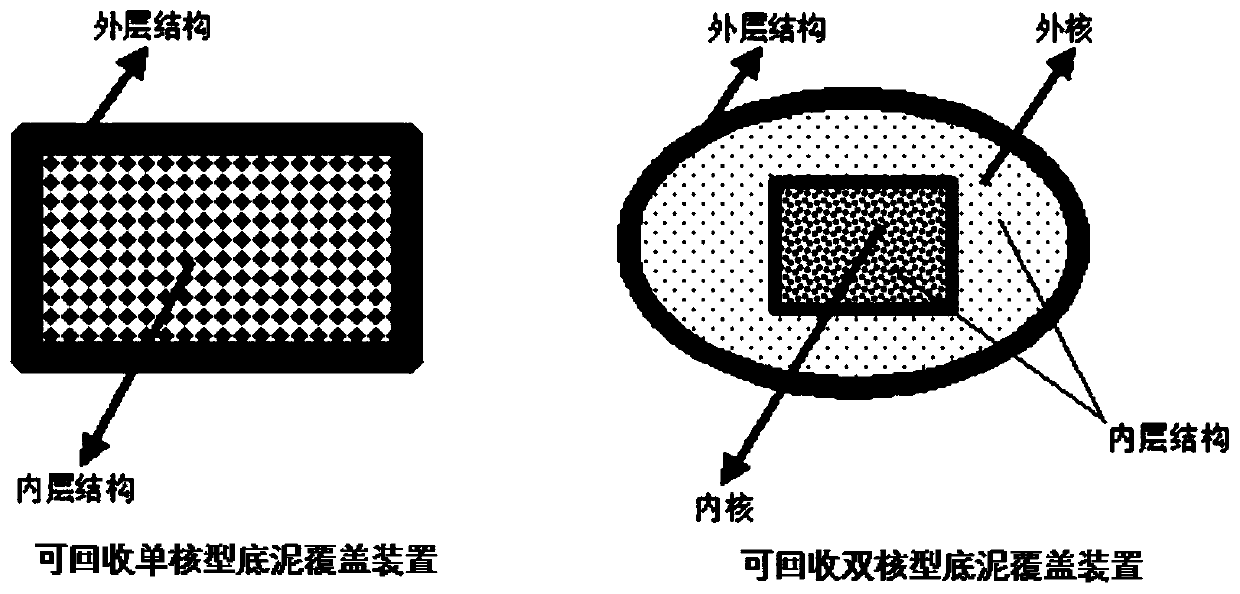

Recyclable sediment covering device and application thereof

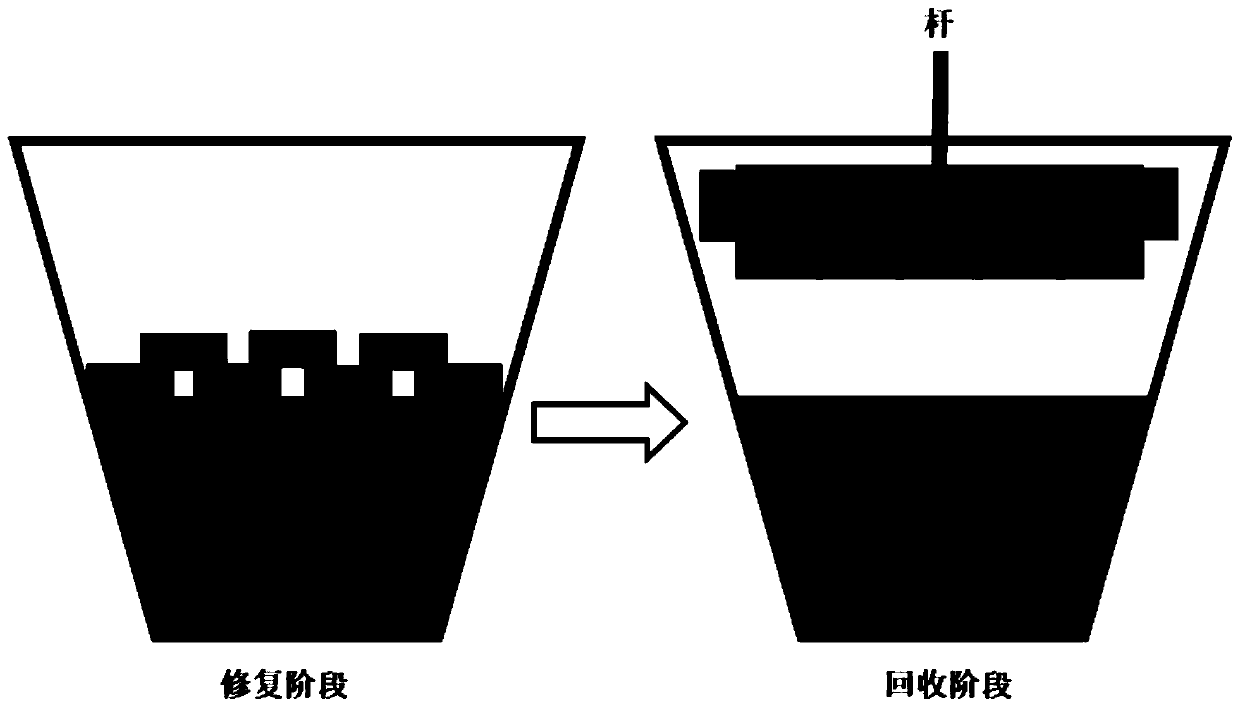

A technology for covering device and sediment, which is applied in the field of endogenous pollution control and remediation in water areas, can solve the problems of reducing material remediation sediment, sediment mixing, and increasing the difficulty of material recovery, achieving broad application prospects and avoiding the difficulty of recovery. , the effect of saving repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

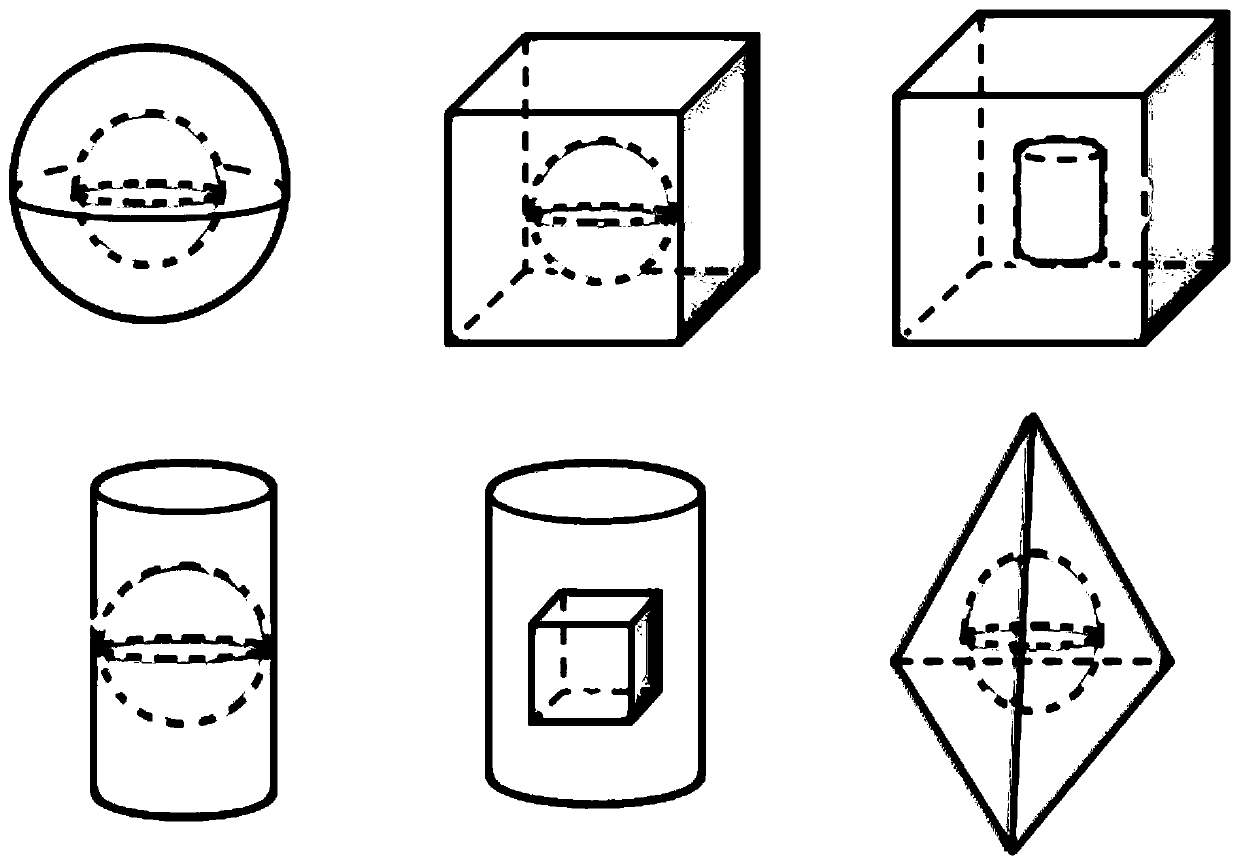

Method used

Image

Examples

preparation example Construction

[0071] The preparation process of the powdery magnetic iron-based material is: the carrier material (at least one selected from bentonite, kaolin, diatomite, zeolite, attapulgite, sepiolite, illite, siderite and activated carbon), Fe 3+ / Fe 2+ Solution (Fe 3+ Prepared with ferric chloride hexahydrate, ferric sulfate or ferric nitrate, Fe 2+ Prepared with ferrous chloride tetrahydrate, ferrous sulfate heptahydrate or ferrous nitrate, Fe 3 + / Fe 2+ The molar ratio of (2-4):1, preferably 2:1, Fe 3+ / Fe 2+ The total concentration of iron in the solution is 0.2-3mol / L) mixing, wherein, the quality of the carrier material and Fe 3+ / Fe 2+ The volume ratio of the solution is (500-10) g: 1 L, put it at 70-80 ° C for 0.5-2 h, then add 0.5-2 mol / L sodium hydroxide or potassium hydroxide solution dropwise, and mix the The pH value of the solution was adjusted to 10-11, and then washed with water for 3-5 times, collected, and dried to obtain a solid material.

[0072] (M

Embodiment 1

[0119] The preparation process of magnetic zirconium-based materials: 10g bentonite and 200mL Fe 3+ / Fe 2+The solution (the concentration of ferric chloride hexahydrate is 0.215mol / L; the concentration of ferrous sulfate heptahydrate is 0.1075mol / L) is mixed, and then reacted at 70°C for 30min, then add 1mol / L NaOH to the solution Solution until the pH value of the mixed solution reaches 10, then continue to react for 1h, then add 100mL of zirconium oxychloride octahydrate solution (initial concentration is 50g / L) to the solution, then add 1mol / L dropwise to the mixed solution L NaOH solution until the pH value of the solution reaches 10, and then centrifuged to obtain a solid material, which is a magnetic zirconium-based material.

[0120] Construction of the recyclable mononuclear sediment covering device: the magnetic zirconium-based material was wrapped with a water-permeable fabric, and three covering devices were constructed, namely covering device 1, covering

Embodiment 2

[0123] The preparation process of magnetic lanthanum-based materials: 10g of bentonite and 200mL of Fe 3+ / Fe 2+ The solution (the concentration of ferric chloride hexahydrate is 0.215mol / L; the concentration of ferrous sulfate heptahydrate is 0.1075mol / L) is mixed, then placed at 70°C for 30min, and then 1mol / L NaOH is added to the solution Solution until the pH value of the mixed solution reaches 10, then continue to react for 1h, then add 100mL of lanthanum chloride hexahydrate solution (initial concentration is 50g / L) to the solution, and then add 1mol / L dropwise to the mixed solution NaOH solution until the pH value of the solution reaches 10, and then centrifuged to obtain a solid material, which is the magnetic lanthanum-based material.

[0124] Construction of the recyclable mononuclear sediment covering device: The magnetic lanthanum-based material was wrapped with a water-permeable fabric, and three covering devices were constructed, namely covering device

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap