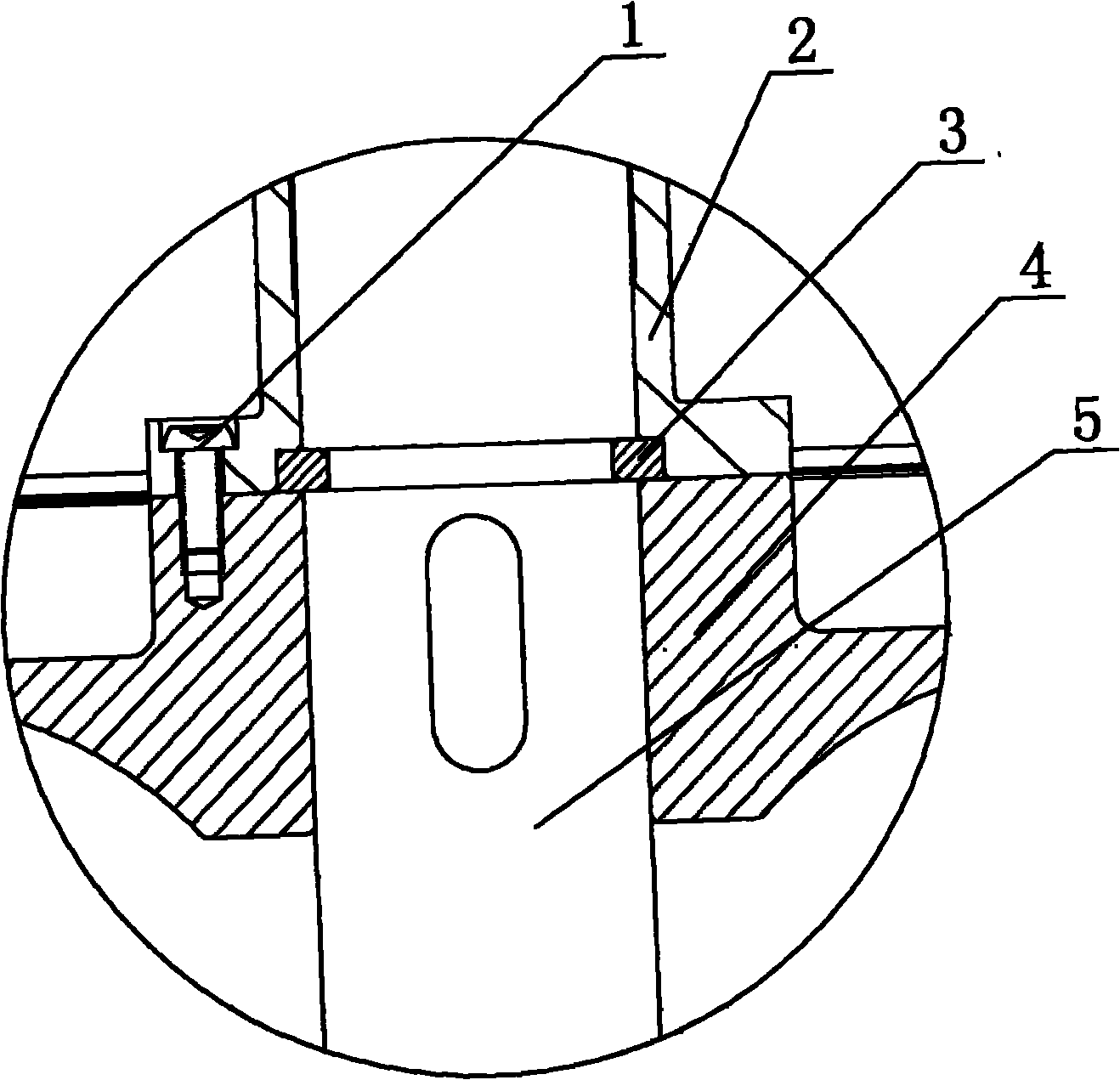

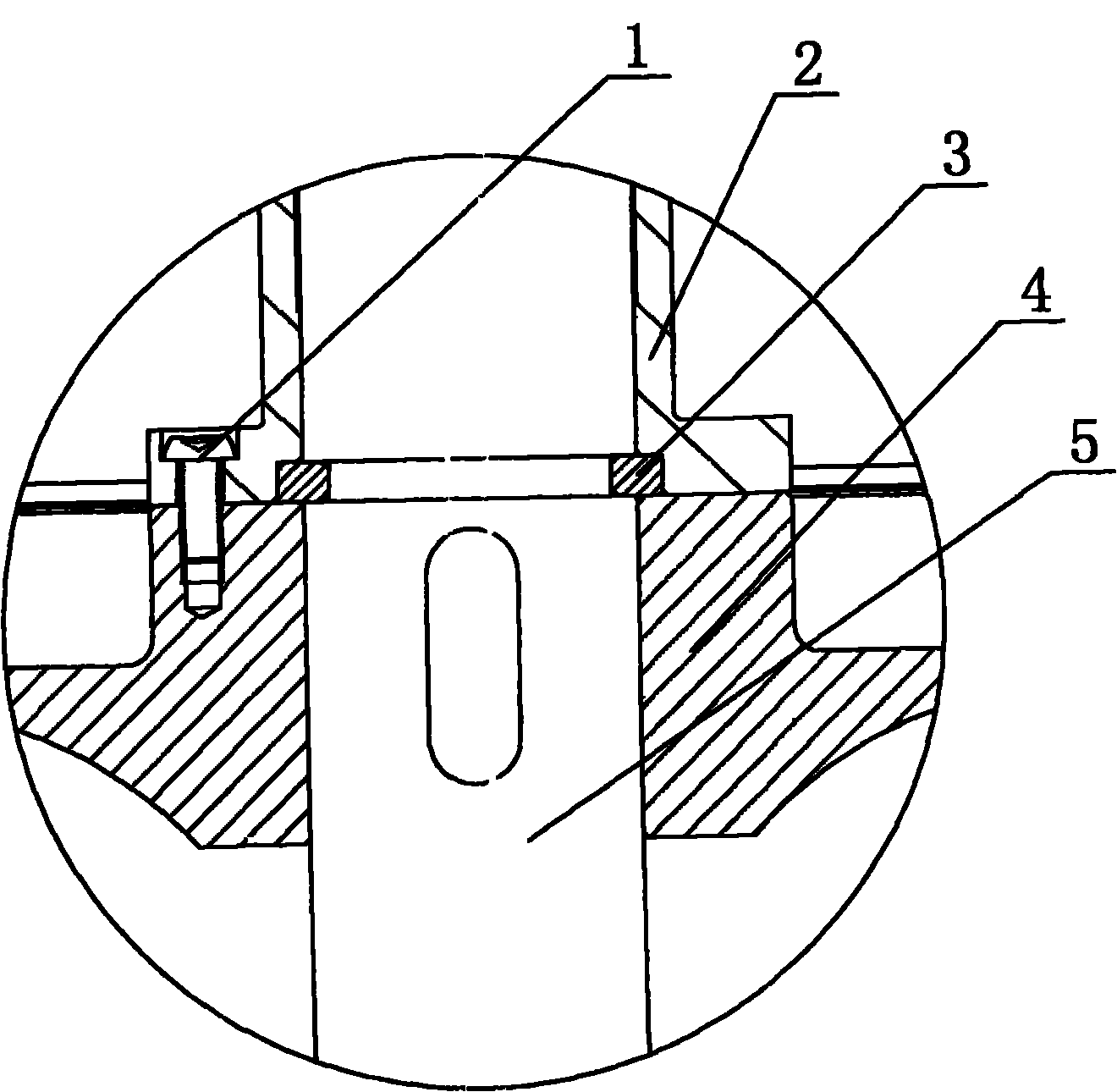

Vertical centrifugal pump impeller positioning device

A centrifugal pump impeller and positioning device technology, which is applied to non-variable pumps, parts of pumping devices for elastic fluids, pumps, etc., can solve the problems of high processing accuracy, high manufacturing cost, and easy falling of impellers , to achieve the effect of low machining accuracy, low manufacturing cost and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] As shown in the vertical centrifugal pump impeller positioning device, the pump shaft 5 is provided with an impeller 4, and the pump shaft 5 on one side of the impeller 4 is provided with a ring groove, and a snap ring 3 is provided in the ring groove, and the snap ring 3 is on the other side. There is a shaft sleeve 2 on the side, and a screw 1 is provided on the shaft sleeve 2. The screw 1 fastens the shaft sleeve 2 and the impeller 4 and is stuck on the snap ring 3. Since the pump shaft 5 on the side of the impeller 4 is provided with a ring groove, A snap ring 3 is provided in the ring groove, and a shaft sleeve 2 is provided on the other side of the snap ring 3, and a screw 1 is provided on the shaft sleeve 2, and the screw 1 fastens the shaft sleeve 2 and the impeller 4 and is stuck on the snap ring 3, each The machining accuracy requirements of these parts are low, the machining is easy, the manufacturing cost is low, the impeller is not easy to fall off, and the nor

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap