Method for forming protein crystal

a protein crystal and protein technology, applied in the direction of natural mineral layered products, peptides, material analysis using wave/particle radiation, etc., can solve the problem of difficult to obtain high-quality protein crystals, and achieve the effect of convenient removal and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Production of a Capsule Containing a Protein Crystal and X-Ray Diffraction Experiment

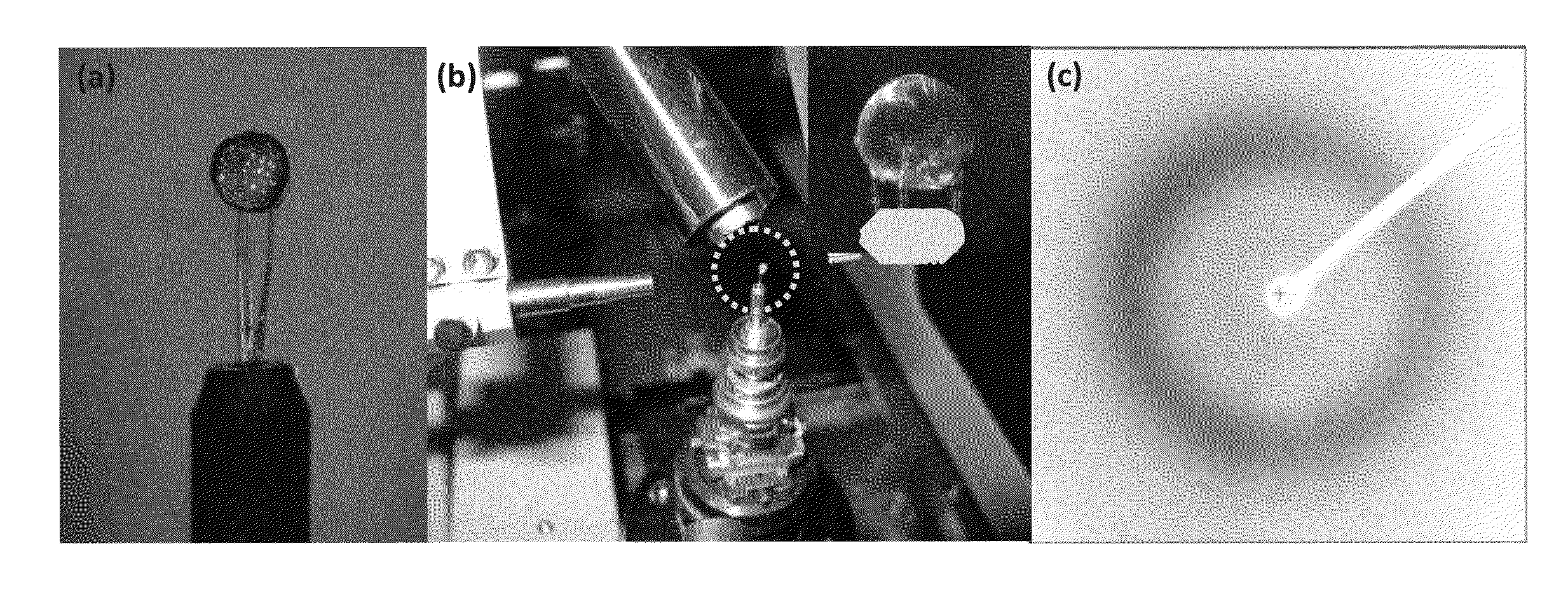

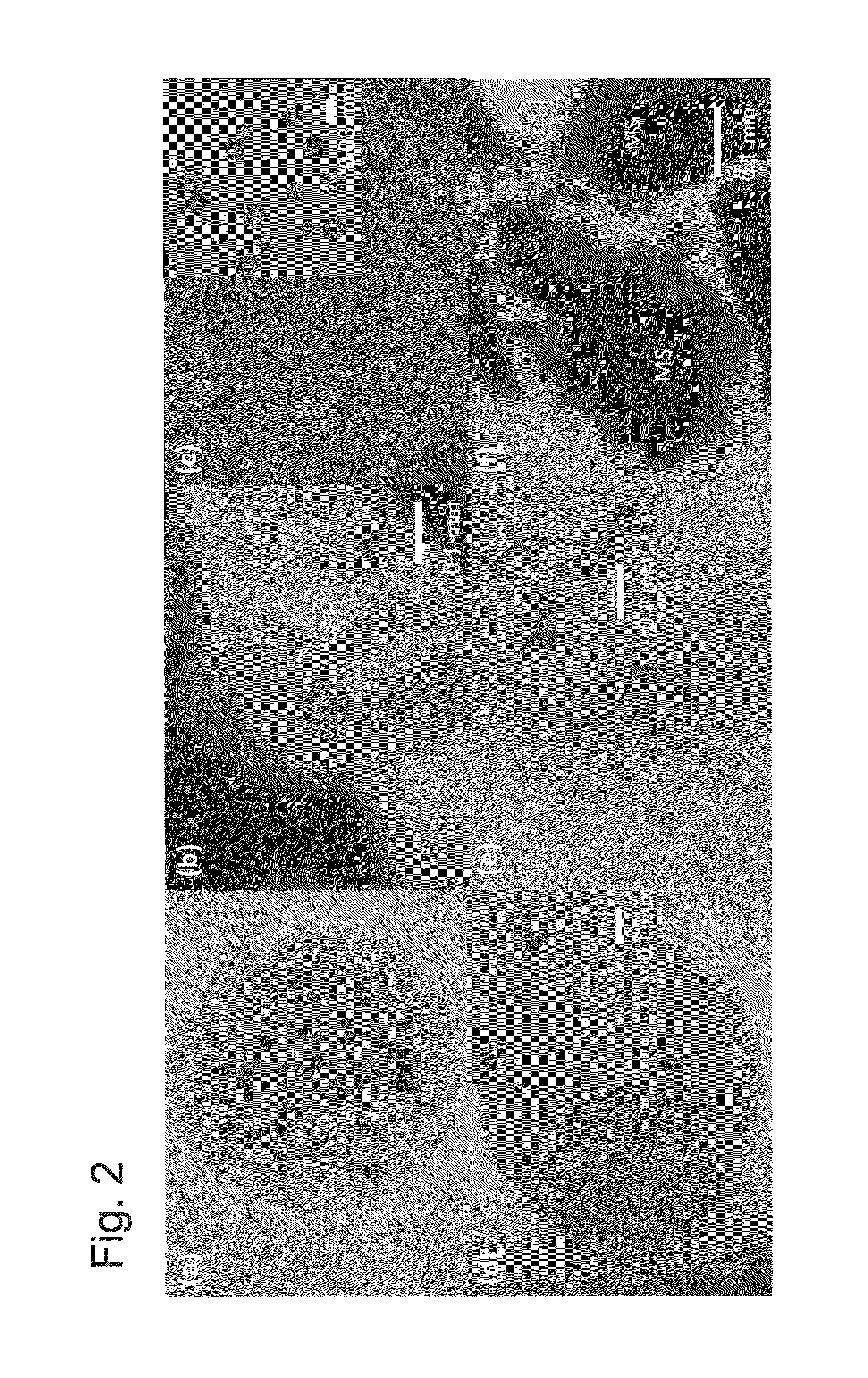

[0070]For production of polymer capsules utilizing ionic cross-linkage and crystallization, a method for producing capsules by ionic cross-linkage of alginate with a calcium ion was performed (FIGS. 1A to D). In the procedure, 12 μl of a 5- to 20-mg / ml protein solution containing 1% sodium alginate was added dropwise to 500 μl of 0.2 M CaCl2-containing crystallization reagent to produce capsules. As a result, five types of proteins ((a) lysozyme from chicken egg white, (b) xylanase from Trichoderma longibrachiatum, (c) diphthine synthase from Pyrococcus horikoshii OT3 (protein ID70067, Y175H), (d) α-ribazole-5′-phosphate phosphatase from Thermus thermophilus HB8 (protein ID00367), and (e) glucose-1-phosphate thymidylyltransferase from Thermus thermophilus HB8 (protein ID00403)) were crystallized successfully (FIGS. 2A to E).

[0071]The compositions of 0.2 M CaCl2-containing crystallization reagent used

example 2

Production of a Capsule Containing a Protein Crystal with Micro-Dispensation and X-Ray Diffraction Experiment

Protein Crystallization

[0079]In this study, more practical protein crystallization with micro-dispensation (0.5 to 1.0 μl of protein solution) and an X-ray diffraction experiment were conducted.

[0080]First, 1.0 μl of a crystallization reagent was dispensed using a dispensing device into a well of a crystallization plate (NUNC 72-well HLA plate). In this regard, to avoid interference with capsule production, contaminated air bubbles were removed. 70 kinds of Ca-containing crystallization reagents were dispensed to the crystallization plate. Compositions of the reagents are shown in Table 2. Next, the crystallization reagent drop was covered with a total of 15-20 μl paraffin oil. Before the sample was dispensed, paraffin oil was added to a mixed solution of a protein and alginate (aqueous solution of several milligrams of a protein, about 20 mM buffer (for lysozyme: acetate buffer

example 3

Storage of a Capsule Containing a Protein Crystal in Liquid Nitrogen

[0085]In this Example, a procedure for storing the protein crystal in liquid nitrogen was established. This procedure is desirable to conduct X-ray crystal structural analysis.

Experimental Procedure

[0086]A washer (inside diameter×outside diameter, 5 mm×12 mm) was fitted to the body of a tip for vacuum tweezers used for an X-ray diffraction experiment (ST-C series, Miruc Optical Co., Ltd.). The tip for vacuum tweezers onto which a capsule containing a protein crystal had been mounted was grasped with a CryoTong (trademark) (21 mm, Hampton Research Corp.) that was cooled with liquid nitrogen under the temperature condition of 100 K. The CryoTong was engaged with the washer of the tip, and the tip was removed from the head of a goniometer. The CryoTong was vertically inverted, and the base of the tip was held with a clamp (Hampton Research Corp.) of which the ends had been processed so that the width conforms to the diame

PUM

| Property | Measurement | Unit |

|---|---|---|

| Composition | aaaaa | aaaaa |

| Crystal structure | aaaaa | aaaaa |

| Volatility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap