System and method for purifying acetylene gas and system and method for preparing ethylene by acetylene hydrogenation

A technology of acetylene gas and acetylene, applied in the system field of acetylene hydrogenation to ethylene, can solve the problems of small dosage, high price, difficult reaction, etc., achieve broad application prospects, easy operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Weigh the quartz sand with a particle size of 10-20 mesh and a volume of 288ml, and place them in the first purifier and the second purifier with a diameter of 1.5cm. According to the actual measurement, the filling height is 40cm. At this time, the purifier The aspect ratio is about 27; the first purifier and the second purifier installed with quartz sand should not be purged with nitrogen to remove the air, the nitrogen flow rate is 50-100ml / min, and purging for 20-60min is enough.

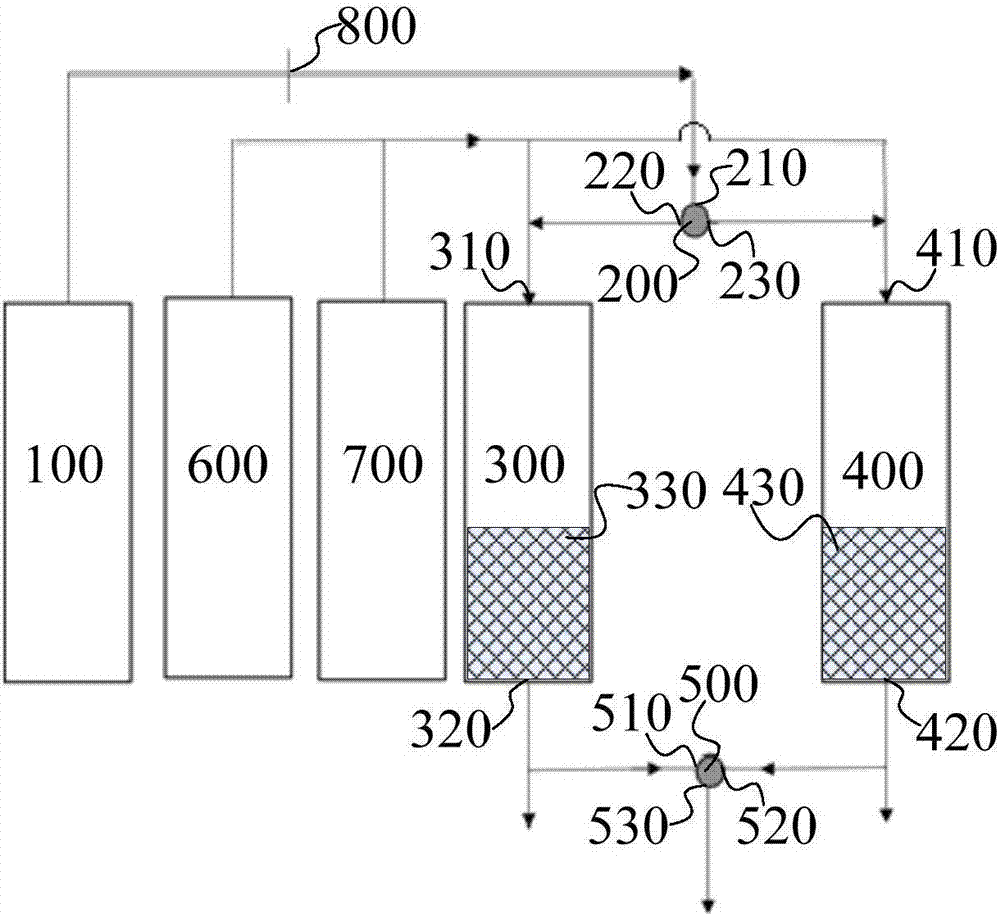

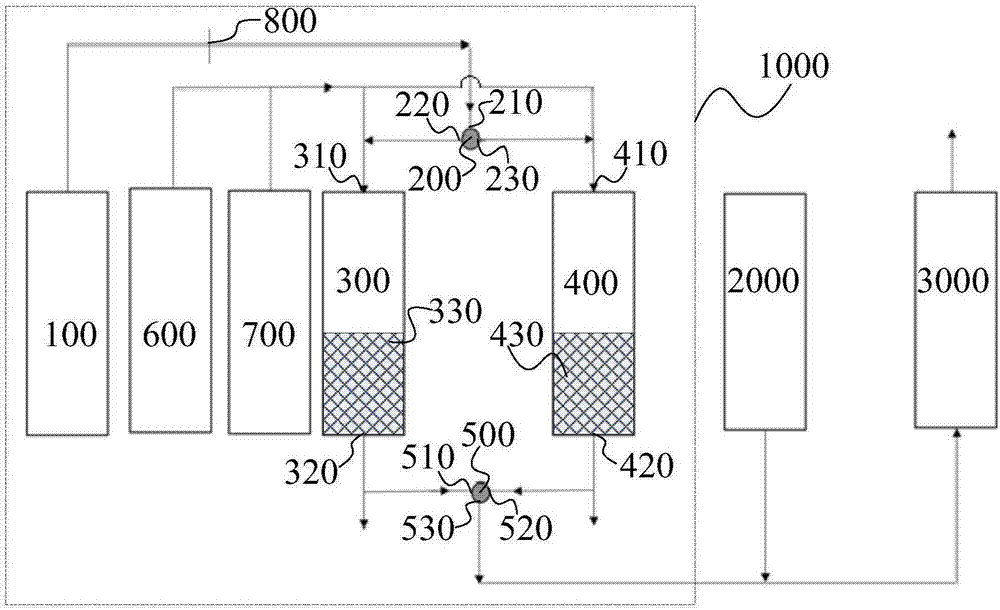

[0082] Then, use the acetylene gas purification system to purify the acetylene gas, and the specific steps include:

[0083] (1) Acetylene is supplied to the first purifier from the acetylene supply device through the first three-way valve, so that the acetylene is purified under the action of quartz sand in the first purifier to obtain the first purified acetylene gas;

[0084] (2) When the quartz sand in the first purifier is deactivated, acetylene is supplied to the second purifier from

Embodiment 2

[0091] Consistent with the conditions in Example 1, when the acetylene gas passes through the first purifier, take a sample and analyze it after 4 hours of use, and the calculation shows that the ratio of the total volume of the acetylene gas treated at this time to the volume filled with the purifier is about 167:1.

[0092] The reaction product was detected and analyzed after the reaction was stable for 4 hours, and the acetylene conversion rate and ethylene selectivity are shown in Table 2.

Embodiment 3

[0094] Consistent with the conditions of Example 1, when the acetylene gas flows through the first purifier, take a sample and analyze it after 5 hours of use, the acetylene gas flow rate is 200ml / min, the filling volume of the quartz sand is 288ml, and it is maintained for 5 hours, and the calculation can be obtained at this time. The ratio of the total volume of acetylene gas to the volume of the cleaning agent is about 200:1.

[0095] The reaction product was detected and analyzed after the reaction was stable for 5 hours, and the acetylene conversion rate and ethylene selectivity are shown in Table 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap