Dry-process granulating machine for anti-tumor medicines

A dry granulator and anti-tumor drug technology, applied in the direction of mold extrusion granulation, etc., can solve the problems that the production packaging cannot be exposed to air, the structure of the granulation equipment is not perfect, and the granulation equipment cannot be in direct contact with the air, etc. The effect of good sealing performance and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings of the description.

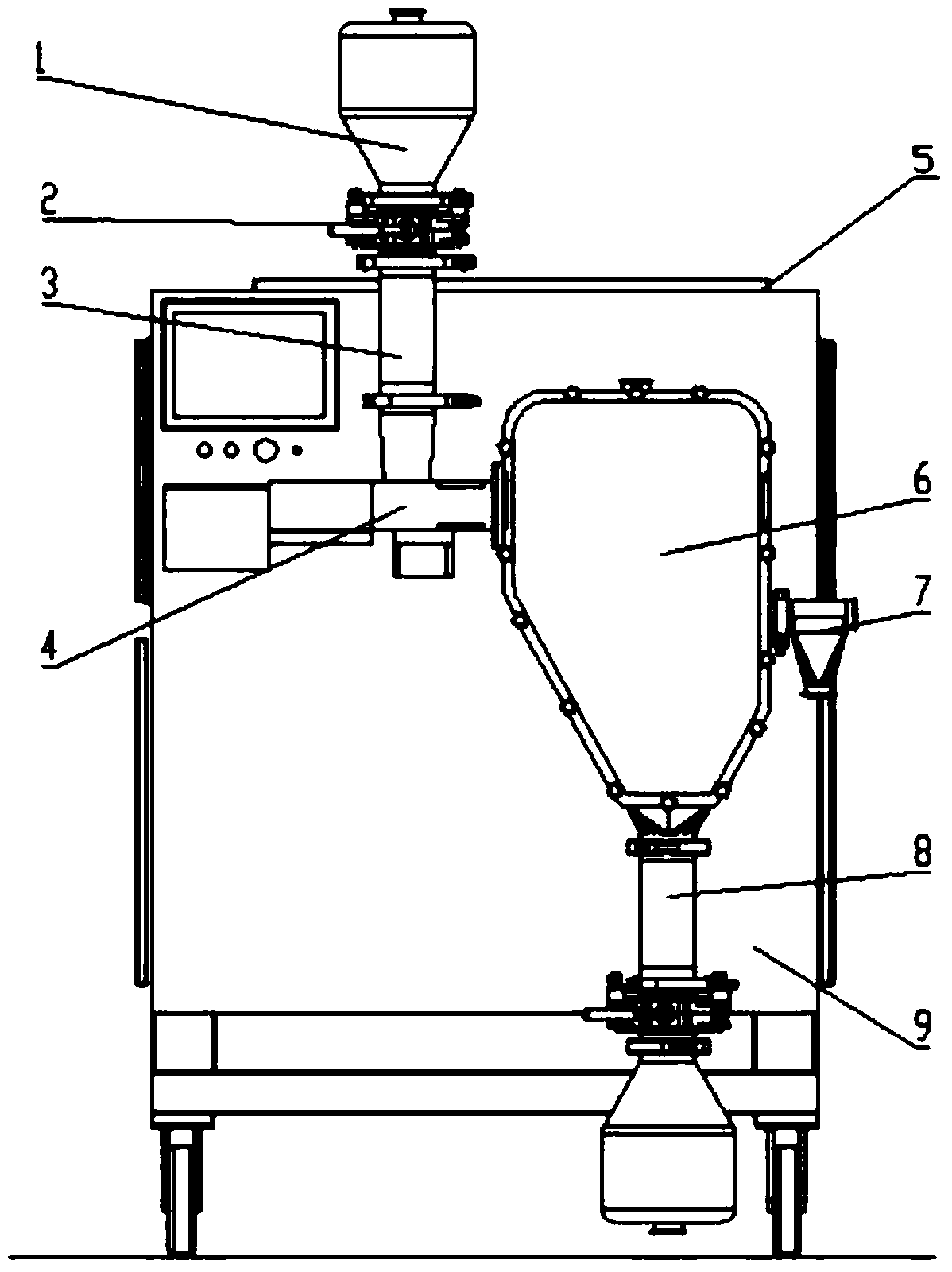

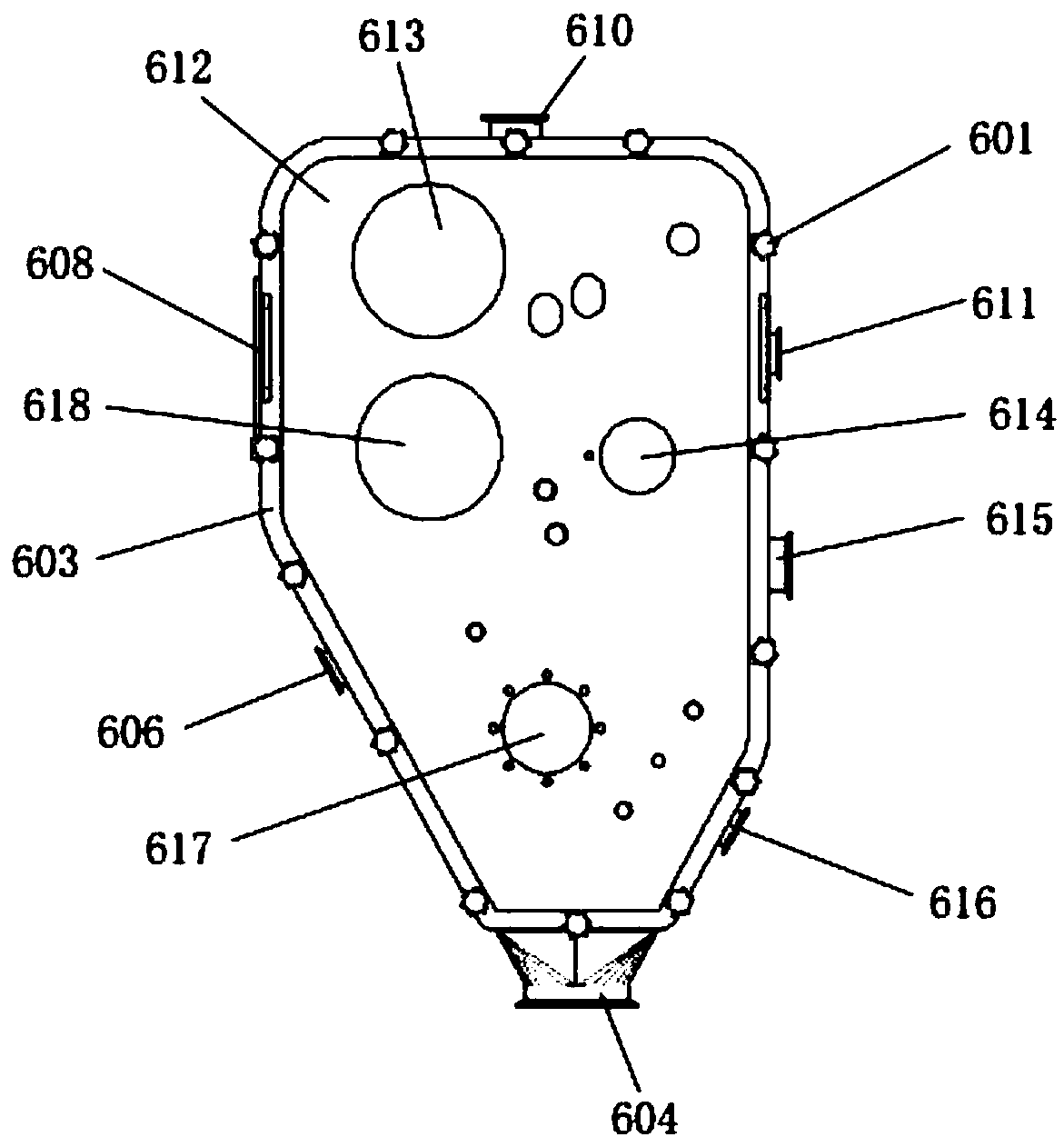

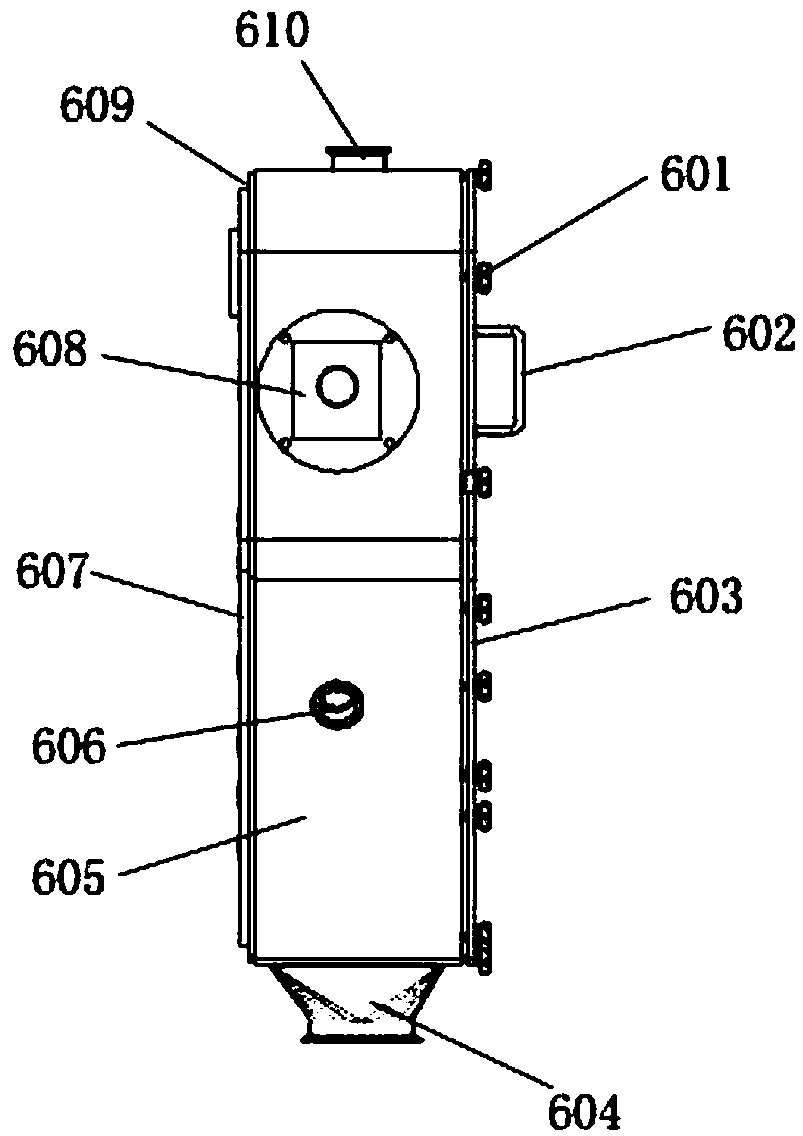

[0032] Such as Figure 1-12 As shown, a dry granulator for antineoplastic drugs includes a box body 5 and a feeding device 4 arranged on the box body 5, an upper pressure roller 93, a lower pressure roller 95, a crushing mechanism and a granulation mechanism, A front cover mechanism 6 is arranged on the outside of the box body 5, and the upper pressing roller 93, the lower pressing roller 95, the crushing mechanism and the granulation mechanism are all arranged in the front cover mechanism 6, and together with the front cover mechanism 6, a granulation area is formed; The device 4 is provided with a feeding device, and the feeding device includes a material barrel 1, a valve 2 and a feeding connecting pipe 3; the front cover mechanism 6 is connected with a discharging device 8; the discharging device has the same structure as the feeding device; The fe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap