Cutting apparatus and rotary blade

a cutting apparatus and rotary blade technology, applied in cell components, electrochemical generators, transportation and packaging, etc., can solve the problems of defective cutting, foreign objects such as cuttings not easily adhered to the smooth surface portion, and the friction against the rotary blade may increase, so as to and prolong the life of the rotary blad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Hereinbelow, embodiments of a cutting apparatus proposed herein will be described. It should be noted that the embodiments described herein are, of course, not intended to limit the present invention. The present invention is not limited to the embodiments described herein unless specifically stated otherwise.

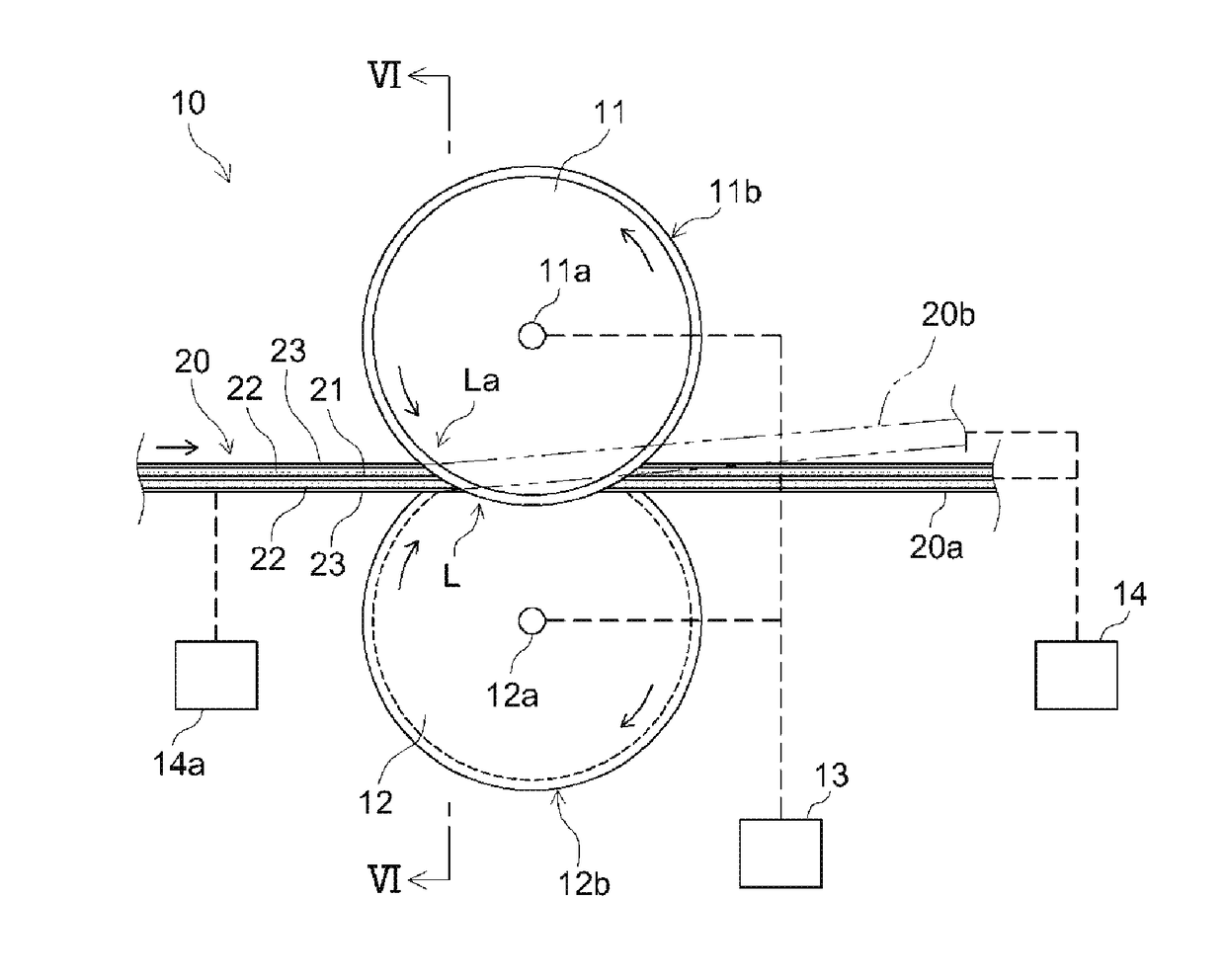

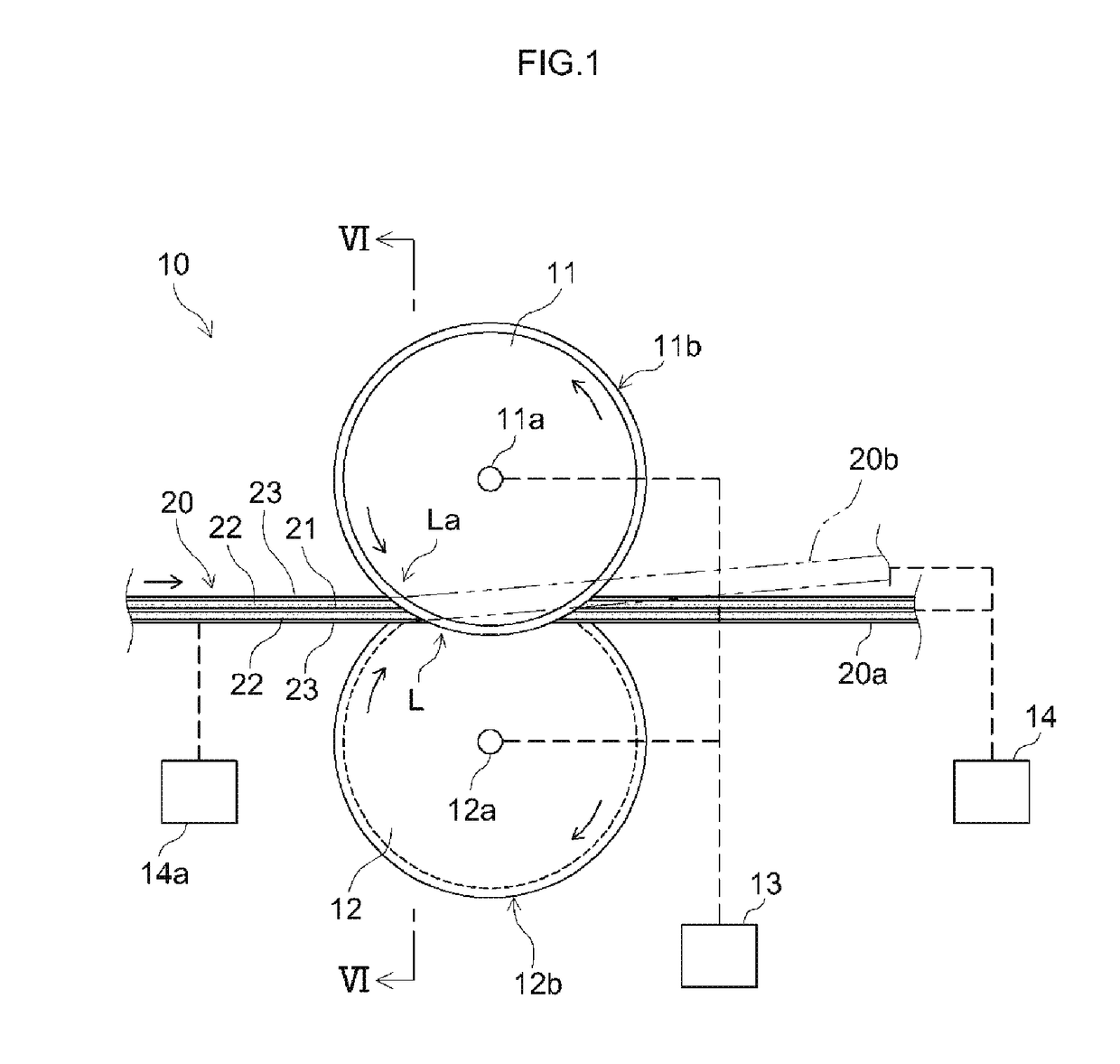

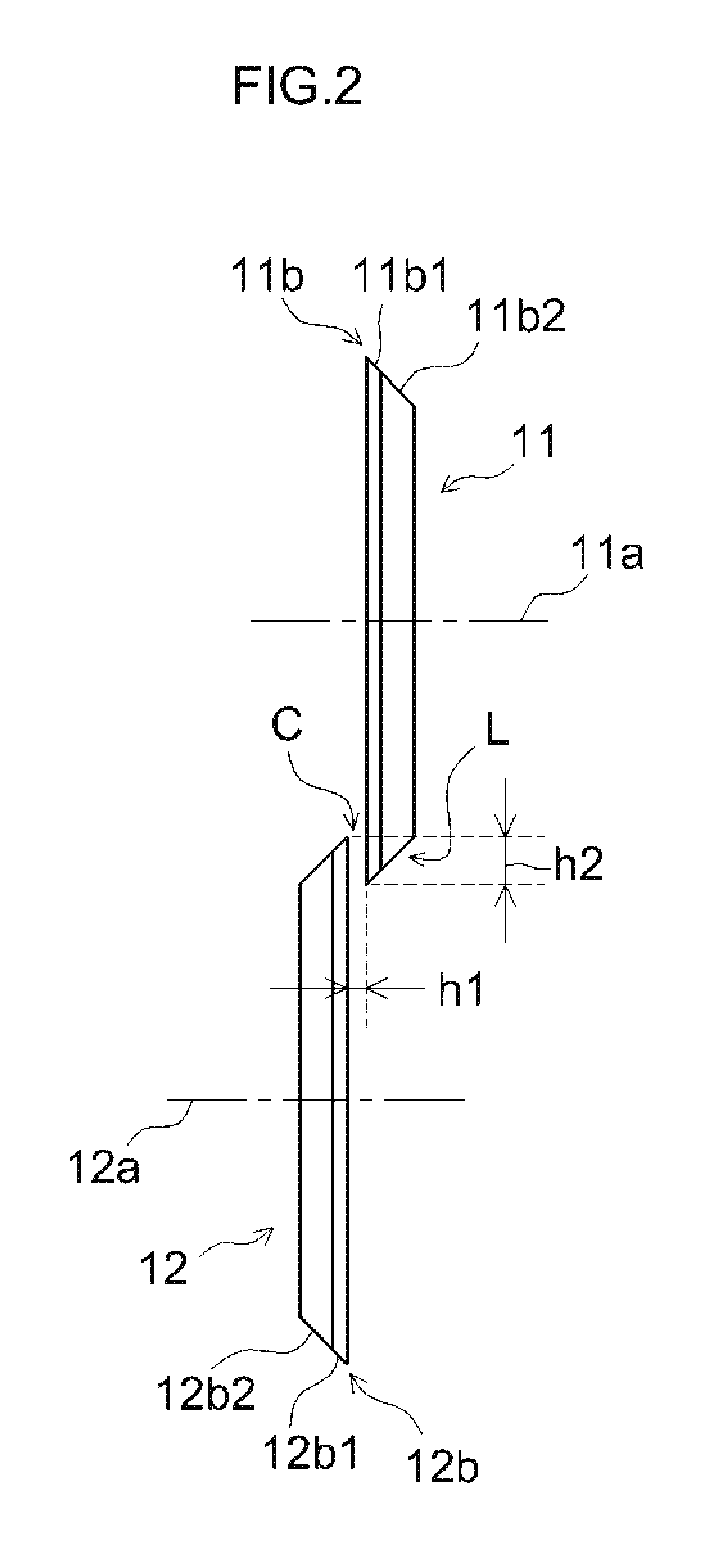

[0020]FIG. 1 is a side view illustrating a cutting apparatus 10 proposed herein. FIG. 2 is a front view illustrating an arrangement of a first rotary blade 11 and a second rotary blade 12 of the cutting apparatus 10. FIG. 3 is a partially enlarged cross-sectional view illustrating a circumferential edge portion 11b (blade edge) of the first rotary blade 11. FIG. 4 is a plan view of an electrode sheet 20 that is to be cut. FIG. 5 is a cross-sectional view of the electrode sheet 20 that is to be cut.

[0021]The electrode sheet 20 to be cut herein is what is called a separator-integrated-type electrode sheet, as illustrated in FIGS. 4 and 5. The electrode sheet 20 includes a curr

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap