Wind power blade tip lengthening method

A technology for wind power blades and extension sections, applied in the field of wind power blade tip extension, can solve the problems of increased construction cost and time, damage, and complicated construction, so as to reduce construction time and cost, improve controllability, and reduce construction complexity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose and technical solution of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

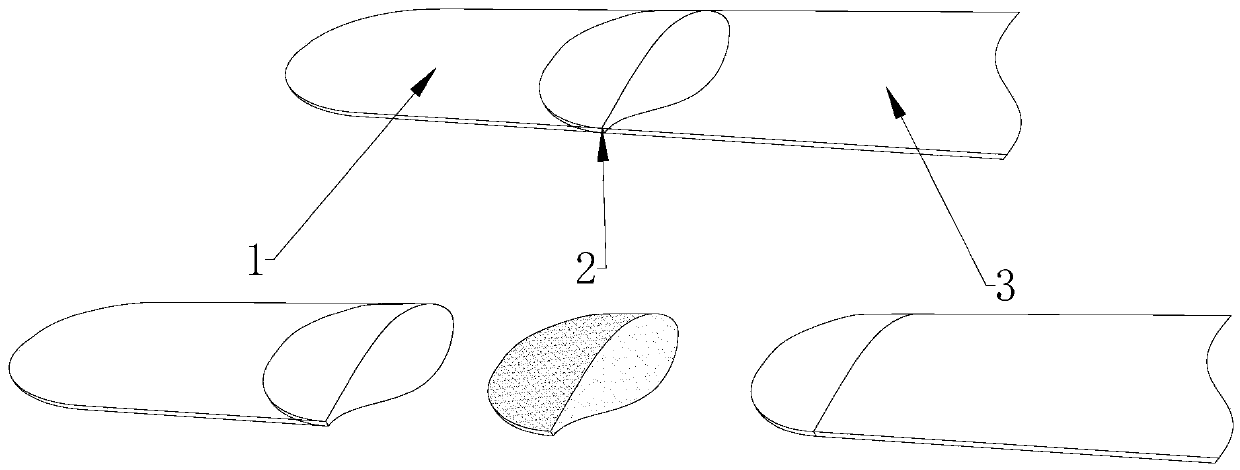

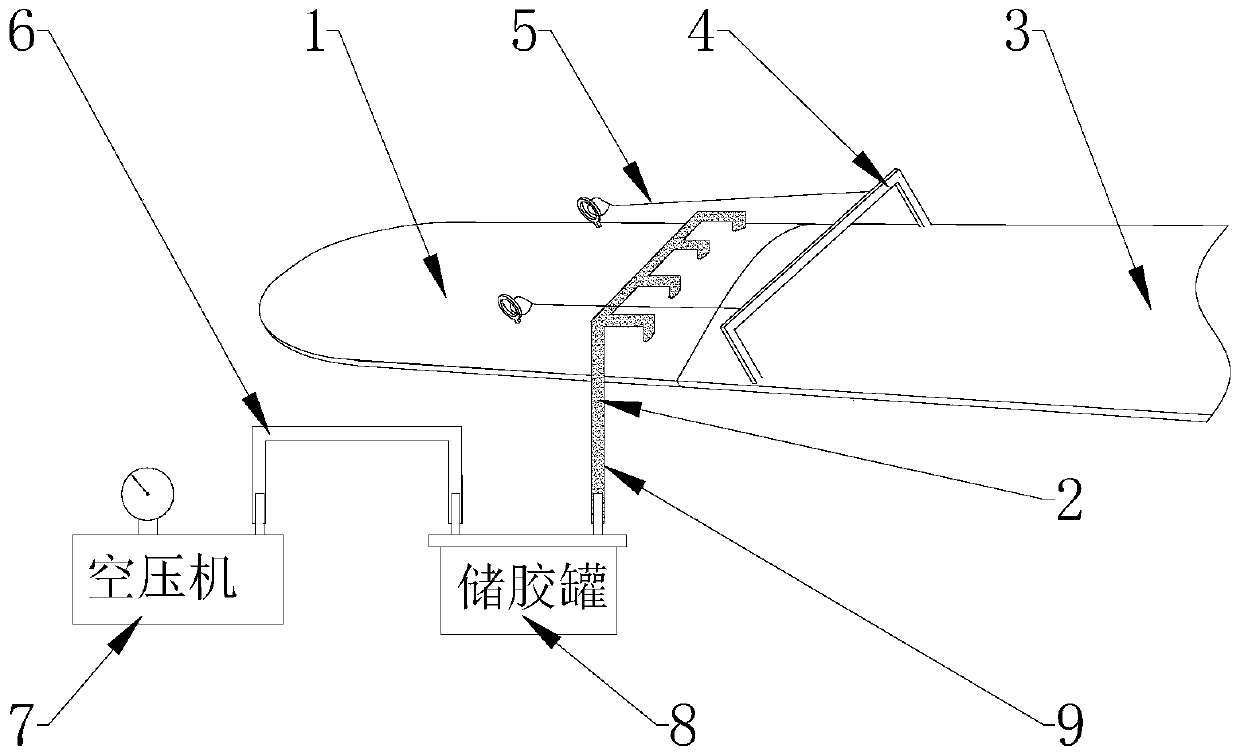

[0027] Such as figure 1 As shown, the blade tip extension method of the present invention is to bond the blade tip extension section 1 to the base blade 3 through the structural glue 2, so as to increase the blade length and achieve the purpose of increasing the power generation. It is characterized in that the method includes Make the blade tip extension, make and install auxiliary tooling, build the glue injection system, glue injection and post-processing four steps.

[0028] 1. Make the blade tip extension

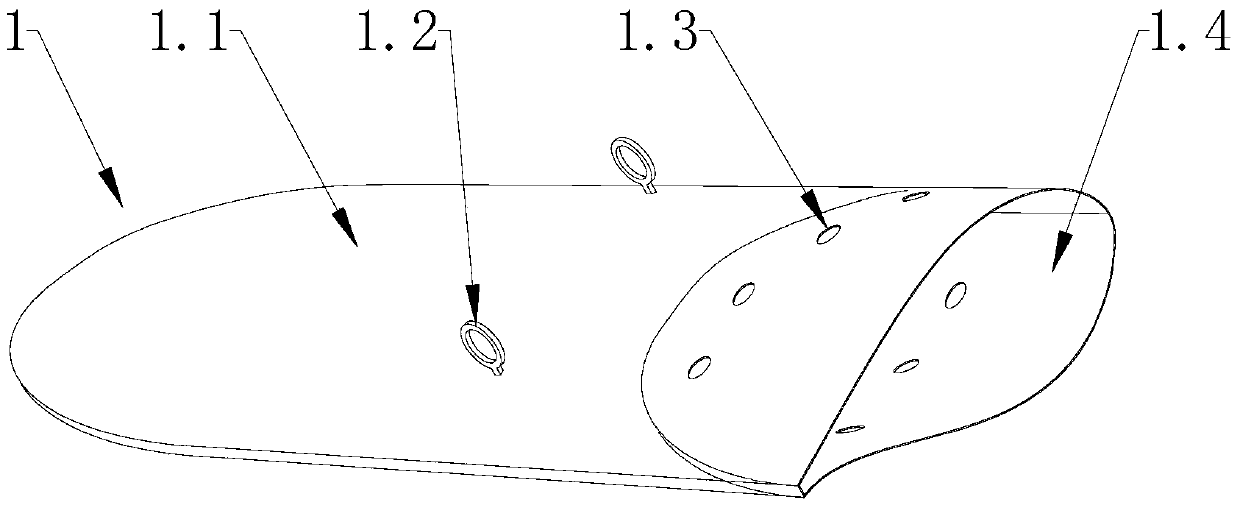

[0029] Tip extension 1 as figure 2 As shown, including extension section connection end 1.4, extension section main body 1.1, suspension ring 1.2 and glue injection hole 1.3, the inner contour of extension section connection

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap