Laser projector shell

A technology for laser projectors and casings, which is applied in optics, instruments, projection devices, etc., can solve the problem that the combination configuration scheme of the shape cannot be quickly adjusted and replaced, and achieve the effect of improving the appearance and being cheap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, structure and working process of the present invention will be further described.

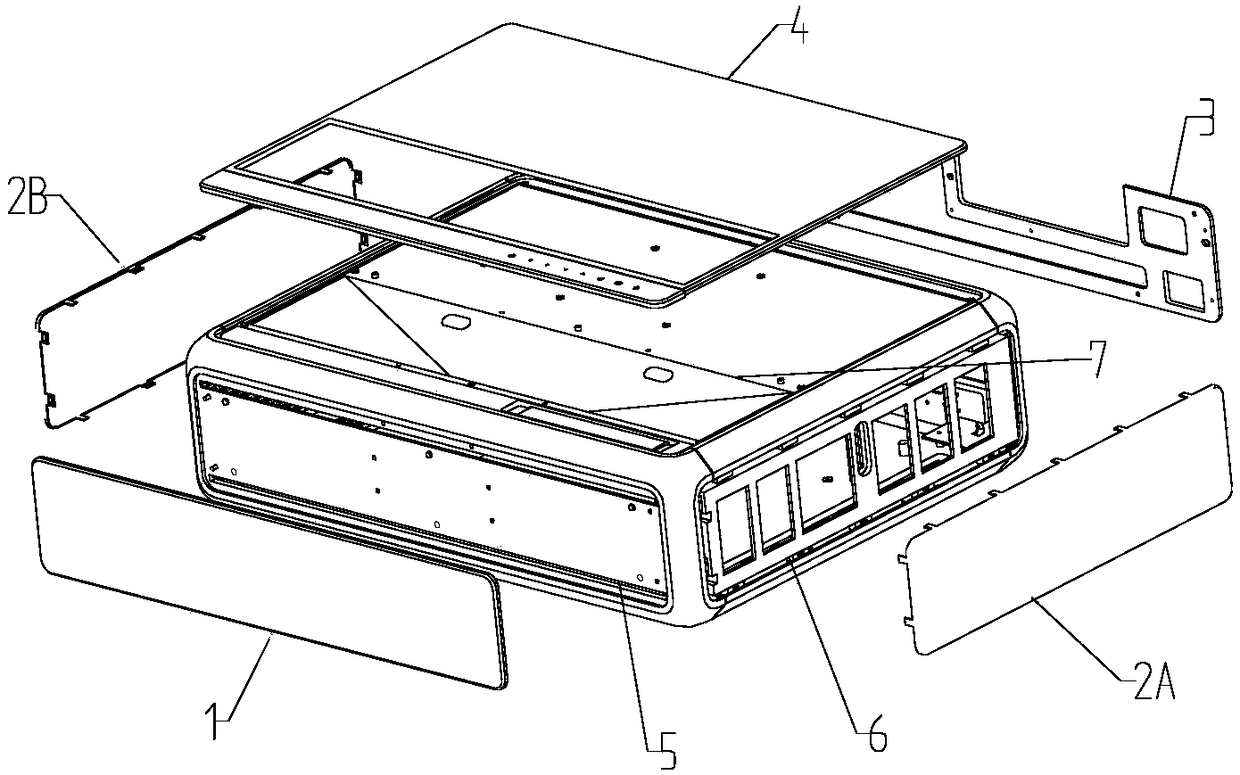

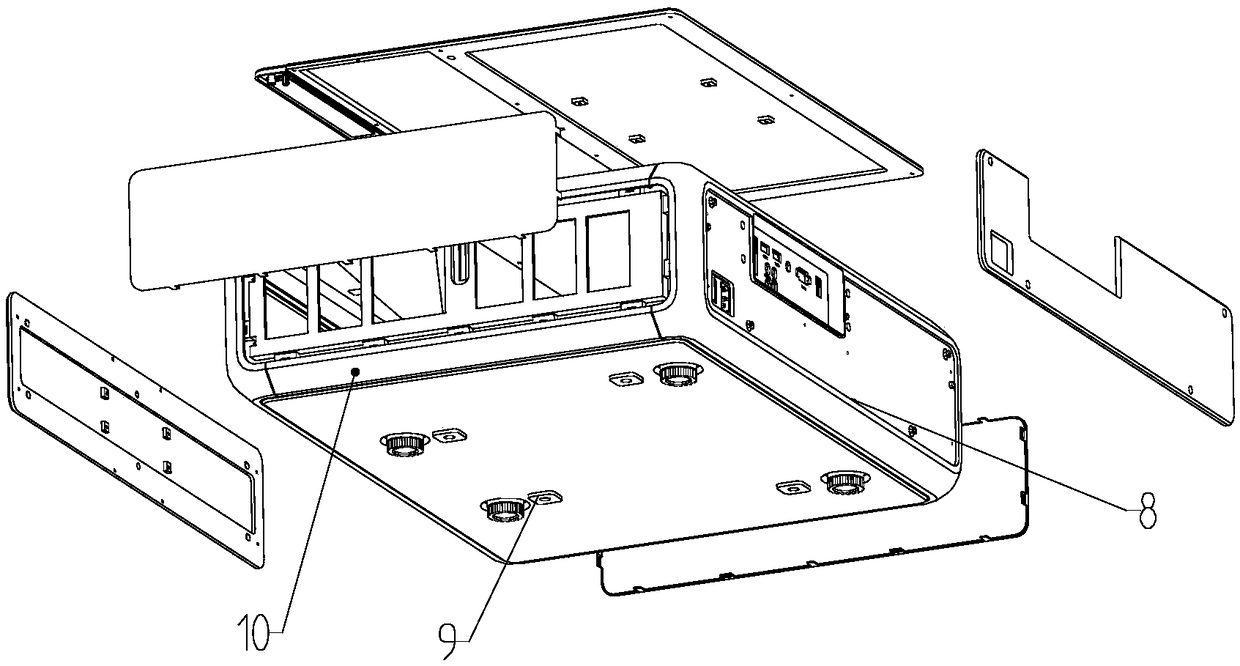

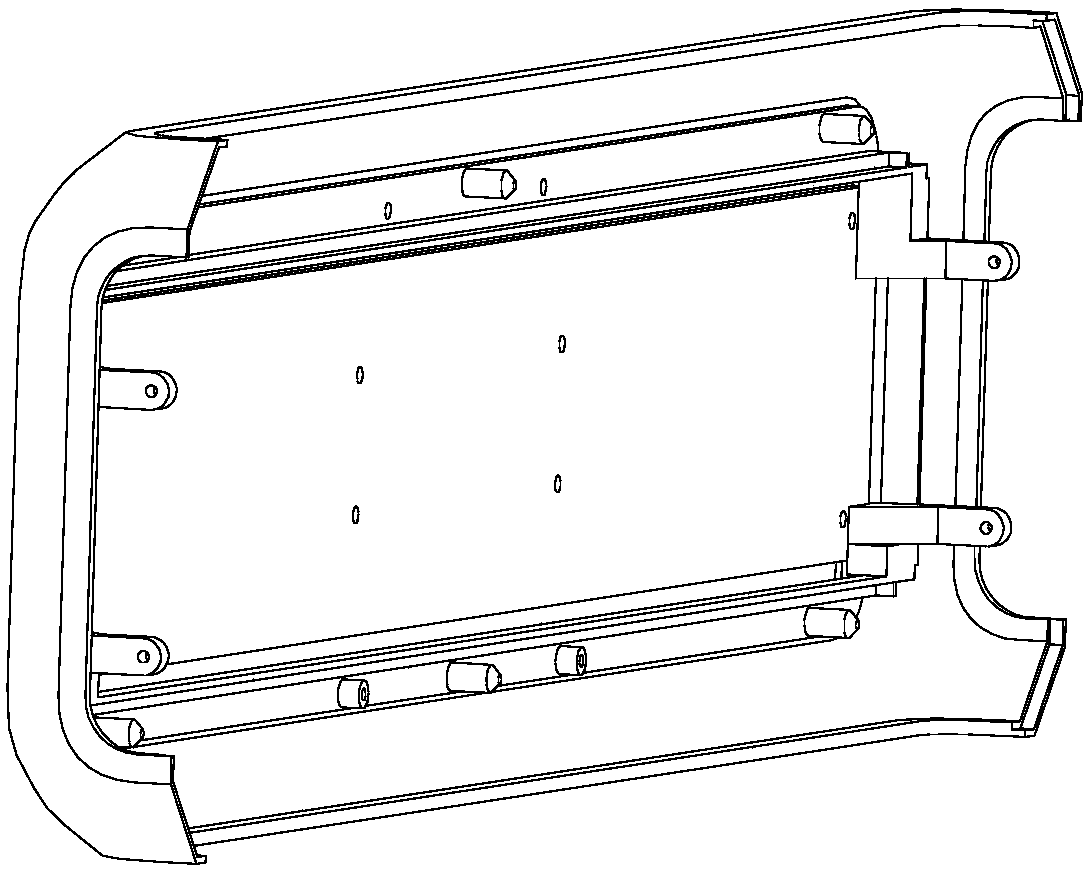

[0029] Such as Figure 1 to Figure 8 As shown, a laser projector casing includes an inner casing and an outer decorative panel, and a connecting mechanism connected to the inner casing is provided on the inner side of the outer decorative panel, wherein the inner casing includes a bottom plate 9, an upper cover 7, and a front cover 5 , rear cover 8, left side plate 6A, right side plate 6B, fixed connection (or be fixed with screw) between left side plate 5A and right side plate 6B and base plate 9; , rear cover 8, left side panel 6A, right side panel 6B are correspondingly assembled upper trim panel 4, front trim panel 1, rear trim panel 3, left trim panel 2A, right trim panel 2B.

[0030] It also includes a decorative frame strip 10, and the decorative frame strip 10 is arranged at the joint between two adjacent surfaces.

[0031] Between t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap