Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Cross-link" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry and biology a cross-link is a bond that links one polymer chain to another. These links may take the form of covalent bonds or ionic bonds and the polymers can be either synthetic polymers or natural polymers (such as proteins).

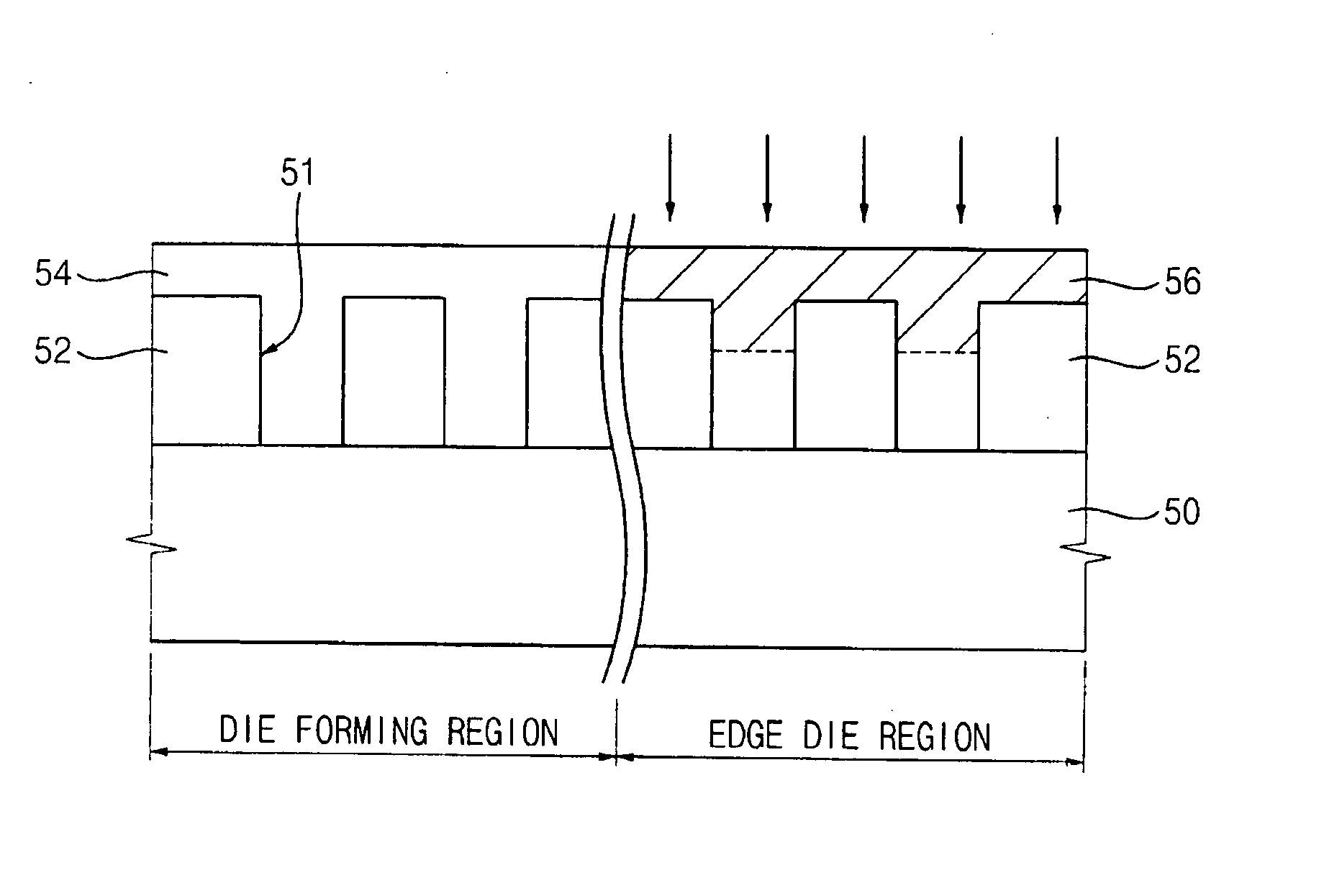

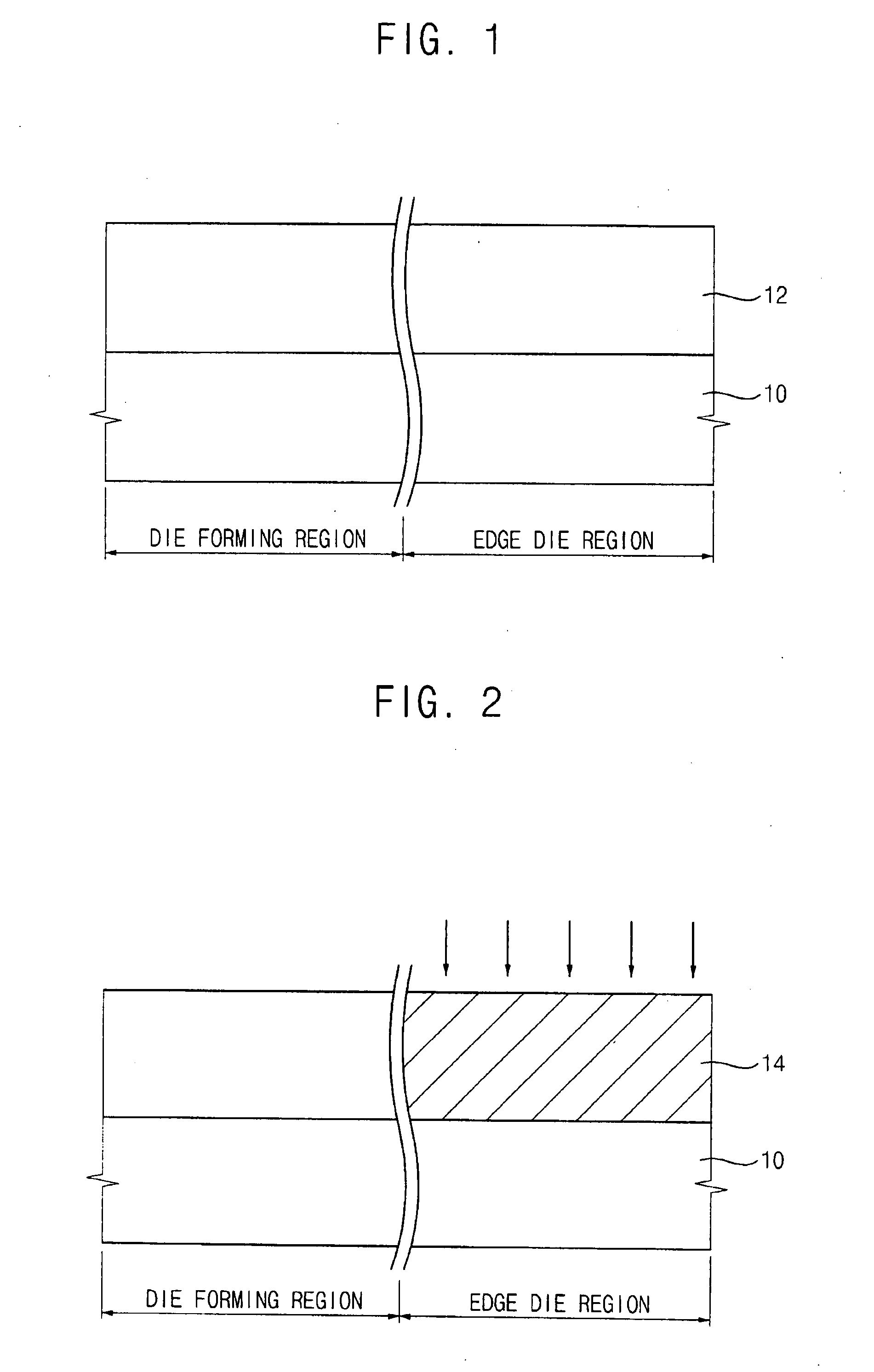

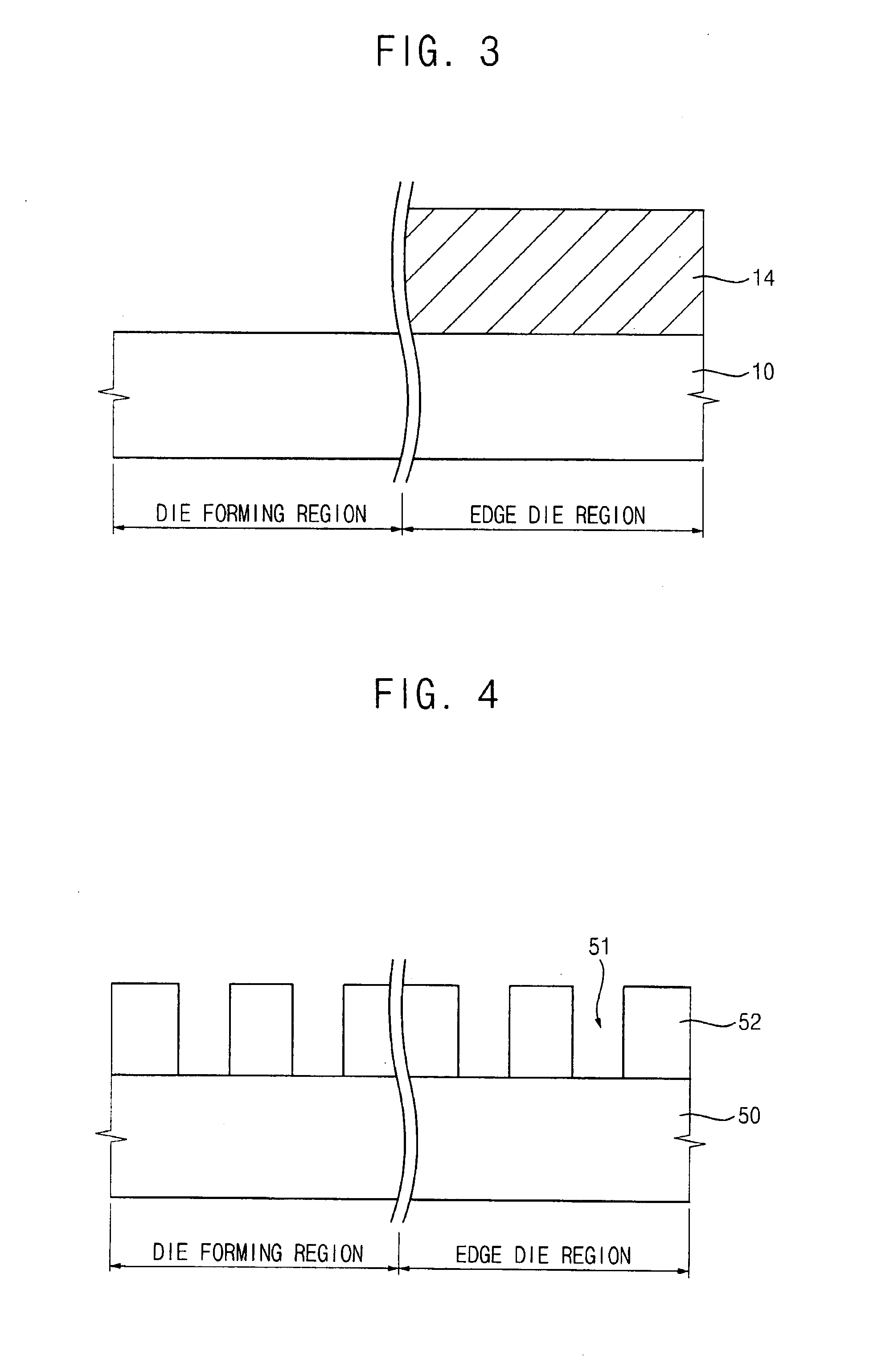

Polymer resin composition, related method for forming a pattern, and related method for fabricating a capacitor

InactiveUS20070249117A1Reduce in quantityReduce processing timeSolid-state devicesSemiconductor/solid-state device manufacturingCross-link(Hydroxyethyl)methacrylate

Owner:SAMSUNG ELECTRONICS CO LTD

Method for raising fluidity of thermoplastic cross-linked rubber

Owner:SHANDONG DAWN POLYMER CO LTD

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation method of hyperbranched polyester modified organic silicon resin and coating comprising resin

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Preparation method and application of surface artemisinin molecule imprinting adsorbing material of vegetable sponge

InactiveCN102600813ASpecific recognition abilityHigh selectivityIon-exchange process apparatusOrganic chemistryCross-linkN dimethylformamide

Owner:UNIV OF JINAN

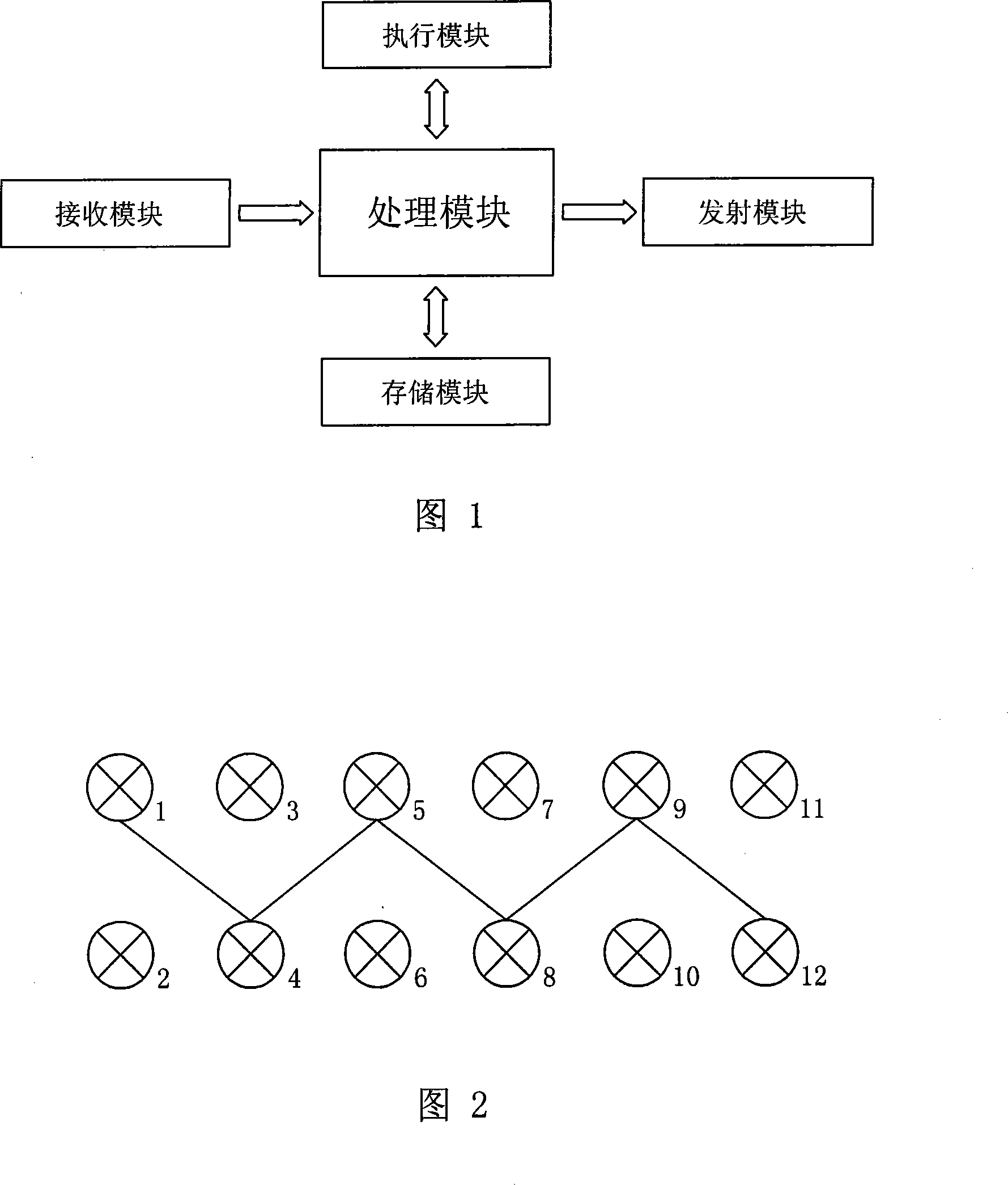

A control method for cross-linked radio relay delivery road lamp

InactiveCN101170859AAvoid the situation that the control command cannot be receivedPrevent execution confusionTransmission systemsElectric light circuit arrangementCross-linkComputer module

Owner:费绍栋

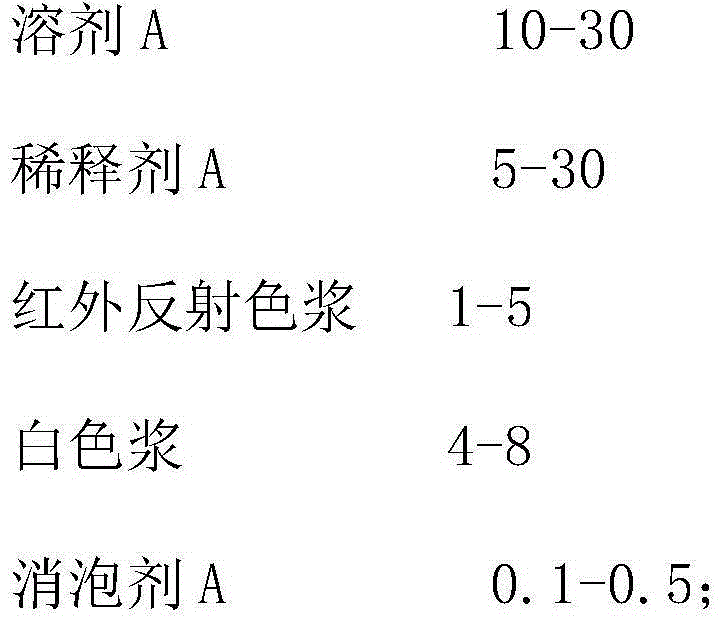

Infrared stealth textile coating fabric

ActiveCN105034523ALow infrared reflectanceImprove stealth performanceSynthetic resin layered productsCross-linkPolymer science

Owner:CTA HI TECH TEXTILES

Method for preparing high-viscosity chitosan quick hemostatic patch

InactiveCN103386146AIncrease viscosityHigh degree of deacetylationAbsorbent padsBandagesCross-linkFreeze-drying

The invention discloses a method for preparing a high-viscosity chitosan quick hemostatic patch. The method comprises the following steps: preparing chitosan gel from high-viscosity chitosan having a deacetylation degree in the range from 80% to 90%, drying the chitosan gel and then immersing one single side of the chitosan gel into a mixed solution of chloroacetic acid and isopropanol for carboxymethylation, and then soaking the chitosan gel into a 30% glycerol solution for 30 minutes and then draining; and finally, carrying out a cross-linking reaction by using a calcium chloride solution so as to introduce calcium ions and thrombin, and then carrying out vacuum freeze-drying, thereby obtaining the high-viscosity chitosan quick hemostatic patch. Raw materials used for the process of the method are low in cost; the process is simple and convenient, and short in period; the obtained chitosan hemostatic patch is high in adhesiveness, and capable of quickly stopping bleeding of a wound under the promotion effect of the calcium ions and the thrombin.

Owner:黄耀江 +2

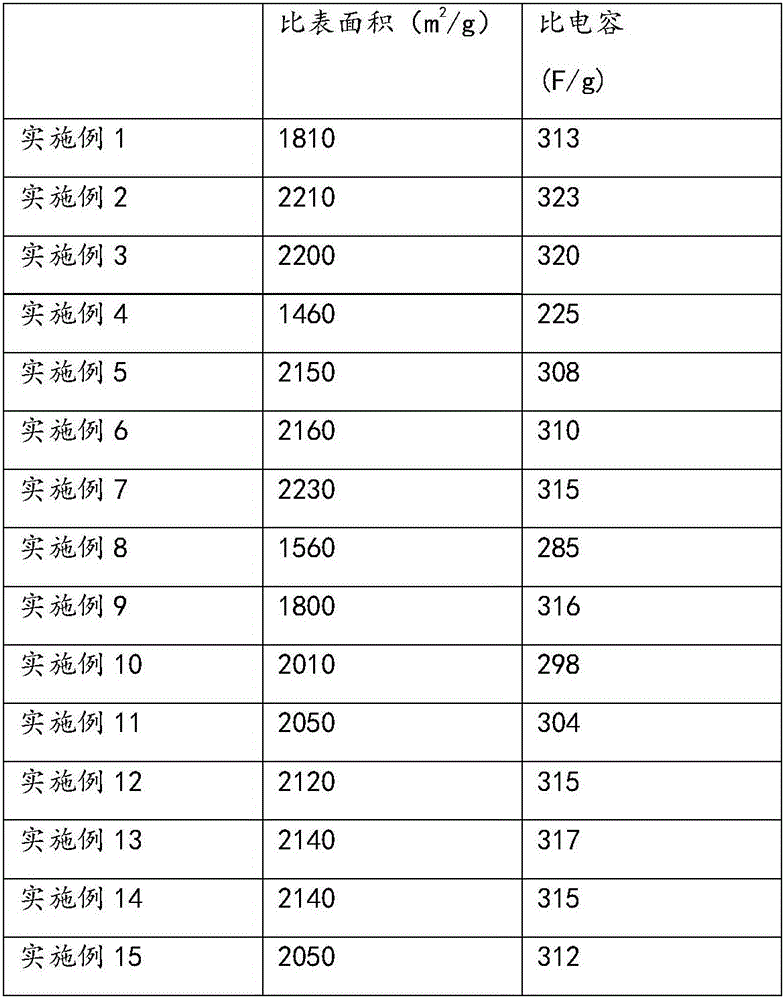

Graphene-based hierarchical pore capacitor carbon and preparation method thereof as well as capacitor

InactiveCN106467299ACurl suppressionSuppress stackingHybrid capacitor electrodesGrapheneCross-linkPorosity

Owner:山东圣泉新能源科技有限公司

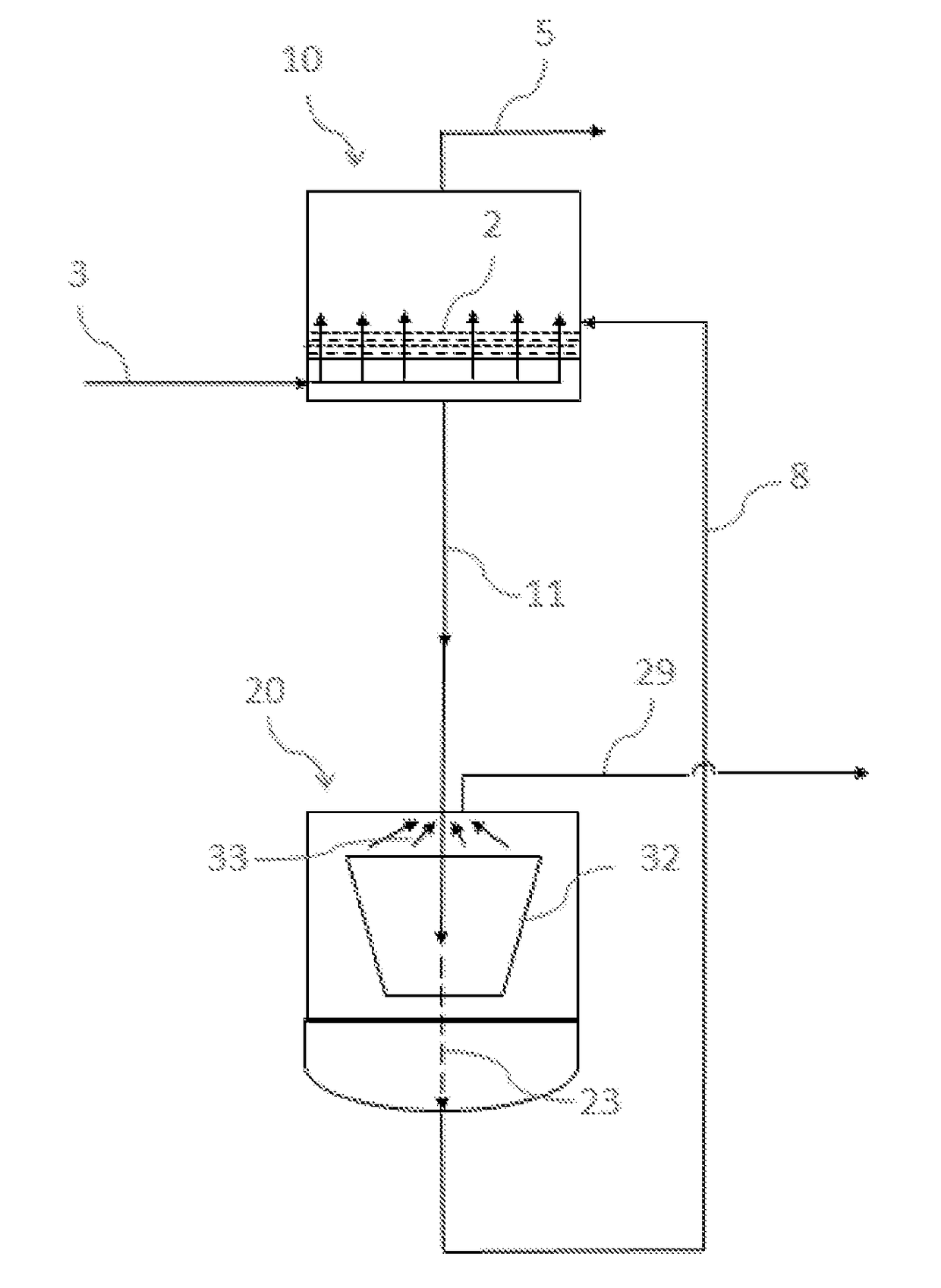

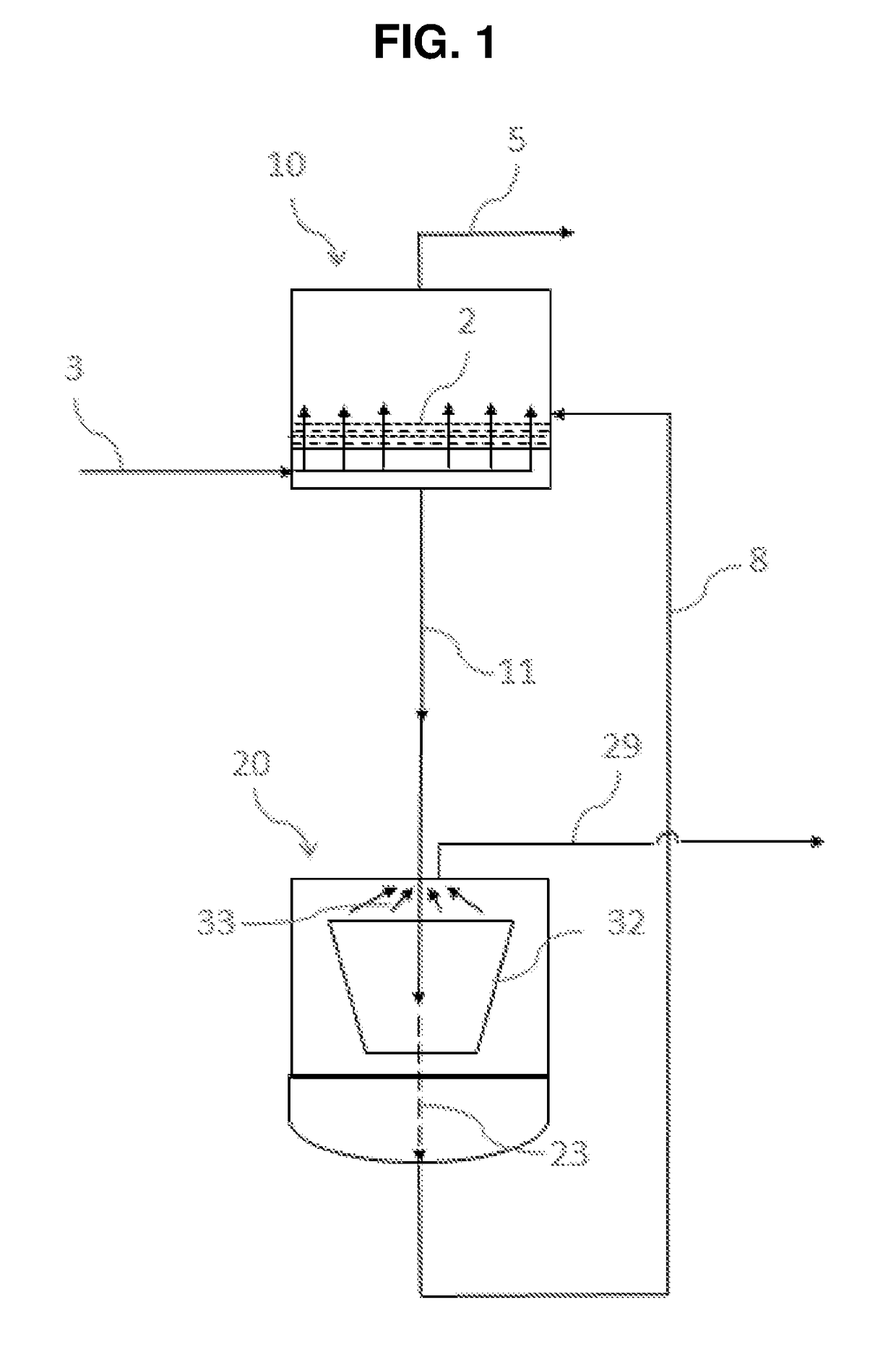

Fuel cell

InactiveUS20120009498A1Complex structureLow costFuel cells groupingCell component detailsCross-linkFuel cells

A fuel cell is provided with a separator that supports an electrolyte / electrode assembly sandwiched therebetween. The separator is provided with: first and second fuel gas supply parts in the center of which fuel gas supply holes are formed; first and second cross-link parts connected to the first and second fuel gas supply parts; and first and second surrounding support parts connected to the first and second cross-link parts. Each first surrounding support part is provided with a set of fuel gas exhaust passages that discharge fuel gas that has gone through a fuel gas passage and been used. The cross-sectional areas of the fuel gas exhaust passages are larger on the downstream sides than on the upstream sides, in terms of the direction of fuel gas flow.

Owner:HONDA MOTOR CO LTD

Tackifier for drilling fluid and preparation method thereof

ActiveCN104311730AImproved rock carrying capacityThe preparation method is simple and feasibleDrilling compositionCross-linkSalt resistance

The invention relates to a tackifier for drilling fluid and a preparation method thereof, and belongs to the technical field of synthesis of processing agents for oil-field drilling fluids. The tackifier is a net-like polymer obtained by mixing acrylamide, a sulfo-group-containing monomer A and a pyrrolidone monomer B according to the mass ratio of 10:(3-5):(0.7-1.5), adjusting the pH value of the solution, adding a cross-linking agent C, a molecular-weight adjusting agent D and an initiator and performing copolymerization crosslinking. The preparation method is simple and practicable, and short in reaction time. The obtained tackifier has good salt resistance, has the temperature resistance up to 135 DEG C, has good effects of increasing shear viscosity and reducing filter loss when being applied to drilling fluids, is capable of substantially improving the cutting carrying capability of the drilling fluids under the condition of high temperature, has the effect obviously better than a tackifier normally used on site, is widely applicable to fresh-water drilling fluids and saturated brine drilling fluids, and has relatively good application prospect.

Owner:CHINA PETROCHEMICAL CORP +1

Thermoplastic Elastomer Composition And Shaped Article

Owner:ZEON CORP

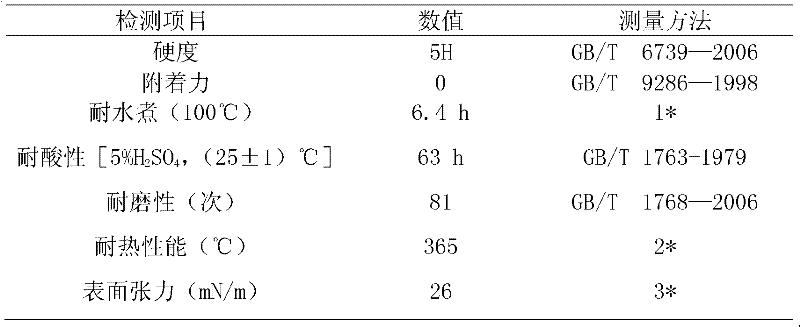

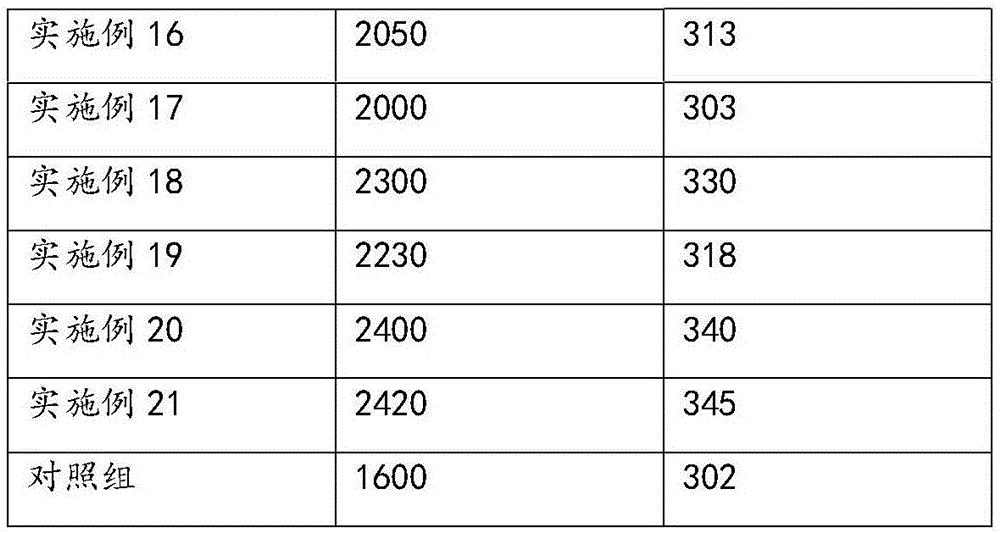

High-hardness matte ceramic antifouling agent, and preparation method thereof

ActiveCN107400461AHas hydrophobic antifouling and antibacterial effectDoes not add glossAntifouling/underwater paintsPaints with biocidesCross-linkHydrogen

Owner:黄艳红

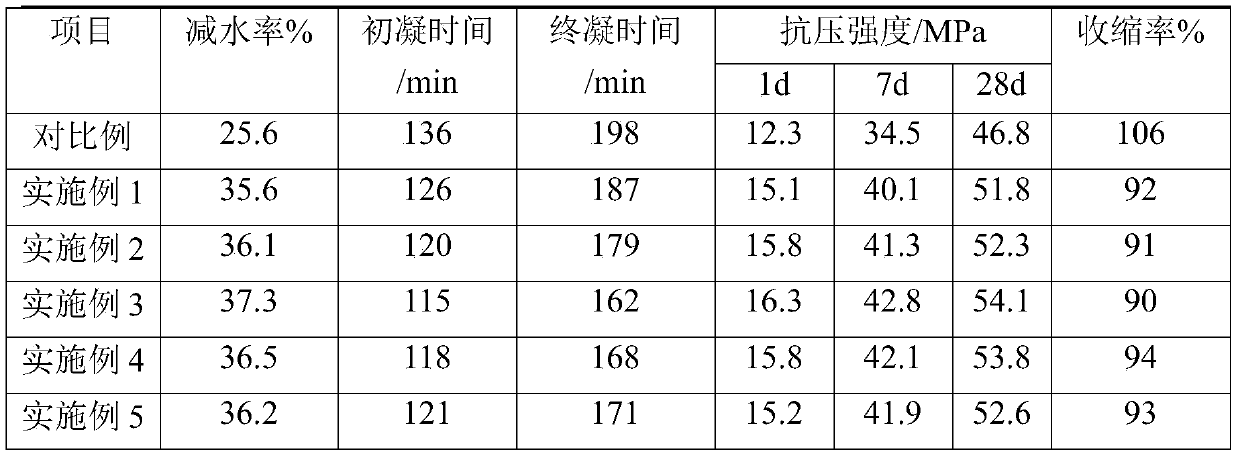

Concrete high-efficiency water reducer and preparation method thereof

Owner:KUNMING ANXIA NEW MATERIAL SCI & TECH CO LTD

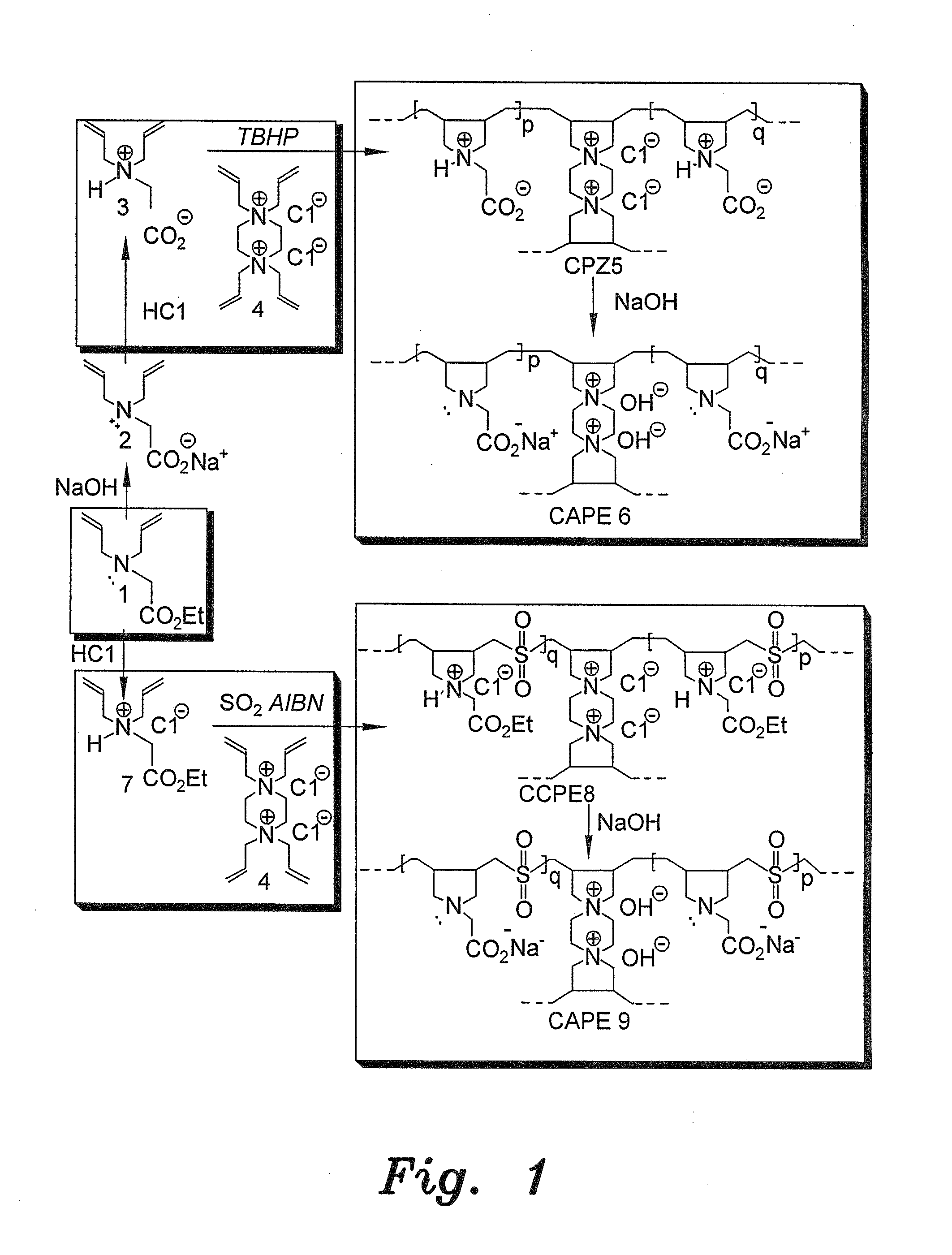

Cross-linked polyaminocarboxylates for the removal of metal ions from aqueous solutions

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

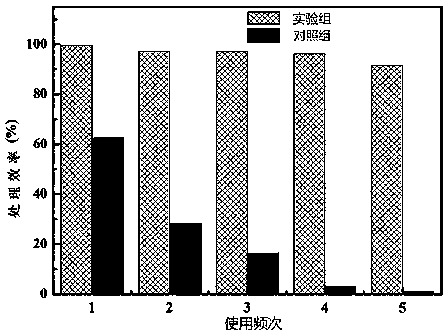

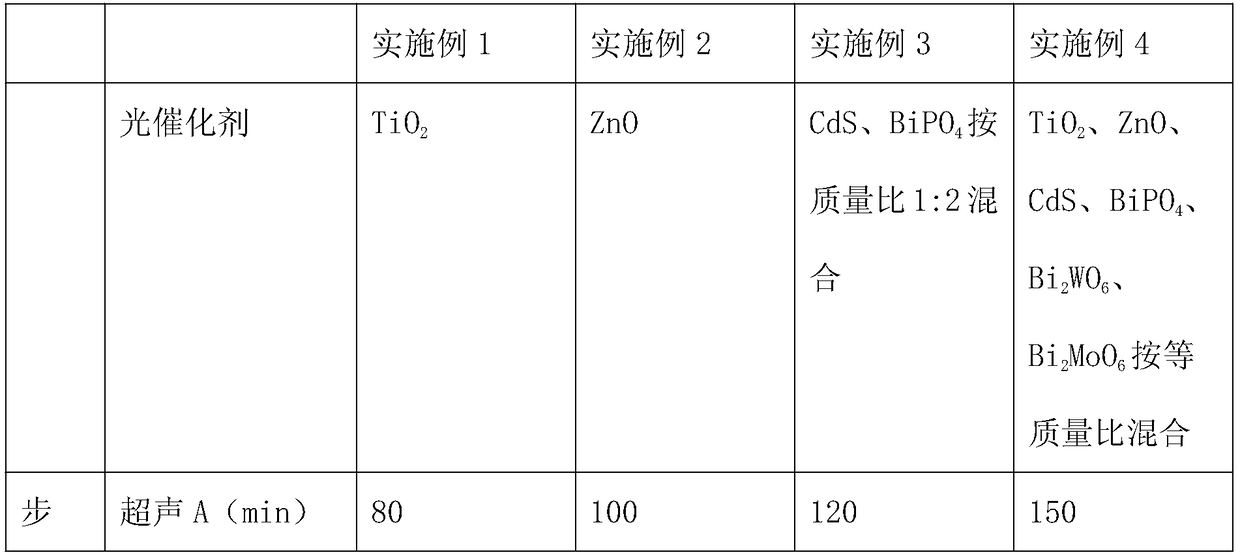

Graphene hybridized photocatalyst hydrogel

ActiveCN108126682AGood dispersionAvoid gatheringWater/sewage treatment by irradiationWater treatment compoundsCross-linkPhotocatalytic degradation

Owner:河北燕园众欣石墨烯科技有限公司

Method for crimping high-pressure cross-linking three-layer co-extrusion continuous produced disc-exchanging conductor

InactiveCN102945710ANo drop in tensile strengthLow technical requirementsConnections effected by permanent deformationCable/conductor manufactureCross-linkElectrical resistance and conductance

Owner:HENGYANG HENGFEI CABLE CO LTD

Automobile external glazing tape manufacturing technique and correction tool applied to technique

PendingCN108723143AIncrease productivityAvoid destructionShaping toolsVehicle componentsCross-linkMetal framework

Owner:上海敏孚汽车饰件有限公司

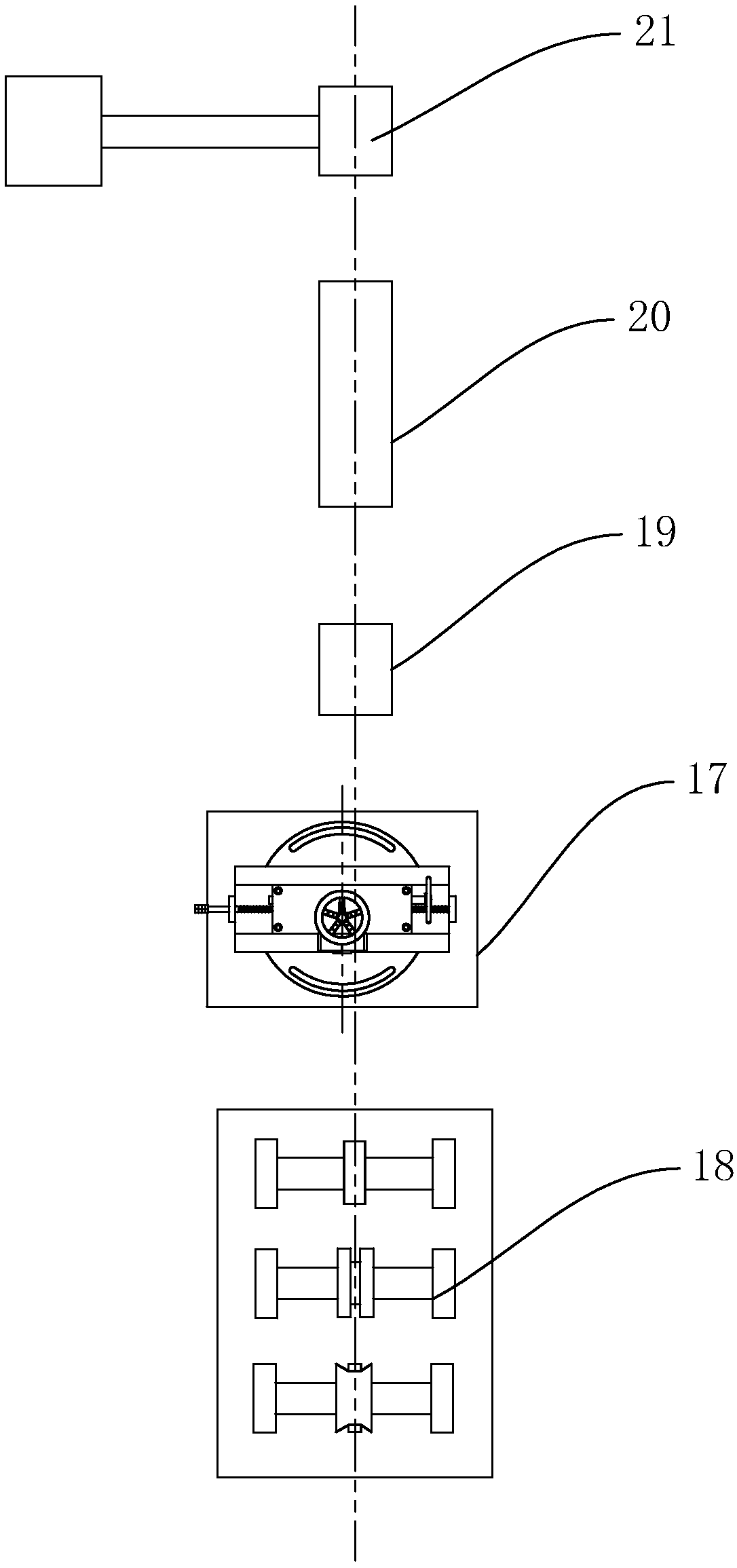

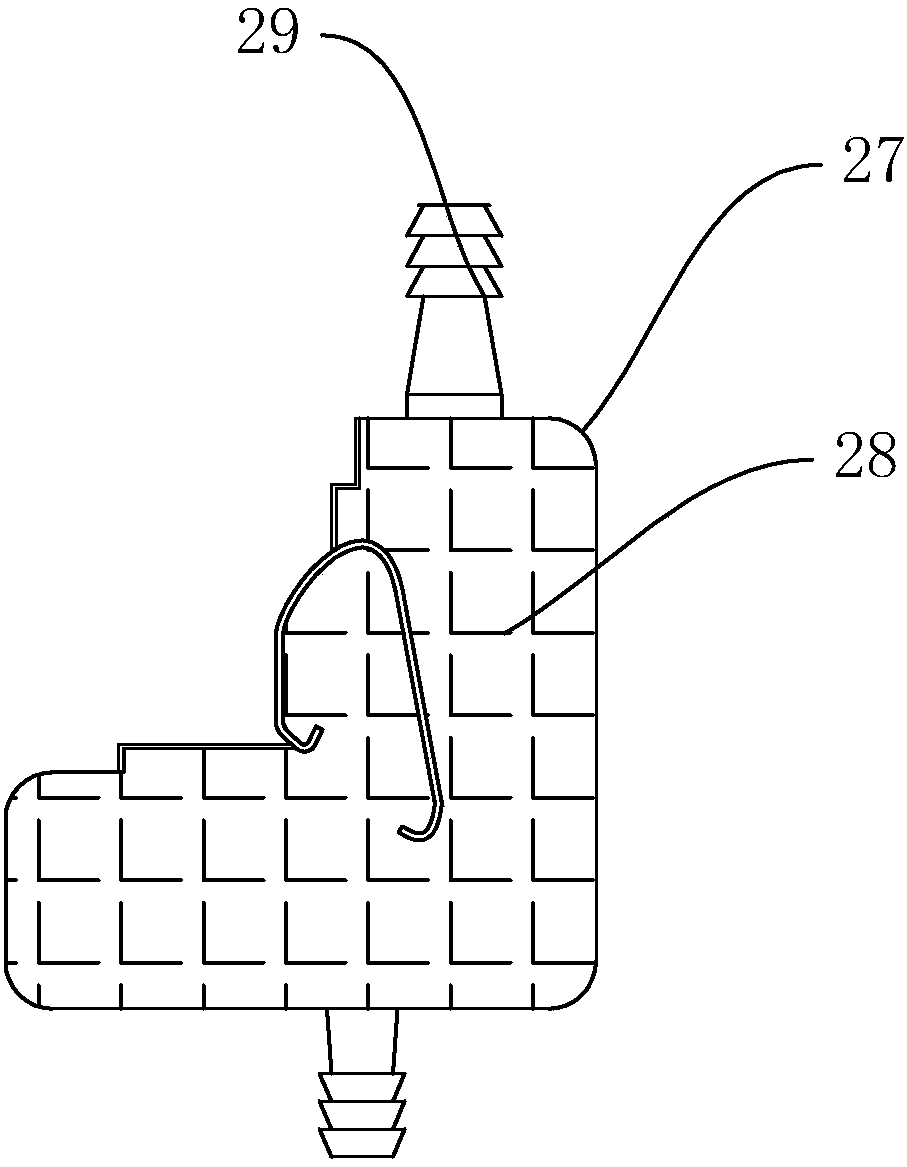

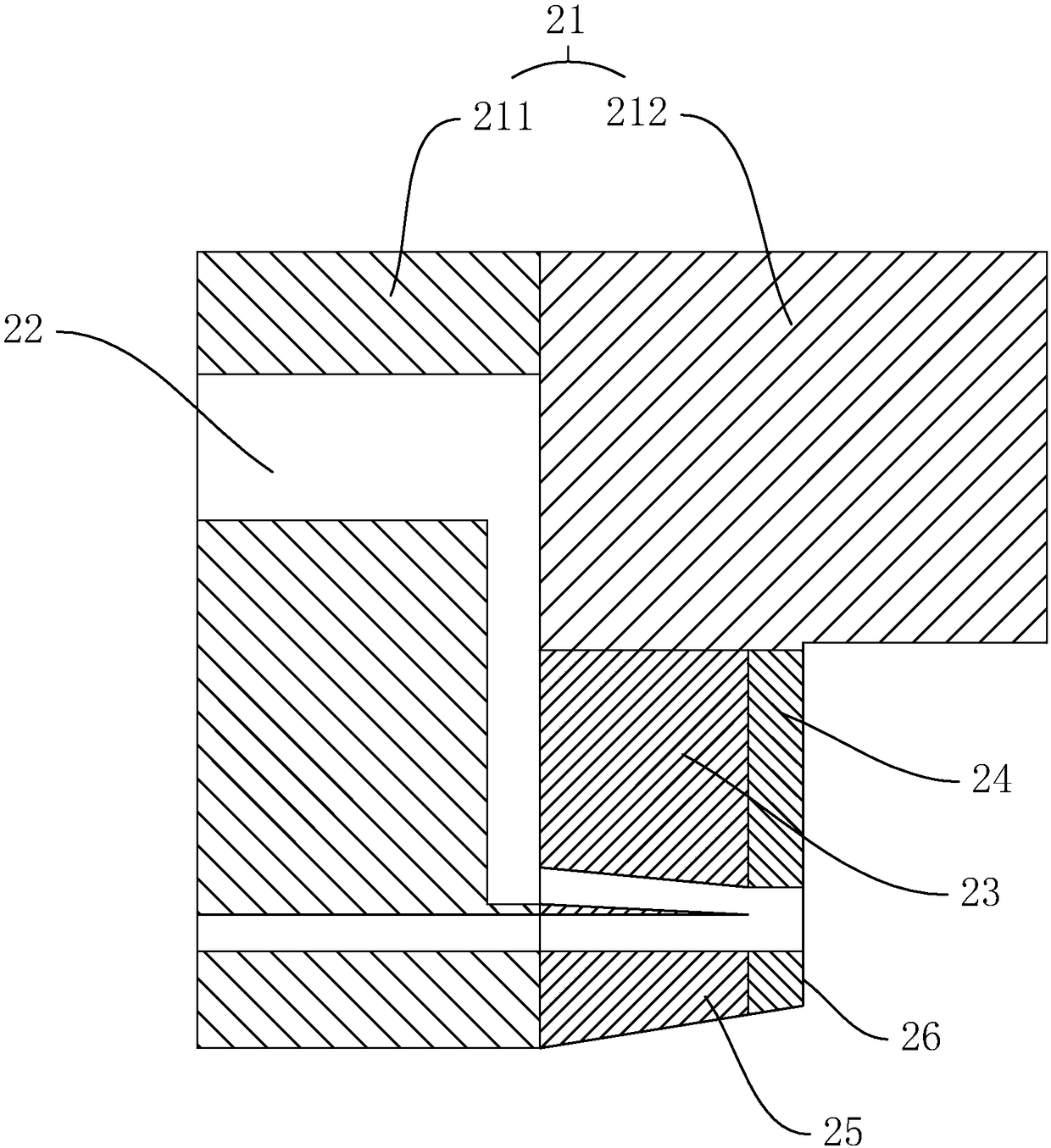

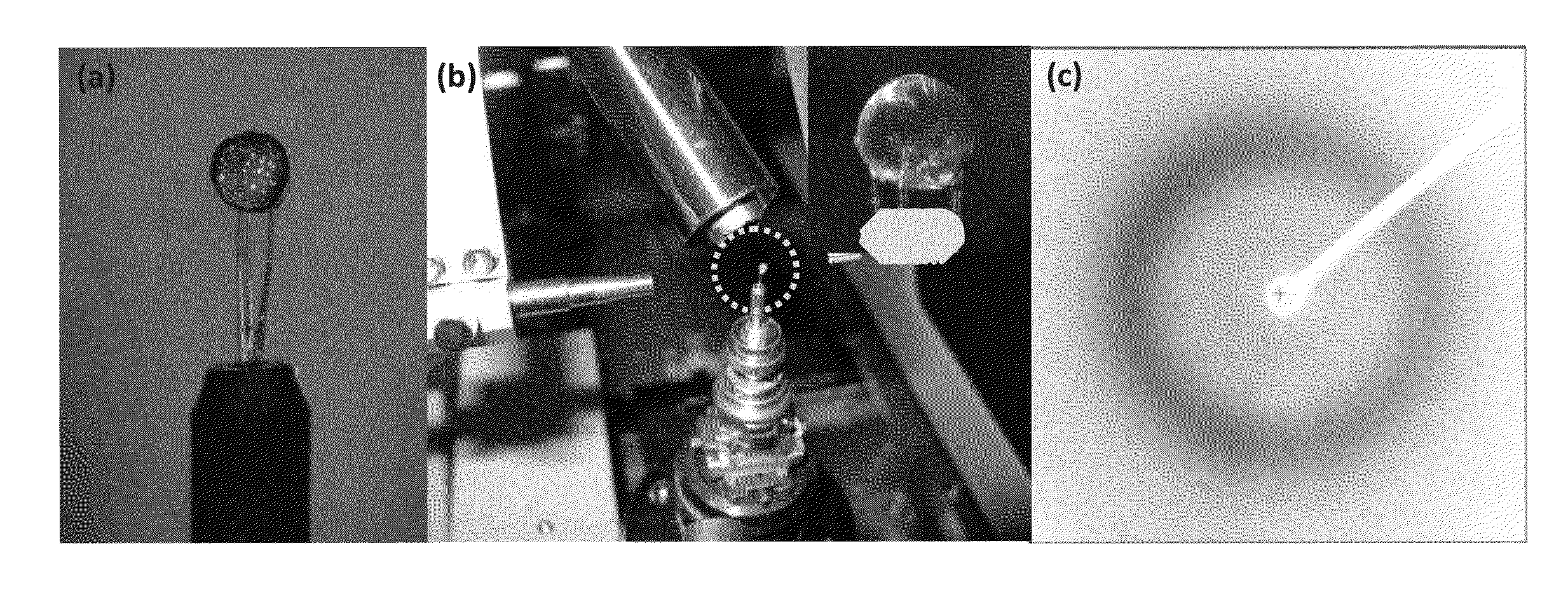

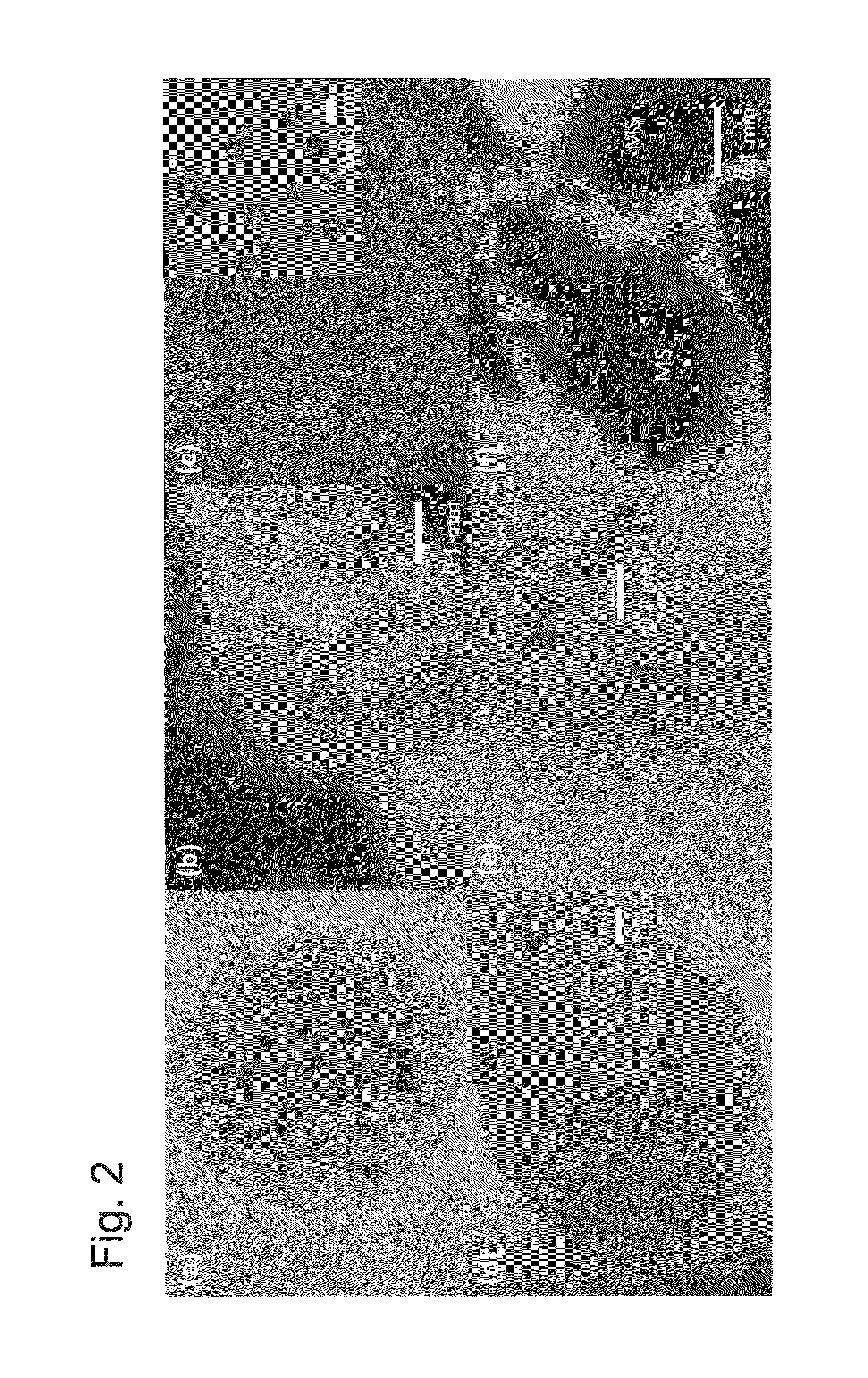

Method for forming protein crystal

InactiveUS20130196160A1Easily taken outEasy to handlePackage sterilisationLaboratory glasswaresCross-linkProtein solution

Owner:RIKEN

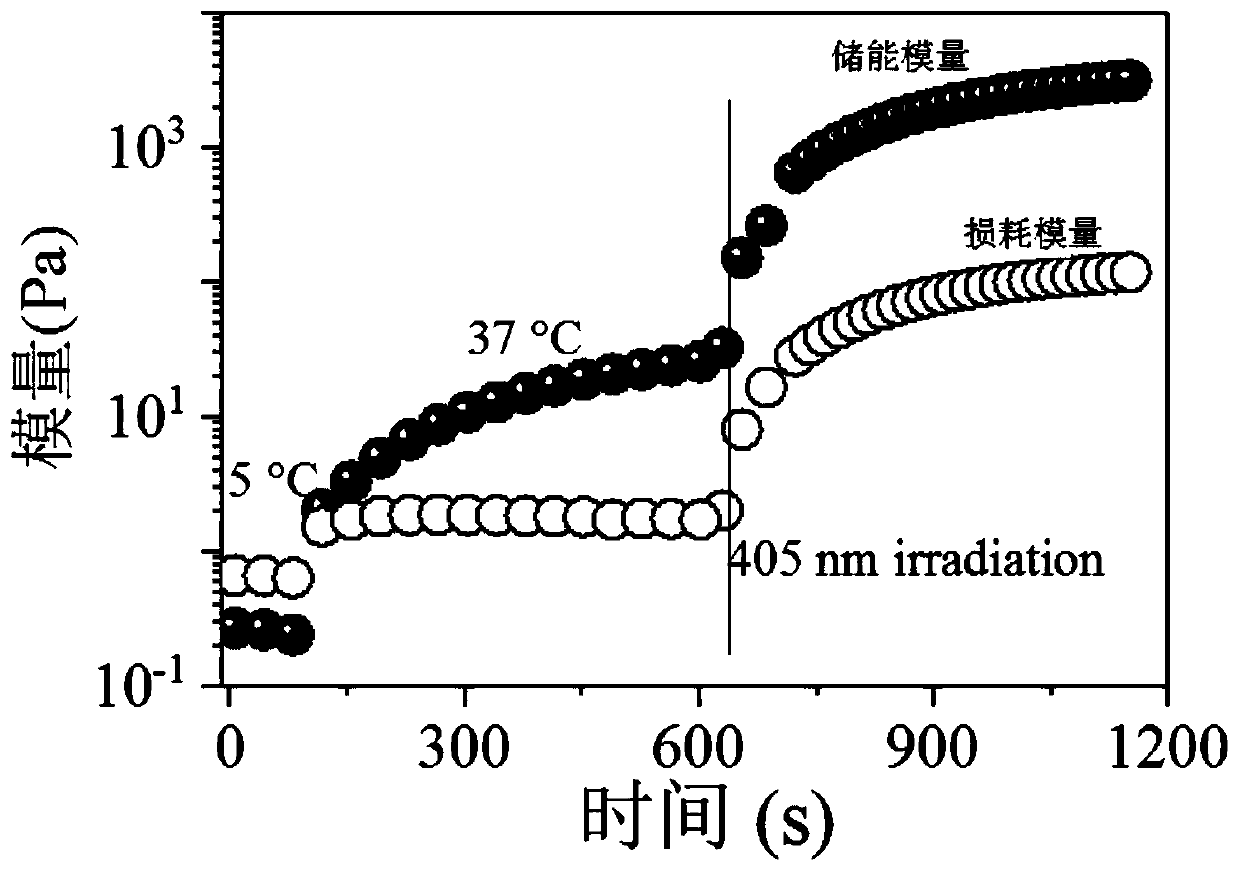

Preparation method of double-response hydrogel ink

ActiveCN109988320AAdjustable transition temperatureMeet the mechanical requirements of the microenvironmentCross-linkUltimate tensile strength

Owner:XIAN UNIV OF TECH

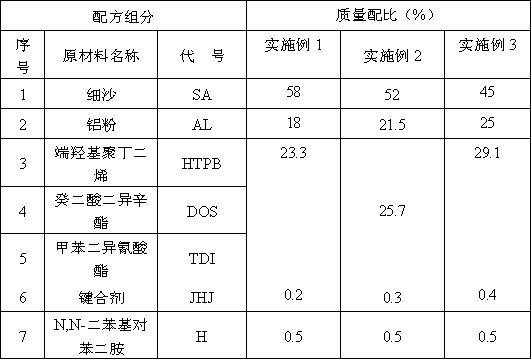

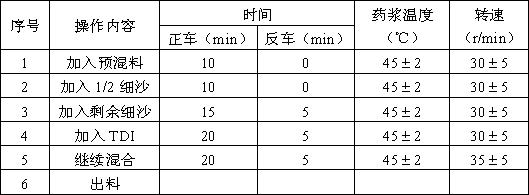

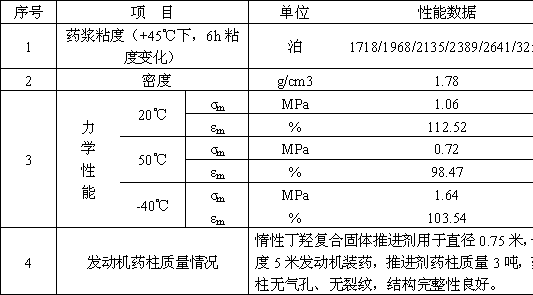

Low-cost inert hydroxyl terminated polybutadiene (HTPB) composite solid propellant and preparation method thereof

InactiveCN110204408AAdjust mechanical propertiesNot easy to absorb moisturePressure gas generationCross-linkSlurry

Owner:江西航天经纬化工有限公司

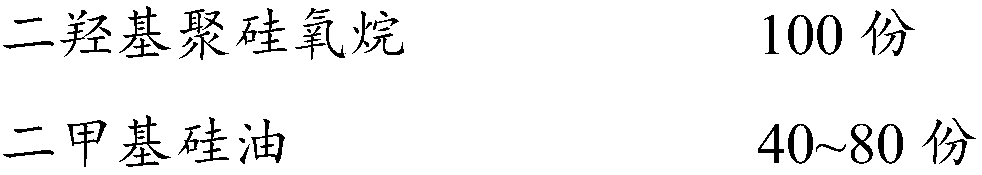

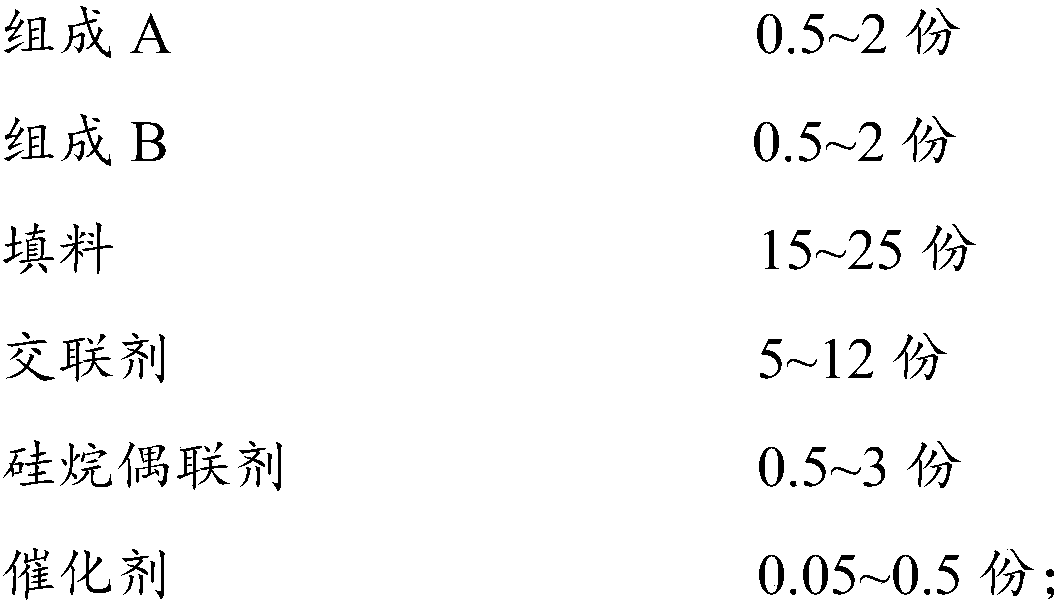

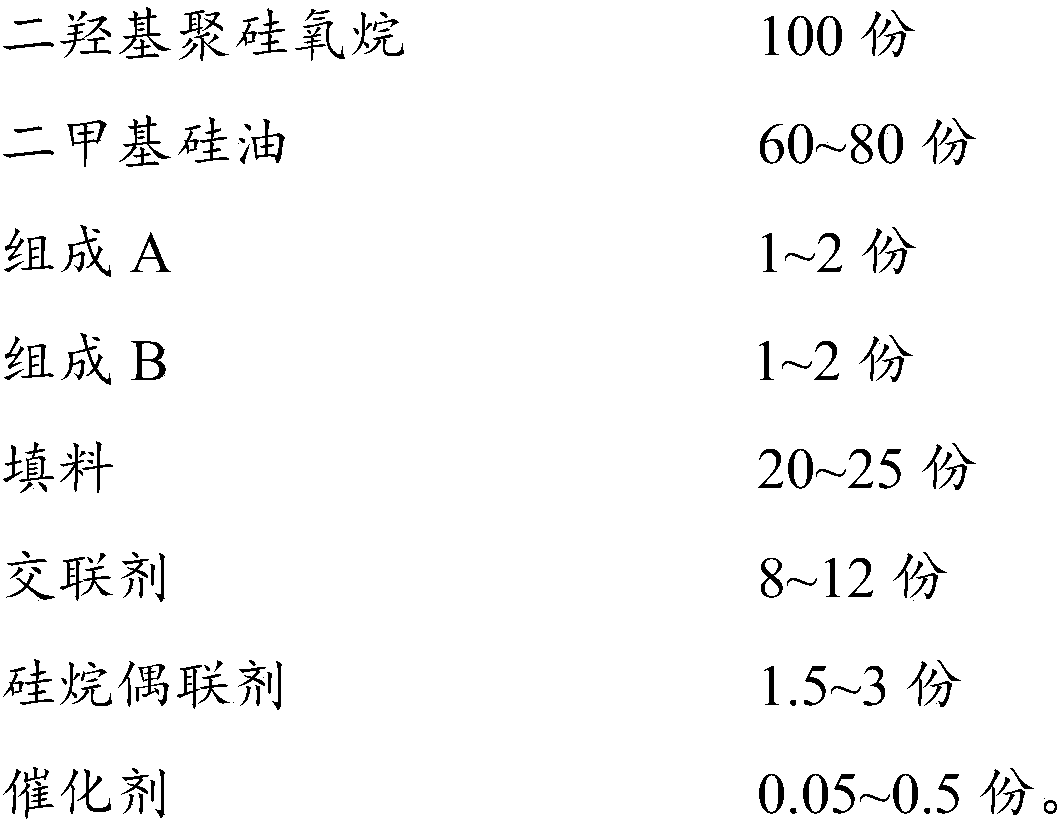

Ketonic oxime type silicone sealant and preparation method thereof

InactiveCN108192561AExcellent and long-lasting anti-mold effectAvoid yellowingNon-macromolecular adhesive additivesCross-linkThiazole

Owner:GUANGZHOU BAIYUN CHEM IND

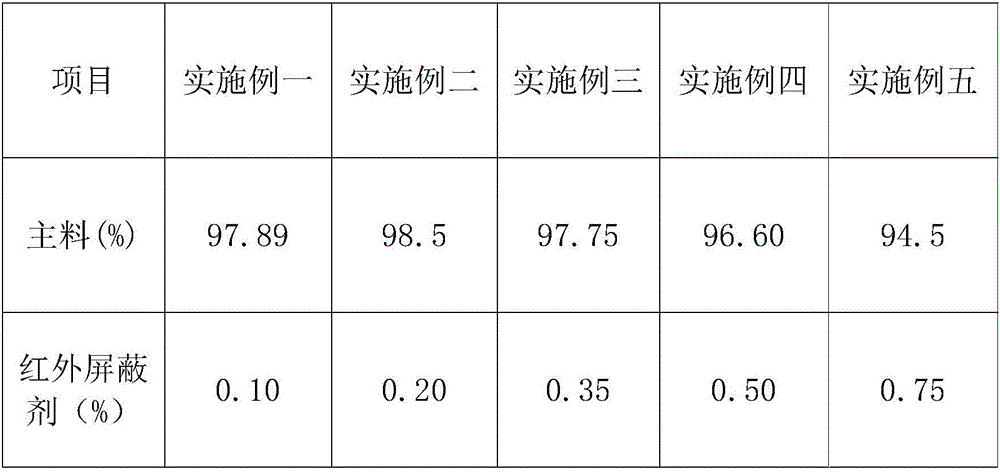

Infrared shielded EVA photovoltaic film

ActiveCN106590471AReduce the temperatureIncrease output powerNon-macromolecular adhesive additivesPhotovoltaic energy generationCross-linkInfrared

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

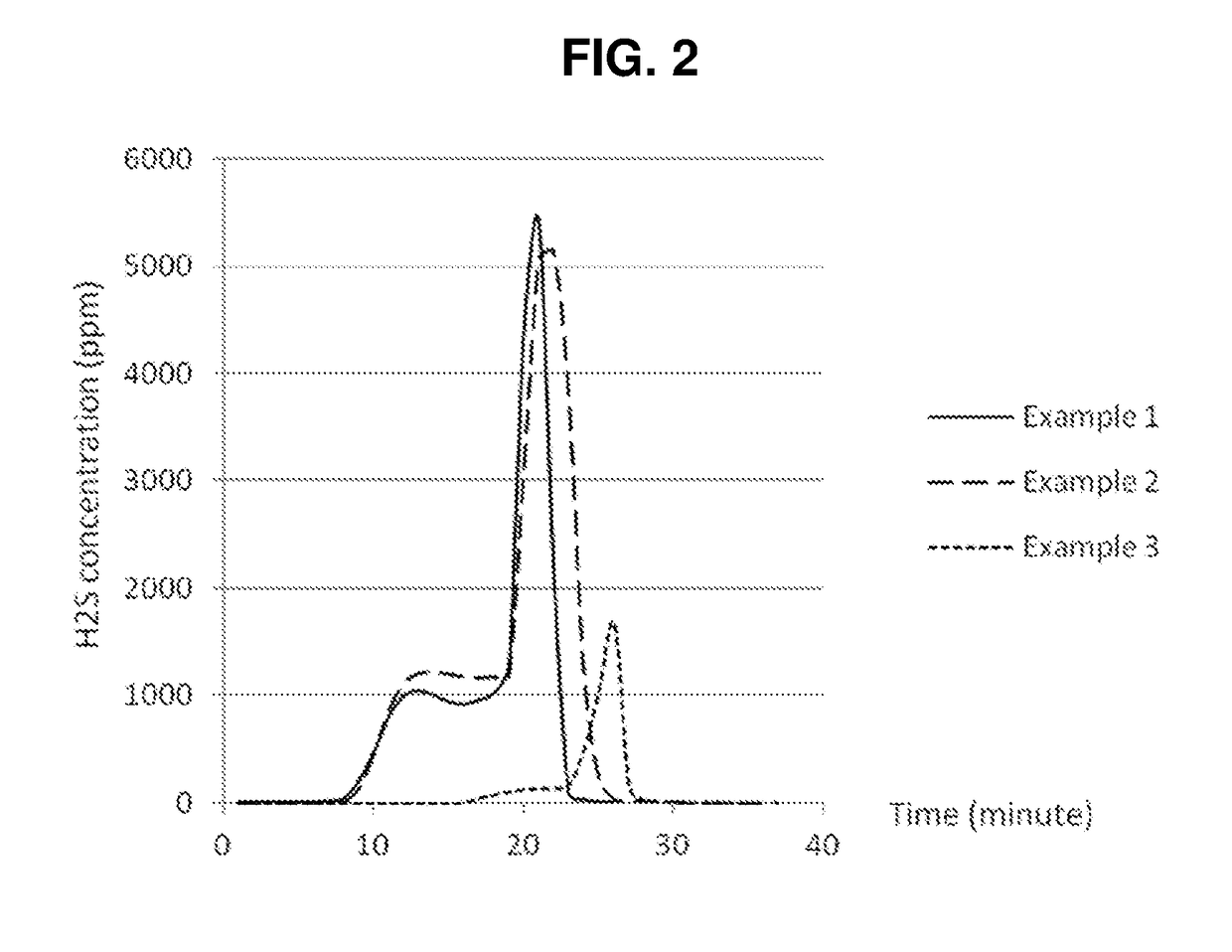

Cross-linked macroporous polymer used for selective removal of hydrogen sulfide from a gas stream

Owner:DOW GLOBAL TECH LLC

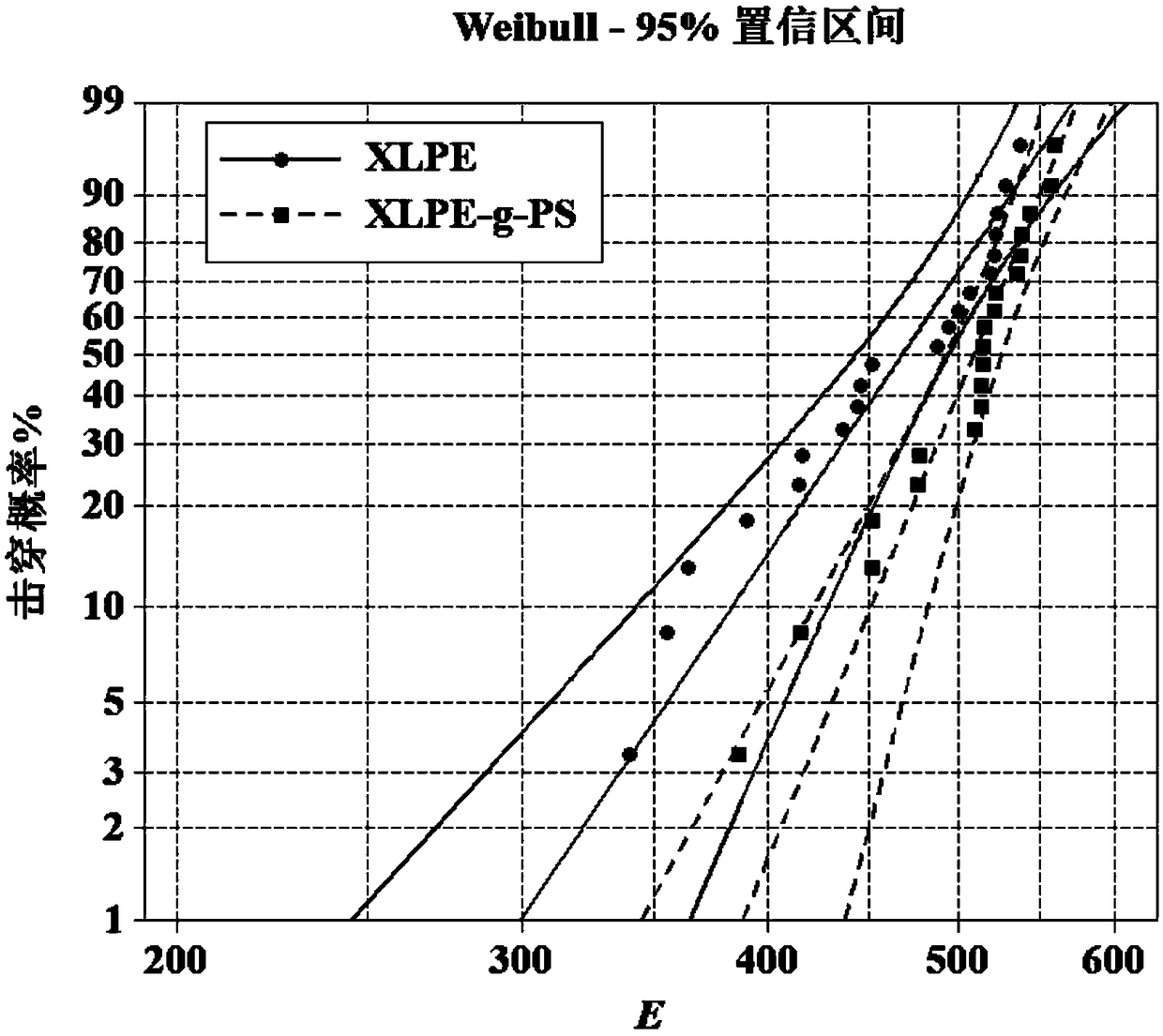

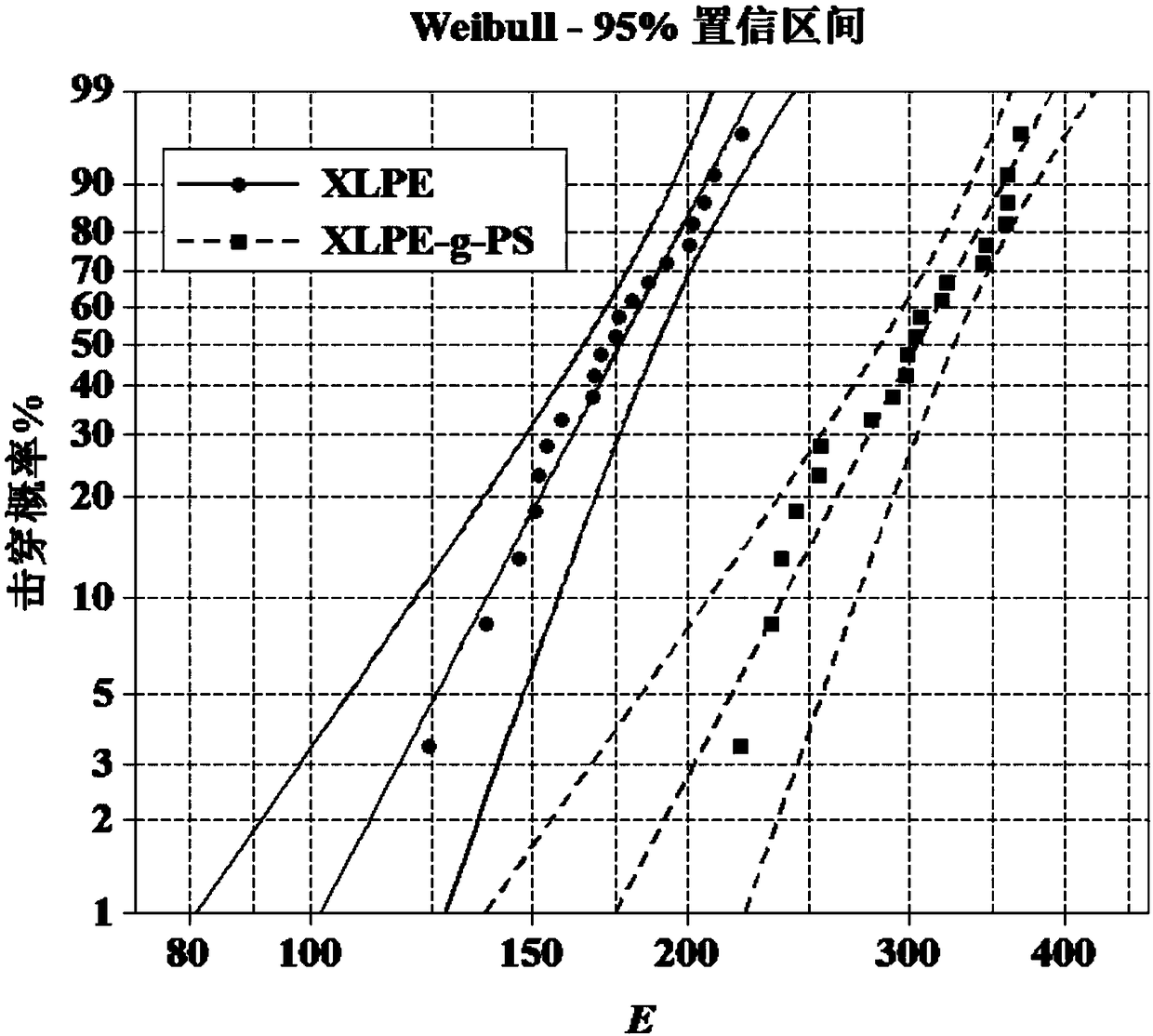

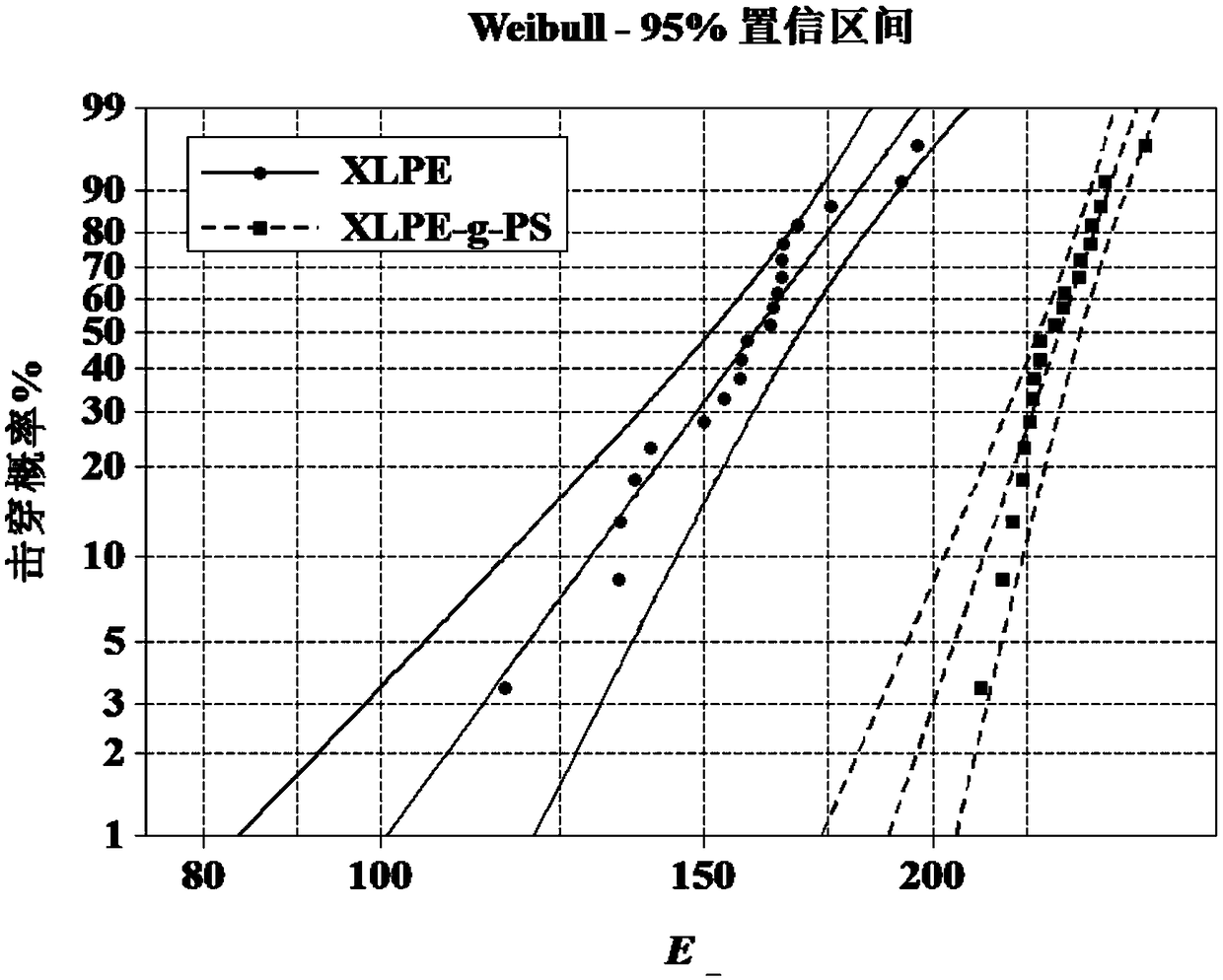

High voltage direct current cable insulating material and preparation method thereof

ActiveCN109265791AHigh DC breakdown field strengthIncreased DC breakdown field strengthPlastic/resin/waxes insulatorsLow-density polyethyleneCross-link

Owner:XI AN JIAOTONG UNIV +1

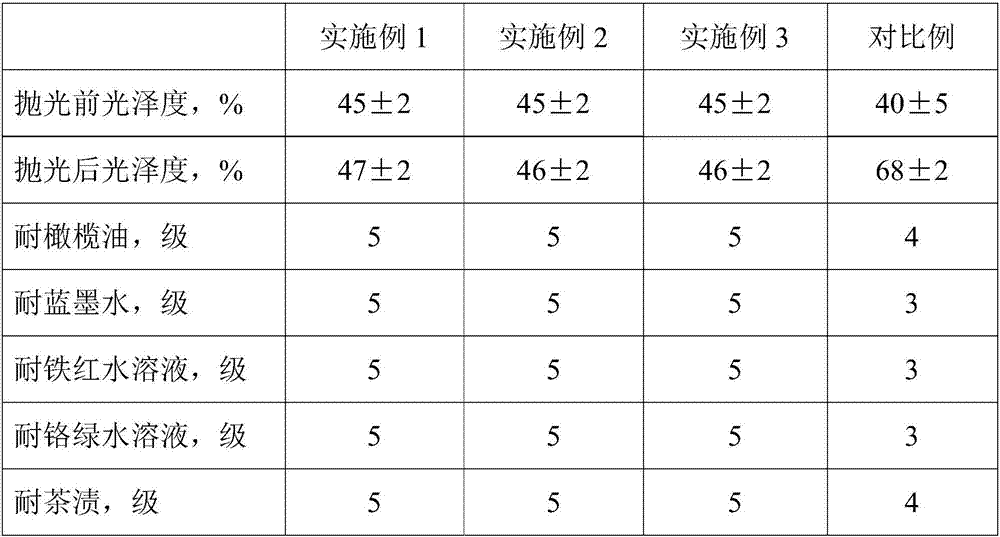

Solvent-free type colorized anti-skid road surface adhesive

ActiveCN103923595ALong application periodIncrease stickinessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkAdhesive

Owner:广东保路威环保材料有限公司

Method for carrying out mechanical activating high-concentration pulp grinding in wet state

InactiveCN110093800AIncrease granularityIncrease surface areaPulp beating/refining methodsCross-linkHigh concentration

Owner:GUANGXI KELIN CHENGLIN SCI & TECH +2

Floor tile for paving outdoor plastic basketball court and production method of floor tile

InactiveCN106630959ALow laying requirementsImprove laying efficiencySingle unit pavingsCeramic materials productionEpoxyCross-link

Owner:河南同伟建材有限公司

Adhesive for glass fiber mat and preparation method thereof

InactiveCN104877613AImprove surface activityGood temperature and shear resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkGlass fiber

Owner:合肥启华环保科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap