Centrifugal pump with variable impeller width

A centrifugal pump, a variable technology, applied in the field of centrifugal pumps, can solve the problems of unable to monitor the water flow and water pressure inside the pump body, and the centrifugal pump cannot adjust the width of the impeller, so as to achieve the effect of preventing overpressure damage and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

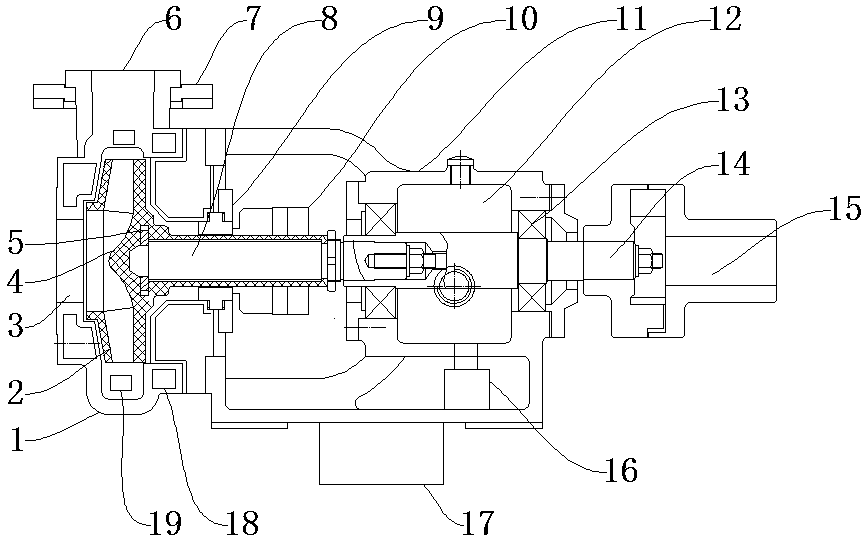

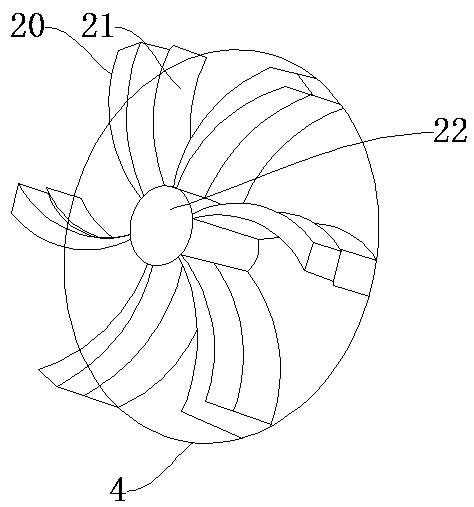

[0027] Such as Figure 1-Figure 4 As shown, a centrifugal pump with variable vane width includes a centrifugal pump main body 1, an inlet sealing ring 2, an impeller mounting seat 4, a connecting ear plate 7, and a sealing sleeve 10. The centrifugal pump main body 1 is internally provided with the Inlet sealing ring 2, a water inlet 3 is installed above the inlet sealing ring 2, and the water inlet 3 inputs external water into the inside of the centrifugal pump main body 1, and the other side of the inlet sealing ring 2 is provided with the impeller Mounting seat 4, a pump transmission shaft 8 is installed on one side of the impeller mounting seat 4, and the pump transmission shaft 8 drives the impeller mounting seat 4 to move, between the impeller mounting seat 4 and the pump transmission shaft 8 A flat key 5 is provided, and the flat key 5 connects the impeller mounting sea

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap