Preparation method of modified lithium battery positive electrode material, modified lithium battery positive electrode material and lithium battery positive electrode structure

A technology for positive electrode materials and lithium batteries, applied in battery electrodes, structural parts, secondary batteries, etc., can solve the problems of poor electrical conductivity of lithium battery positive electrode materials, improve charge and discharge cycle performance, increase service life, and avoid specific capacity Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

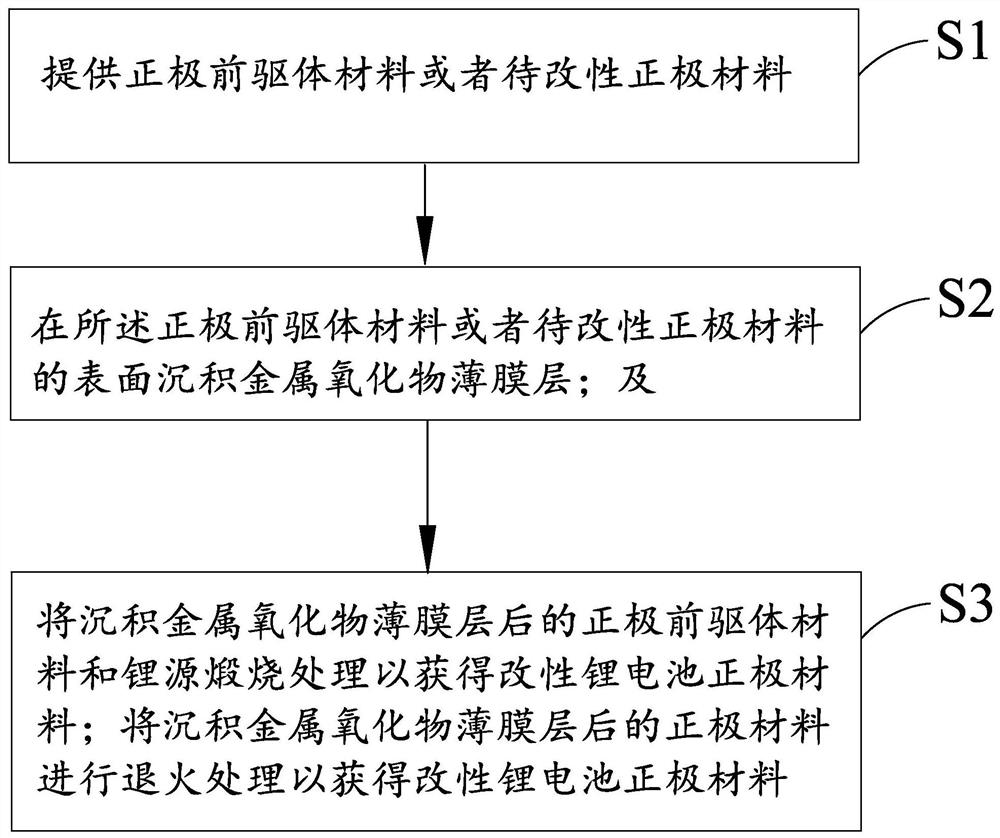

[0033] see figure 1 , the first embodiment of the present invention provides a method for preparing a modified lithium battery positive electrode material, comprising the following steps:

[0034] S1. Provide positive electrode precursor material or positive electrode material to be modified;

[0035] S2. Depositing a metal oxide film layer on the surface of the positive electrode precursor material or the positive electrode material to be modified; and

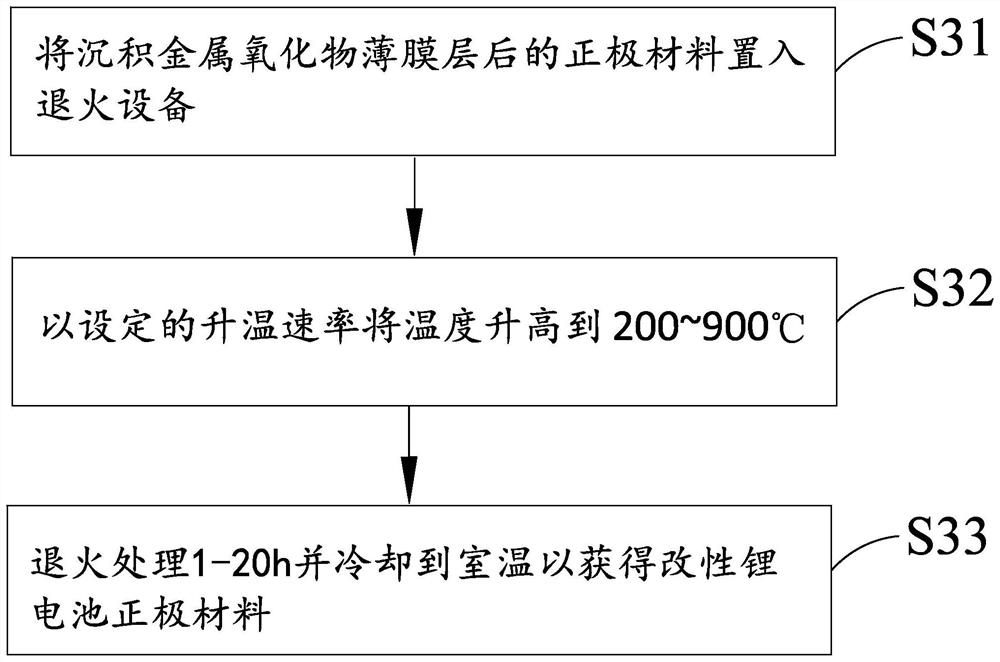

[0036] S3. Calcining the positive electrode precursor material and the lithium source after depositing the metal oxide thin film layer to obtain a modified lithium battery positive electrode material or annealing the positive electrode material after depositing a metal oxide thin film layer to obtain a modified lithium battery positive electrode Material.

[0037] In step S1, in some specific embodiments, the positive electrode material to be modified includes a lithium battery positive electrode material containing manganese

Example Embodiment

[0096] Embodiment 1 (illustrate by taking the positive electrode material to be modified as lithium manganate particles as an example):

[0097] 1.1. Preparation of lithium manganate particles to be modified:

[0098] Weigh 10g MnCO 3 Put it in a boat-shaped crucible, calcined in a tube furnace, the atmosphere introduced was air, the heating rate was 5°C / min, the calcining temperature was 540°C, and the calcining time was 5h, to obtain Mn 2 o 3 powder, the powder and LiOH·H 2 O was mixed according to the stoichiometric ratio of 1:1, ground evenly in a mortar, then placed in a boat-shaped crucible, and calcined in a tube furnace with oxygen as the atmosphere, the heating rate was 5°C / min, and the calcination temperature was 700° C., calcination time is 20 h, and lithium manganate particles to be modified are obtained.

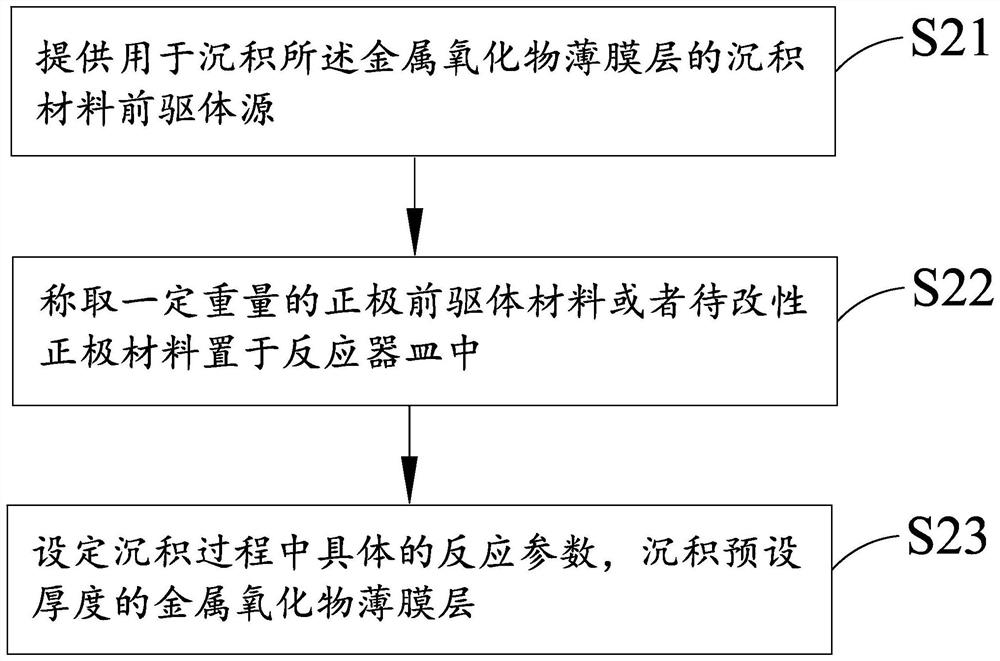

[0099] 1.2. Coating the surface of the prepared lithium manganate particles to be modified with a metal oxide film layer, the specific steps are as follows

Example Embodiment

[0119] Embodiment 2: (Illustrate with the lithium manganate precursor material to be modified as an example):

[0120] 2.1. Preparation of lithium manganate precursor particles to be modified:

[0121] Weigh 10gMnCO 3 Put it in a boat-shaped crucible, calcined in a tube furnace, the atmosphere introduced was air, the heating rate was 5°C / min, the calcining temperature was 540°C, and the calcining time was 5h, to obtain Mn 2 o 3 The powder is to obtain the lithium manganate precursor particles to be modified.

[0122] 2.2. Coating the surface of the prepared lithium manganate precursor particles to be modified with a metal oxide film layer, the specific steps are as follows:

[0123] Weigh 10g of the lithium manganate precursor particles to be modified prepared by the aforementioned steps, and place them in the reaction barrel of the atomic layer deposition equipment;

[0124] Evacuate the reaction chamber of the atomic layer deposition equipment to a vacuum range of: 0.05 T

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap