Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Bonding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bonding Strength. Bonding strength is defined as the maximum force born by unit bonding area, which mainly depends on the own strength of adhesives (cohesive power) and the adhesive strength (adhesive power) between adhesives and adherends.

Method for metallizing ceramic surface and method for connecting ceramic with aluminum

ActiveUS20120121896A1Hot-dipping/immersion processesSoldering apparatusMicrometerAlloy thin film

A process for metalizing a ceramic surface or attaching a ceramic to a metal is provided. The process may comprise: immersing the ceramic into an aluminum or aluminum alloy melt, making the ceramic move or stay still relative to the melt to adhere the melt to the ceramic; and then removing the ceramic from the melt to unaffectedly cool the film adhered thereto. The process can attach an aluminum or aluminum alloy thin film having a thickness of several to tens of micrometers on a ceramic surface. The thin film is formed by solidification, and does not have microscopic faults such as oxide film inclusions or pores, therefore having proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.This invention discloses a process for metalizing the surface of a ceramic and a process for attaching a ceramic to a metal. A process for attaching an aluminum or aluminum alloy thin film to a ceramic surface comprises the steps of: immersing a ceramic surface to be metalized into a aluminum or aluminum alloy melt, and making the ceramic move or stay still relative to the melt to adhere the melt of the aluminum or aluminum alloy to the metalizing surface of the ceramic; and then removing the metalizing surface of the ceramic from the melt to unaffectedly cool the aluminum or aluminum alloy liquid film adhered thereto to obtain a ceramic having the aluminum or aluminum alloy thin film attached to the surface. The process to attaching aluminum or aluminum alloy thin film on the surface of a ceramic of the present invention can attach an aluminum or aluminum alloy thin film having a thickness of several micrometers to tens of micrometers on the surface of a ceramic. The thin film is formed by the solidification of the aluminum of aluminum alloy liquid film attached on the surface of a ceramic, and it does not have the microscopic faults such as oxide film inclusions or pores, therefore having the proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.

Owner:TSINGHUA UNIV

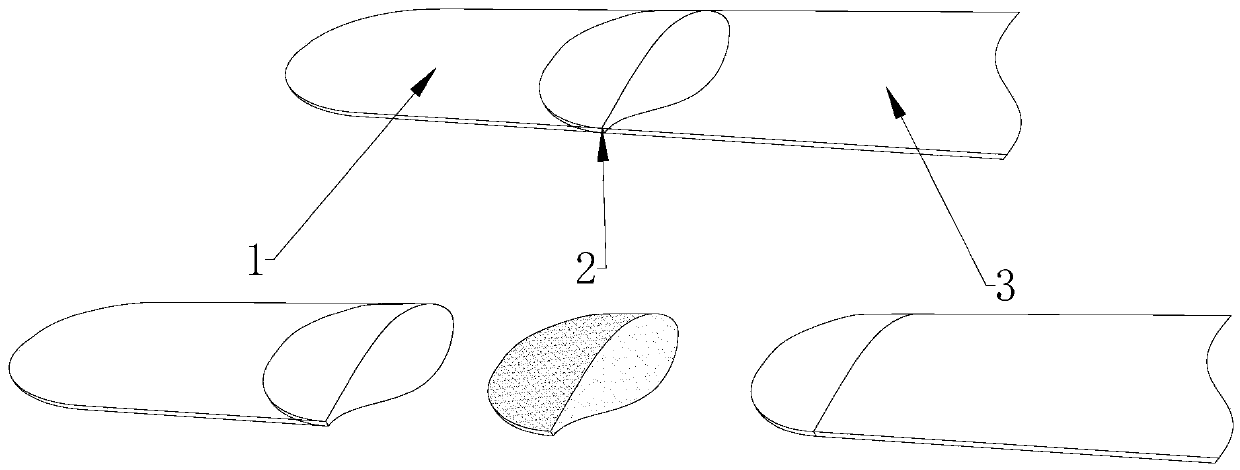

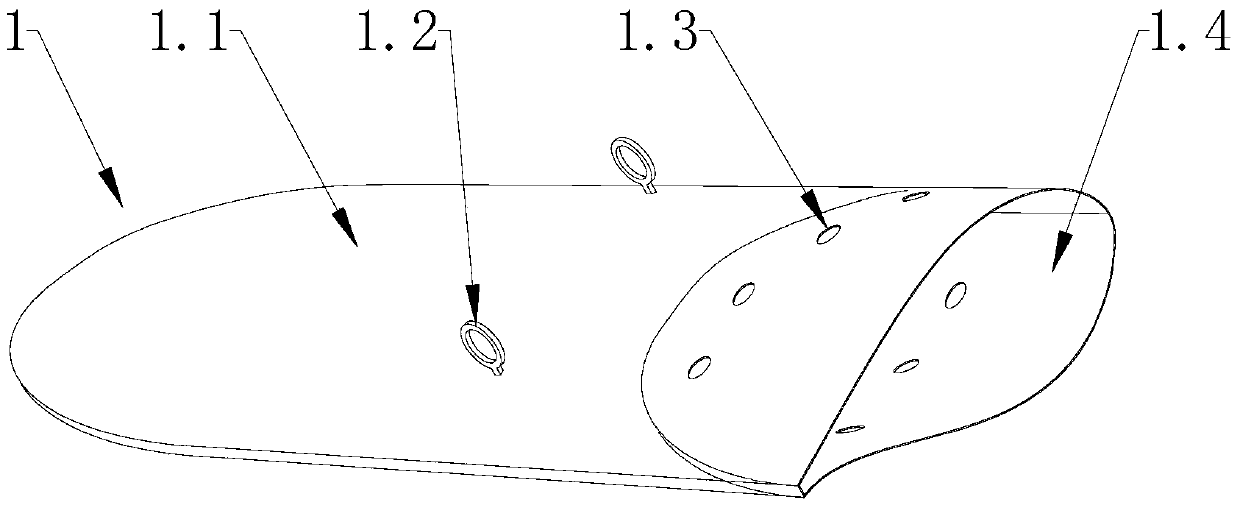

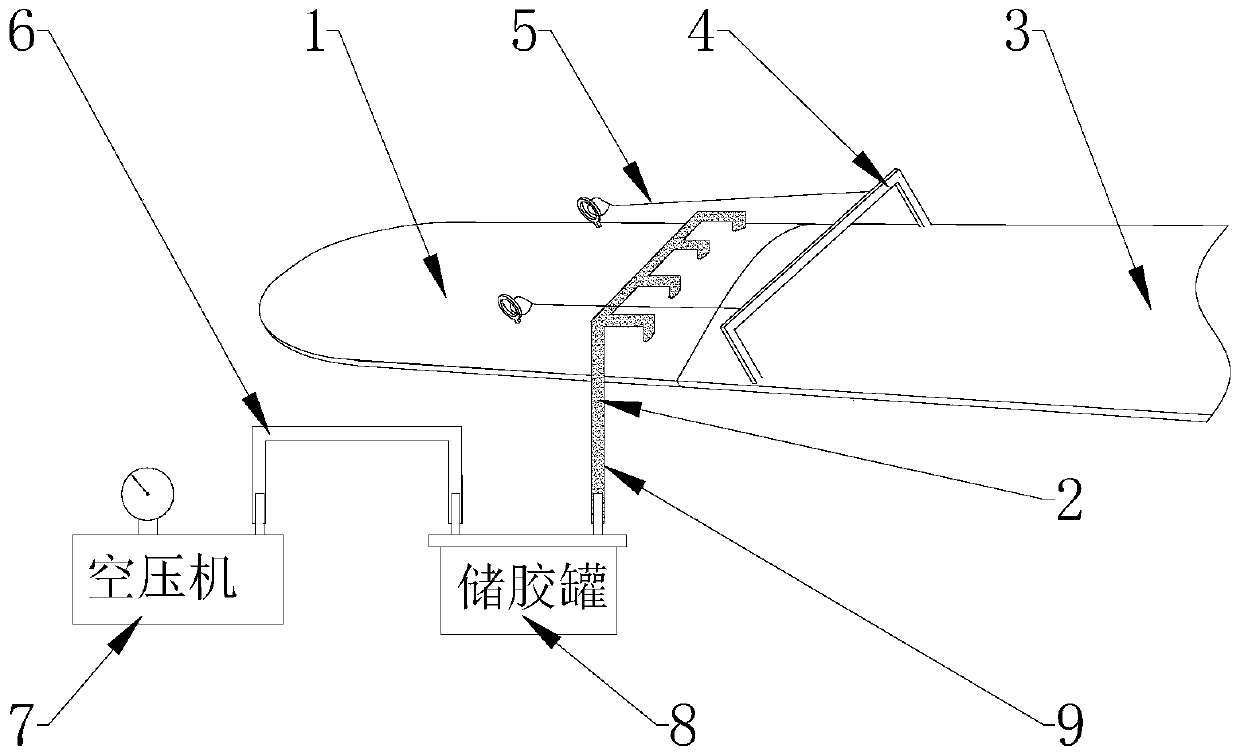

Wind power blade tip lengthening method

InactiveCN105500696AIncrease the lengthHigh bonding strengthEngine manufactureFinal product manufactureElectricityAdhesive

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method for preparing diamond-like composite coating on surface of piston ring

InactiveCN101665940AImprove wear resistanceImprove the lubrication effectVacuum evaporation coatingSputtering coatingLow temperature plasmaMagnetic filtration

The invention relates to a method for preparing a diamond-like composite coating with high hardness and good abrasion proof and self lubricating properties on the surface of a piston ring. In the method, a nitriding layer with high bonding strength, high hardness and good abrasion resistance is formed on the surface of the piston ring by the low-temperature plasma nitriding treatment, a non-hydrogen diamond-like surface layer with solid lubricating property is deposited by the combination of magnetic filtration cathode arc and magnetic control sputtering, and finally the nitriding / diamond-likecomposite coating, which is dense and smooth and possesses excellent abrasion proof and self-lubricating properties, is obtained on the surface of the piston ring. Compared with the durionising piston ring or CrN plating piston ring, the coating of the piston ring of the invention has higher comprehensive performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

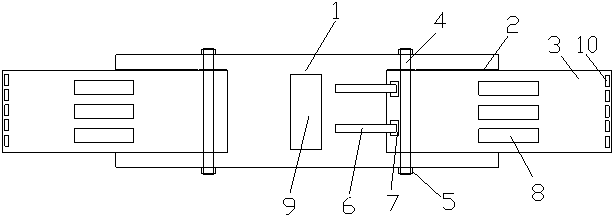

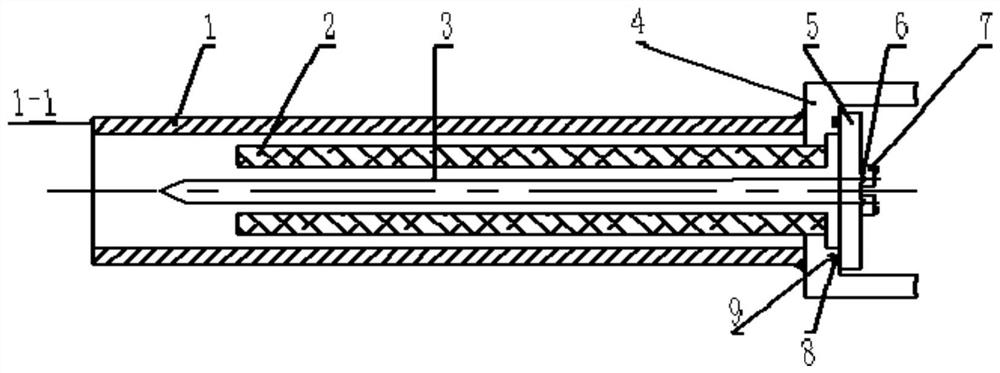

Method and device for electrolytic machining of massive array tiny pits through wedge-shaped runner

ActiveCN103600144APrevent inflowConsistent strengthMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses a method and a device for electrolytic machining of massive array tiny pits through a wedge-shaped runner, and belongs to the technical field of electrolytic machining. The method includes processing the surface of a mask plate to enable the surface to fit with the surface of a workpiece anode; fixing a wedge-shaped tool cathode above the mask plate to enable the wedge-shaped runner to be formed between the wedge-shaped tool cathode and the mask plate; connecting the workpiece anode and the wedge-shaped tool cathode with an anode and a cathode of a power source respectively; feeding an electrolyte into the wedge-shaped runner, wherein the electrolyte reaches the surface of the workpiece anode through penetrating group holes in the mask plate; switching on the power source for electrolytic machining. The runner is arranged to be wedge-shaped, so that electric field intensity and electrolyte flowing speed are enabled to be progressively increased along the direction of the runner, both corrosion strength and speed of a workpiece are enabled to tend to be uniform, and uniformity and machining accuracy of electrolytic machining are improved. A PDMS (polydimethylsiloxane) template is taken as the mask plate, bonding strength of the mask plate and the workpiece anode can be guaranteed, stray corrosion, of the electrolyte, to places around a machining area can be effectively reduced, and locality and uniformity of electrolytic machining can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Molybdenum fibre reinforced resin concrete material

InactiveCN101759397AGood physical and mechanical propertiesHigh compressive strengthKinetosomesResin-Based Composite

Owner:SHANDONG UNIV

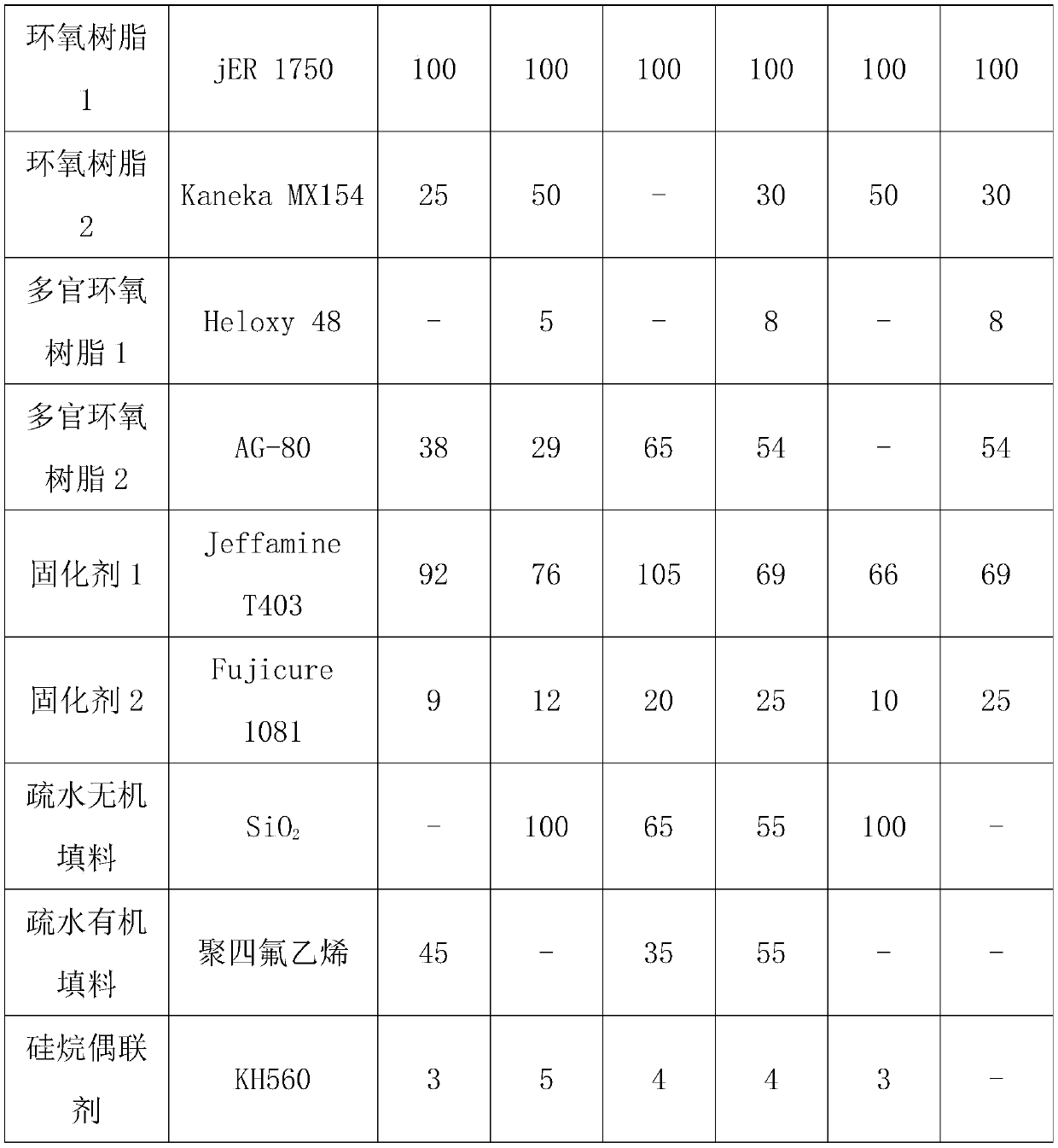

Single-component epoxy structure adhesive for waterproof sealing and preparation method thereof

InactiveCN110564347AHigh strengthHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyHigh humidity

Owner:上海汉司实业有限公司

Method for preparing chloroprene rubber adhesive agent

InactiveCN101781538APromote environmental protectionHigh affinitySolesGraft polymer adhesivesPolymer scienceBenzoyl peroxide

Owner:NANTONG GUANGTAI BIOCHEM PROD

Method for testing PCB pad bonding strength

InactiveCN105158154AProtect from thermal shockAvoid adding processesUsing mechanical meansMaterial analysisSolder ballUltimate tensile strength

A disclosed method for testing PCB pad bonding strength comprises the following steps: 1) presetting a solder ball at one end of a test pull pin, and arranging a first soldering-flux wrapping layer on the surface of the solder ball; 2) arranging a second soldering-flux wrapping layer on a PCB sample pad; 3) enabling the test pull pin and the target PCB sample pad to be in vertical centering relationship; 4) enabling the first soldering-flux wrapping layer on the preset solder ball and the second soldering-flux wrapping layer on the pad to be contacted with each other; 5) fusing the preset solder ball on the test pull pin with the target PCB sample pad, so as to form a new welding point; 6) finishing welding between the test pull pin and the target PCB pad; 7) vertically pulling the test pull pin upwards, recording the maximum peeling force and drafting a pull curve; and 8) repeating the steps 1)-7), so as to obtain the pad cratering failure mode, the maximum peeling force and the pull curve of multiple target PCB sample pads and realize evaluation on the PCB pad bonding strength. The method possesses the advantages of concise steps and high operationality, and is relatively beneficial for realizing full-automatic on-line quality detection.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Testing method for ultra-high bonding strength of coating

InactiveCN109238958AReduce contact areaReduce areaPreparing sample for investigationUsing mechanical meansAbrasive blastingEpoxy

Owner:广东省工业分析检测中心 +1

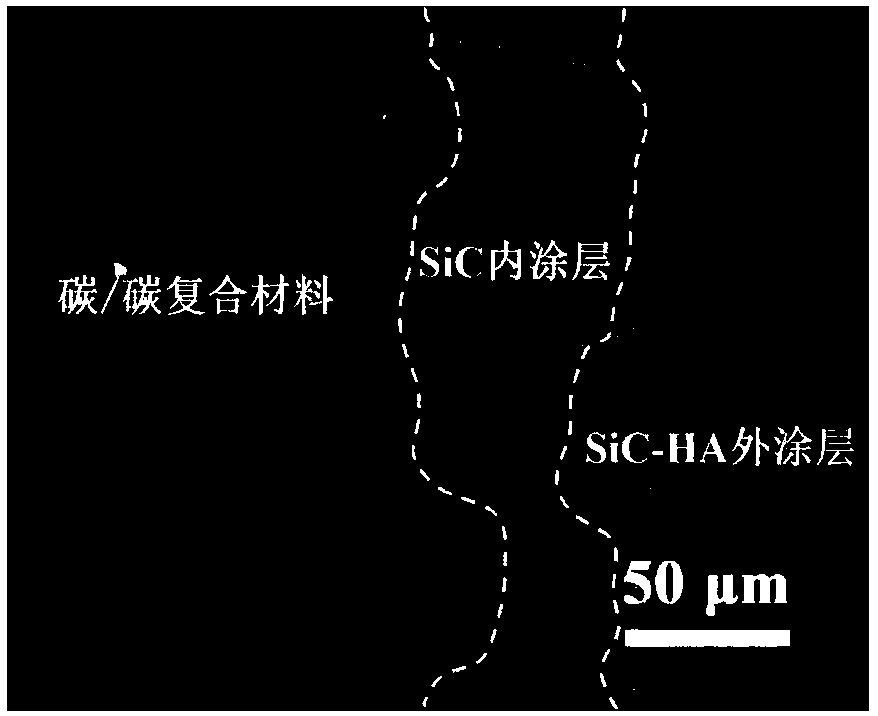

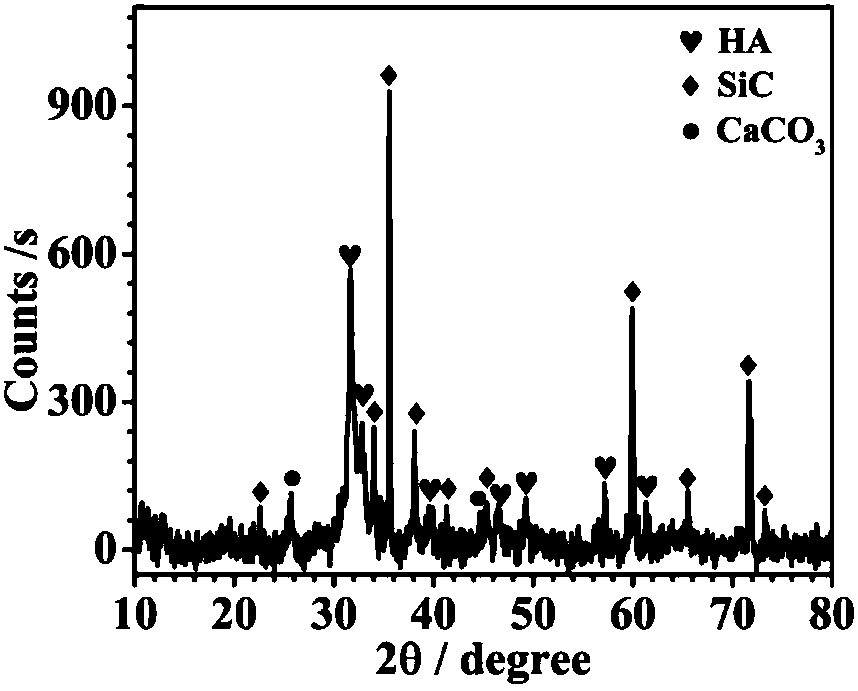

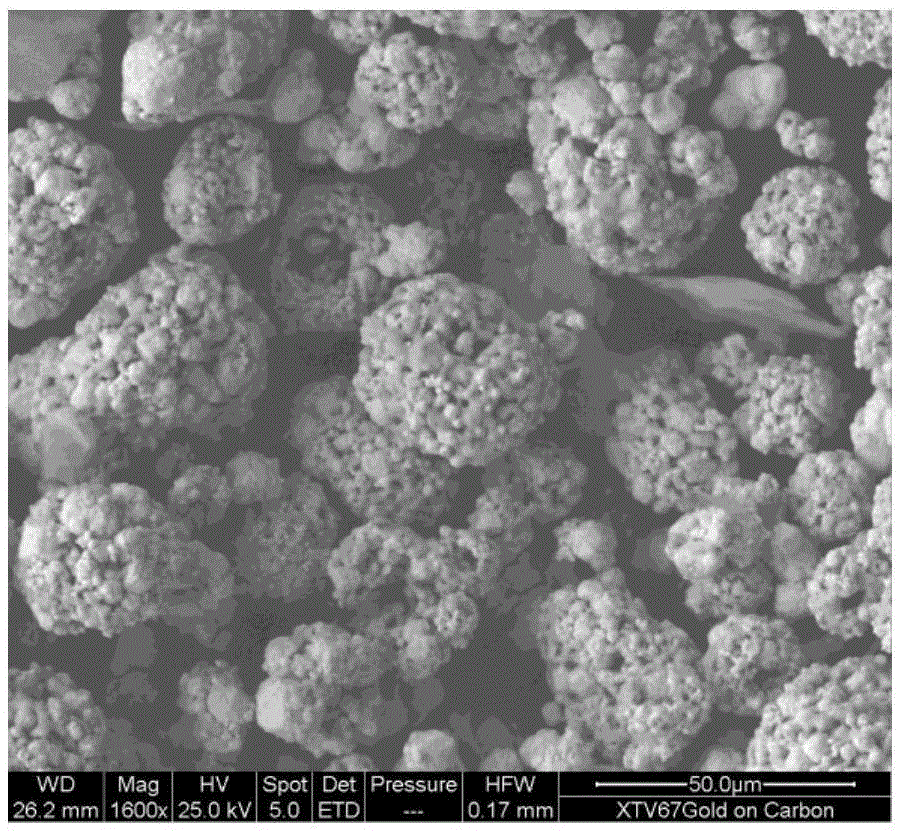

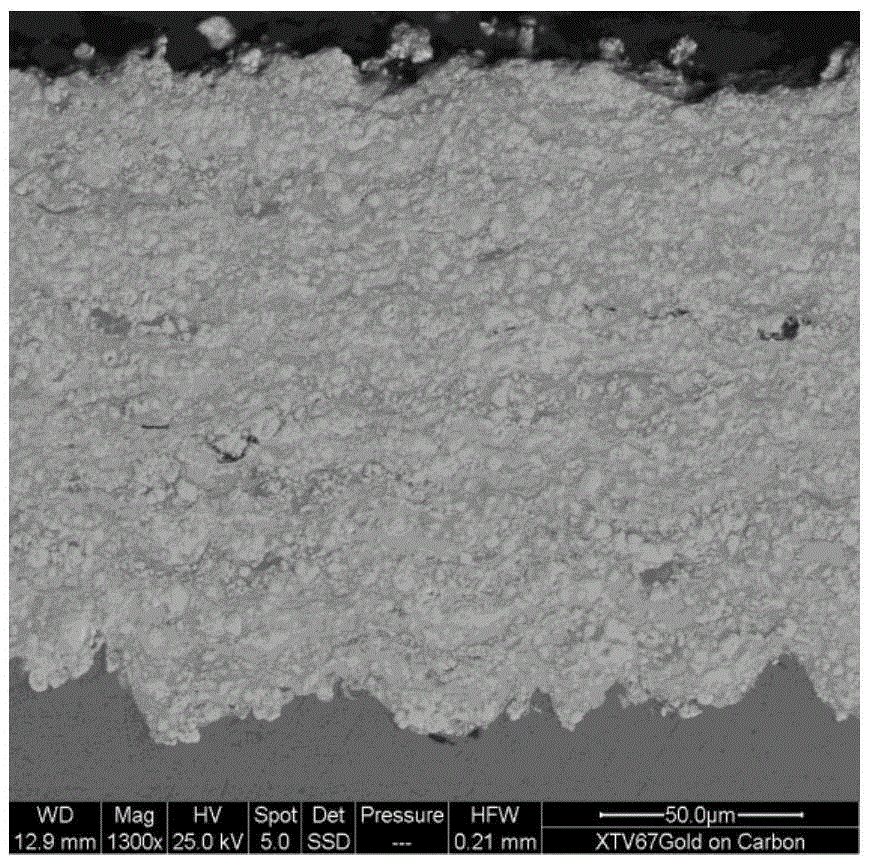

Carbon/carbon composite material modified by silicon carbide and hydroxyapatite gradient coating and preparation method thereof

InactiveCN108546156AFew and dense surface defectsRelieve heat stressCarbon compositesHa coating

Owner:NORTHWESTERN POLYTECHNICAL UNIV

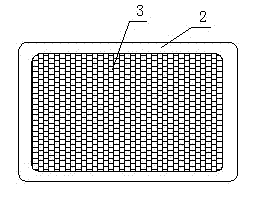

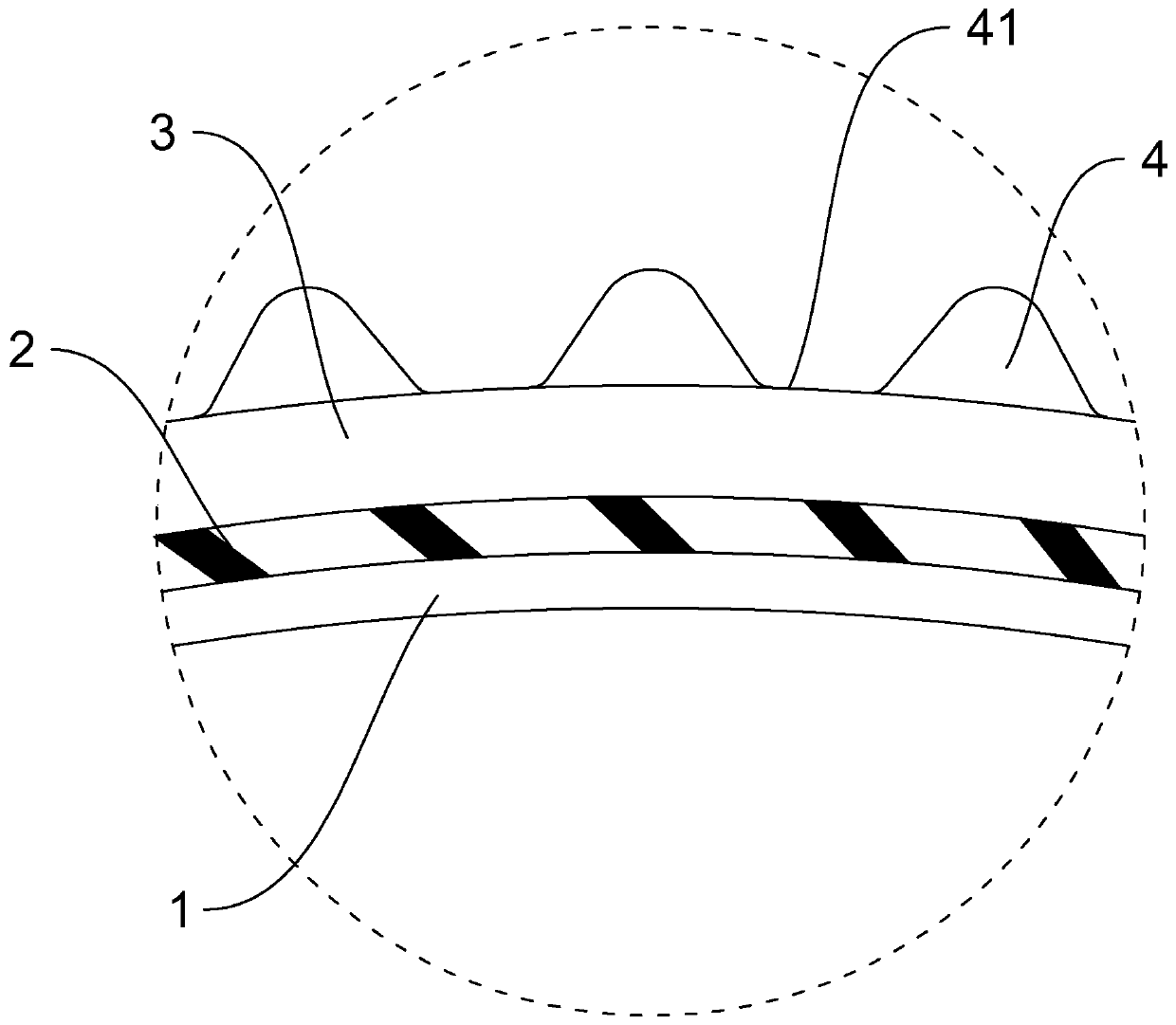

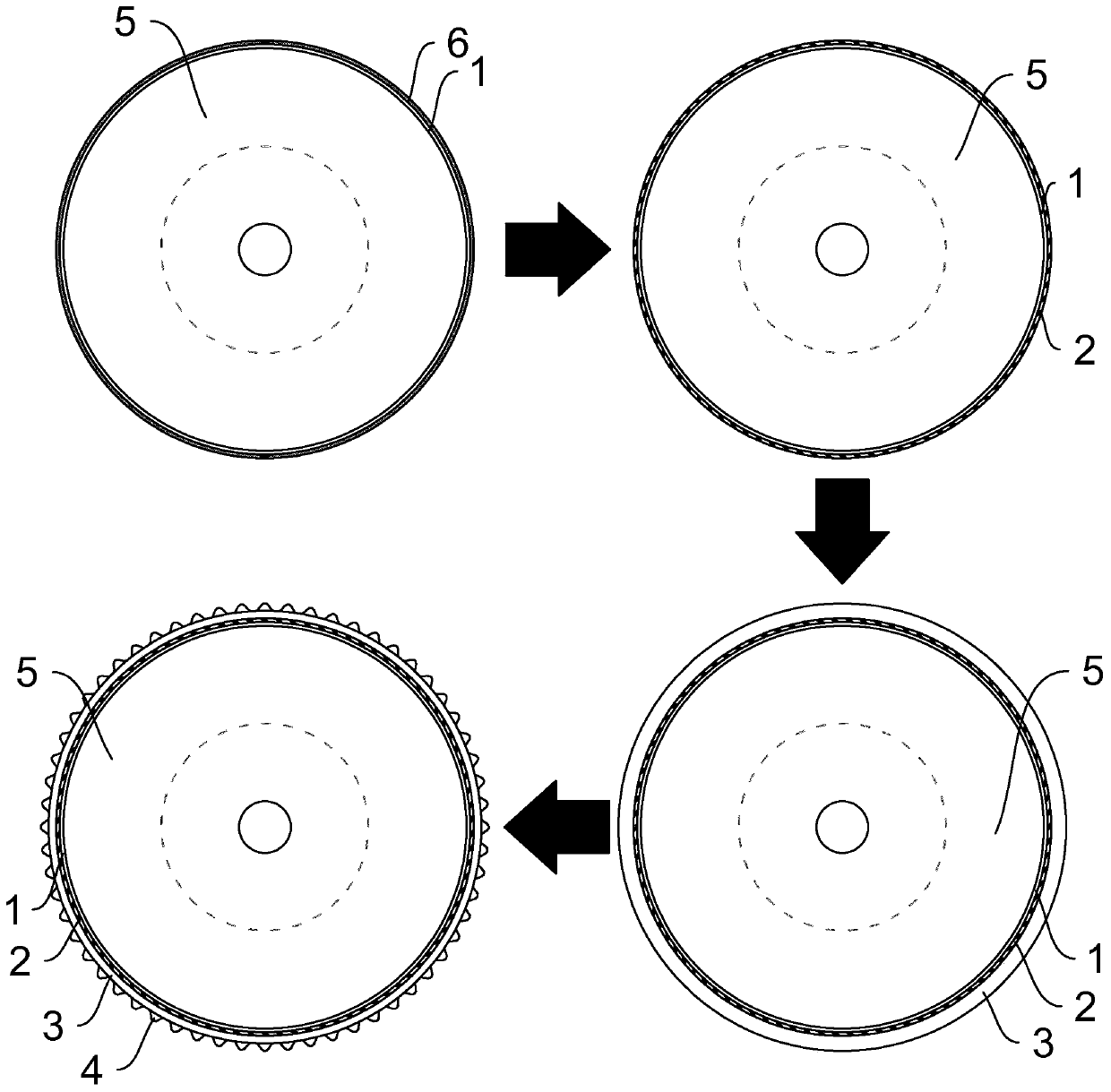

Rubberized fabric material with polyester cotton lining and capable of preventing chemical penetration

ActiveCN109501415AHigh bonding strengthThe physical and mechanical properties have not declinedSynthetic resin layered productsClothingsPolyesterVulcanization

The invention discloses a rubberized fabric material with a polyester cotton lining and capable of preventing chemical penetration. The rubberized fabric comprises base cloth, wherein two side surfaces of the base cloth are respectively coated with a fluororubber layer and a chlorobutyl rubber layer; polyester cotton cloth is compounded outside the fluororubber layer. According to the rubberized fabric material, the polyester cotton cloth is laminated to the fluororubber layer, so that the bonding strength of the rubberized fabric is improved; the two surfaces of the base cloth are respectively coated with fluororubber and chlorobutyl rubber; the one layer of polyester cotton cloth is laminated to the fluororubber layer; after drum type primary vulcanization, secondary vulcanization is performed in a vulcanizing tank, and thereby a finished product is obtained. Compared with the prior art in China, the rubberized fabric material has the advantages that the bonding strength of the rubberized fabric is improved while physical and mechanical properties, medium resistance and protecting performance are prevented from being reduced.

Owner:SHANXI XINHUA CHEM

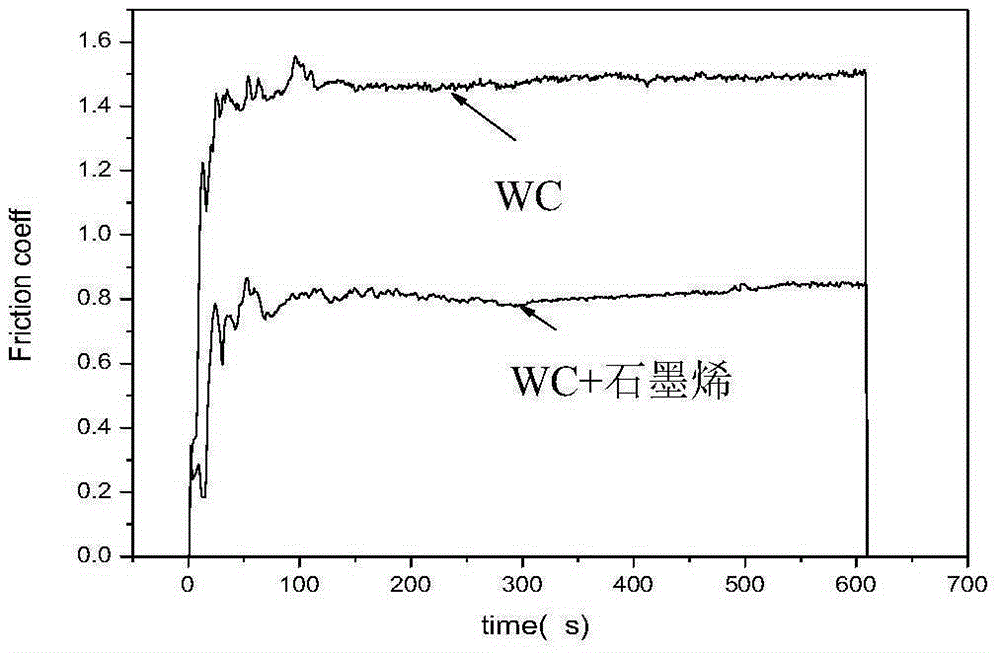

Graphene modified self-lubricating wear-resistant coating

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

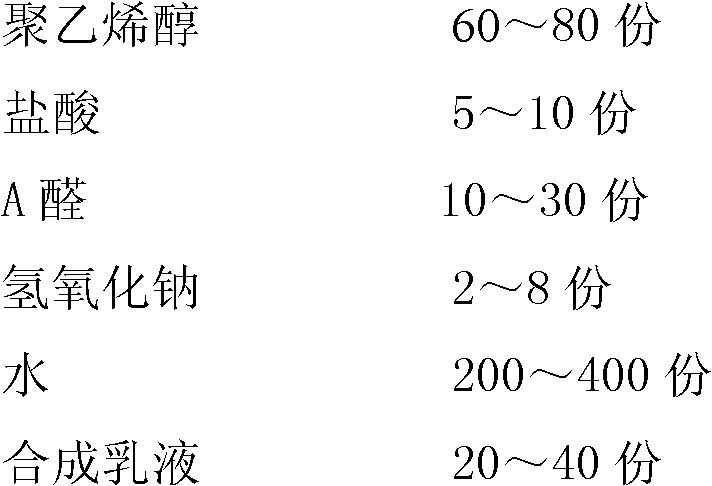

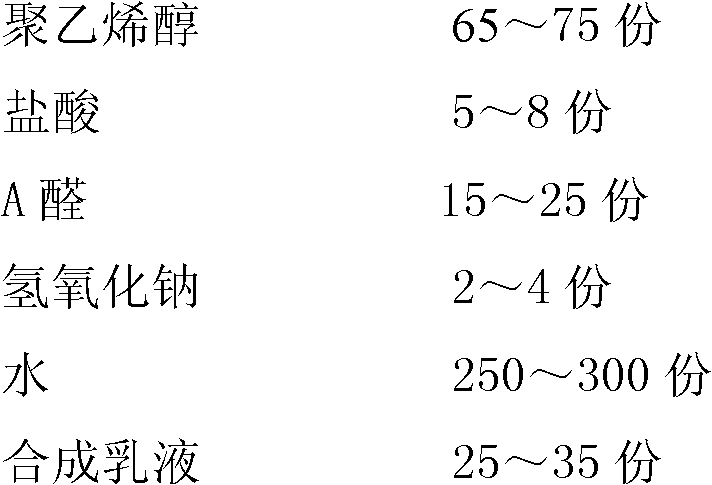

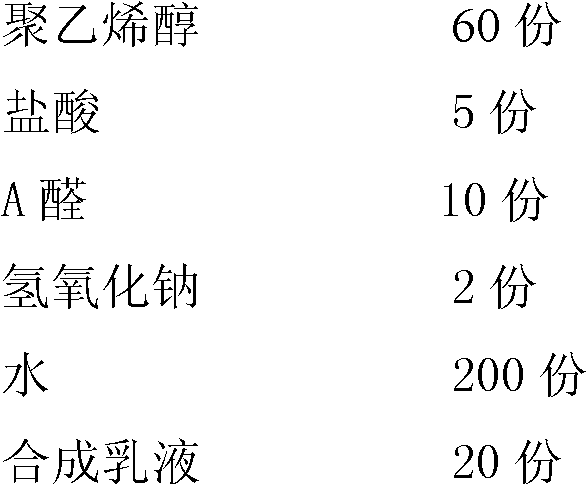

Polymer bonding mortar and preparation method thereof

The invention discloses a polymer bonding mortar and a preparation method of the polymer bonding mortar. The bonding mortar uses a modified redispersible powder to replace the traditional sizing material, the redispersible powder modified by paraffin and micron sized silica aerogel is better in water resistance and dispersibility, the bonding strength between the redispersible powder and an aggregate is stronger, in addition, a certain amount of aramid pulp and activated carbon powder are added as the aggregate, the degree of compacting of the mortar and the internal permeability of the mortar are improved, the bonding speed of the mortar is accelerated, the uneven hydration is avoided, the solidified mortar is excellent in anti-permeability, an introduced water retention particle is a long-acting reversible product, the water retaining property of the mortar is effectively improved, and the comprehensive performance of the mortar are further improved. The prepared bonding mortar is green and environmentally friendly, is economical and efficient, and has a prominent application advantage in an external wall insulation system.

Owner:HEFEI SHENZHOU CONSTR GRP CO LTD

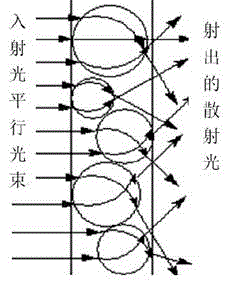

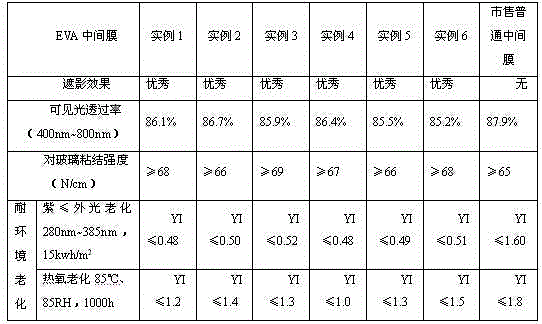

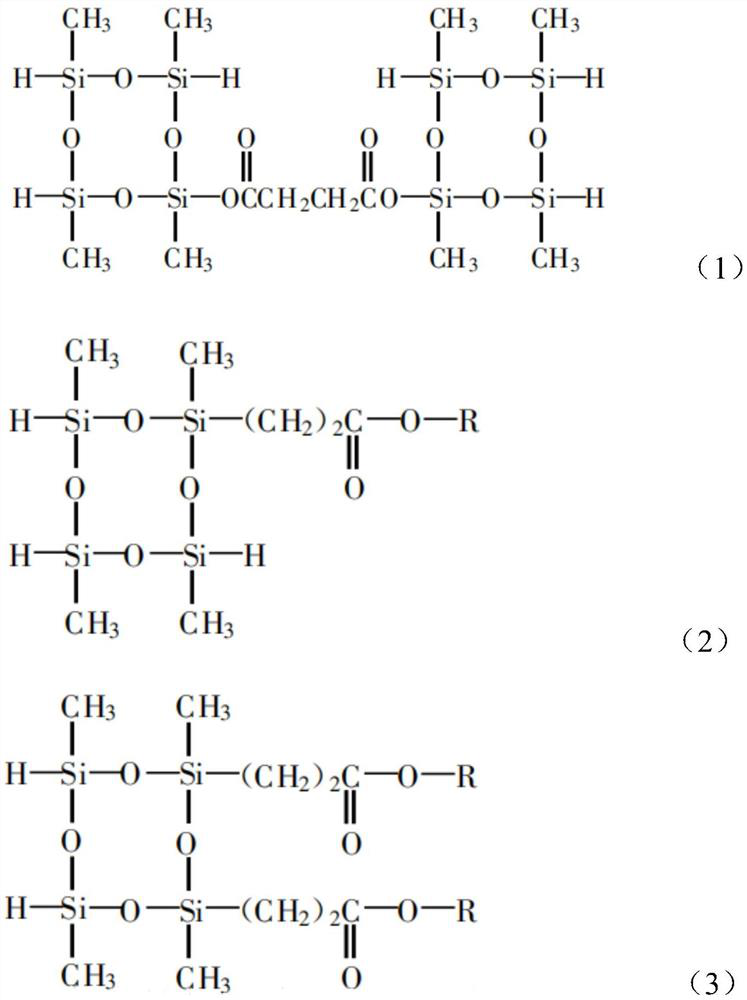

Laminated glass intermediate film with shielding capacity and high transparency as well as preparation method thereof

InactiveCN104098828AAchieve light transmissionAchieve the optical effect of shadingPolymer scienceCross linker

Owner:NANJING KIN YONG FA PLASTIC MFG

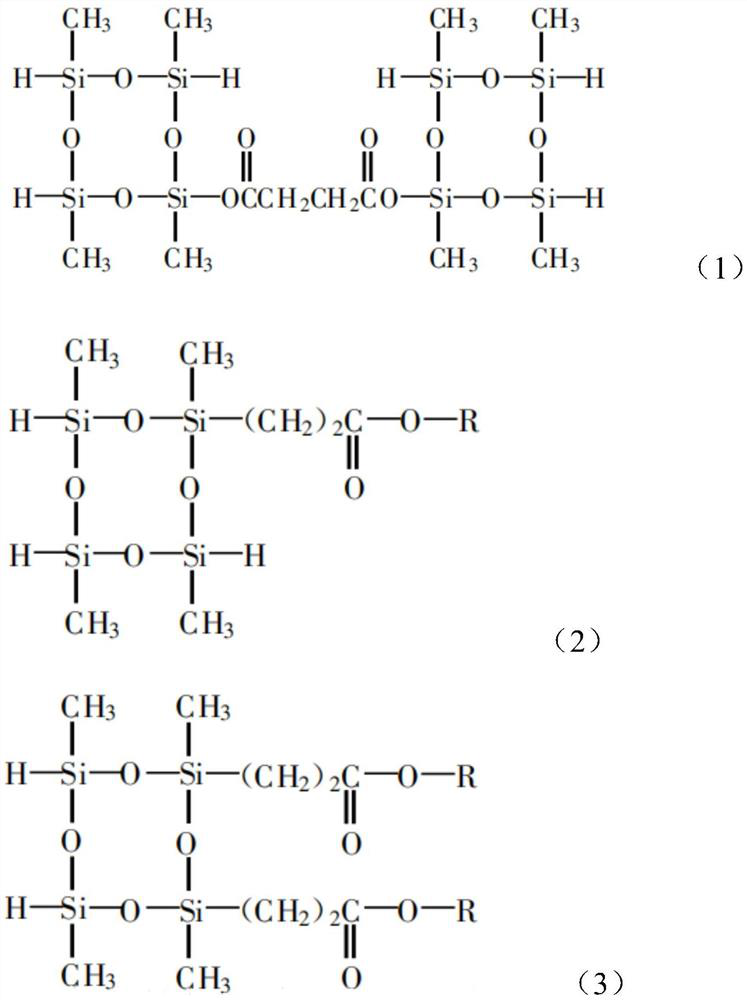

Two-component organic silicon composition for mold top packaging and preparation method thereof

Owner:广东皓明有机硅材料有限公司

Sintered neodymium-iron-boron magnet coated with interpenetrating polymer network coating and preparation method thereof

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Bamboo and paper double-surface mat

InactiveCN103082763AImprove tensile propertiesImproved wrinkle and fold resistanceBed-coversAdhesivePulp and paper industry

Owner:王吉喜

Method for manufacturing polyurethane flexible foam packing plates

InactiveCN103786231AHigh bonding strengthIncrease elasticityPolyureas/polyurethane adhesivesWood working apparatusPolyurethane adhesiveSingle plate

Owner:孟可星

Plastering adhesive cement for external wall surface

Owner:重庆琨森建筑材料有限公司

Multilayer interposer with high bonding strength

InactiveUS20160349315A1Simple structureEasy to operateElectronic circuit testingSemiconductor/solid-state device detailsInterposerInterconnection

Disclosed is a multilayer interposer with high bonding strength, which is used in wafer testing. The multilayer interposer with high bonding strength comprises a plurality of thin-film layer structures overlapping sequentially. One of the thin-film layer structures comprises at least one first conductive blind via. An interconnection layer electrically connected to the first conductive blind via is configured on the surface of the one of the thin-film layer structures, and the interconnection layer comprises at least one head portion. Another one of the thin-film layer structures comprises at least one second conductive blind via. The bottom of the second conductive blind via contacts both of the corresponding head portion and part of the surface of the one of the thin-film layer structures. Thereby, the bonding strength between layers can be dramatically increased, and the resistance to the thermal shock can be also increased.

Owner:CHUNGHWA PRECISION TEST TECH

Preparation method of high bonding type salt storage asphalt pavement material

The invention relates to a preparation method of a high bonding type salt storage asphalt pavement material and belongs to the technical field of building materials. According to the technical scheme,heavy saline-alkali soil is adopted as a raw material, and subjected to high-temperature calcining and wire drawing in fusion; by a high-concentration saline-alkali material in the saline-alkali soil, wires are drawn and fibers are collected, and by full bonding with resin particles, the bonding property between the material and resin is effectively improved; by excellent bonding property betweenmixed resin and asphalt, the bonding strength of the material is further improved; in the technical scheme, the saline-alkali soil is adopted as a modifying raw material, organic matters carbonized by high temperature are mostly decomposed, a small part of the organic matters form porous carbide and are loaded to the surface of a fiber material, and by excellent structural property of the surfaceof the carbide, the bonding strength between the material and the resin is improved, so that the bonding property and the mechanical strength of the compound asphalt material are further improved.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

High-temperature pressure fusion manufacturing method of composite pipe internally coated with stainless steel

Owner:山东胜利长龙管道科技有限公司 +1

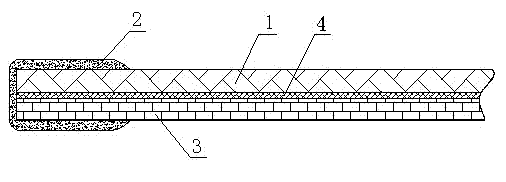

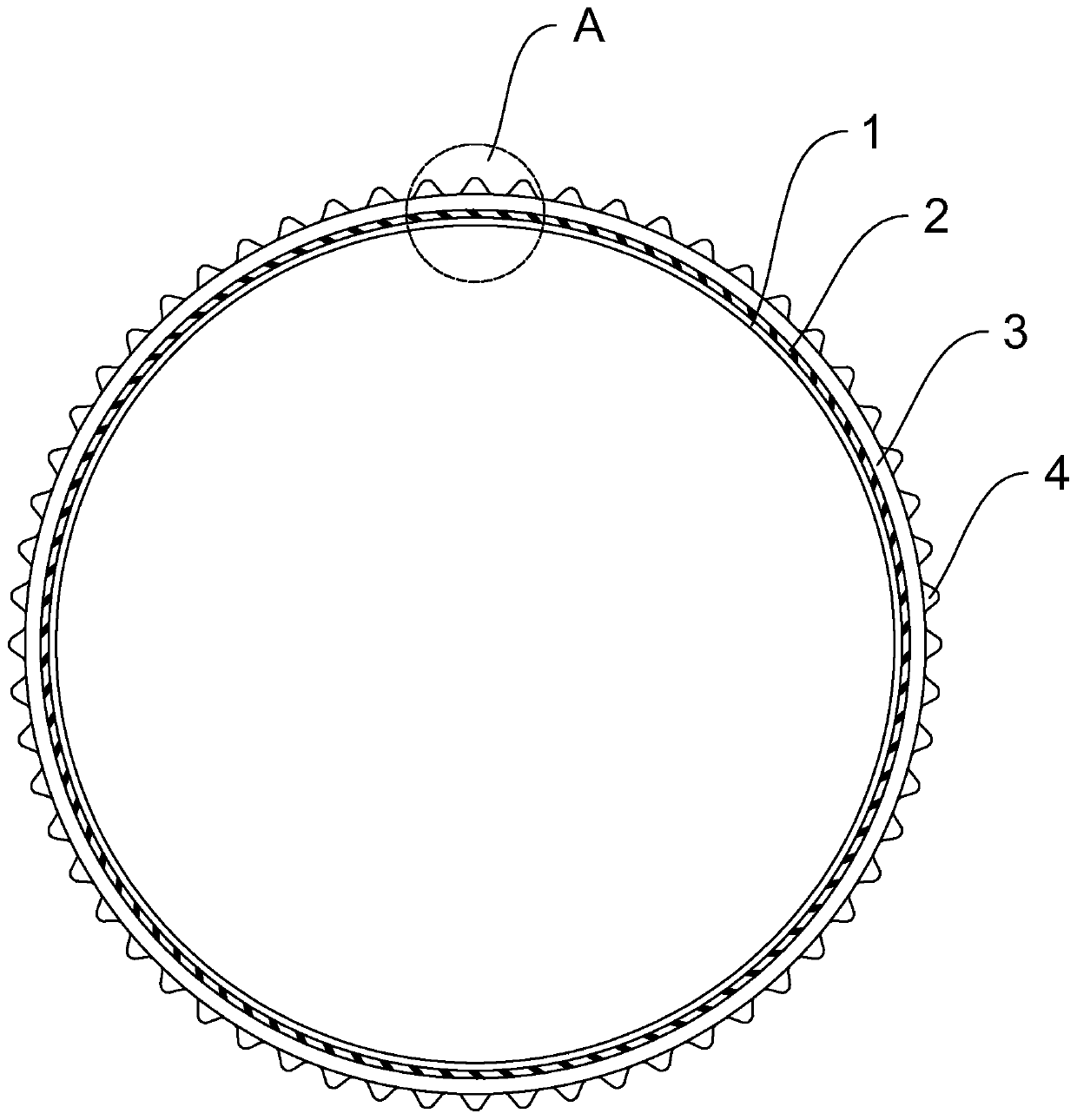

Colorful V-ribbed belt and preparation method thereof

ActiveCN111207181AHigh bonding strengthNot easy to fall offFibre treatmentDriving beltsAdhesiveEngineering

Owner:NINGBO FENGMAO FAR EAST RUBBER

Co-Mn-Si-Fe nanometer welding layer for welding and preparation method

InactiveCN104889597AImprove performanceExtended service lifeArc welding apparatusWelding/cutting media/materialsUltimate tensile strengthWear resistance

The invention relates to a Co-Mn-Si-Fe nanometer welding layer for welding and a preparation method. The Co-Mn-Si-Fe nanometer welding layer for welding comprises the following components in percentage by mass: 46-63% of Co, 29-37% of Mn, 7-9% of Si, 7-9% of Fe, 2-3% of Al2O3, and 0.5-1.5% of additive. The additive is Ni60A. The method comprises the following steps: Co, Mn, Si, Fe and Al2O3 are prepared to nanometer balls by an atomization method; the nanometer balls are uniformly mixed with grinded Ni60A to prepare nanometer welding rods; and finally, the nanometer welding rods are welded on the surface of a part to form the nanometer welding layer. The prepared nanometer welding layer has such advantages as high bonding strength, wear resistance and good corrosion resistance, realizes the repairing of the part, improves the service performance of the part, and prolongs the service life of the part.

Owner:WUHU DINGHAN REMFR TECH

High-bonding-strength conductive adhesive for repairable microelectronic assembly and preparation method thereof

InactiveCN112694851AImprove electrical performanceEpoxy resin adhesivesElectrically-conducting adhesivesPolymer scienceEthyl group

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

Leather adhesive and preparation method thereof

InactiveCN102807829AGood flexibilityHigh bonding strengthNatural rubber adhesivesWax adhesivesAdhesiveHigh adhesion

Owner:太仓市联林活性炭厂

Method for improving endurance of battery electric vehicle based on connection of aluminum skin and steel vehicle body

InactiveCN111976845AGuaranteed flatnessGuaranteed bonding strengthSuperstructure connectionsSurface cleaningAdhesive glue

The invention discloses a method for improving the endurance of a battery electric vehicle based on connection of an aluminum skin and a steel vehicle body. The method comprises the following steps that the aluminum skin is treated, firstly, the inner surface of the aluminum skin is dried for 15 minutes after being cleaned, then prime coating operation is carried out, and drying is also carried out for 15 minutes after prime coating operation; a steel vehicle body framework is polished and then subjected to prime coating operation; limiting adhesive tape is pasted on the steel vehicle body framework; an area defined by the limiting adhesive tape on the steel vehicle body framework is glued; the aluminum skin is pasted on the steel vehicle body framework, and the aluminum skin is positionedthrough a clamp so as to adjust the height; the front end flange of the aluminum skin is nailed to achieve temporary fixation; the aluminum skin is tensioned; flame treatment is carried out to relieve stress so as to tightly attach the aluminum skin to the steel vehicle body framework; the front end flange of the aluminum skin is nailed and cut off; and the aluminum skin and the steel vehicle body are fixedly connected. According to the method for improving the endurance of the battery electric vehicle based on connection of the aluminum skin and the steel vehicle body, the aluminum skin andthe steel vehicle body are connected by adopting a glue bonding scheme, so that the flatness of the aluminum skin is ensured while the bonding strength is ensured.

Owner:NANJING GOLDEN DRAGON BUS

High-temperature, high-pressure, high-sensitivity and long-life tungsten-rhenium thermocouple

PendingCN114088227AThe coating has good high temperature oxidation resistanceHigh densityThermometer detailsThermometers using electric/magnetic elementsRheniumThermocouple Wire

Owner:JINDUICHENG MOLYBDENUM CO LTD

Motorcycle pedal and processing technology thereof

ActiveCN112175492AGood compatibilityImprove wear resistanceSpecial surfacesFoot-restsOxide ceramicMonoglyceride

The invention relates to the field of motorcycle accessories, and discloses a motorcycle pedal and a processing technology thereof. According to the motorcycle pedal, the surface of the pedal is treated by a surface treating agent, and the surface treating agent comprises the following raw materials in parts by weight: 50-60 parts of alkyd resin, 10-15 parts of amino resin, 5-8 parts of nano magnesium oxide, 3-4 parts of alumina ceramic, 5-6 parts of a monoglyceride maleate acidified product, 1-2 parts of dimethylolpropionic acid, and 1-2 parts of a cross-linking agent. The processing technology comprises the steps of phosphating treatment, surface treating agent preparation and pedal spray processing. The invention has the following advantages and effects: the mixed product of alkyd resinand amino resin and the addition of alumina ceramic and nano magnesium oxide enhance the wear resistance, the aluminum oxide ceramic and the monoglyceride maleate are mixed, so that the compatibilityamong the components is improved, the bonding strength of the surface treating agent and the pedal plate is improved, and the crosslinking compounding of the monoglyceride maleate acidified substanceand dimethylolpropionic acid can enhance the crosslinking density and enhance the wear resistance of the pedal.

Owner:WENZHOU OUHAI QUXI MOTORCYCLE FITTINGS FACTORY

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap