Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Lanthanum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum is a chemical element with the symbol La and atomic number 57. It is a soft, ductile, silvery-white metal that tarnishes slowly when exposed to air and is soft enough to be cut with a knife. It is the eponym of the lanthanide series, a group of 15 similar elements between lanthanum and lutetium in the periodic table, of which lanthanum is the first and the prototype. It is also sometimes considered the first element of the 6th-period transition metals, which would put it in group 3, although lutetium is sometimes placed in this position instead. Lanthanum is traditionally counted among the rare earth elements. The usual oxidation state is +3. Lanthanum has no biological role in humans but is essential to some bacteria. It is not particularly toxic to humans but does show some antimicrobial activity.

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

Nano-grade lanthanum titanium compound oxide, its preparation method and application

InactiveCN1394680AReduce viscosityReduce the temperatureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOligomerLactide

Owner:CHONGQING UNIV

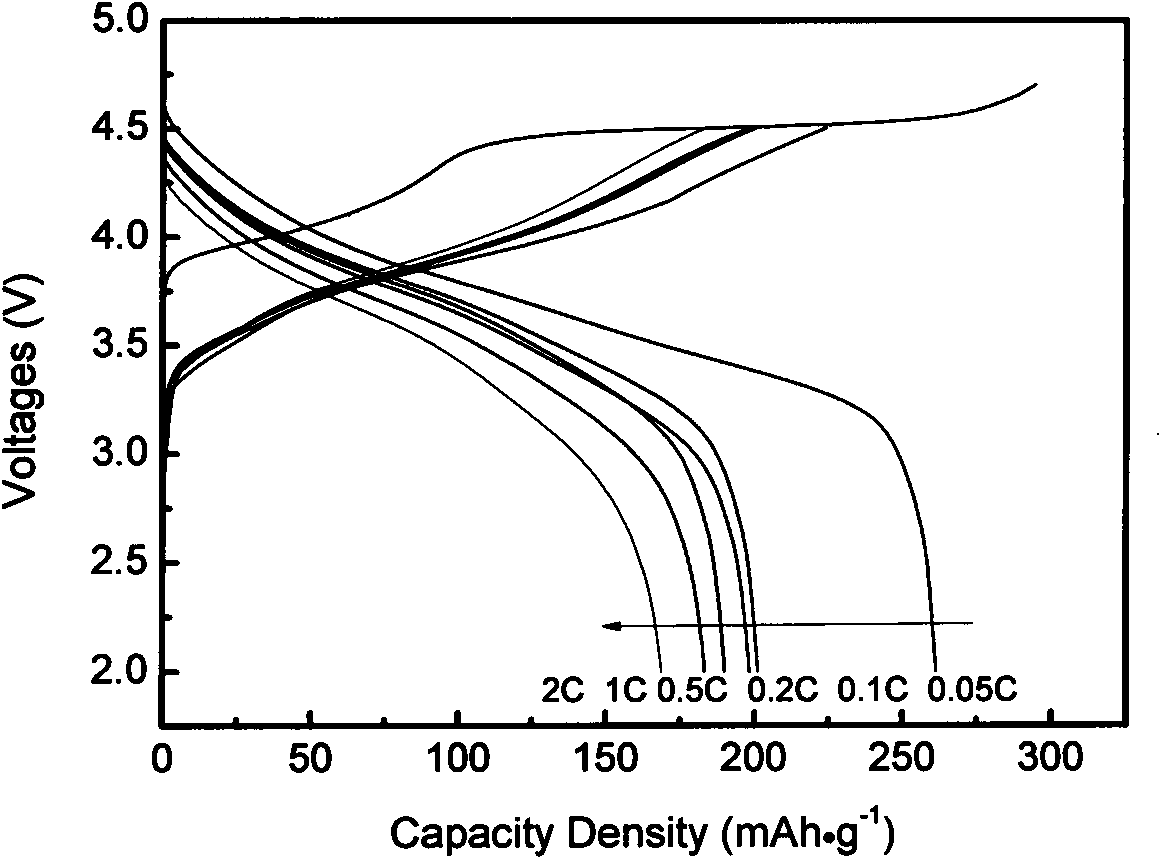

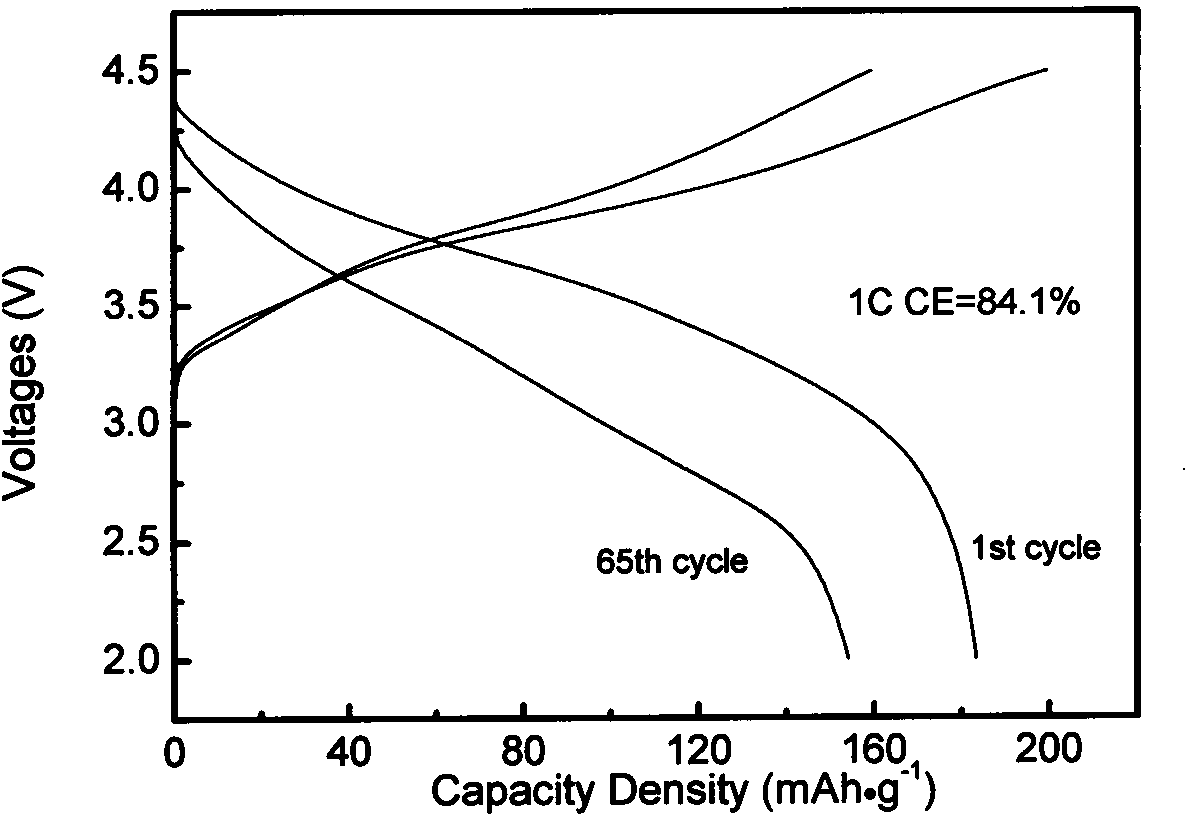

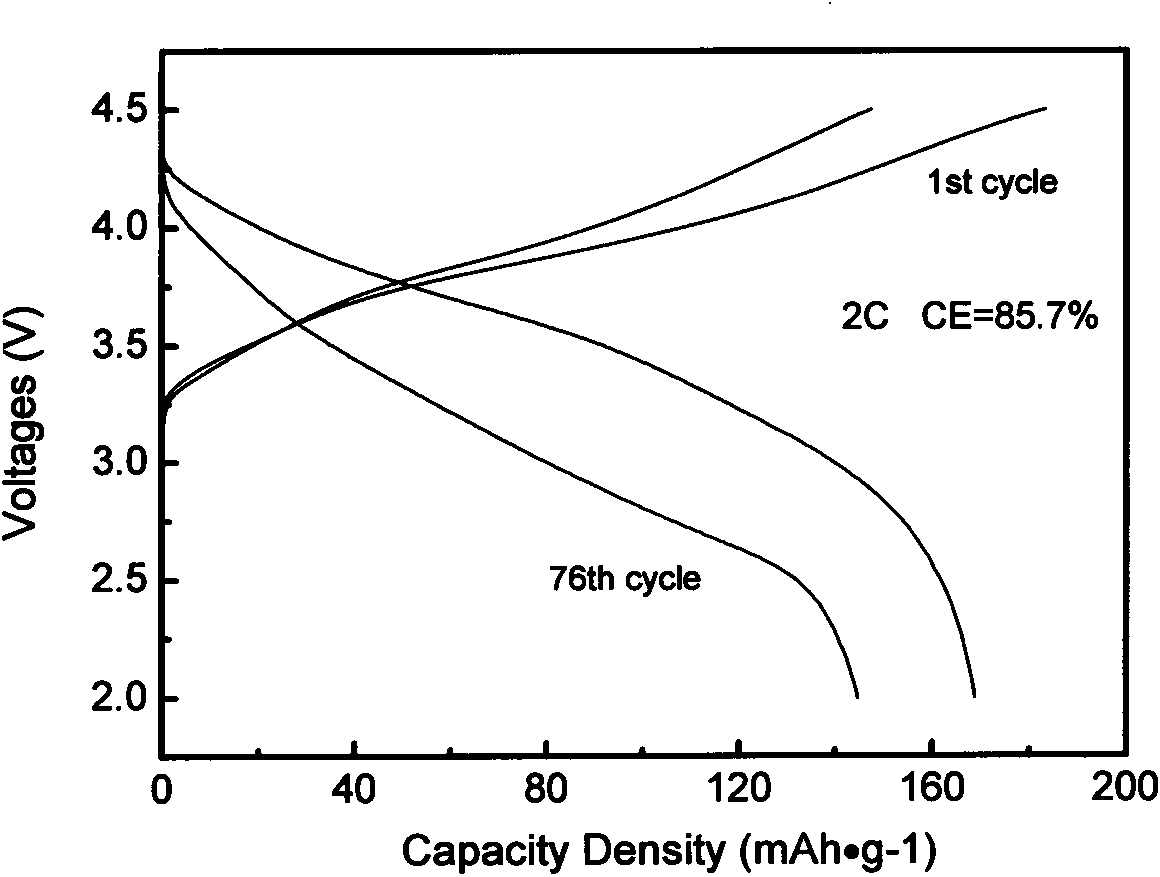

Modified lithium-rich manganese-based cathode material for lithium ion battery

ActiveCN103682290AImprove the first Coulombic efficiencyImprove cycle performanceCell electrodesManganeseStrontium

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

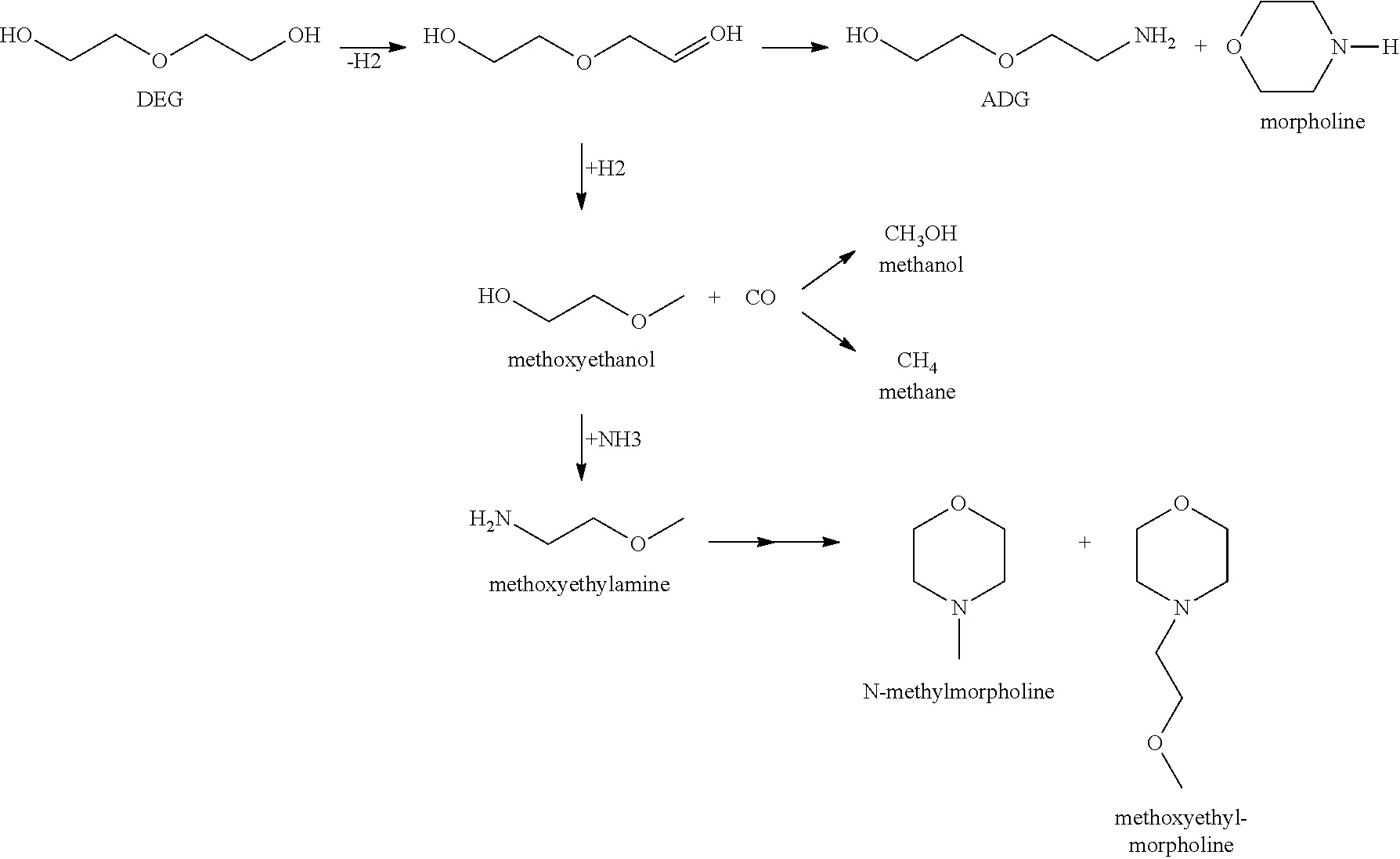

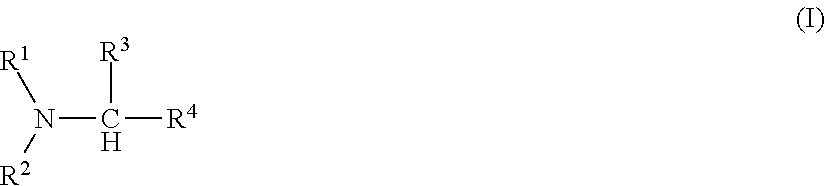

Catalyst and process for preparing an amine

ActiveUS8318982B2Enhances their economic viabilitySpeed up the conversion processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCeriumKetone

Owner:BASF AG

Modified graphene reinforced magnesium matrix metal material and preparation method thereof

The invention discloses a modified graphene reinforced magnesium matrix metal material and a preparation method thereof. The modified graphene reinforced magnesium matrix metal material comprises the following components in percentages by mass: 0.02-0.5wt% of modified graphene, 5.9-11.2wt% of copper, 1.2-4.6wt% of silicon dioxide, 1.4-5.6wt% of aluminum oxide, 1.3-7.8wt% of carbon nanotubes, 4.5-7.9wt% of nickel, 1.3-3.8wt% of titanium dioxide, 1.3-4.6wt% of lanthanum oxide and the balance of magnesium. The mechanical property of the modified graphene reinforced magnesium matrix metal material can still be good at the temperature of minus 20 DEG C; and the performance parameters such as the tensile strength and the elongation of the magnesium matrix metal material are increased, and are higher than the performance parameters of commercial alloy by 7-11%.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

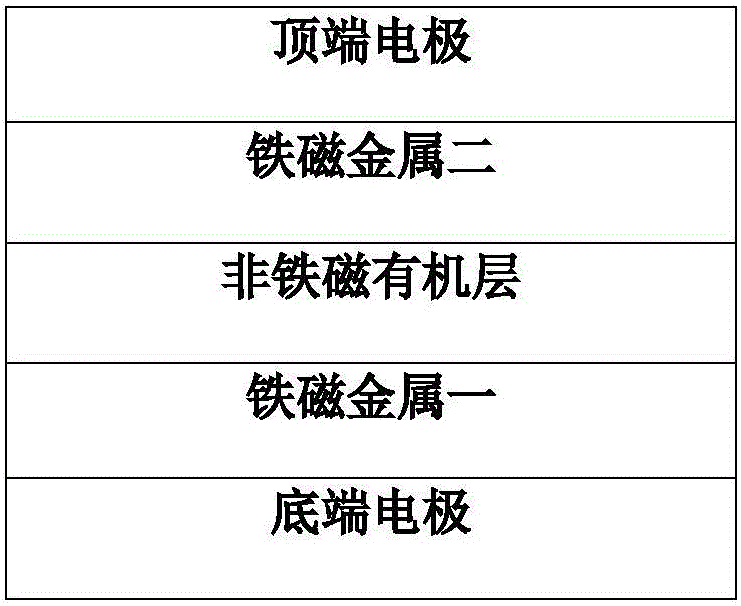

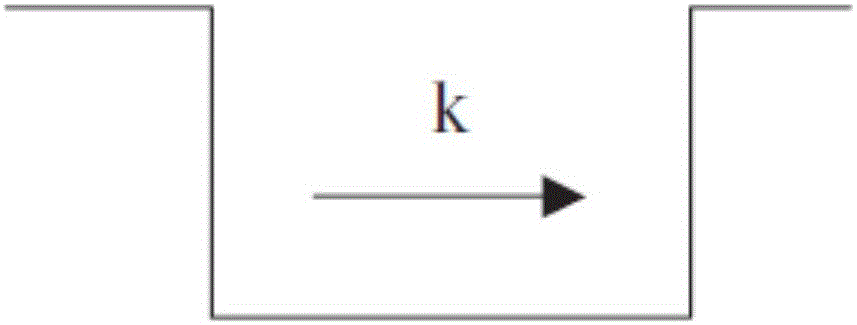

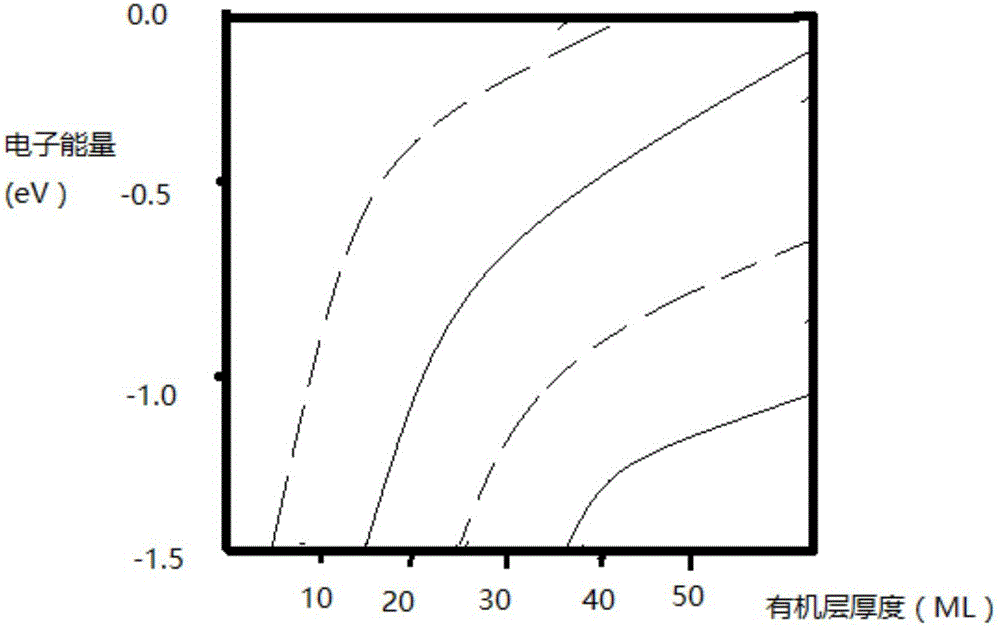

Light control-based organic spin memory cell

ActiveCN105931662AMagnetic-field-controlled resistorsGalvano-magnetic material selectionPhysicsLanthanum

Owner:BEIHANG UNIV

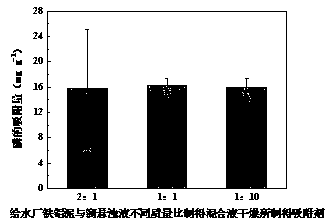

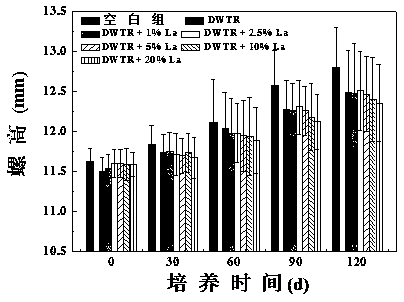

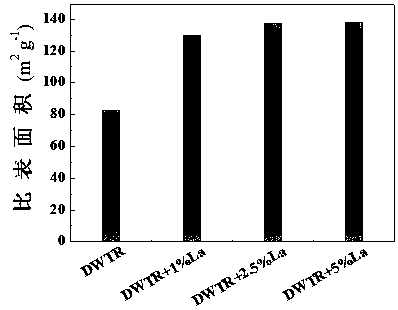

Phosphorus adsorbent based on water supply plant iron-aluminum mud and preparation method of phosphorus adsorbent

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

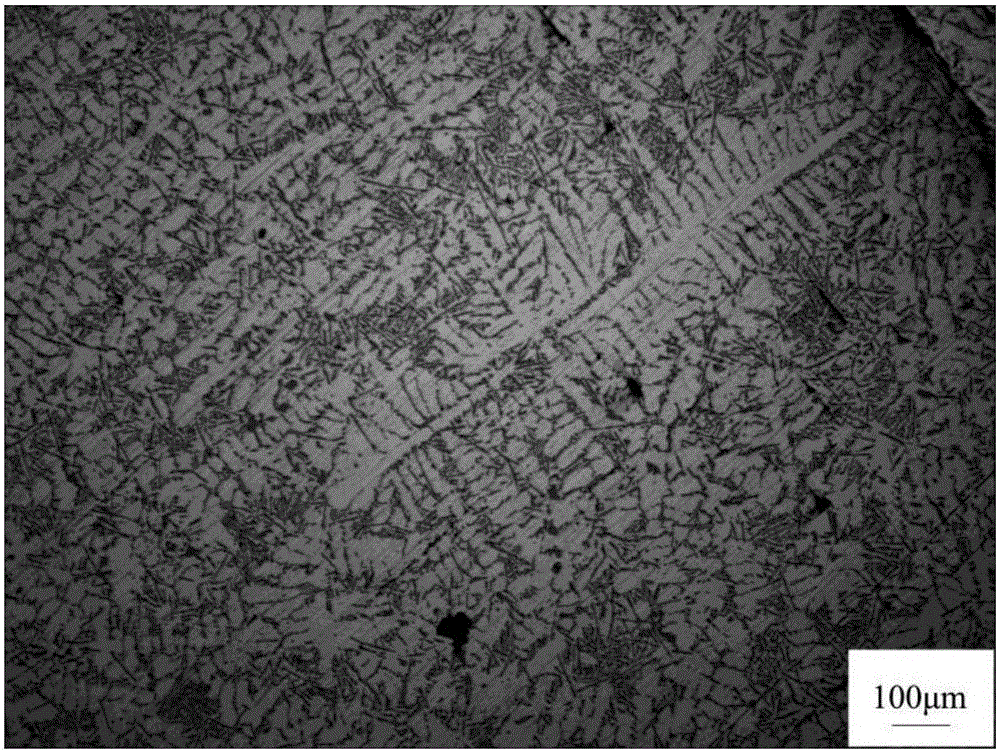

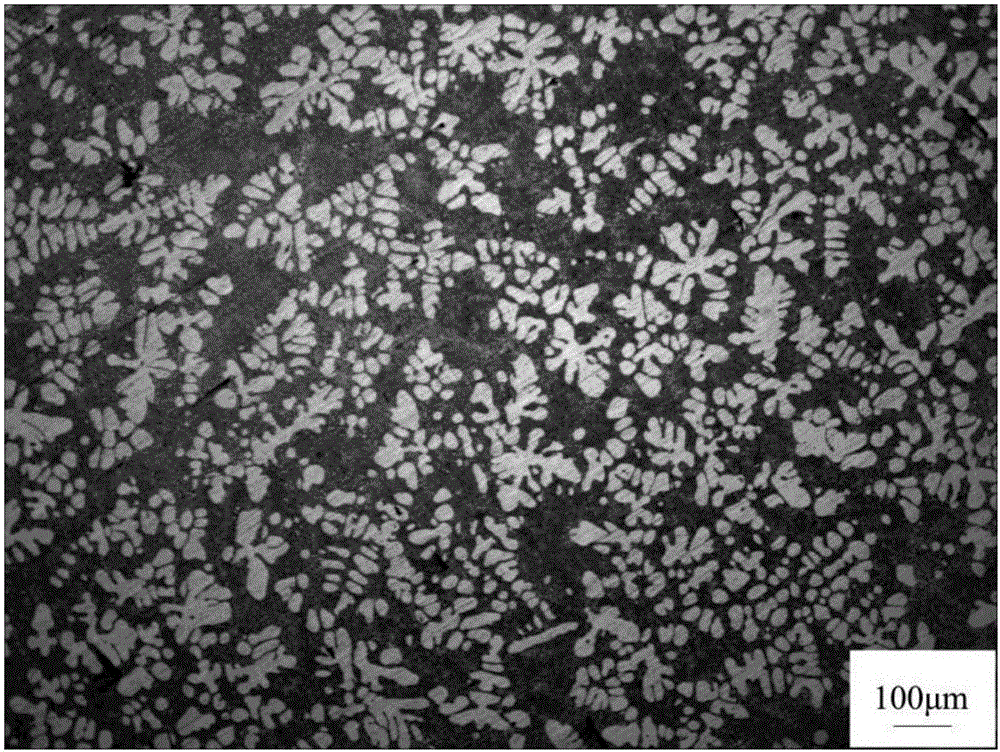

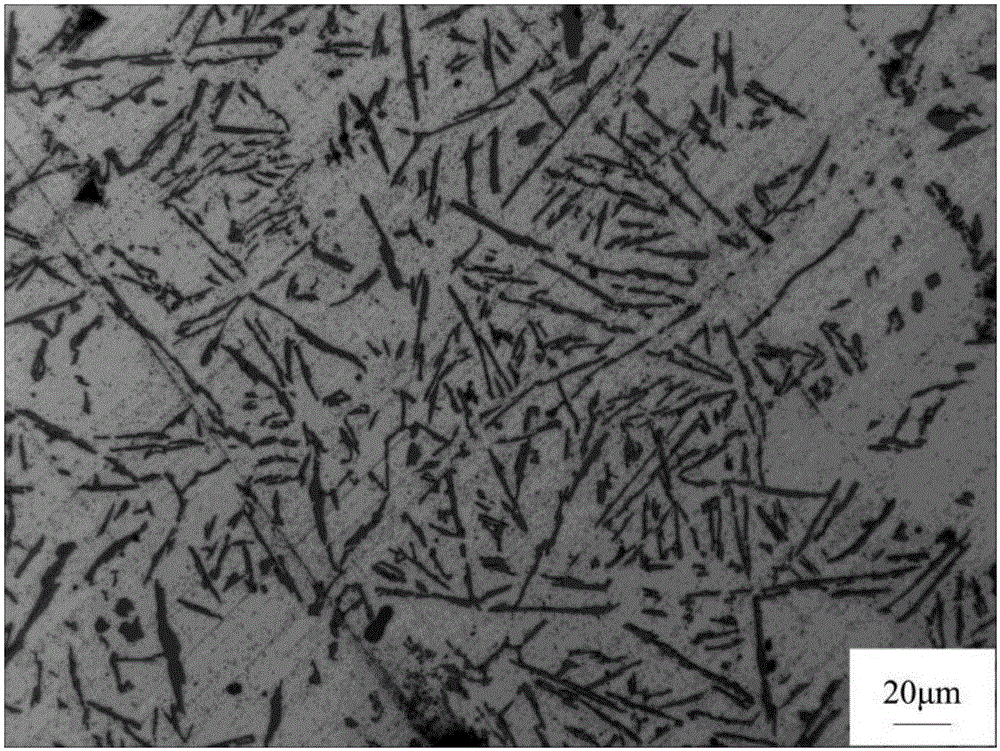

Aluminum-lanthanum-boron-strontium intermediate alloy for cast aluminum-silicon alloy and preparation method of aluminum-lanthanum-boron-strontium intermediate alloy

InactiveCN106191490AGood metamorphic effectAvoid reactionSilicon alloyCastability

Owner:SOUTHEAST UNIV

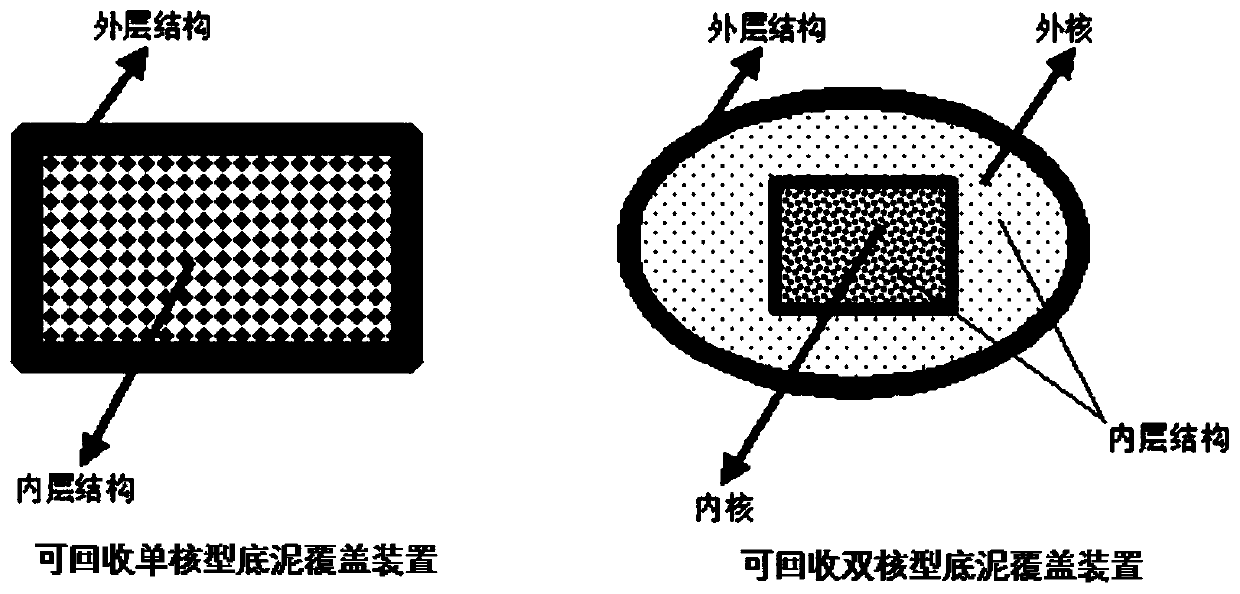

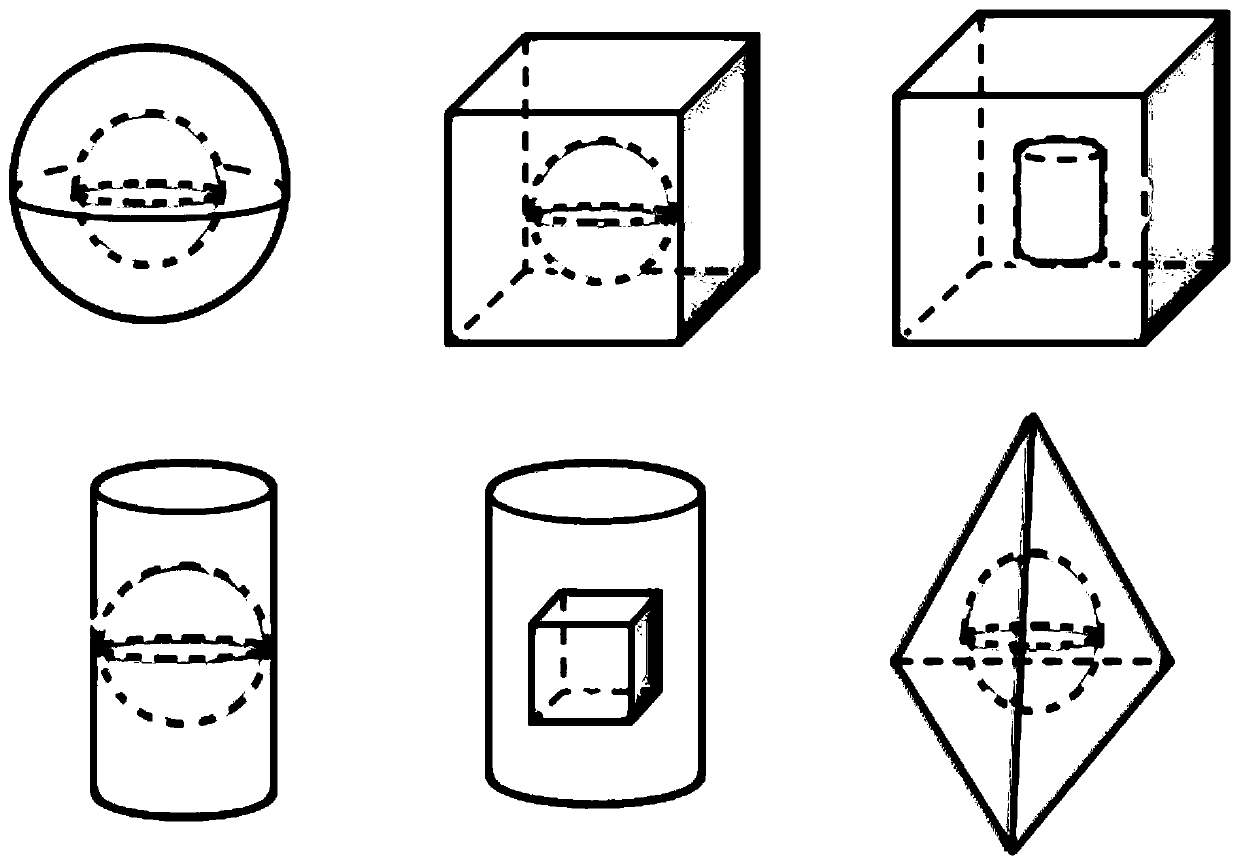

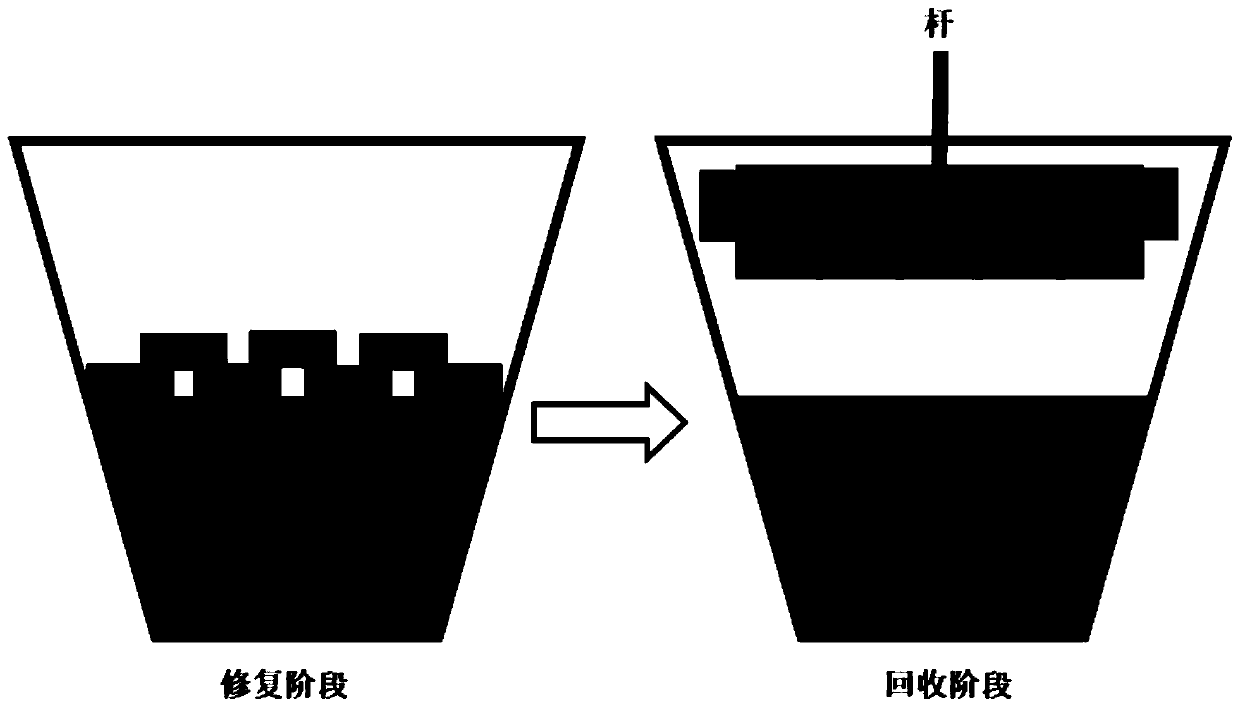

Recyclable sediment covering device and application thereof

InactiveCN111186971AReduce repair costsAvoid churnSludge treatmentOther chemical processesEngineeringStructural engineering

Owner:SHANGHAI OCEAN UNIV

High-efficient composite filter material prepared by blending melt-blown polypropylene with modified pseudo-boehmite and used for sewage treatment and preparation method thereof

InactiveCN104759266AImproved purification and adsorption capacityStable and efficient structureOther chemical processesAlkali metal oxides/hydroxidesRare earthLanthanum

Owner:BENGBU DEMO FILTRATION TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap