Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Rough surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface roughness often shortened to roughness, is a component of surface texture. It is quantified by the deviations in the direction of the normal vector of a real surface from its ideal form. If these deviations are large, the surface is rough; if they are small, the surface is smooth.

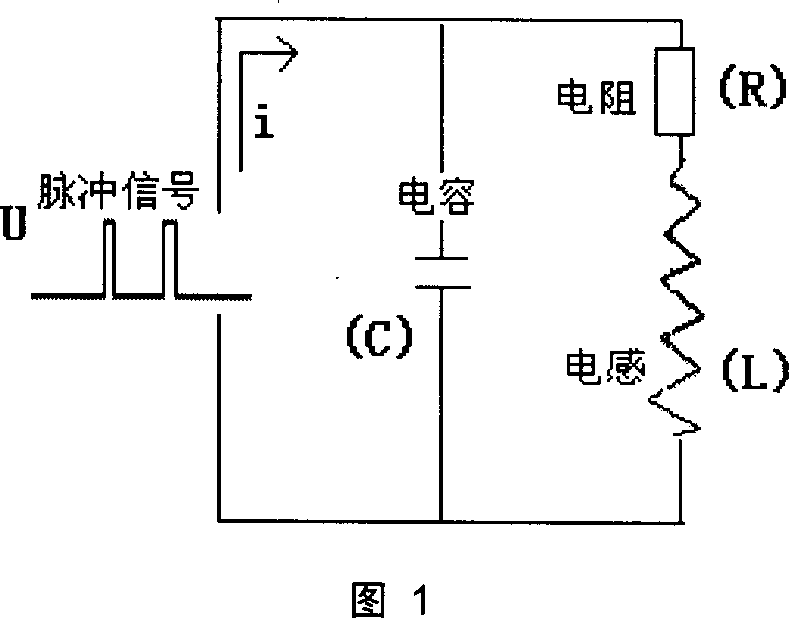

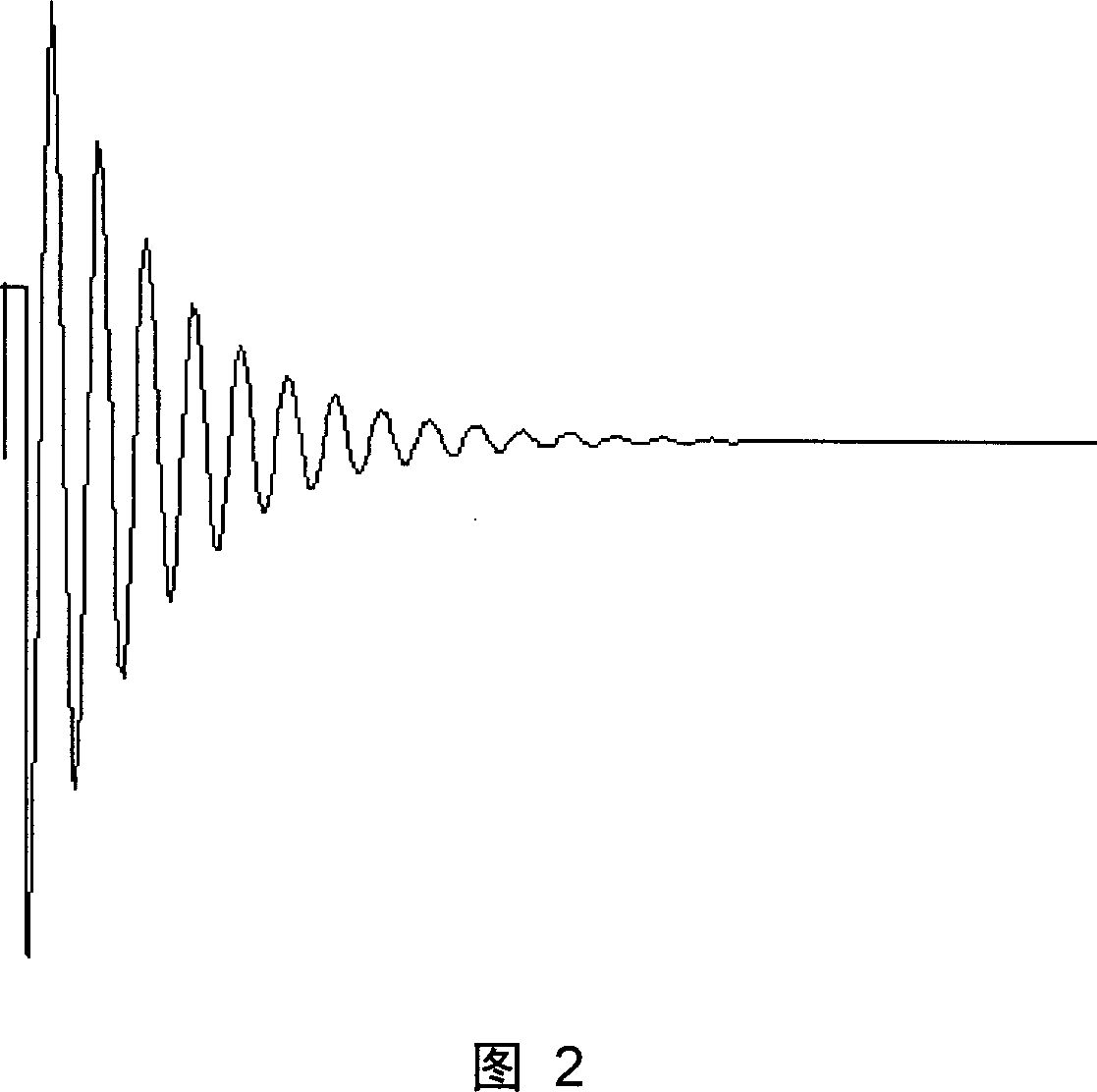

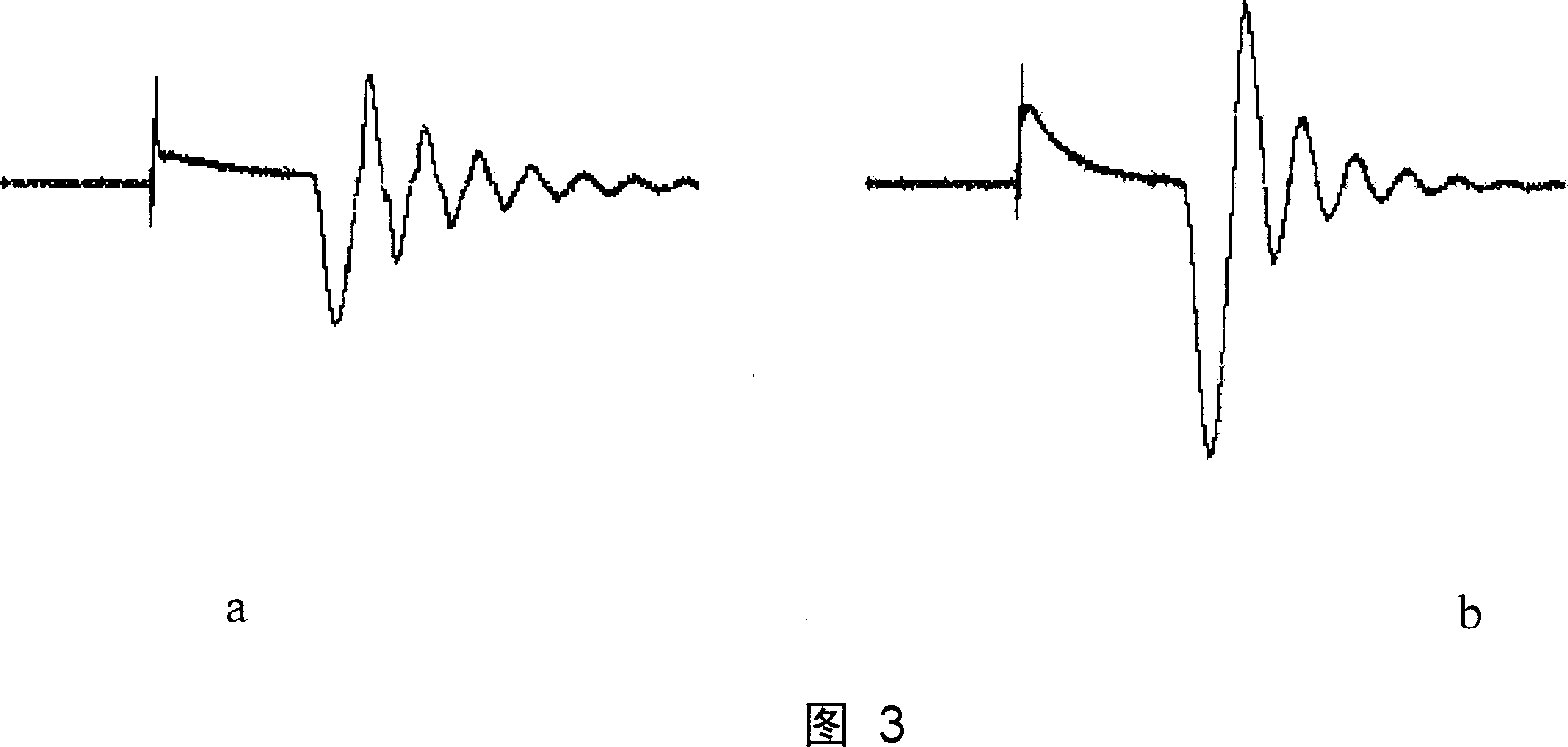

Resonance eddy detection method for surface crack

InactiveCN1924568AEasy to manufactureNon-destructiveMaterial magnetic variablesRough surfaceMagnetic testing

Owner:TSINGHUA UNIV

Stainless steel plate 8K mirror surface processing method

ActiveCN102962731AImprove the finishImprove anti-corrosion performancePolishing machinesFlexible-parts wheelsRough surfacePolishing

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

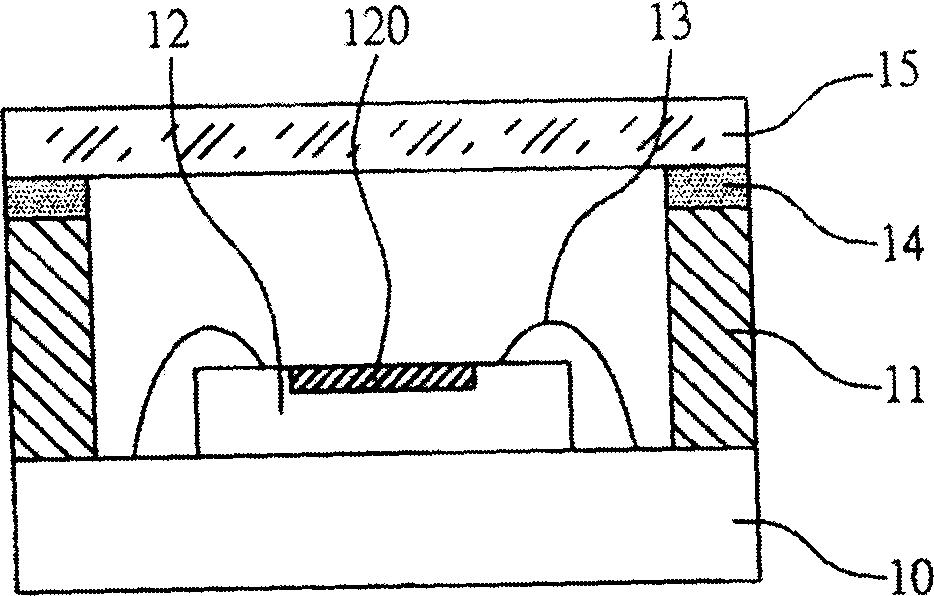

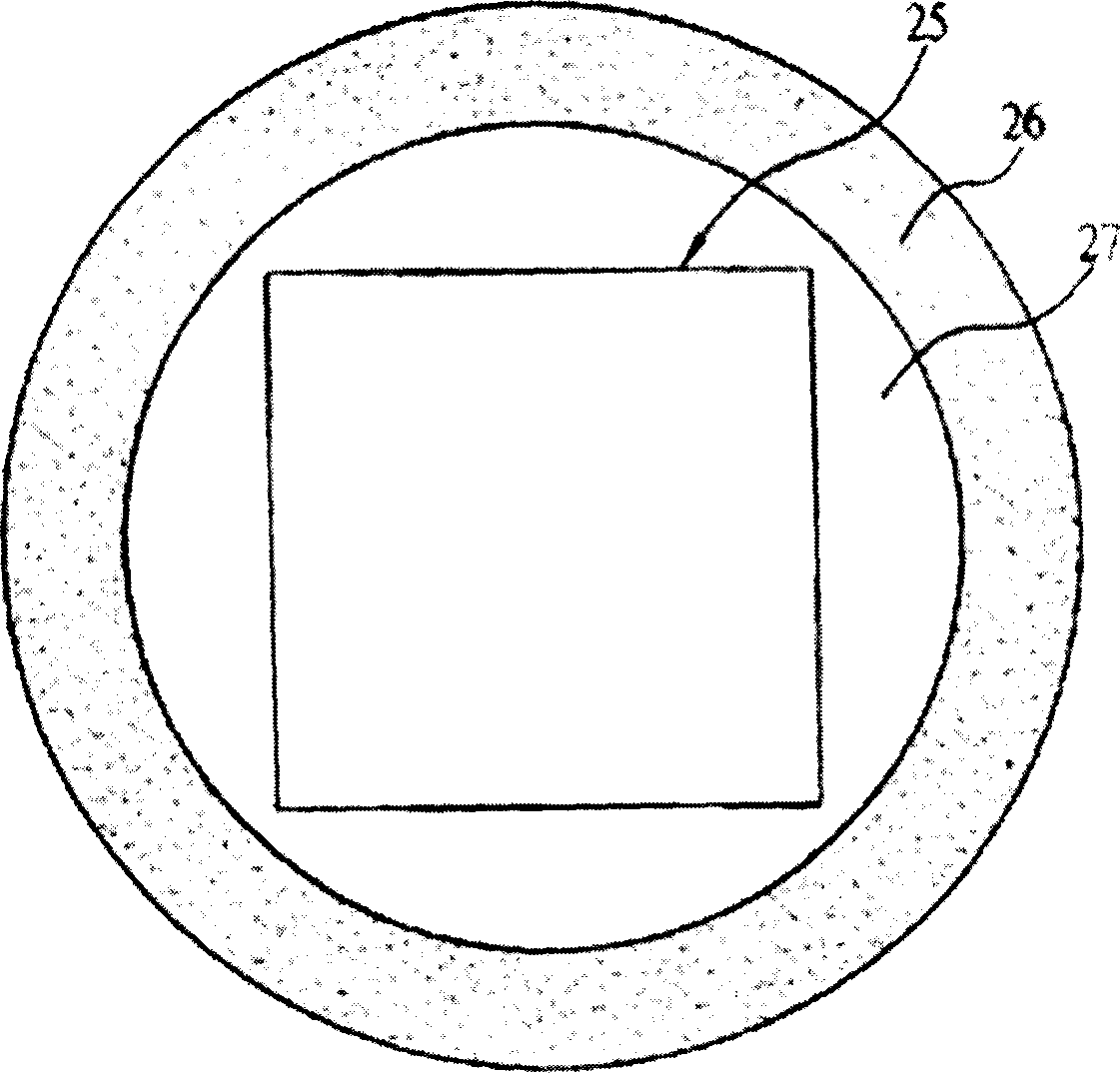

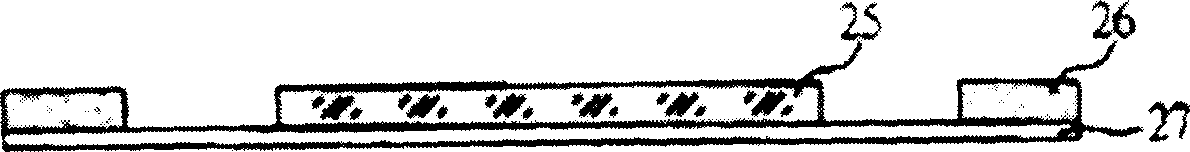

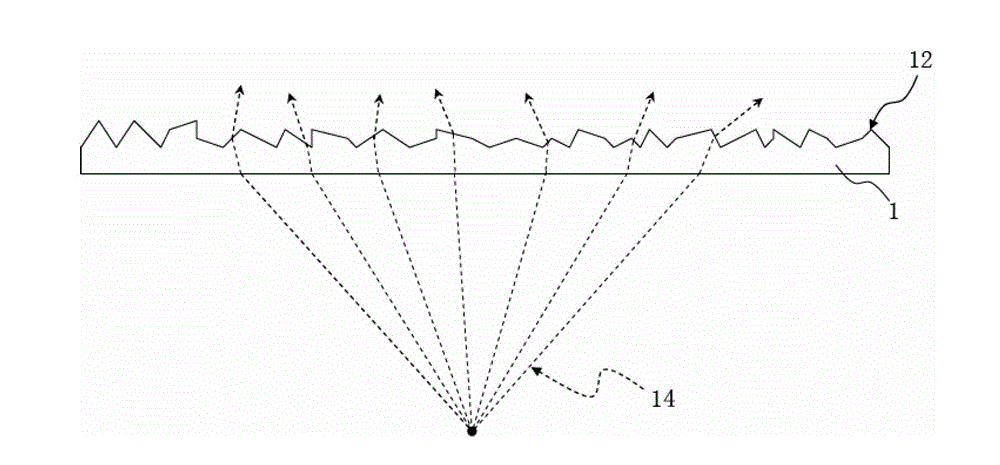

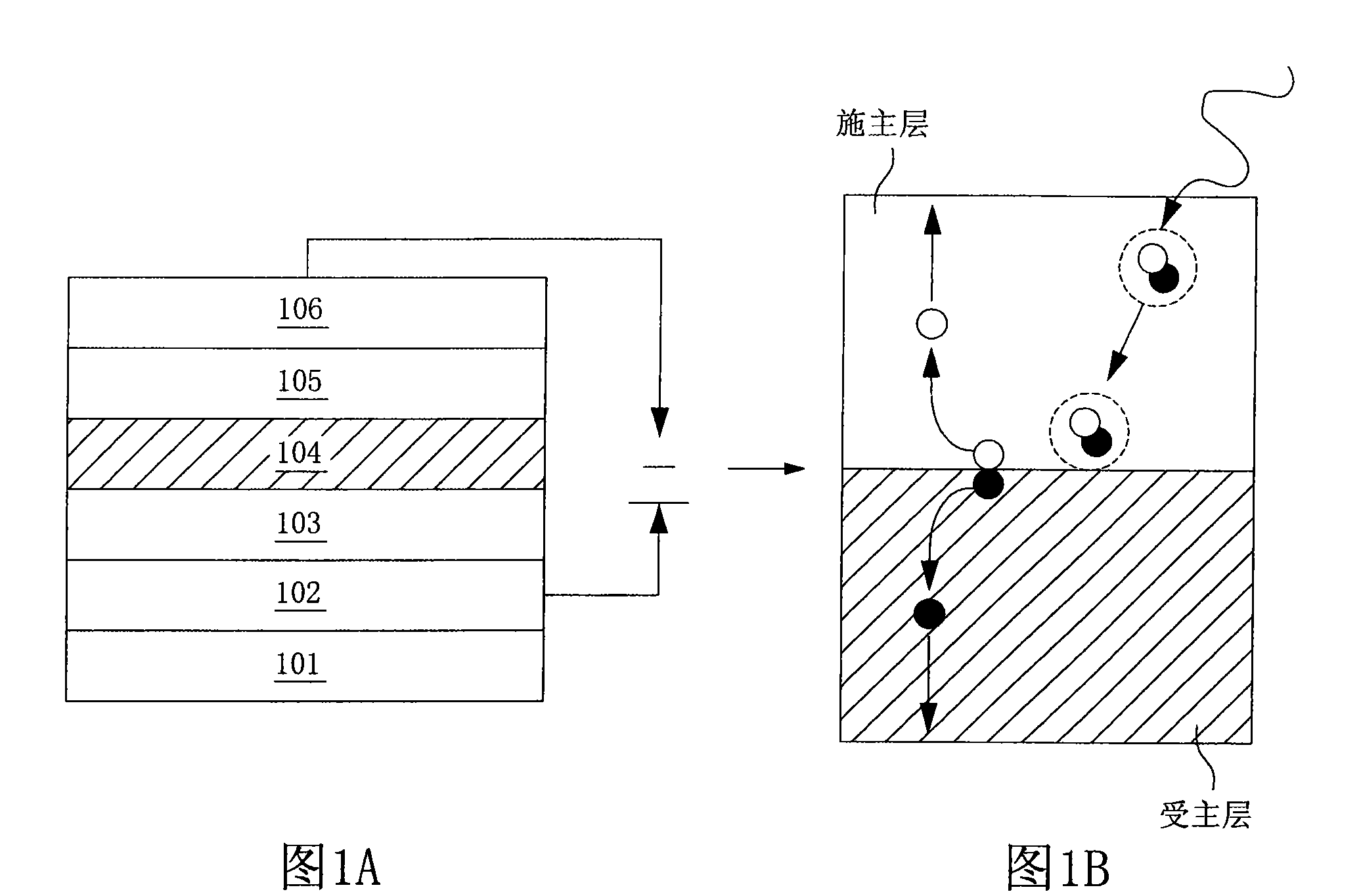

Light-emitting diode and manufacturing method thereof

ActiveCN101771110AImprove light extraction efficiencyImprove luminous brightnessSemiconductor devicesRough surfaceConvex structure

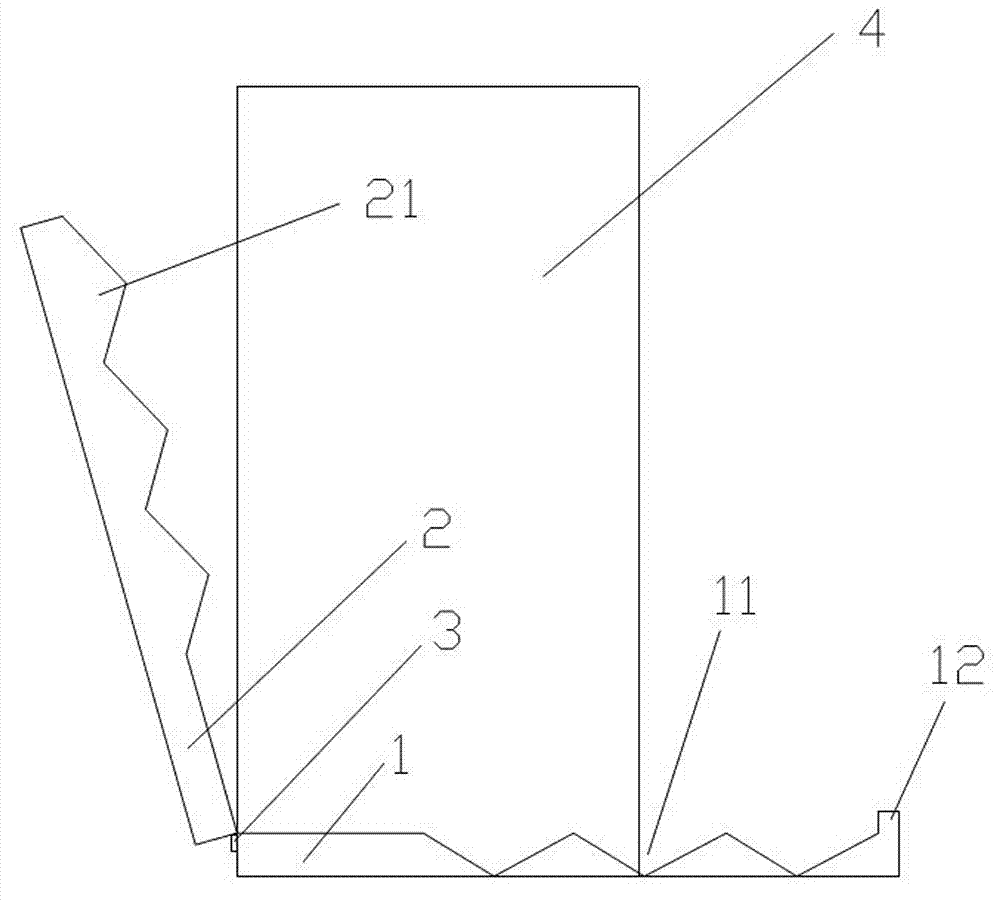

The invention provides a light-emitting diode and a manufacturing method thereof, and the structure of the light-emitting diode sequentially comprises a substrate, an n-type GaN layer, a light-emitting layer, a p-type GaN layer, an ohmic contact layer, a passivation layer, a p electrode and an n electrode from bottom to top, and is characterized in that a plurality of convex hemispherical, semi-elliptical or other irregularly-shaped convex structures are arranged on the upper surfaces of the substrate and the ohmic contact layer. The rotary coating method is utilized in the technical method for respectively forming layers of masks on the substrate and the ohmic contact layer, and then the plurality of convex hemispherical, semi-elliptical or other irregularly-shaped convex structures are formed on the substrate and the ohmic contact layer respectively by etching the masks, thereby forming the rough upper surfaces. The light extraction efficiency of the light-emitting diode can be improved through the two layers of the rough surfaces which achieve the micron level, or even the nanometer level, thereby reducing the production cost while greatly improving the light-emitting brightness.

Owner:DALIAN MEIMING EPITAXIAL WAFER TECH

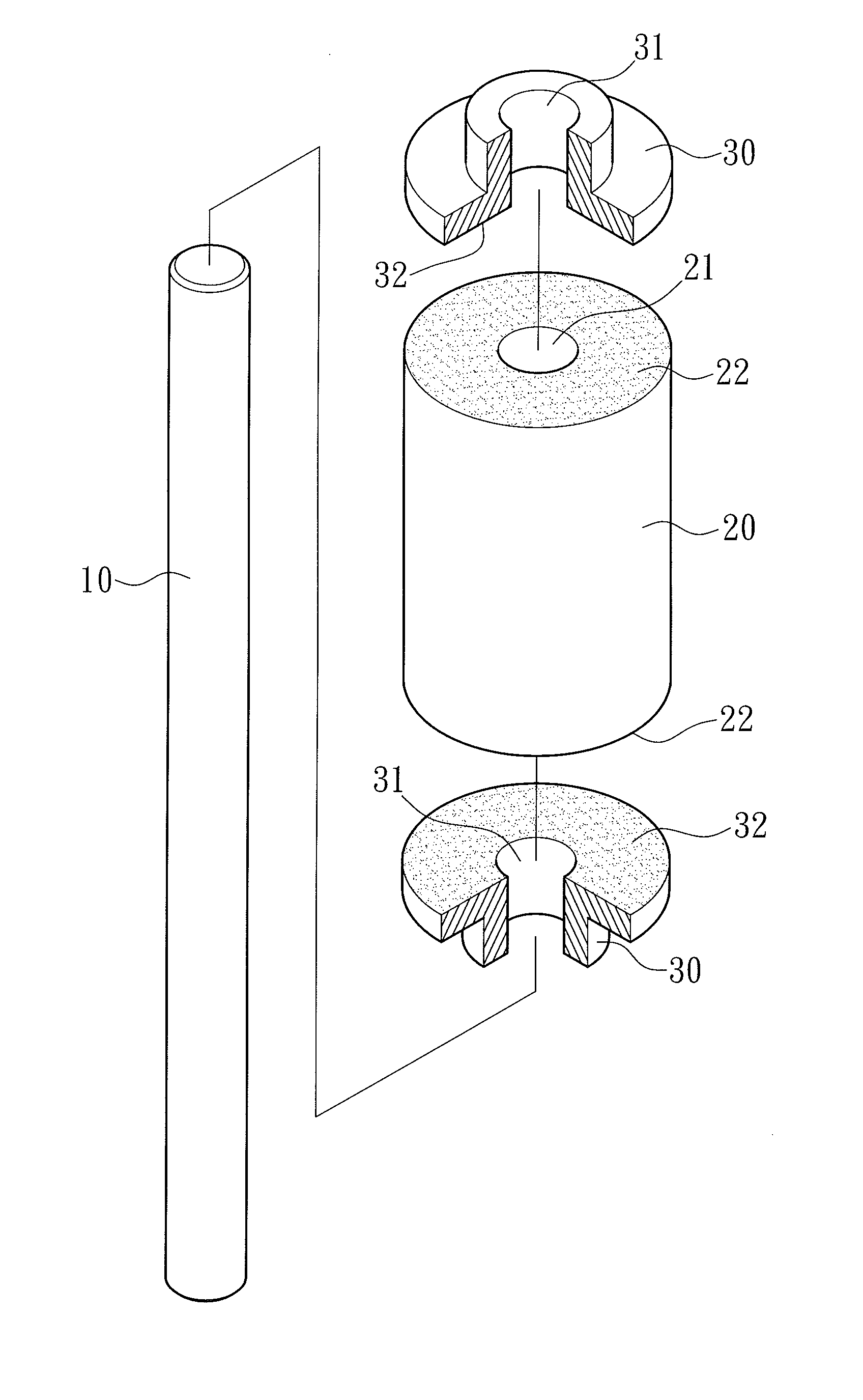

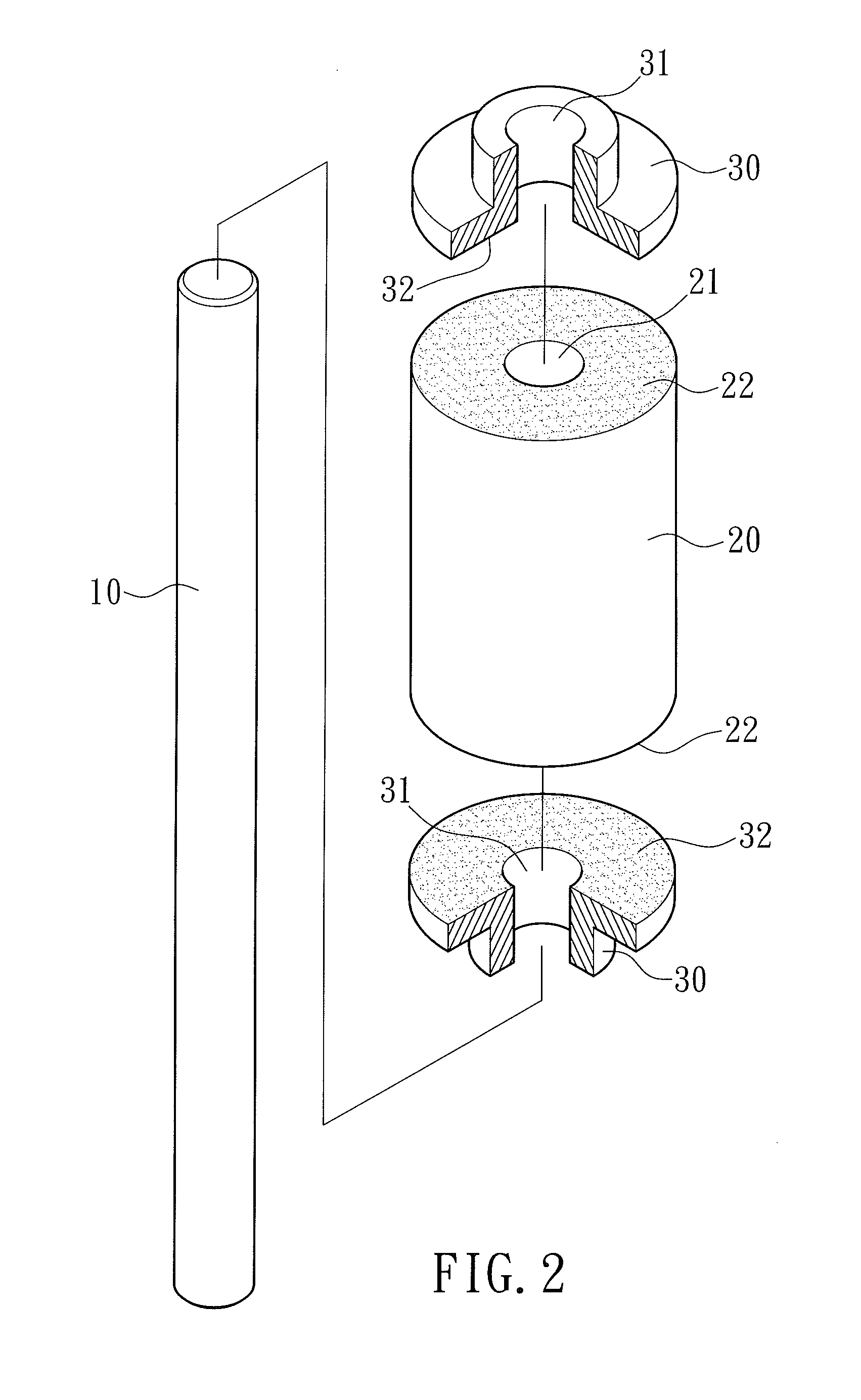

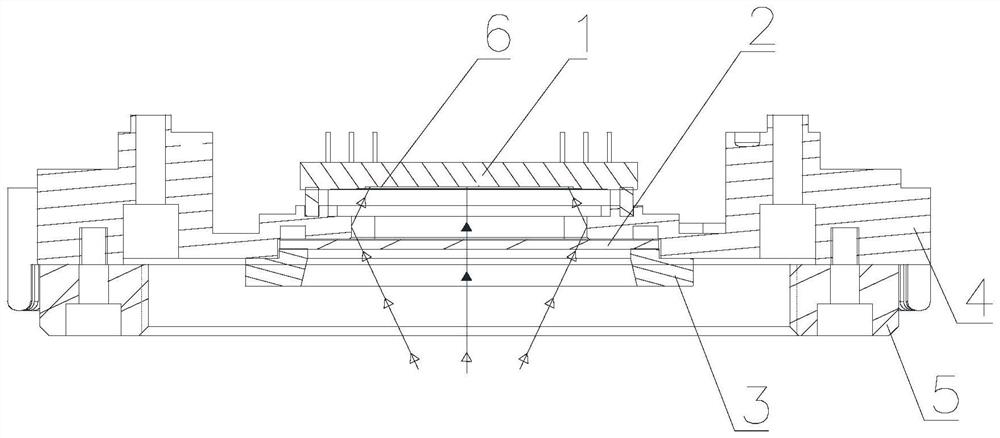

Rotor Structure Including Fixing Seats Securely Coupling A Shaft and A Magnet Together

InactiveUS20110062812A1Avoid breakingMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsRough surfaceEngineering

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Image sensor package, optical glass therefor and processing method

InactiveCN1905140AEnsuring the ability to receive optical signalsPrevent intrusionSemiconductor/solid-state device detailsFinal product manufactureRough surfaceOptoelectronics

Owner:SILICONWARE PRECISION IND CO LTD

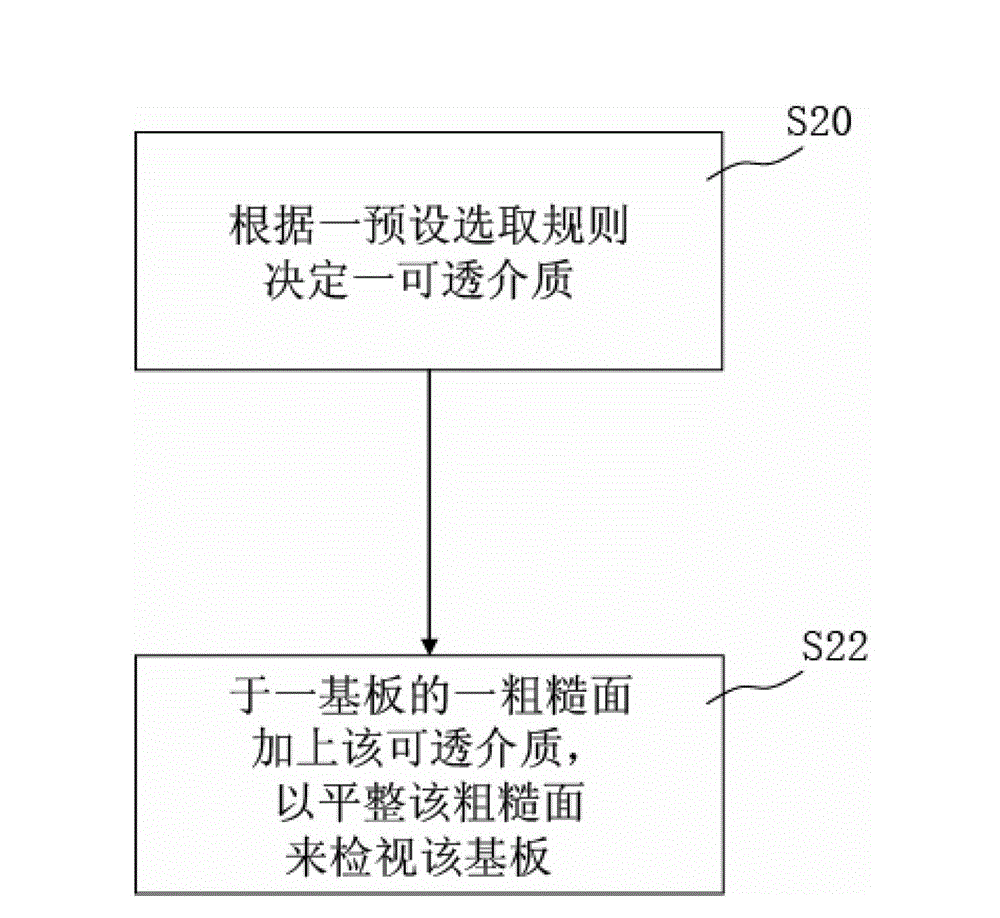

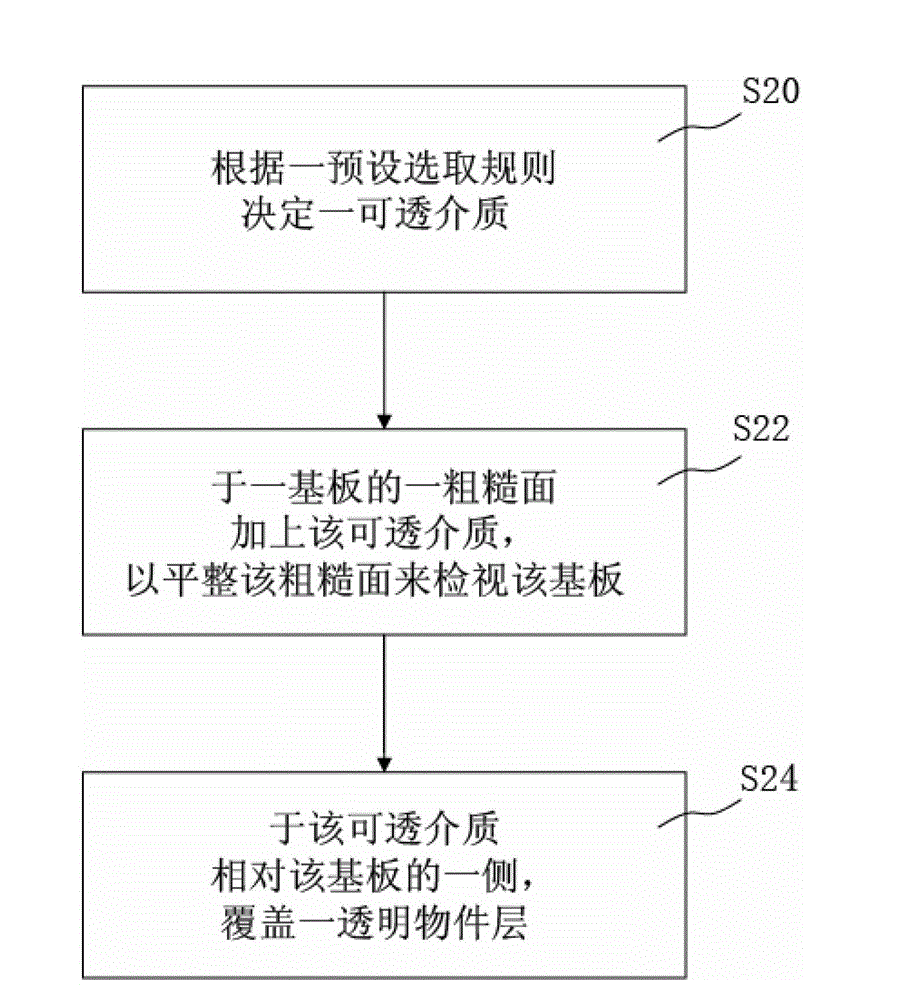

Viewing method for substrate with uneven surface

InactiveCN103943524AIncreased risk of damageAvoid increasing process costSemiconductor/solid-state device testing/measurementRough surfaceComputer science

Owner:YOMORE TECH

Preparation method of polyester fiber with rough surface

InactiveCN106978645AConducive to fixationGood removal effectFibre typesHollow filament manufactureActivated sludgePolyester

Owner:SHANGHAI NEW TECHTEXTILES +1

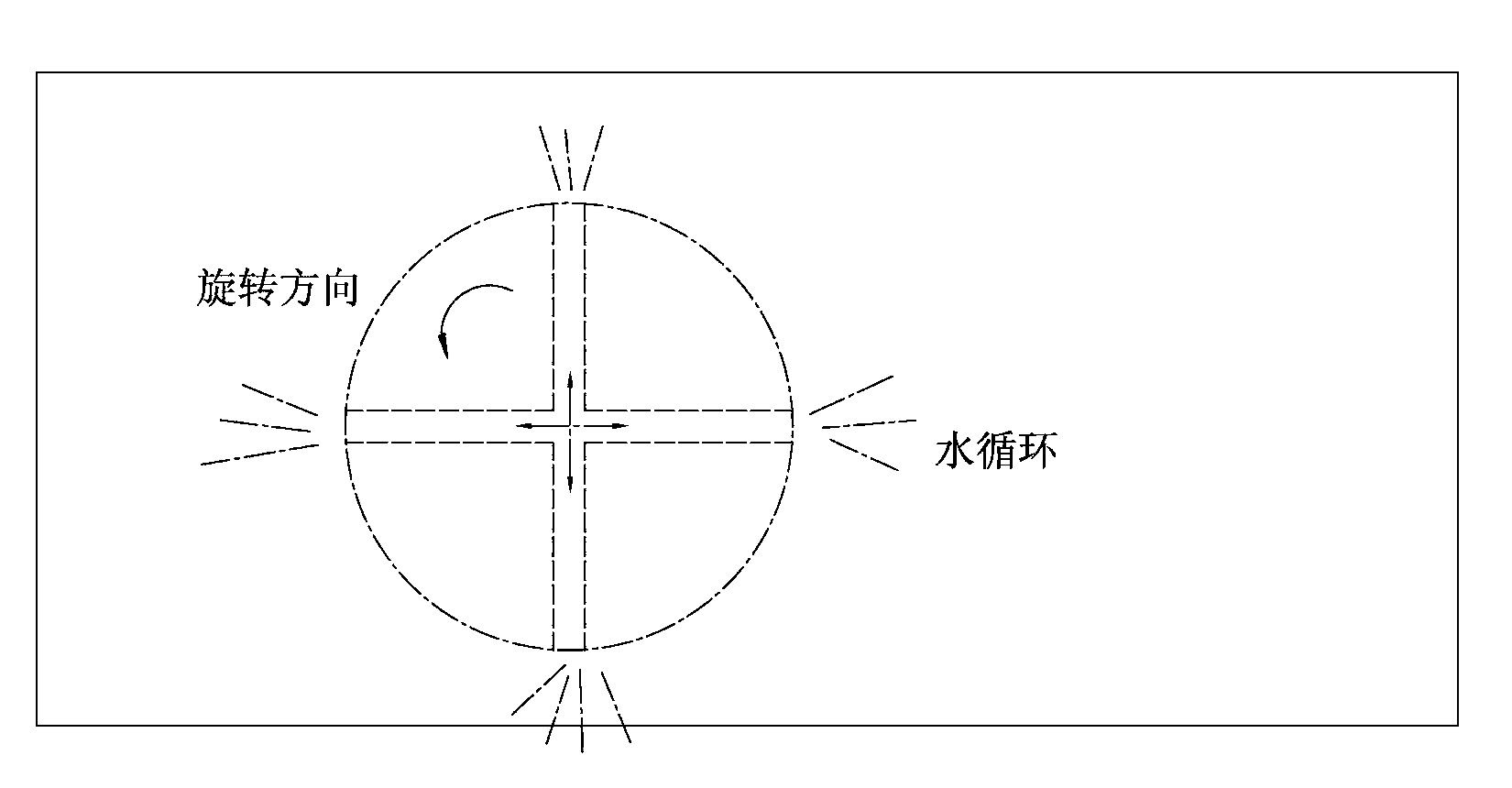

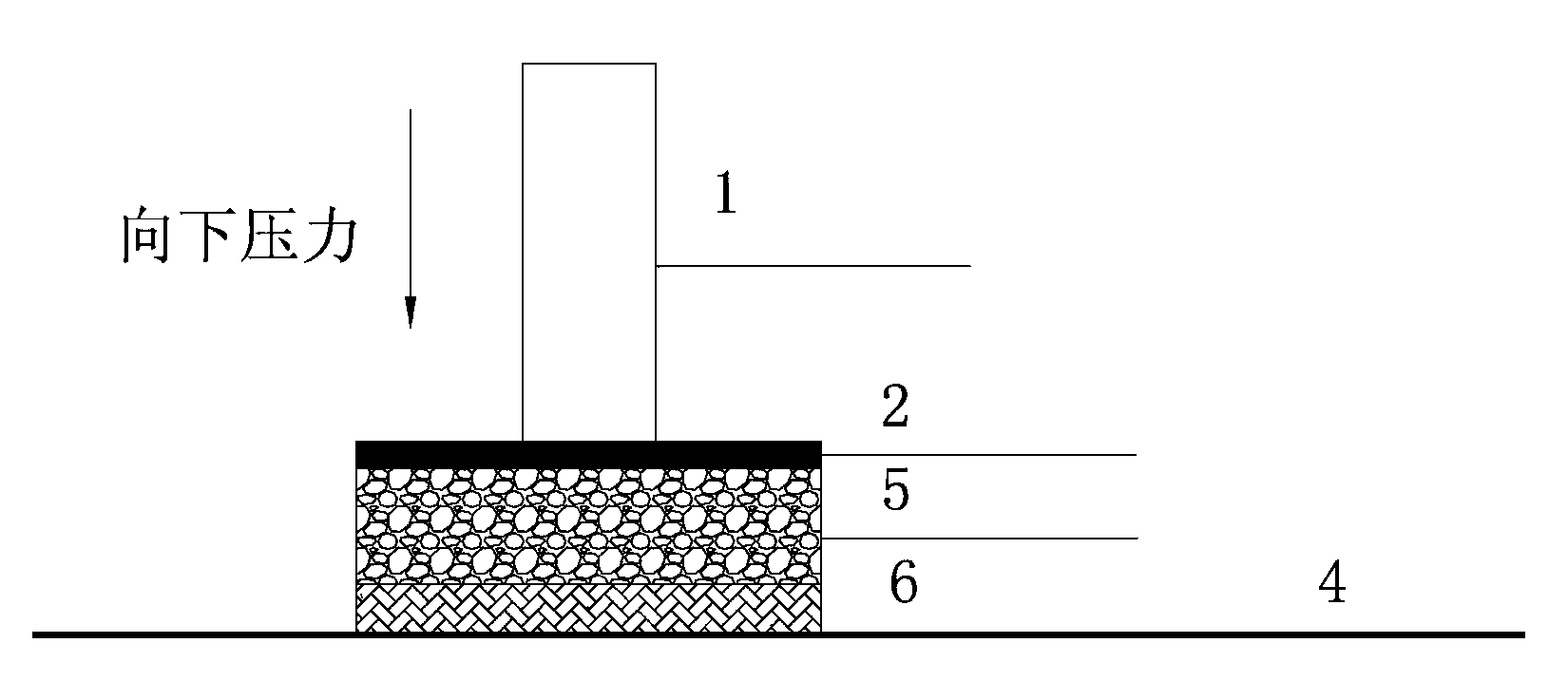

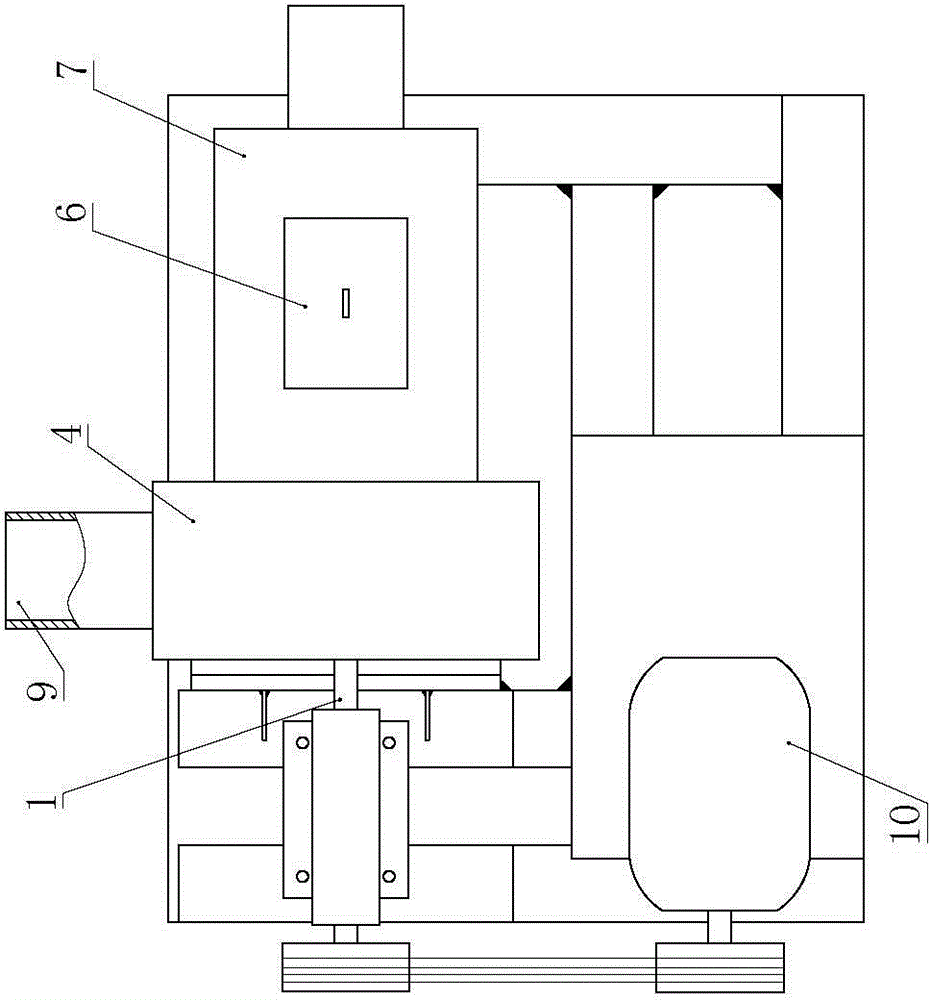

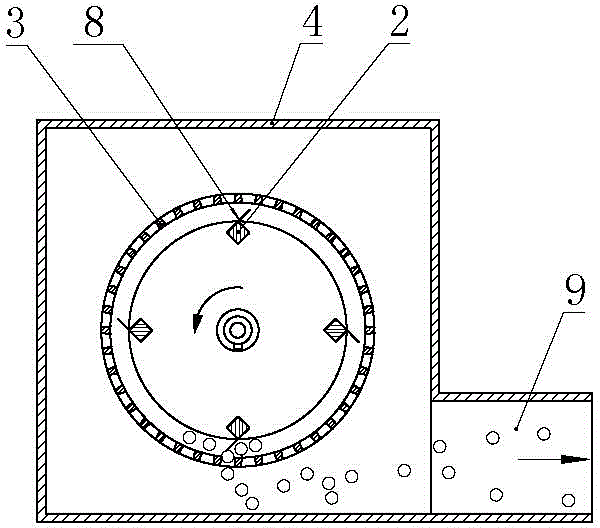

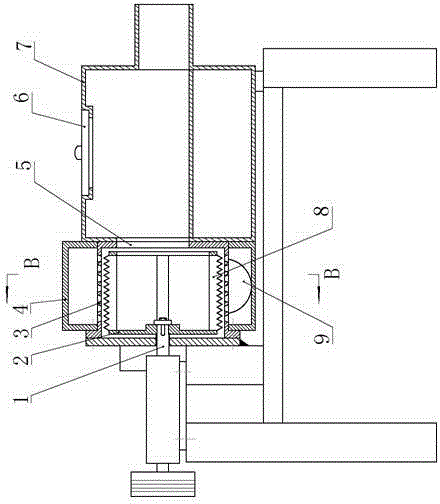

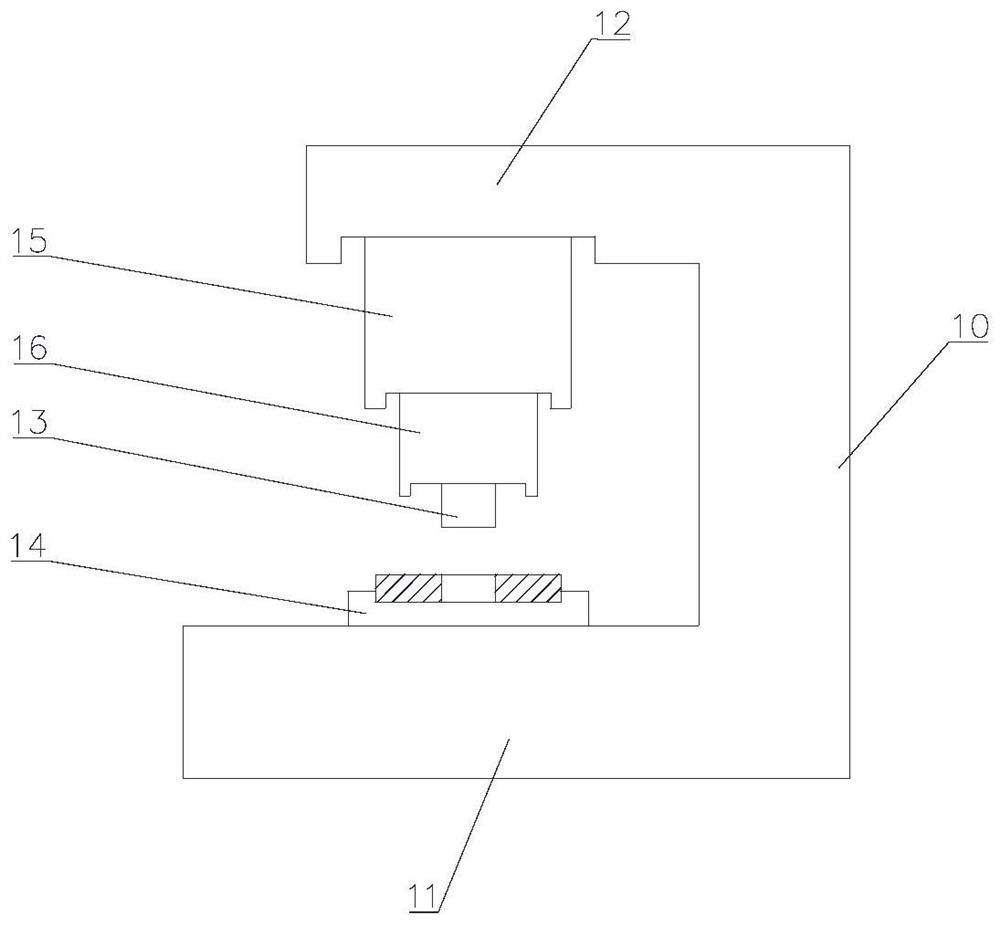

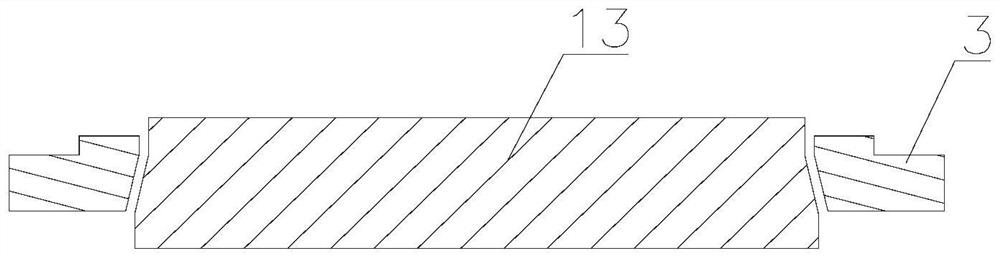

Treatment machine for increasing surface roughness of plastic foam particles

InactiveCN104690954ASmooth entryStir wellRough surfaceSuction force

Owner:LONGKOU ZHENGREN ENERGY SAVING BUILDING MATERIALSEQUIP MFG

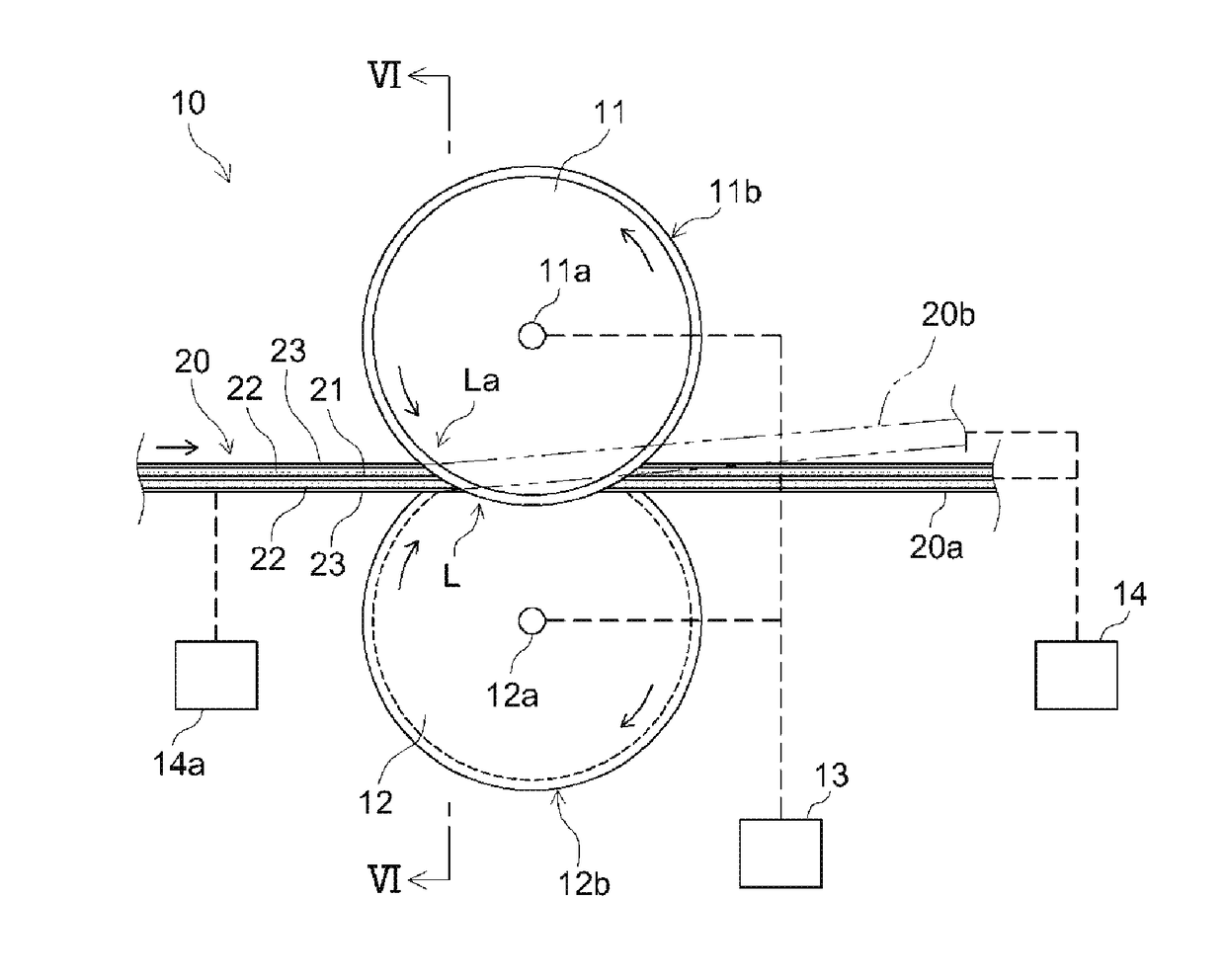

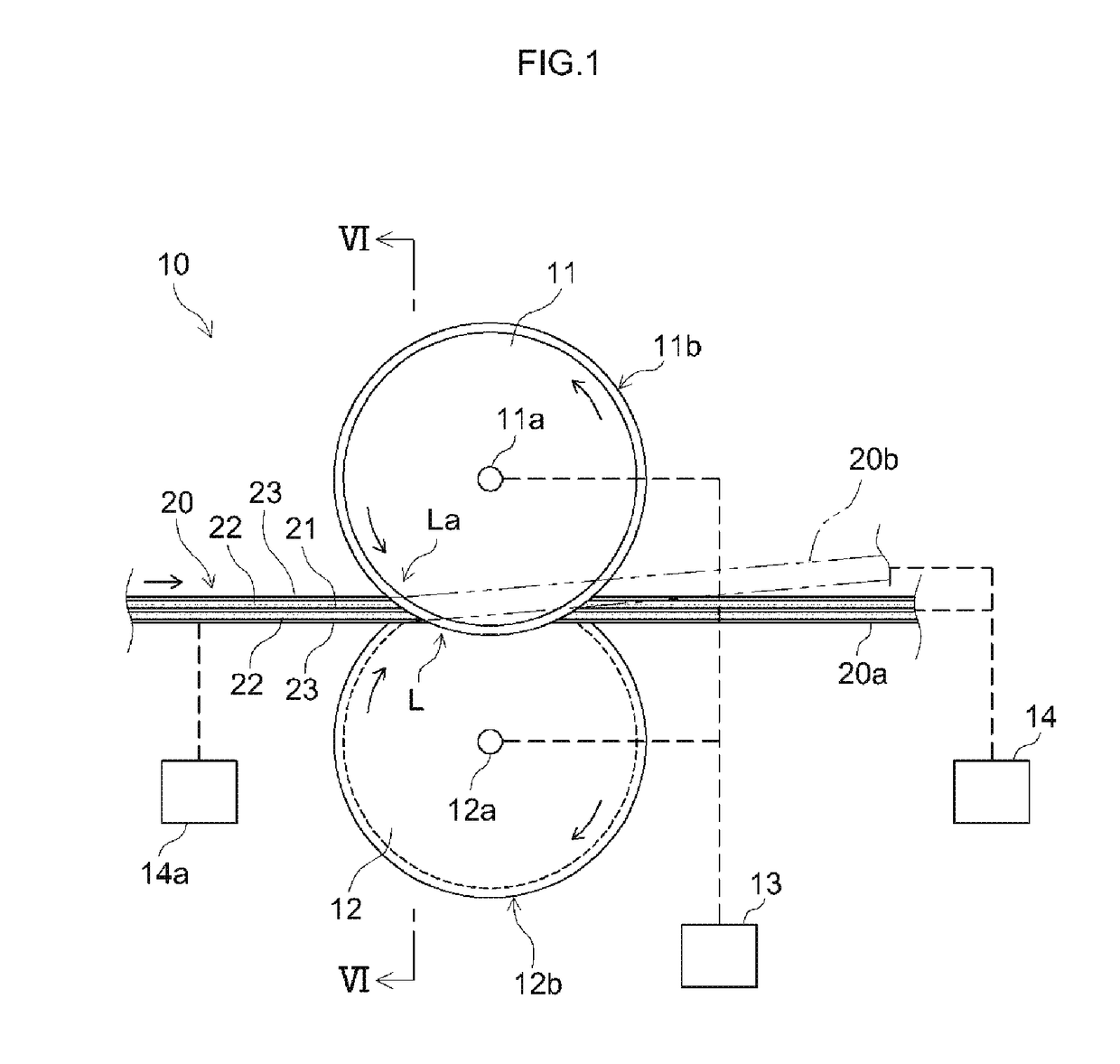

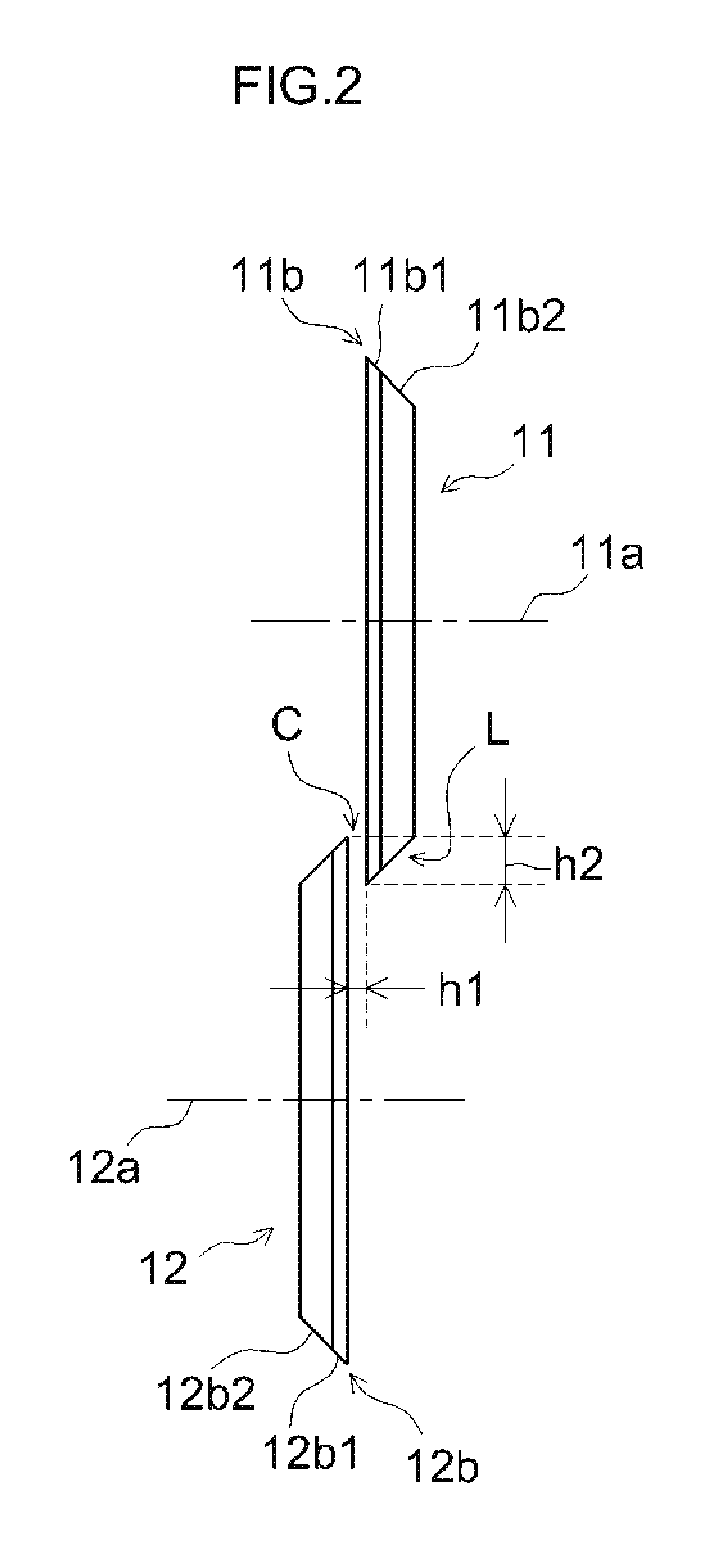

Cutting apparatus and rotary blade

ActiveUS20180282105A1Prolong lifeGreat tolerance for variationCell electrodesLi-accumulatorsRough surfaceEngineering

Owner:TOYOTA JIDOSHA KK

Rust steel simulation method based on surface random roughness

PendingCN114757074ADesign optimisation/simulationComplex mathematical operationsRough surfaceRandom roughness

The invention discloses a numerical method for simulating rusted steel based on surface random roughness, which specifically comprises the following steps: taking the rusted steel surface as a two-dimensional / three-dimensional random rough surface, and obtaining the corrosion rate of the steel according to an actual measurement or empirical formula. The arithmetic mean height, the root mean square height and the maximum height of the rusted steel surface corresponding to the corrosion rate are obtained through a morphology scanning or formula calculation mode, a one-dimensional / two-dimensional random rough surface is simulated and generated through a Monte Carlo method, and finally the distance from the lowest point of the rusted surface to other surfaces is calculated according to the corrosion rate. And combining the obtained rough surface with other planes to generate steel corrosion models under different corrosion degrees.

Owner:TIANJIN UNIV

Diffuse reflection structure of scientific-grade CMOS camera and processing method and equipment thereof

PendingCN114488654APrevent reflections from spotting lightMeet the needs of diffuse reflectionTelevision system detailsDiffusing elementsCMOSRough surface

Owner:福州鑫图光电有限公司

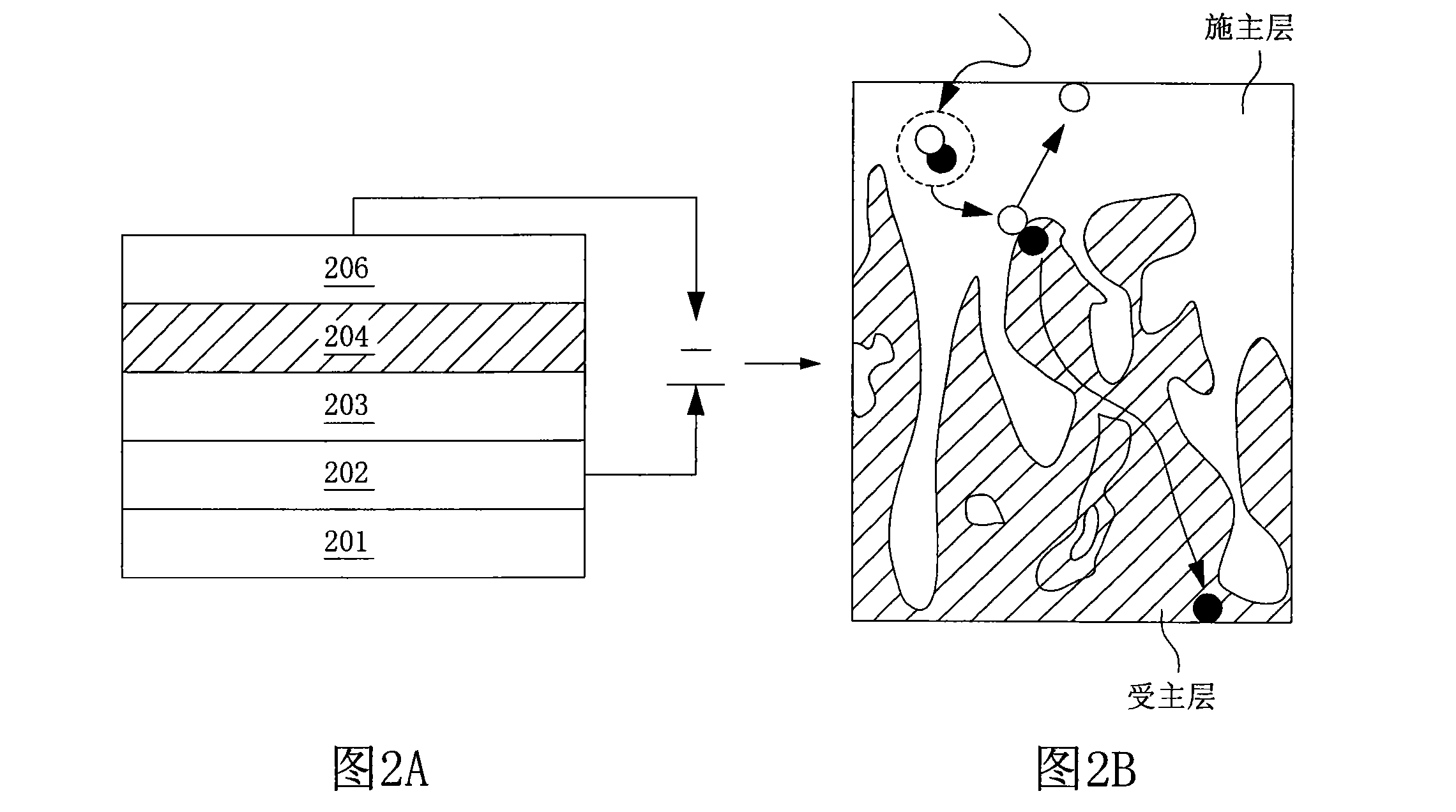

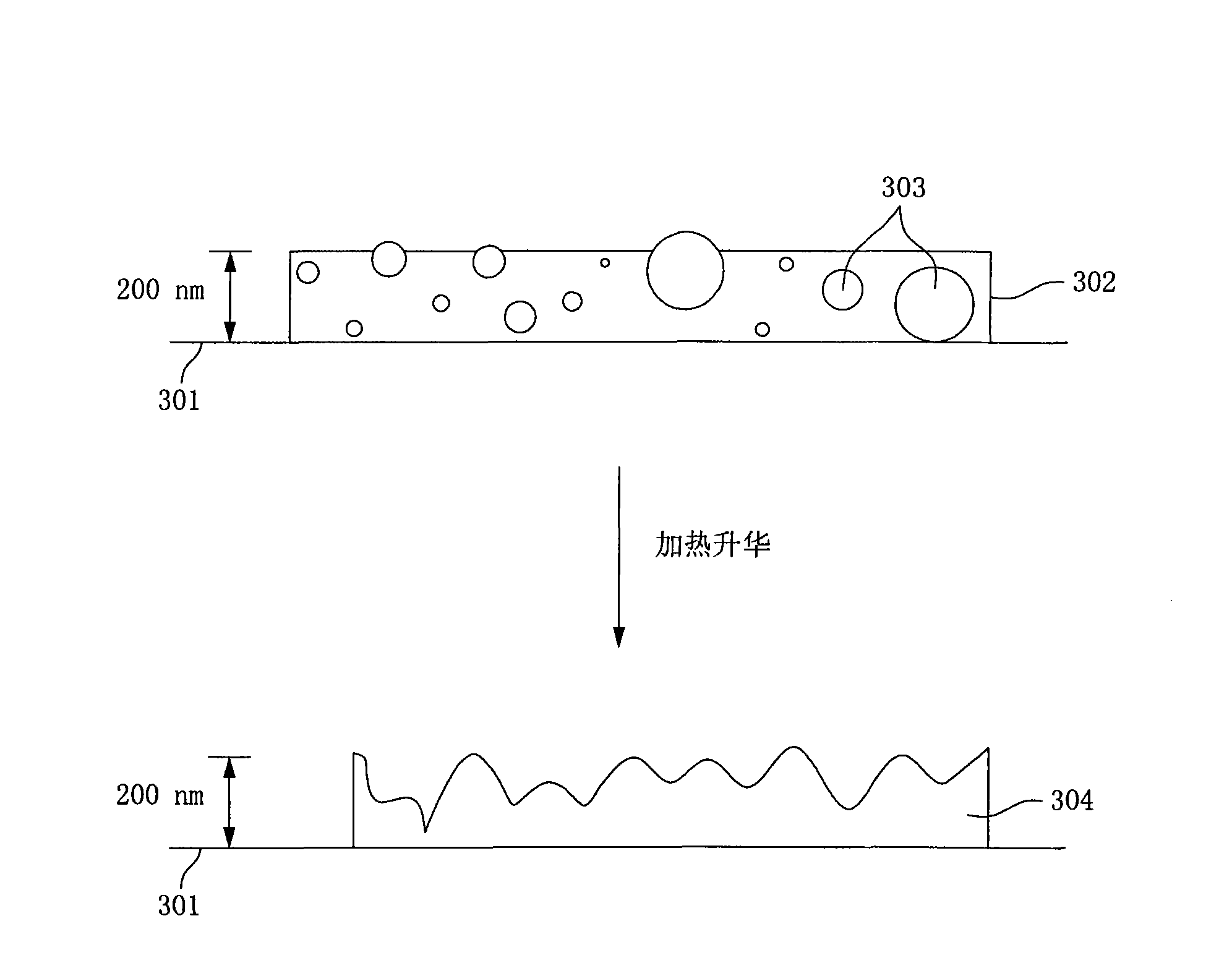

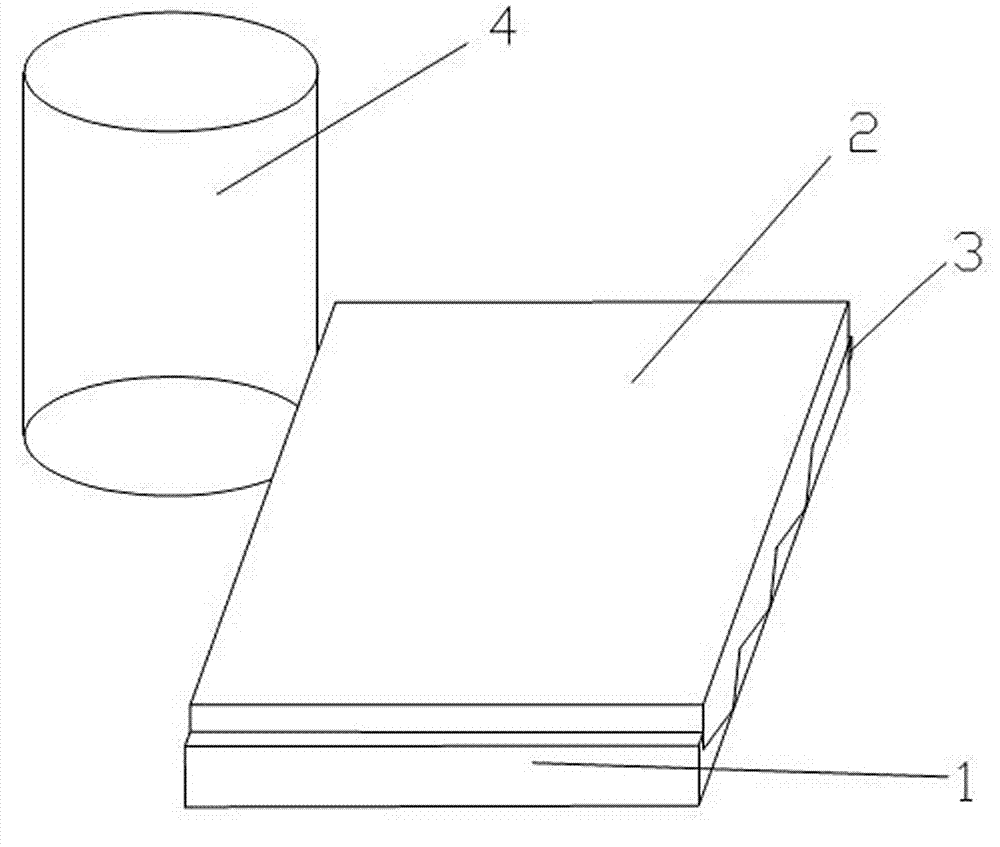

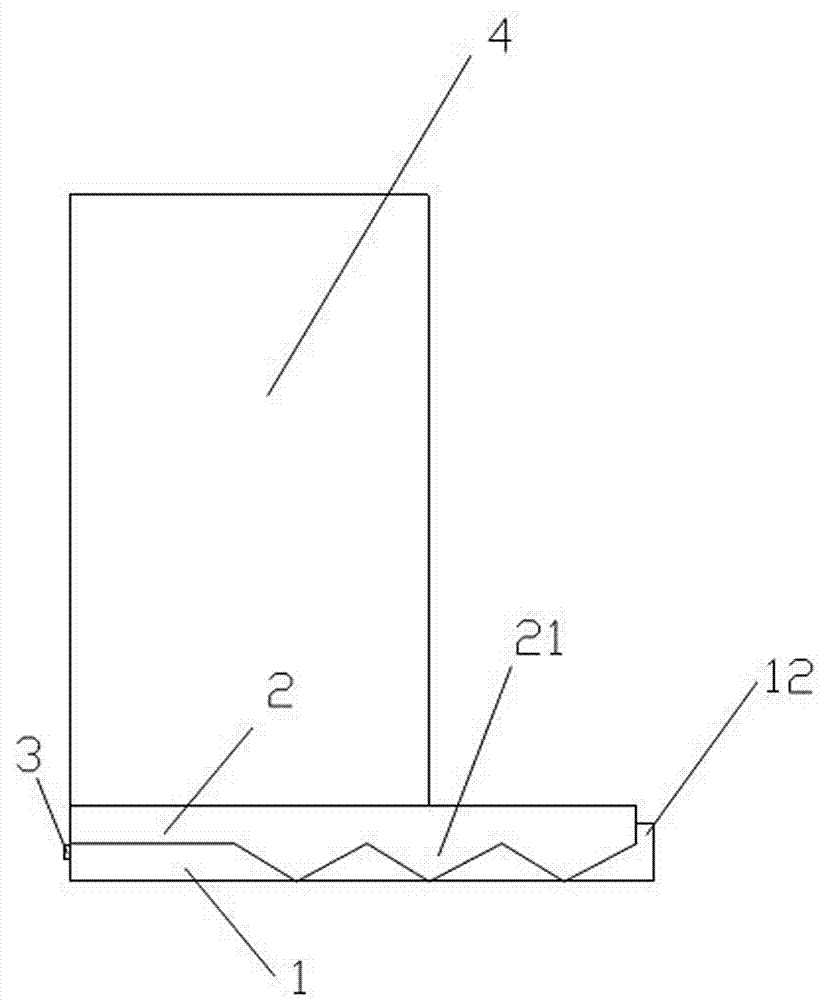

Semiconductor film of organic film solar battery as well as forming method and manufacturing method thereof

Owner:RYTEC CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap