Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Acetylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetylene (systematic name: ethyne) is the chemical compound with the formula C₂H₂. It is a hydrocarbon and the simplest alkyne. This colorless gas is widely used as a fuel and a chemical building block. It is unstable in its pure form and thus is usually handled as a solution. Pure acetylene is odorless, but commercial grades usually have a marked odor due to impurities.

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

Antistatic teflon film and preparation thereof

InactiveCN101481483ADoes not affect electrical insulationImprove mechanical propertiesOther chemical processesTetrafluoroethyleneAntistatic agent

Owner:广州市东泓氟塑料股份有限公司

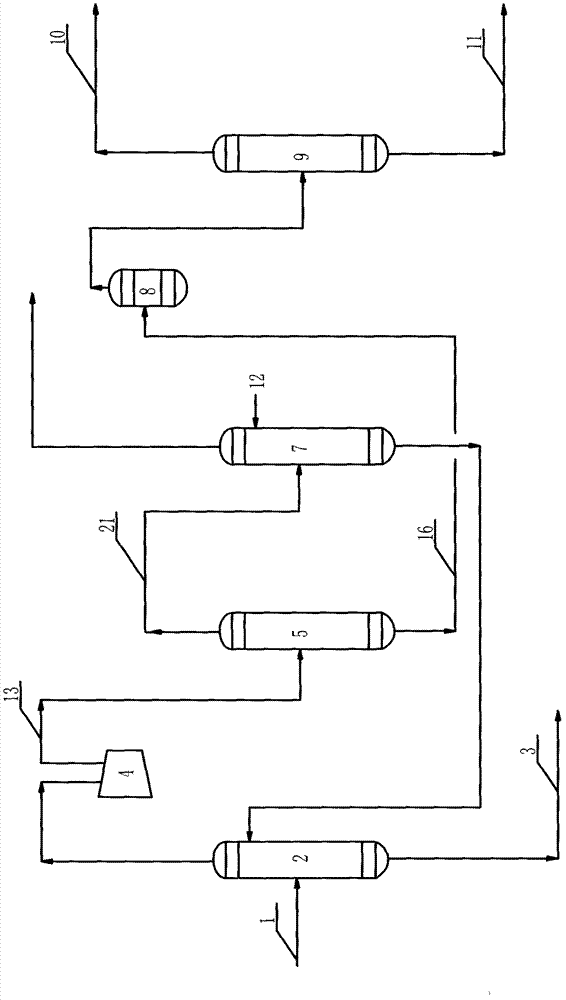

Method for separating low-carbon olefin gas

ActiveCN103242123ALow powerLow operating pressureDistillation purification/separationEthylene productionGas phaseDistillation

Owner:CHINA PETROLEUM & CHEM CORP +1

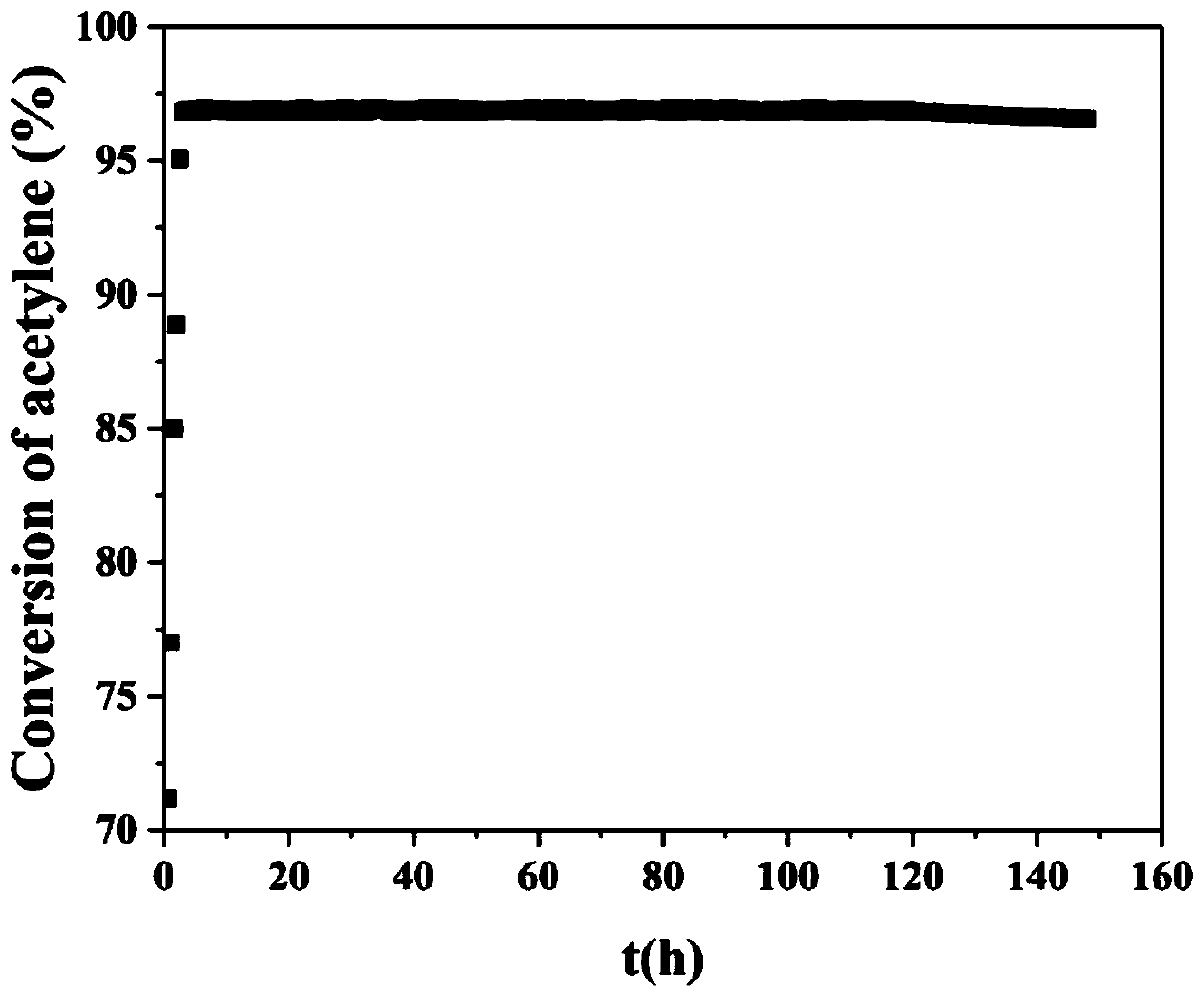

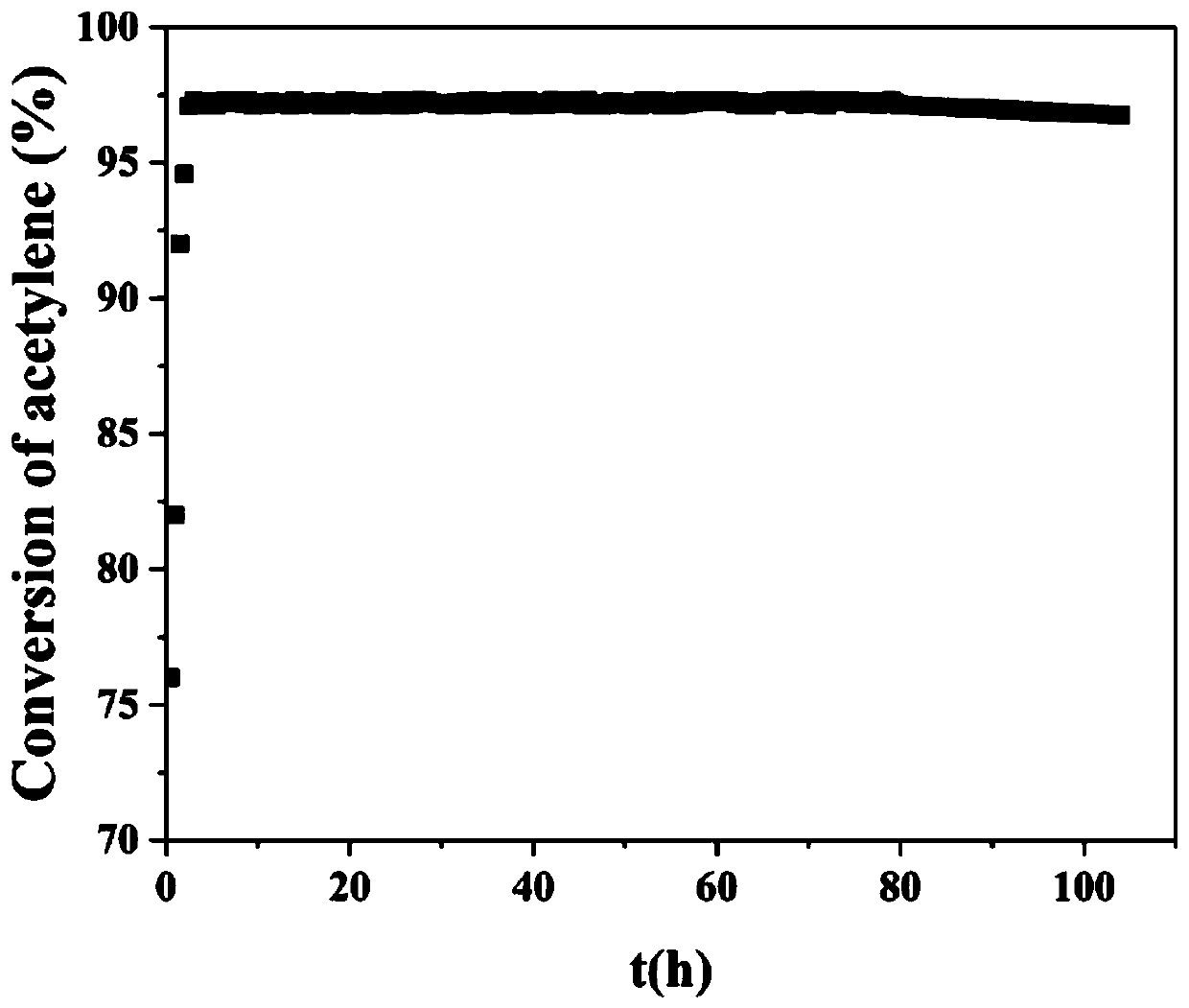

Trivalent copper catalyst and preparation method thereof and application to hydrochlorination of acetylene

ActiveCN110743621AStable structureImprove stabilityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystNitrogenous heterocyclic compound

Owner:ZHEJIANG UNIV OF TECH

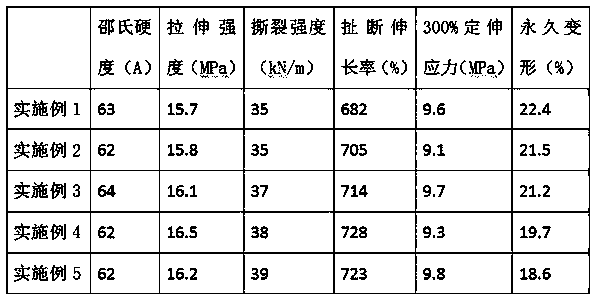

Preparation method of high-strength tire curing bladder

InactiveCN110698776AStrong responsivenessImprove adhesionDomestic articlesPolymer scienceActive agent

Owner:YONGYI RUBBER CO LTD

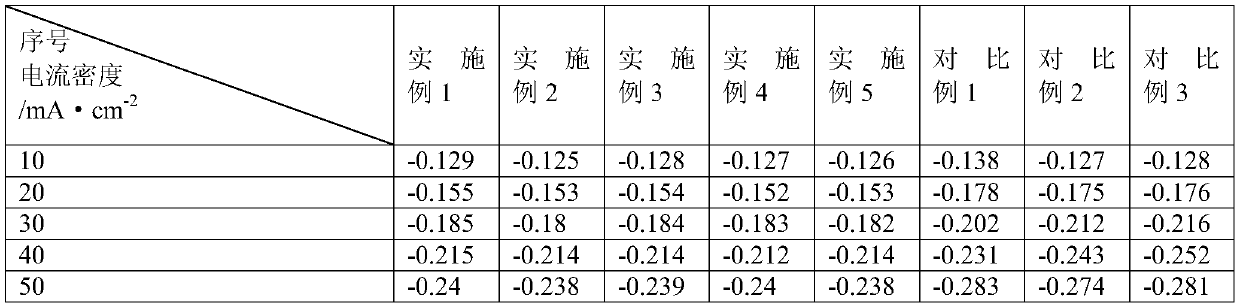

Preparation method of aluminum-air battery cathode reduction catalyst

ActiveCN111193037ALarge specific surface areaFully contactedMaterial nanotechnologyCell electrodesActivated carbonPtru catalyst

Owner:CHAOWEI POWER CO LTD

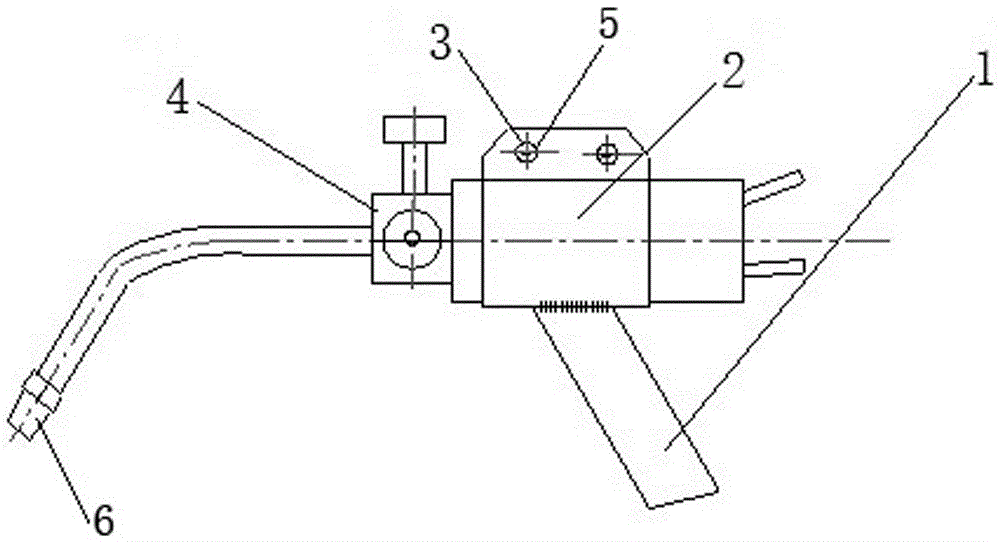

Handheld oxygen-acetylene welding torch

InactiveCN106369604ASolve the characteristicsFix the angle problemGaseous fuel burnerEngineeringWelding defect

Owner:JIANGXI HONGDU AVIATION IND GRP

LNg synergistic metal cutting gas

PendingCN113249151AReduce usageEmission reductionGaseous fuelsGas flame welding apparatusSulfonatePhysical chemistry

Owner:锦州烈火环保科技有限公司

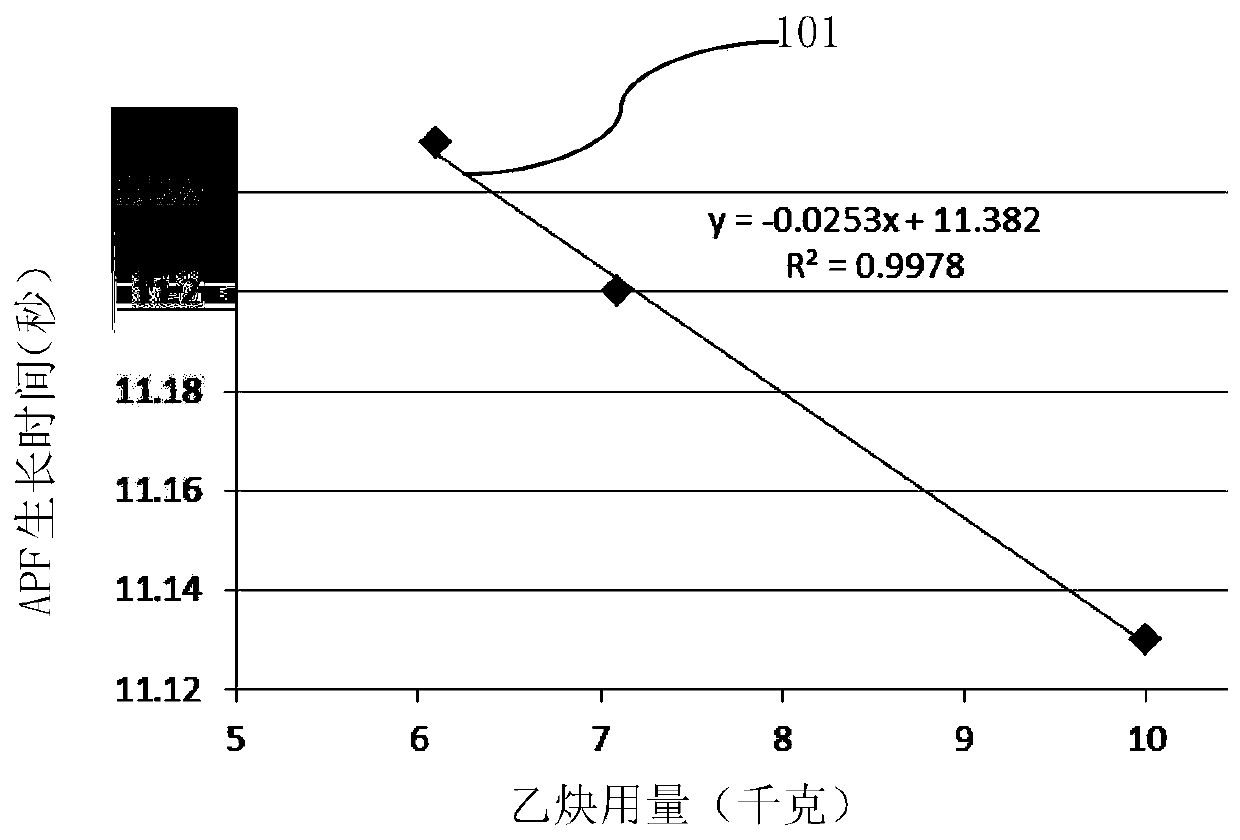

Film thickness monitoring method for amorphous carbon film

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

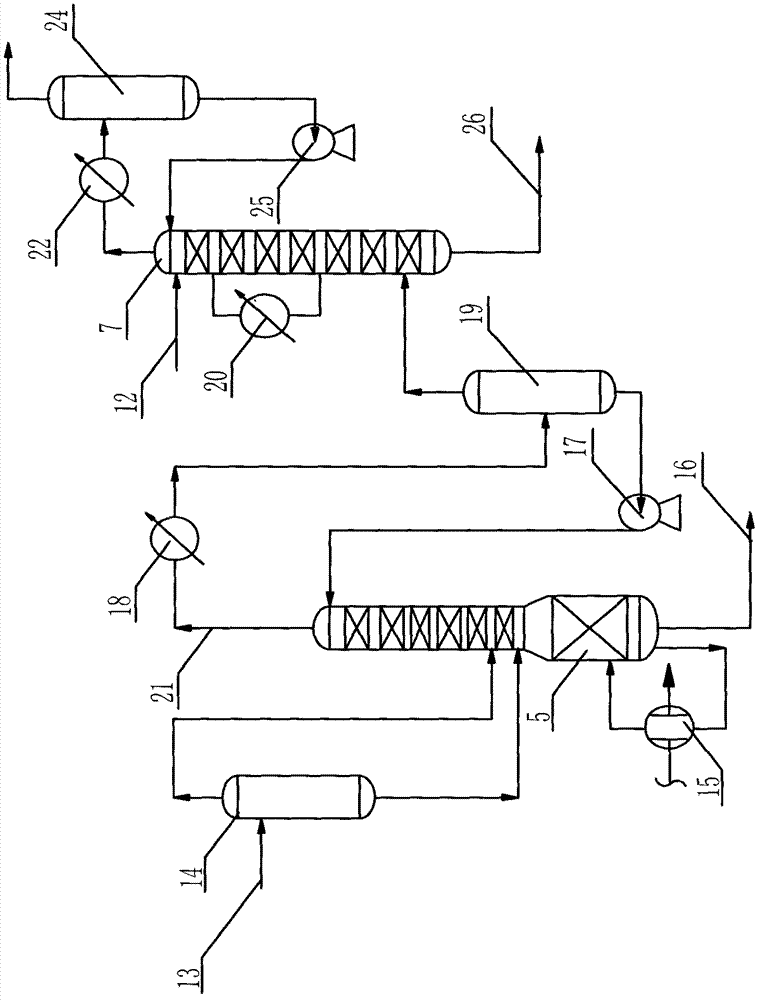

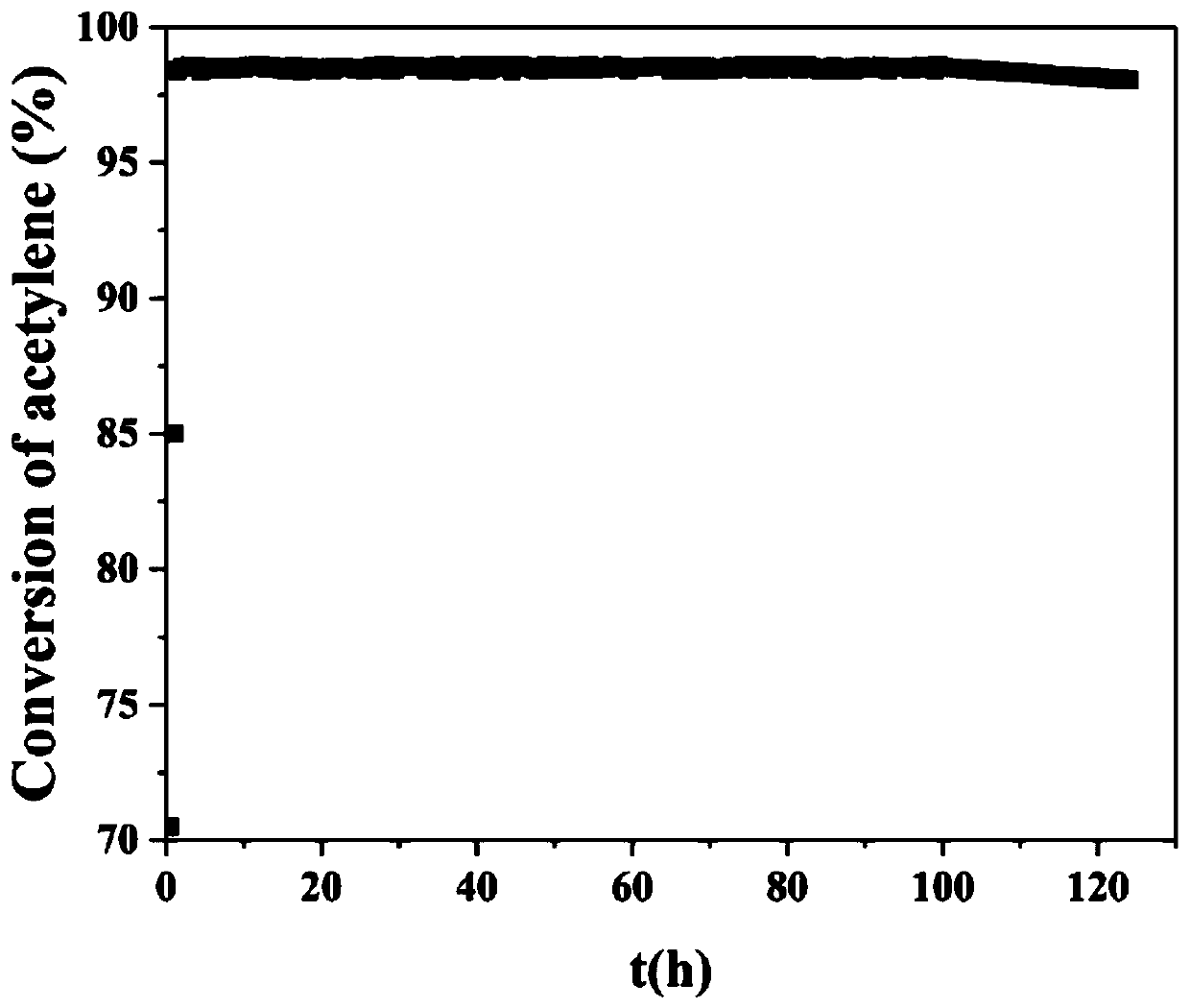

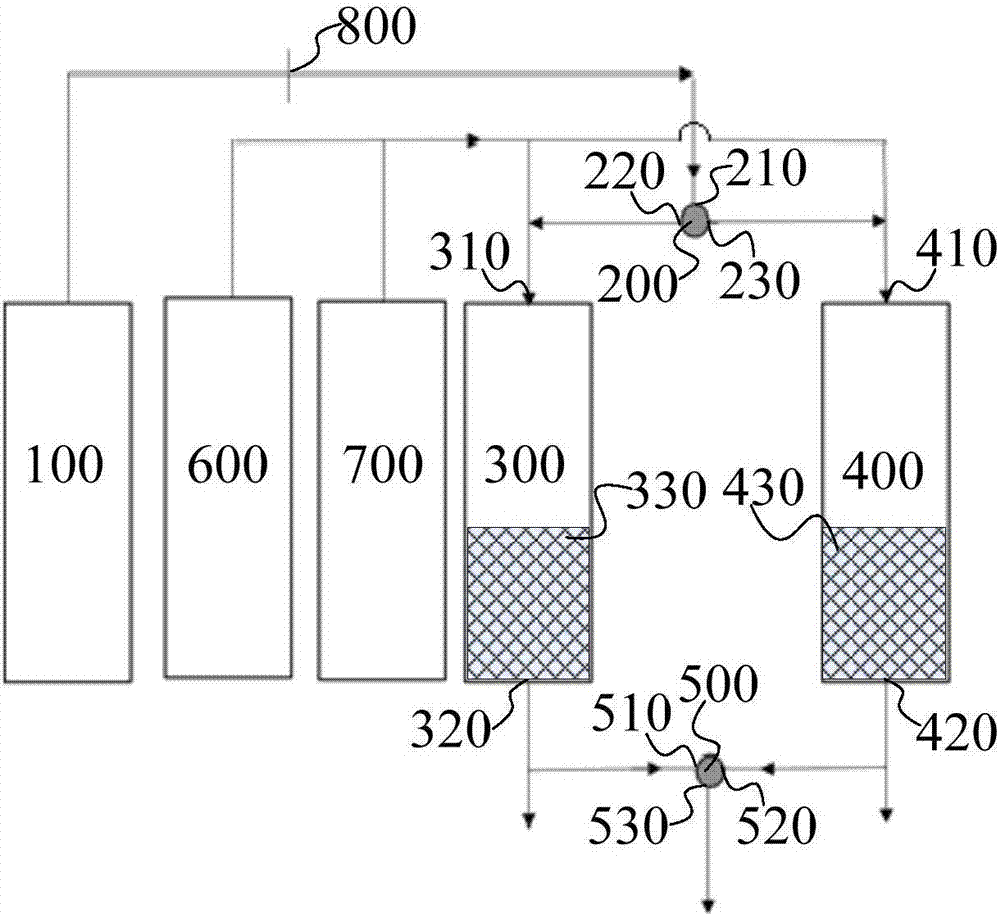

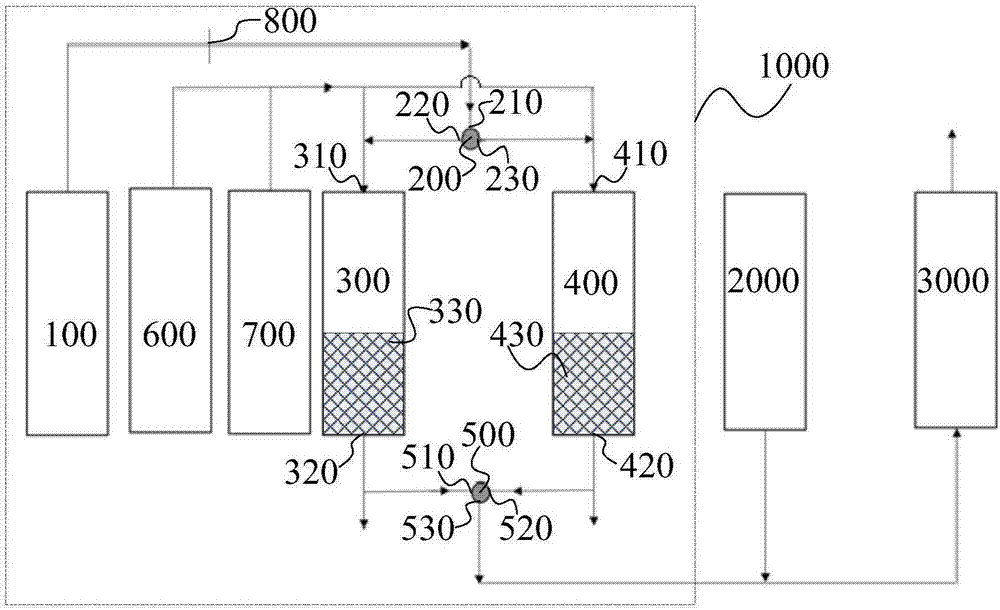

System and method for purifying acetylene gas and system and method for preparing ethylene by acetylene hydrogenation

PendingCN107973689ASimple and fast operationStable in natureGas treatmentHydrocarbon by hydrogenationNitrogen gasBottle

Owner:BEIJING HUAFU ENG

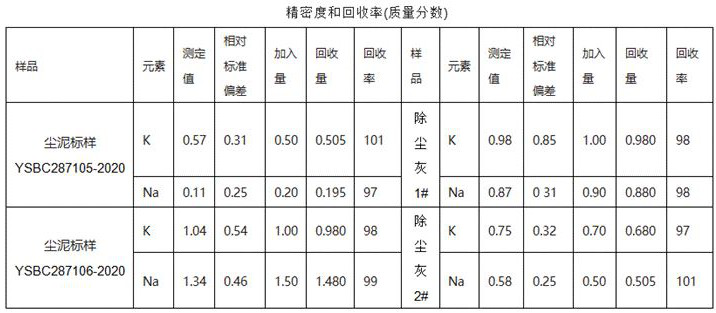

Method for determining microelements in fly ash of European smelting furnace

PendingCN114674771AEfficient methodReduce labor intensityColor/spectral properties measurementsAcid dissolutionDust control

Owner:XINJIANG BAYI IRON & STEEL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap