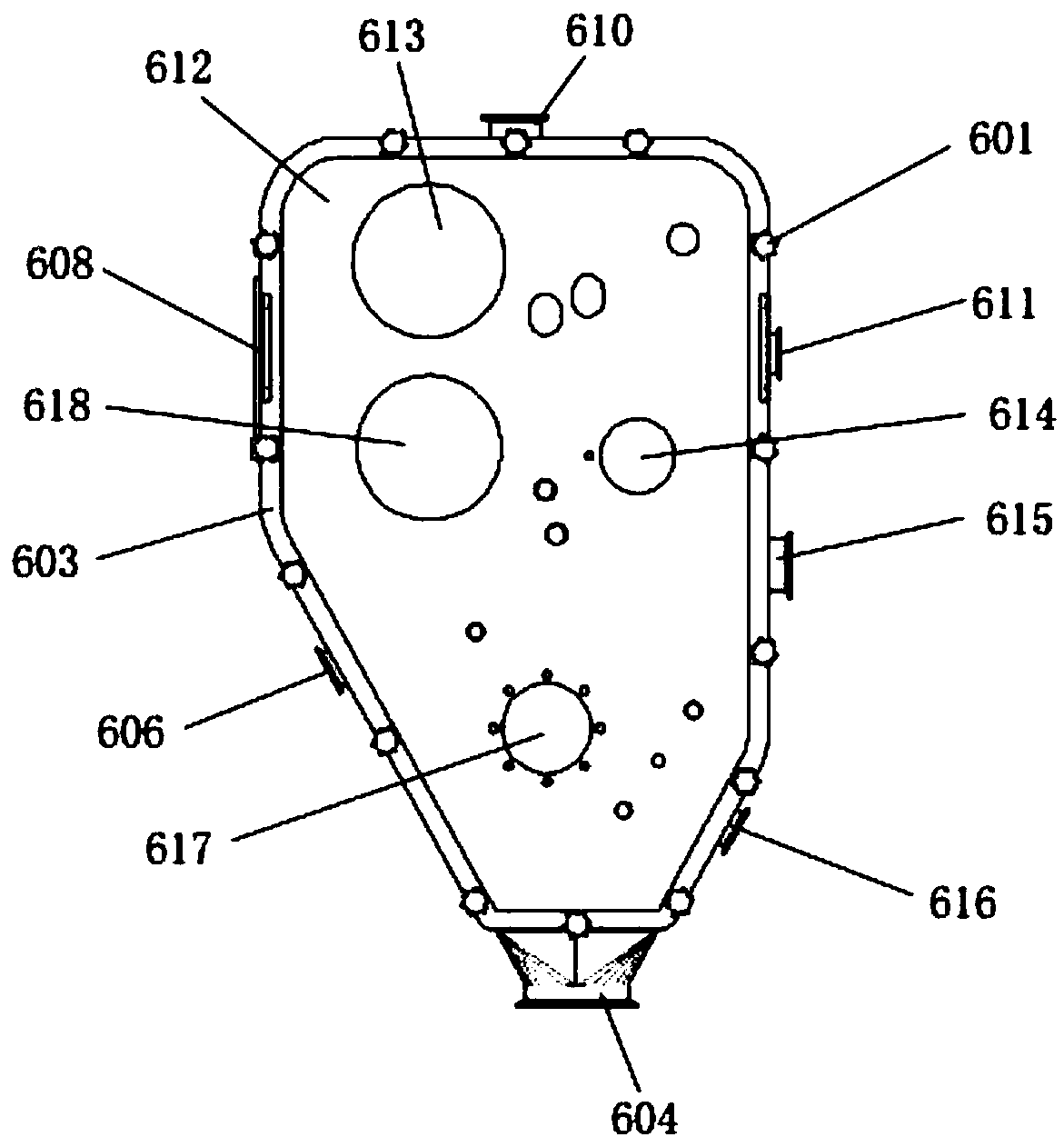

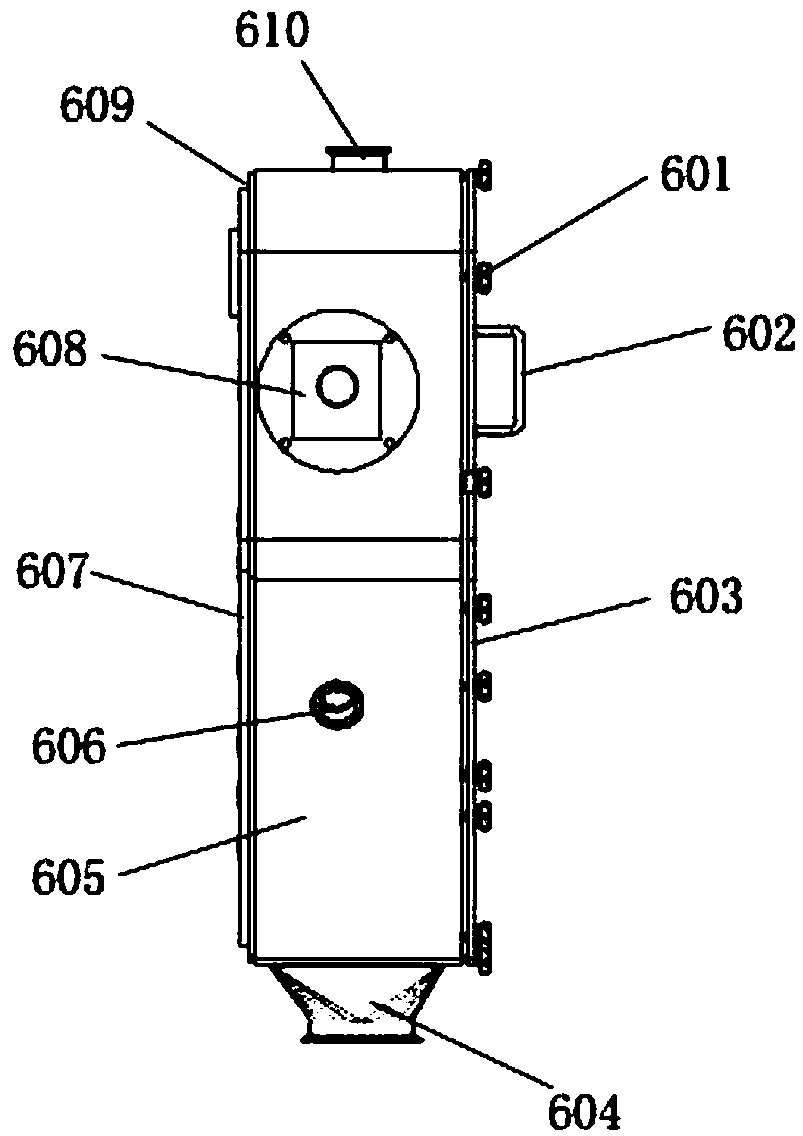

Dry-process granulating machine for anti-tumor medicines

PendingCN109513398AGranulation by pressingAnti-Tumor DrugsFront cover

Owner:南京迦南比逊科技有限公司

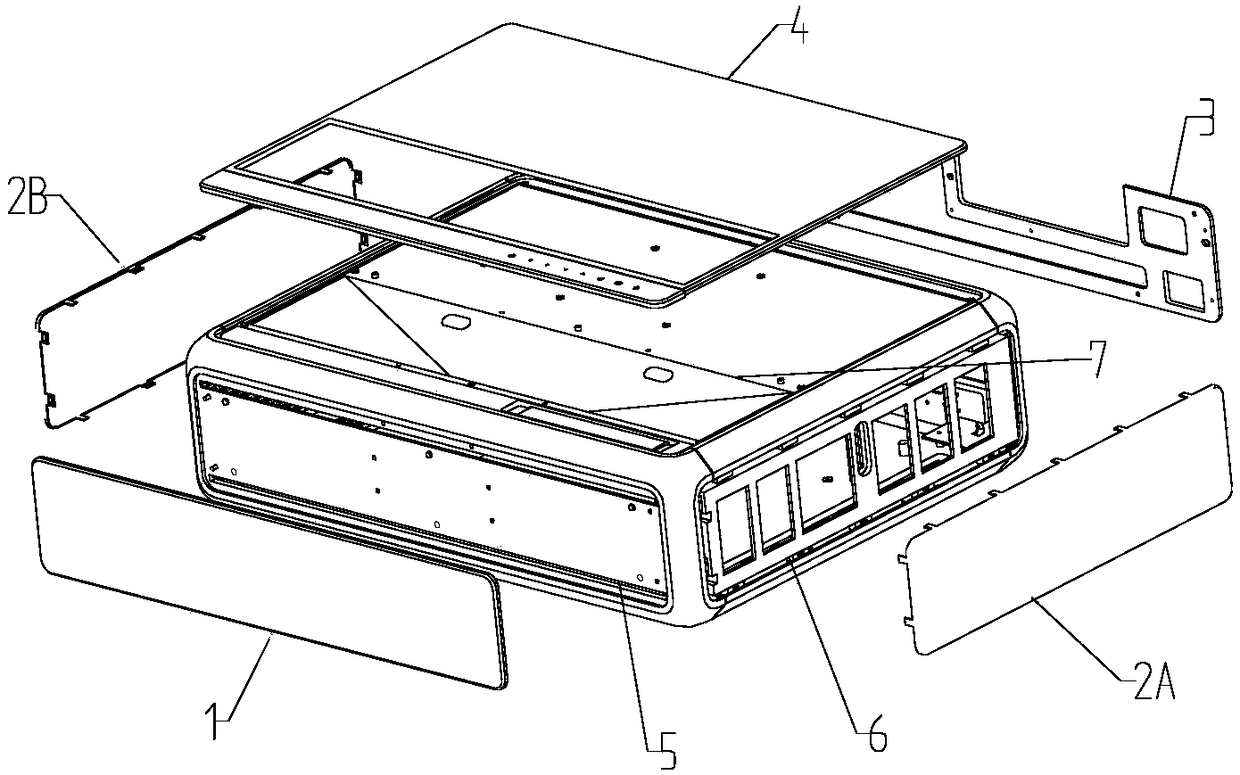

Loudspeaker box

PendingCN112153501AFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsLoudspeakerFront cover

Owner:RUISHENG NEW ENERGY DEV CHANGZHOU +1

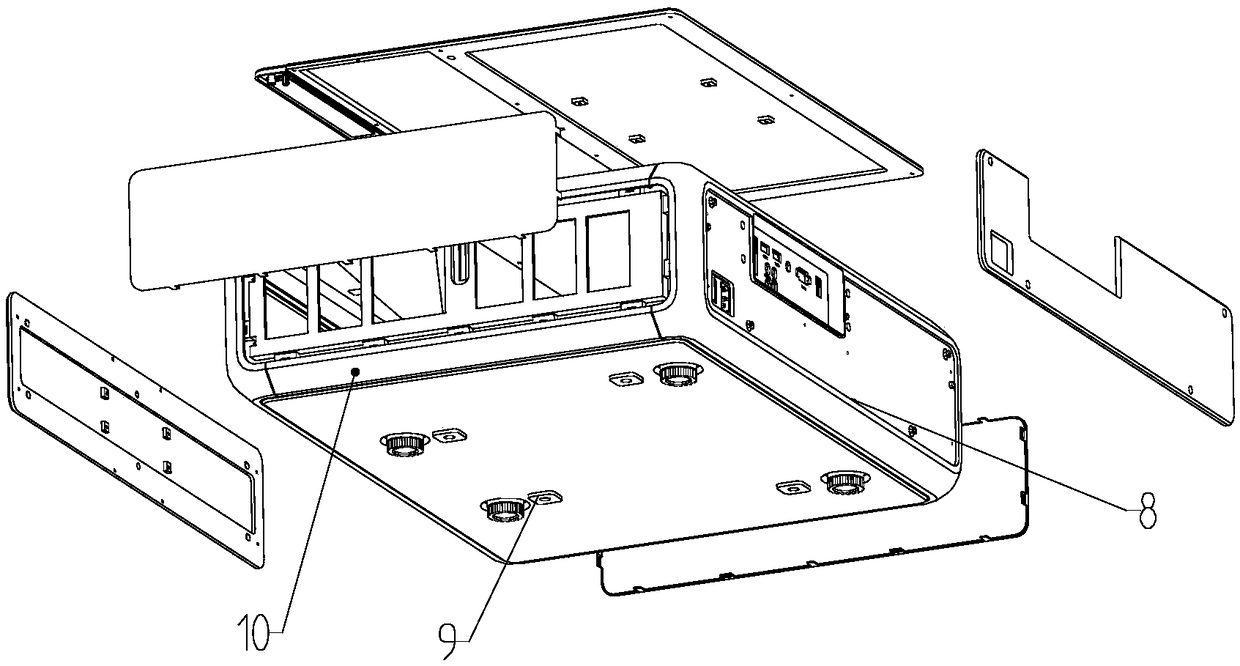

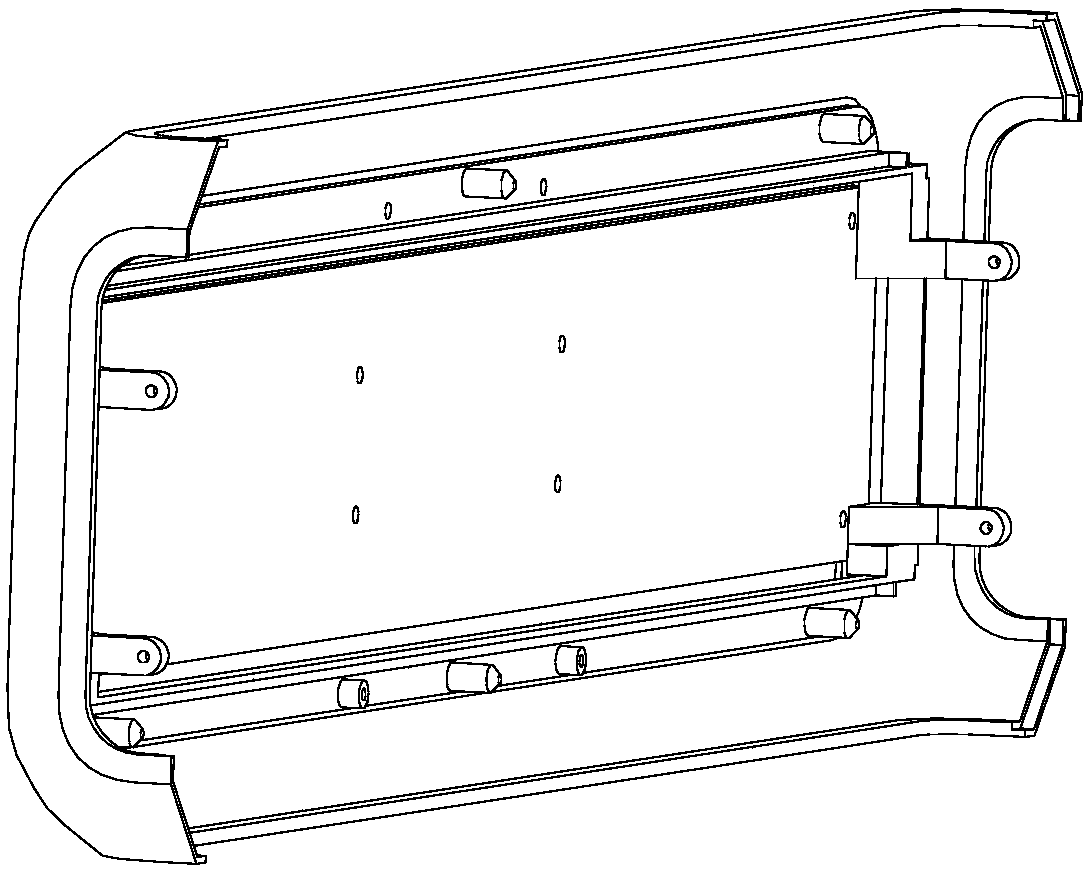

Laser projector shell

Owner:中航国画(上海)激光显示科技有限公司

Attached custom clock

Owner:NANTONG XINYING DESIGN SERVICE

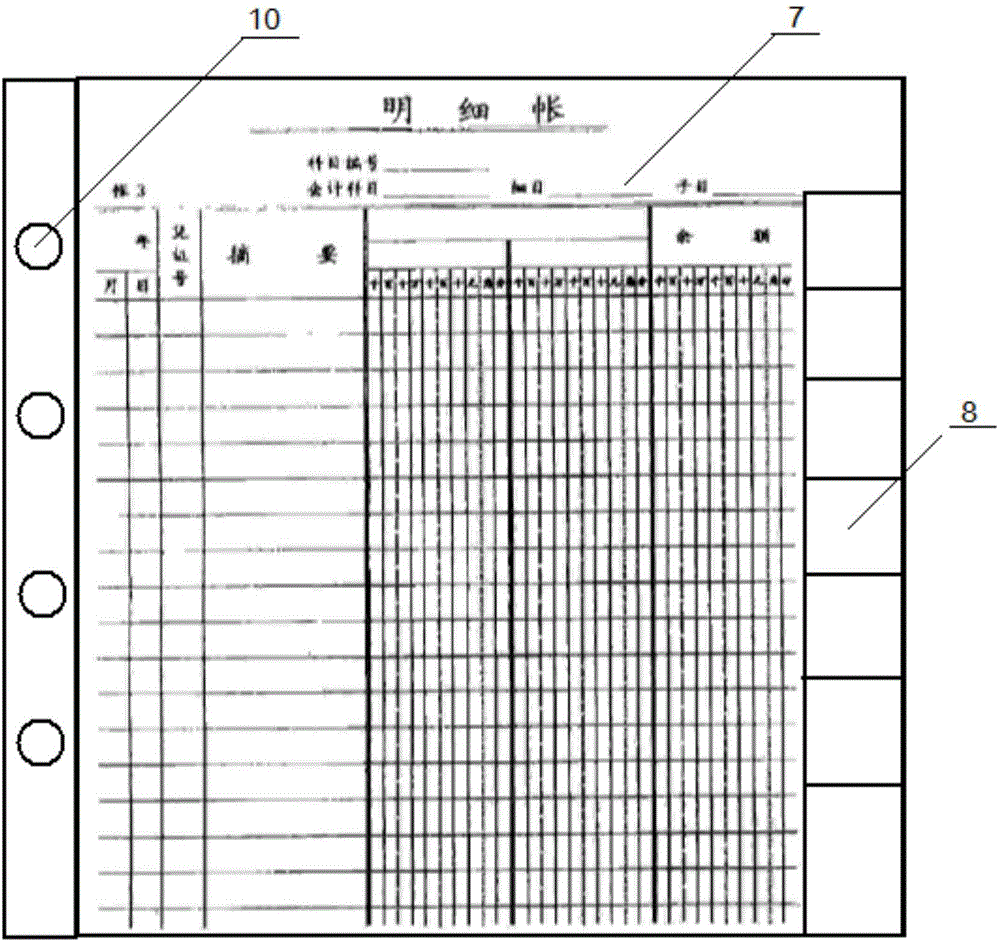

Two-person secret account book

Owner:吴珊

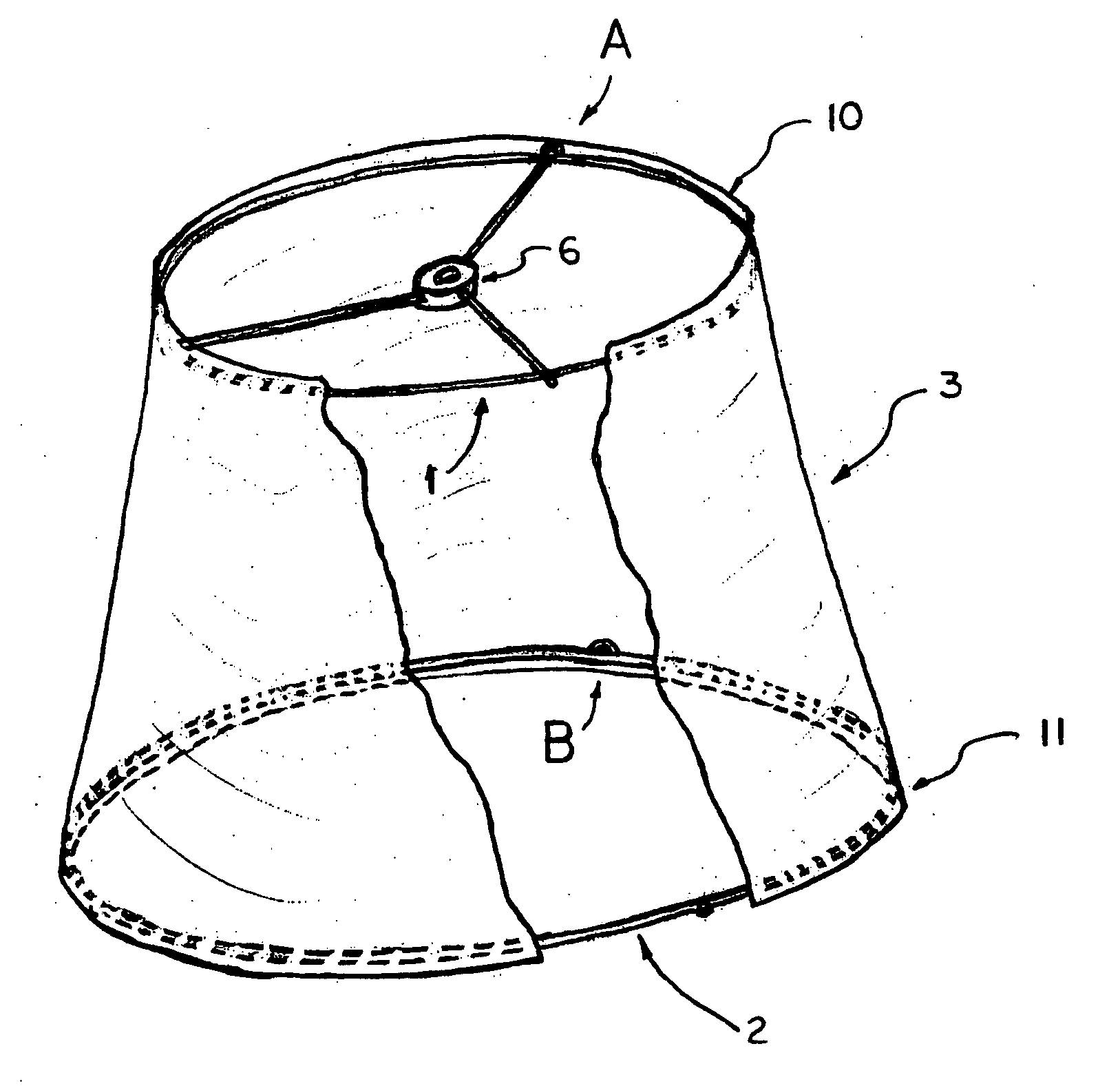

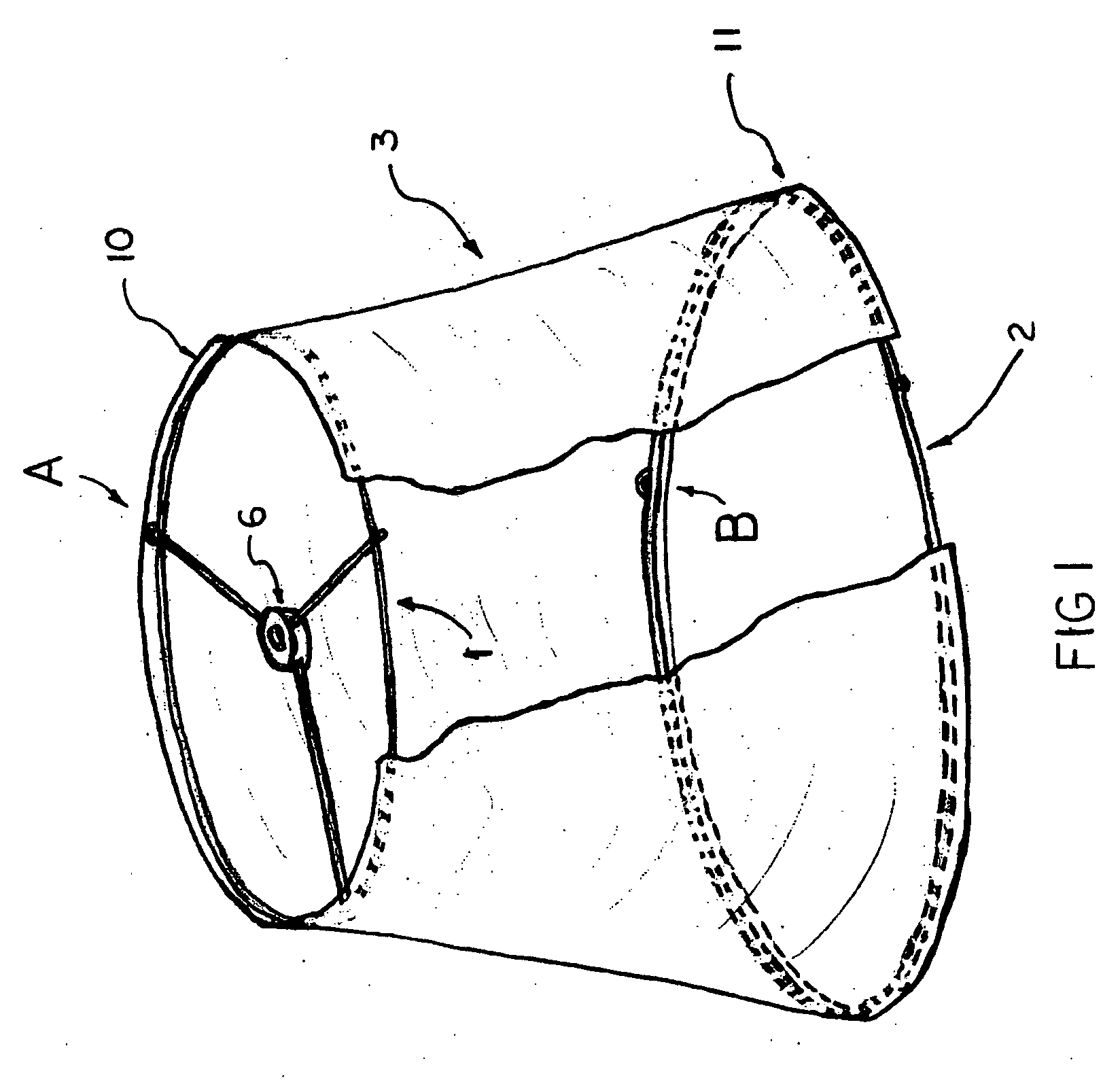

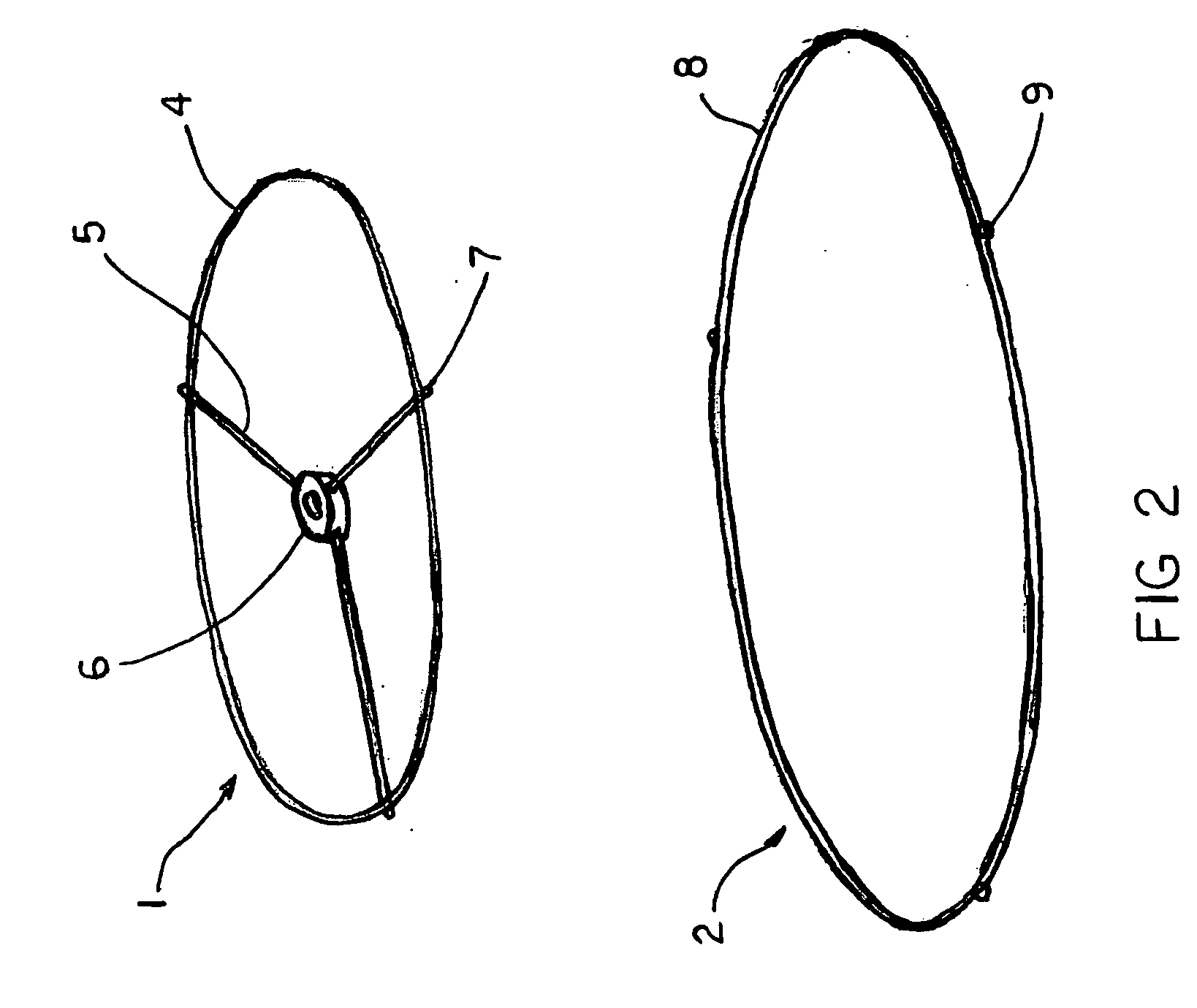

Knock soen hardback collapsile lampshade

Owner:CANEL LIGHTING

Flat cover of machine front cover for vehicle, and machine front cover for vehicle including the same

InactiveCN101272667AStable bootImprove operational reliabilityCasings/cabinets/drawers detailsInstrument housingEngineeringControl material

The invention relates to a flat cover used in the machine front cover of an automobile and a machine front cover used in the automobile which includes the flat cover. In the invention, a front cover (30) is used in the front face of the machine (20) used in a closed automobile. The appearance of the back face of the front cover (30) is formed by the flat cover (40). The upper end of a multilayer high-tech shock controlling material (44) in the flat cover (40) bends toward the vertical direction of the multilayer high-tech shock controlling material (44) to form an upper end plate (50). Furthermore, the two ends of the upper end plate (50) are formed by bending a supporting plate (52) toward the vertical direction of the upper end plate (50). Besides, the two ends of the multilayer high-tech shock controlling material (44) are formed by bending toward the vertical direction of the multilayer high-tech shock controlling material (44). The supporting plate (52) assembles to form a side cover (54). The invention with the structure has the advantages that: deformation of the flat cover can be avoided; the reliability of operation of the machine front cover used in the automobile can be improved; the manufacturing cost also can be reduced.

Owner:LEJIN ELECTRONICS KUNSHAN COMPUTER CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap