Equipment and method for guaranteeing decolorizing efficiency in process of extracting salt from coking desulfurization waste solution

A technology for coking desulfurization waste liquid and decolorization efficiency, which is applied in chemical instruments and methods, water/sewage treatment equipment, adsorbed water/sewage treatment, etc. efficiency, ensure continuous production, and avoid the effect of tower blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

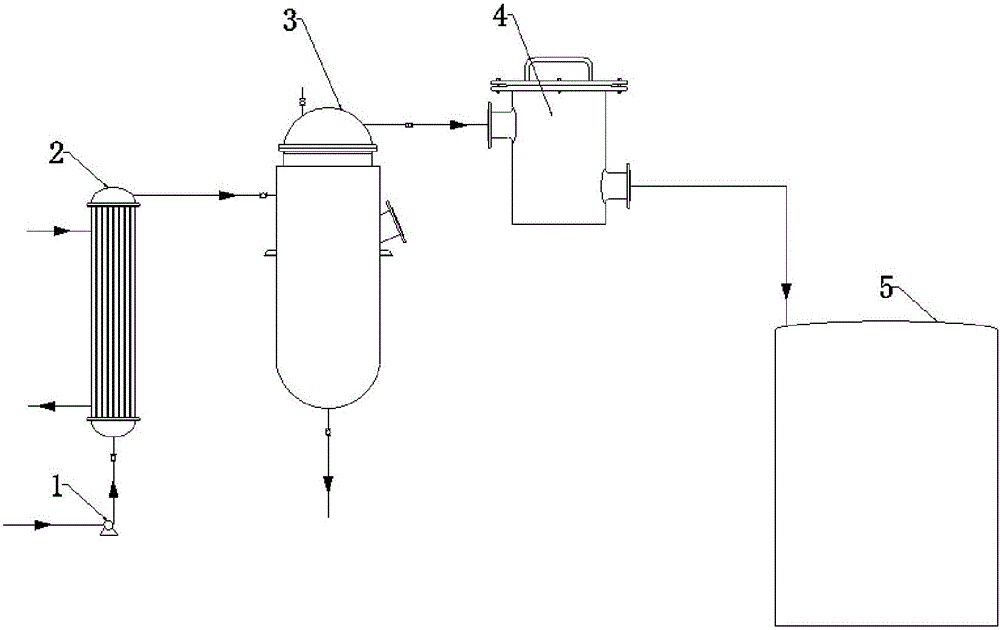

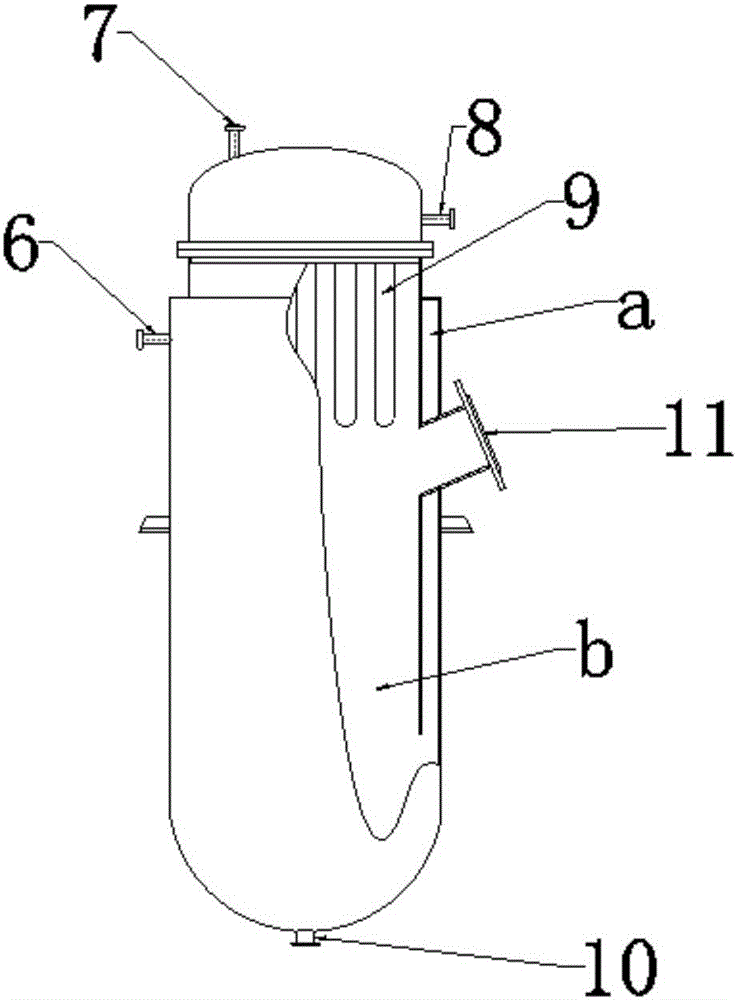

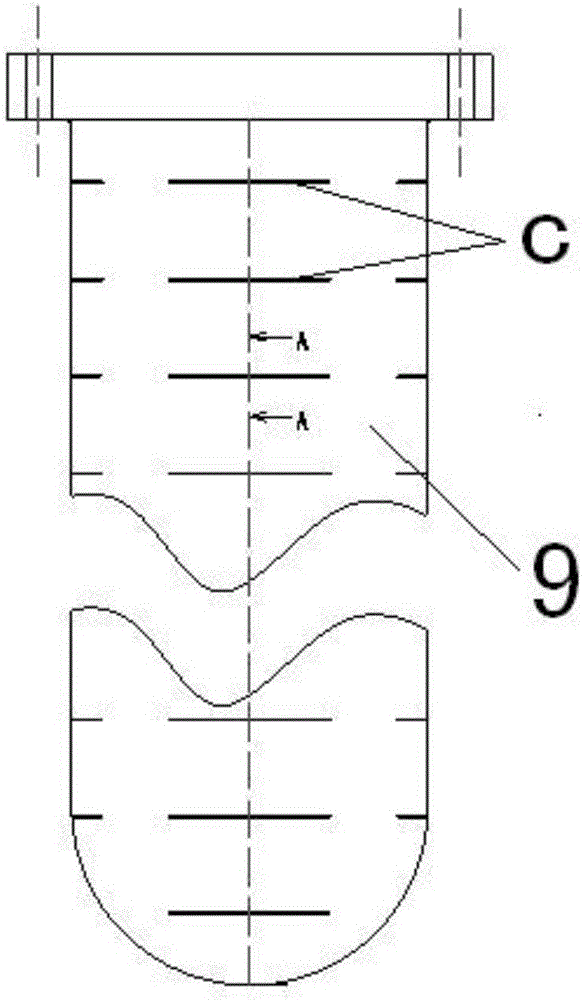

[0035] Such as figure 1 As shown, this embodiment is a device for ensuring the decolorization efficiency in the process of extracting salt from coking desulfurization waste liquid, including a decolorization feeding pump 1, a preheater 2, a decolorization tower 3, and a basket filter 4 which are sequentially connected through pipelines And decolorization supernatant liquid storage tank 5. Such as figure 2 As shown, the decolorization tower 3 is a jacket type, including a jacket layer a and an inner layer b positioned on the outside, the lower part of the jacket layer a communicates with the inner layer b, the lower part of the inner layer b has activated carbon, and the upper part There are several hollow filter cartridges 9, the upper part of the outer wall of the decolorization tower 3 has a decolorization tower feed port 6, the bottom has an activated carbon discharge port 10, and the middle part has an activated carbon addition port 11 extending through the jacket layer a i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap