Image sensor package, optical glass therefor and processing method

An image sensor, optical glass technology, applied in the direction of electric solid device, semiconductor device, glass manufacturing equipment, etc., can solve the problems of delamination, moisture or impurity intrusion, sticking, etc., to reduce the difference of thermal expansion coefficient, ensure the reception The effect of the ability of light signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Figure 3A to Figure 3D is a schematic diagram of the optical glass processing method used in the image sensor package of the present invention.

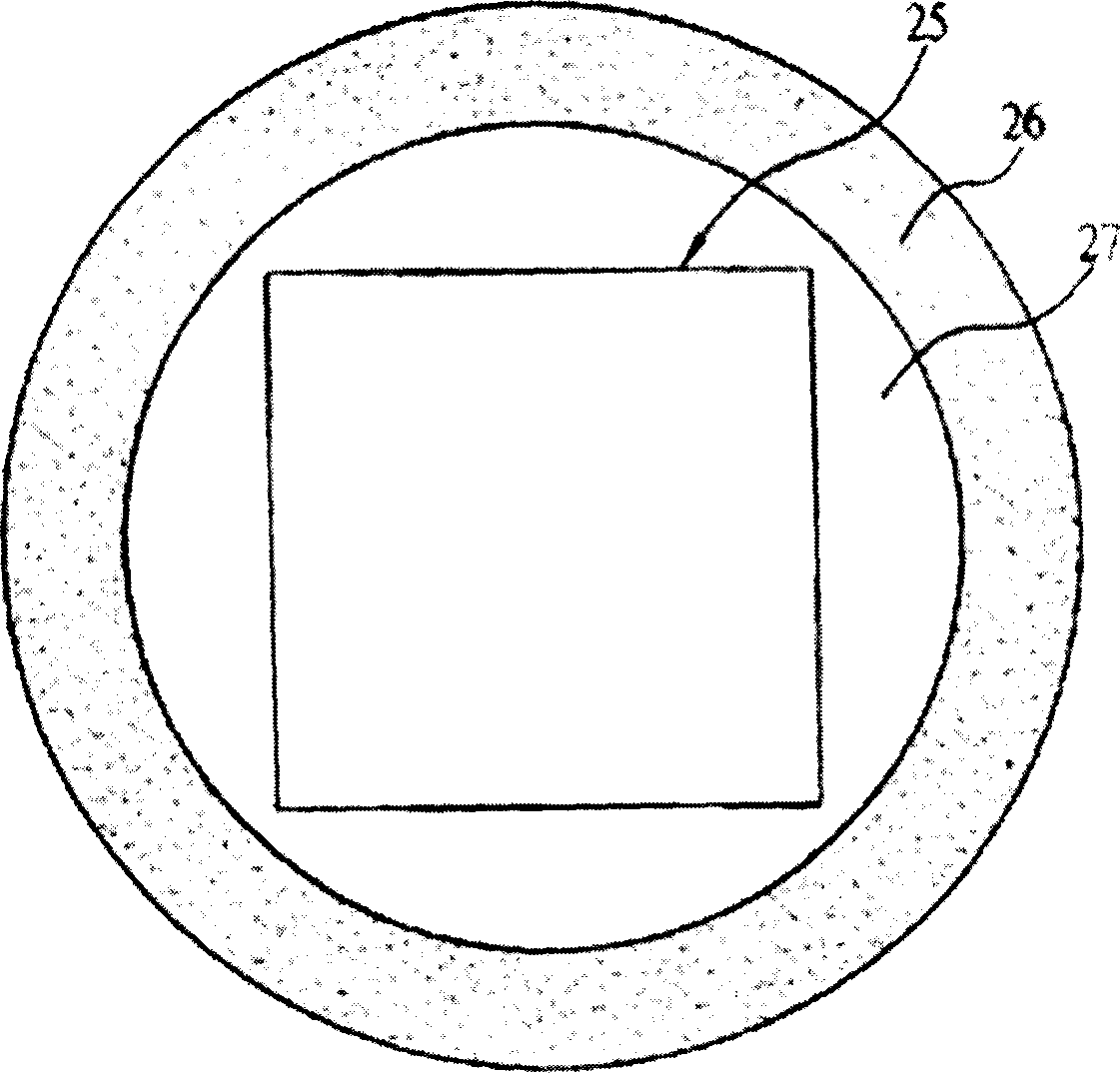

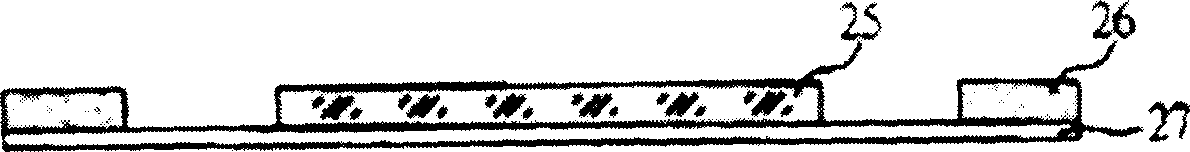

[0018] Such as Figure 3A As shown, a whole piece of optical glass 35 is firstly provided, and a plurality of cutting paths S are pre-divided on the whole piece of optical glass 35 for subsequent cutting operations to form a plurality of optical glass monomers. The entire piece of optical glass 35 can be glued on a tape 37 surrounded by a wafer ring 36 .

[0019] Such as Figure 3B As shown, a grinding tool such as a grinding wheel is used to grind along the cutting path S to form a rough surface 351 on the surface of the cutting path S of the optical glass.

[0020] Such as Figure 3C As shown, it corresponds to Figure 3B A schematic cross-sectional view of the entire piece of optical glass 35 , wherein the rough grinding surface 351 has a depth of about 1 μm to 10 μm, preferably 5 μm, and a width of the rough grinding su

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap