Suspension bridge main cable rope retracting method

A suspension bridge and cable technology, which is applied in the direction of suspension bridges, bridges, bridge forms, etc., can solve the problems of cable strand crossing, zinc layer falling off, loose wires, etc., and achieve the effect of simple and fast operation, avoiding zinc layer falling off, and reducing the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

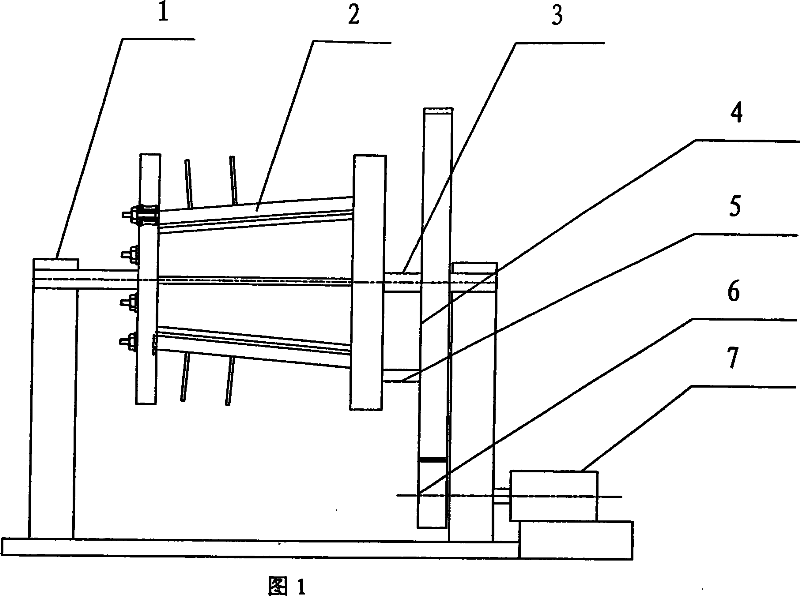

[0018] Referring to Fig. 1, Fig. 1 is a kind of suspension bridge main cable strand receiving device that the present invention adopts, mainly consists of support 1, combined steel plate 2, transmission center shaft 3, large gear shaft 4, dial pin 5, pinion 6 and Motor 7 is made up of. The transmission center shaft 3 is horizontally installed on the bracket 1, and the combined steel plate 2 is set on the transmission center shaft 3; the output end of the motor 7 is connected with the pinion 6, and the pinion 6 meshes with the bull gear 4, and the bull gear 4 is fixedly connected to the transmission center shaft 3, one end of the dial pin 5 is installed inside the gear wheel 4, and the other end is inserted into the combined steel plate 2.

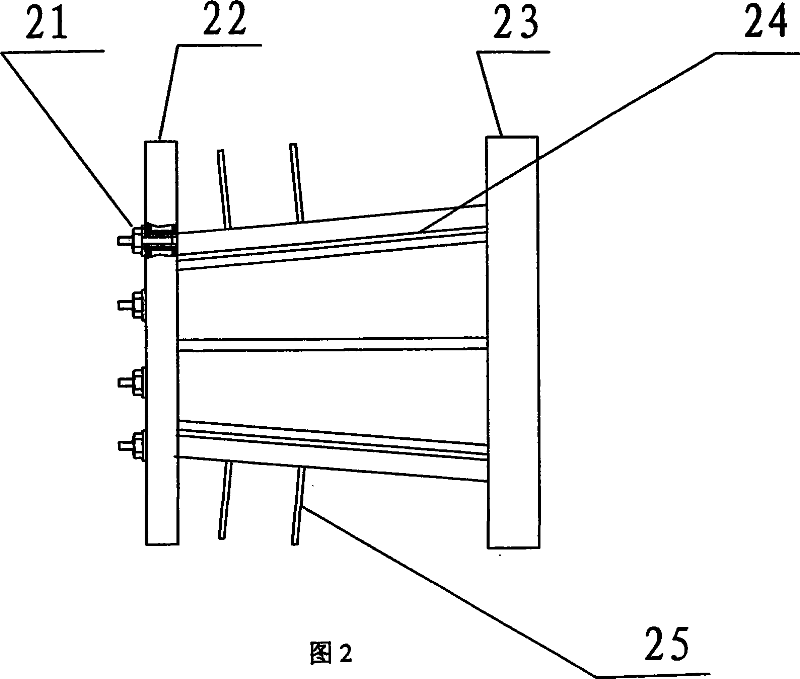

[0019] Referring to FIG. 2 , the combined steel plate 2 is mainly composed of anchor bolts 21 , a front cover 22 , a rear cover 23 , a tapered reel 24 and an isolation post 25 . Described conical reel 24 is arranged between front cover plate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap