Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Wire drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire drawing is a metalworking process used to reduce the cross-section of a wire by pulling the wire through a single, or series of, drawing die(s). There are many applications for wire drawing, including electrical wiring, cables, tension-loaded structural components, springs, paper clips, spokes for wheels, and stringed musical instruments. Although similar in process, drawing is different from extrusion, because in drawing the wire is pulled, rather than pushed, through the die. Drawing is usually performed at room temperature, thus classified as a cold working process, but it may be performed at elevated temperatures for large wires to reduce forces.

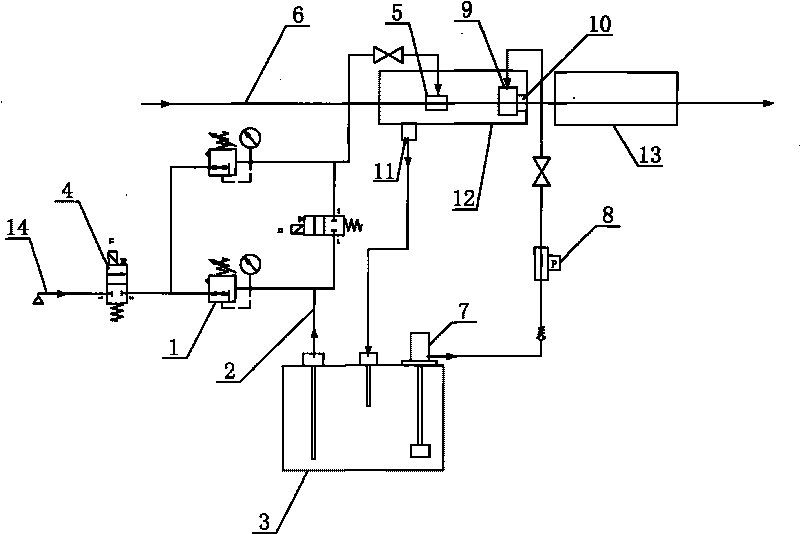

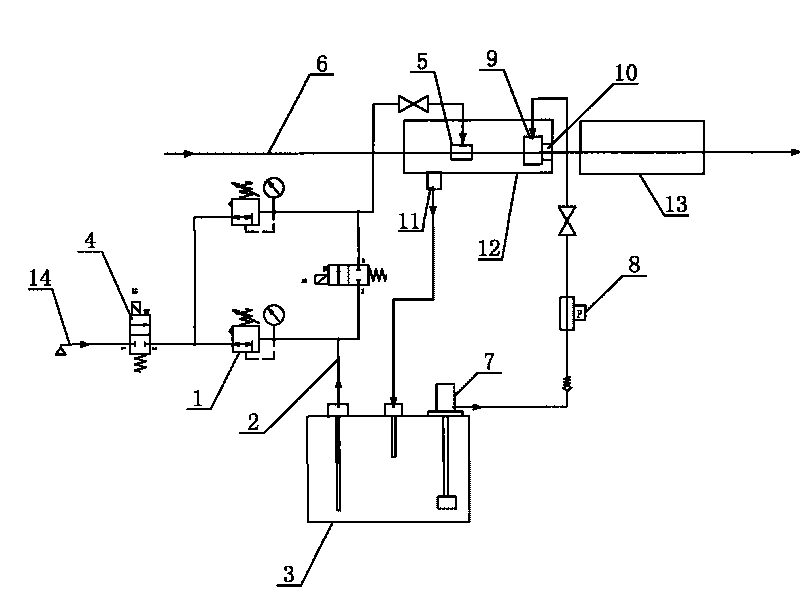

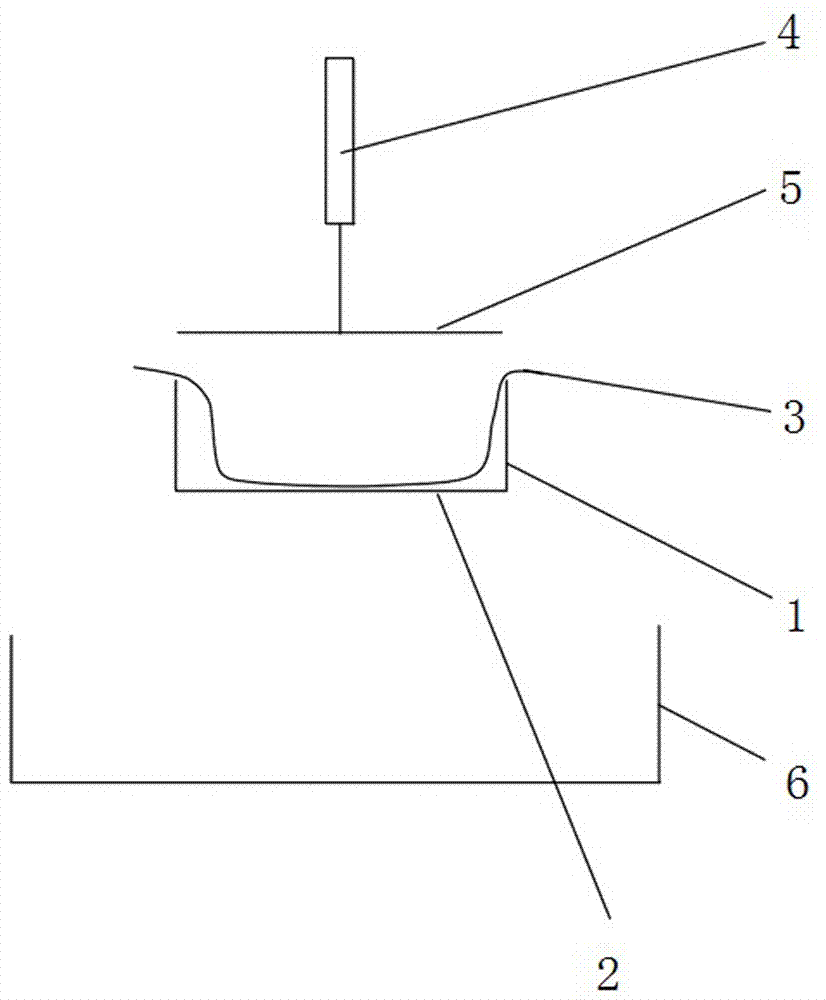

Method for cleaning and oiling flux-cored wire surface and device thereof

InactiveCN101733592AQuality improvementSimple structureWelding/cutting media/materialsSoldering mediaSprayerTee junction

Owner:贵州建新南海科技股份有限公司

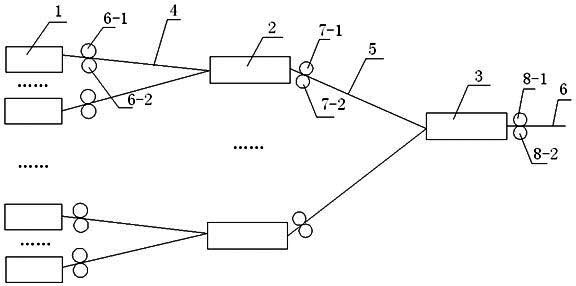

Fixed-size production equipment of steel rope

InactiveCN102002874AHigh tensile strengthImprove efficiencyRope making machinesProgrammable logic controllerEngineering

Owner:JIANGSU JULI WIRE ROPE

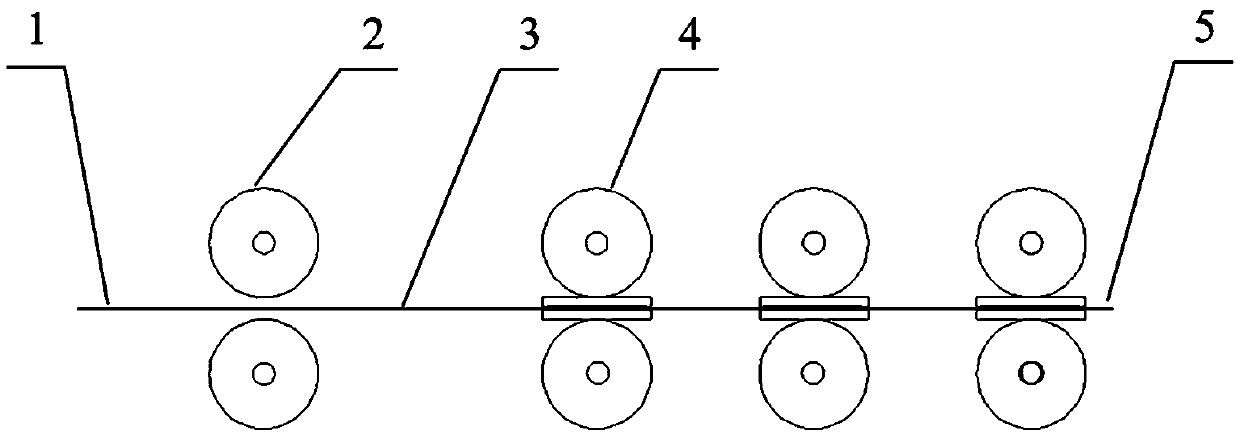

Easy-to-clean bamboo strip wire drawing machine

InactiveCN108262820AProtect physical healthImprove job stabilityCane mechanical workingBark-zones/chip/dust/waste removalWorking environmentEngineering

The invention discloses an easy-to-clean bamboo strip wire drawing machine. The easy-to-clean bamboo strip wire drawing machine comprises a machine box, wherein a wire drawing device is arranged on one side of the machine box, a falling plate is arranged below the wire drawing device, a collecting groove is formed in the end of the falling plate, a rotatable protective cover is arranged on the outer side of the wire drawing device, and an inclined plate is arranged at the lower end of the protective cover; the wire drawing device comprises a bamboo strip inlet, a first rotating wheel set, a first positioning plate set, a slitting knife set, a second positioning plate set and a second rotating wheel set which are sequentially arranged on the side wall of the box in the horizontal direction,the first positioning plate set comprises a first upper positioning plate and a first lower positioning plate, the two sides of the first upper positioning plate and the two sides of the first lowerpositioning plate are provided with first ash blocking plates and guide plates, the second positioning plate set comprises a second upper positioning plate and a second lower positioning plate, and aprotection baffle located on the outer side of the slitting knife set is arranged on one side of the second upper positioning plate. The easy-to-clean bamboo strip wire drawing machine has the characteristics of being good in working environment and convenient to clean.

Owner:ZHEJIANG LIANGYUE BOARD IND CO LTD

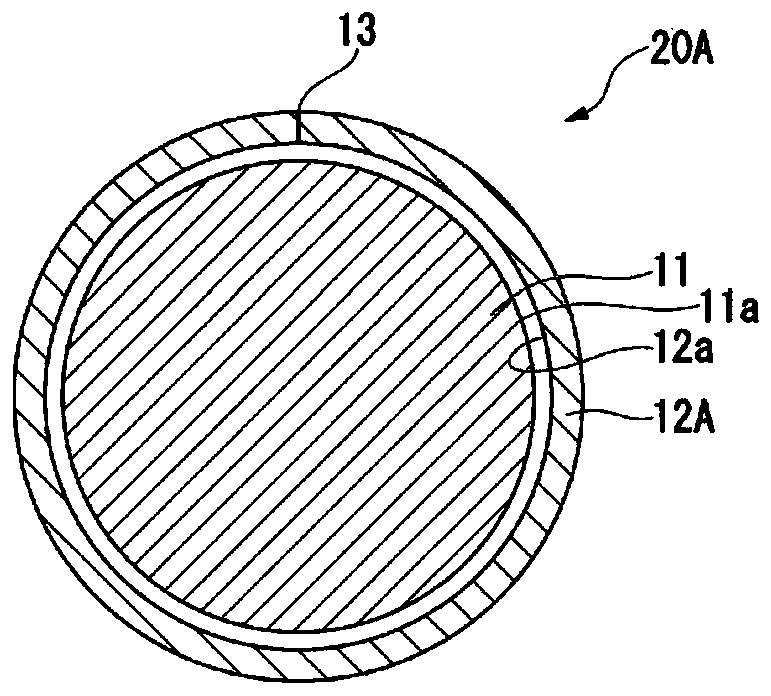

Self-lubricating hard alloy wire drawing die and preparation method thereof

InactiveCN109226301AImprove drawing process qualityAchieve self-lubricating effectDrawing diesManufacturing technologyHigh energy

Owner:SOUTHEAST UNIV

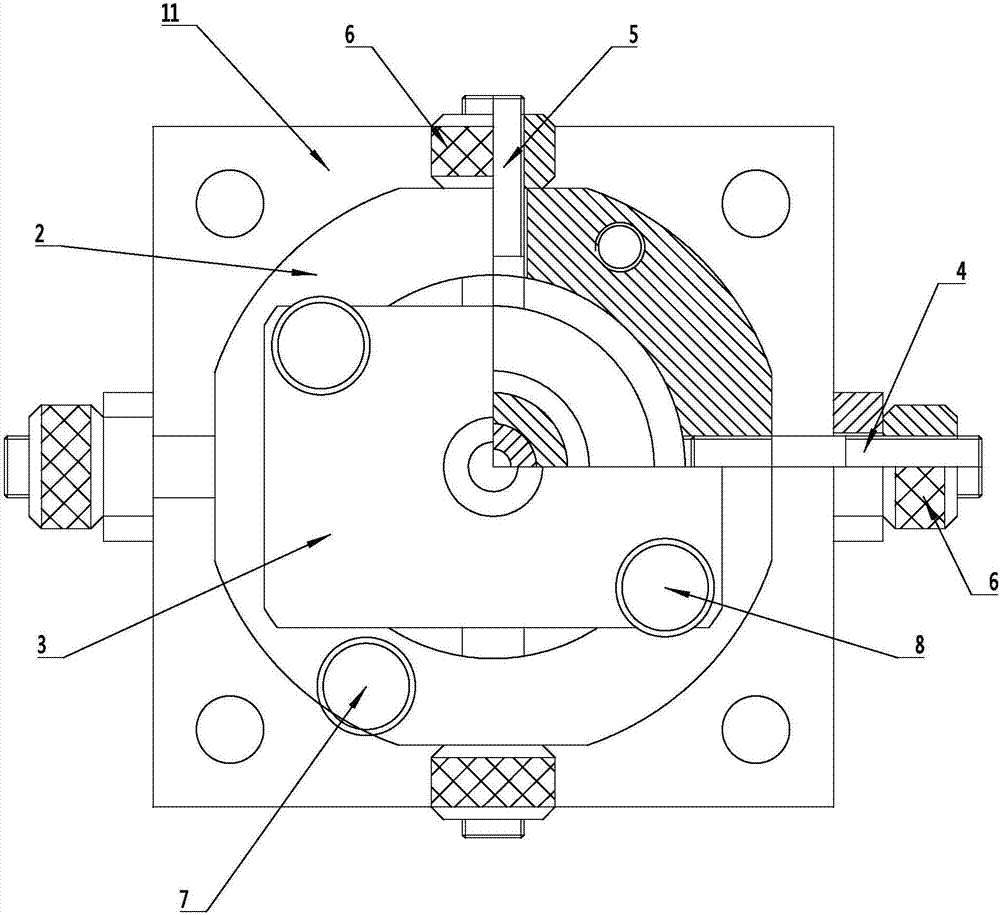

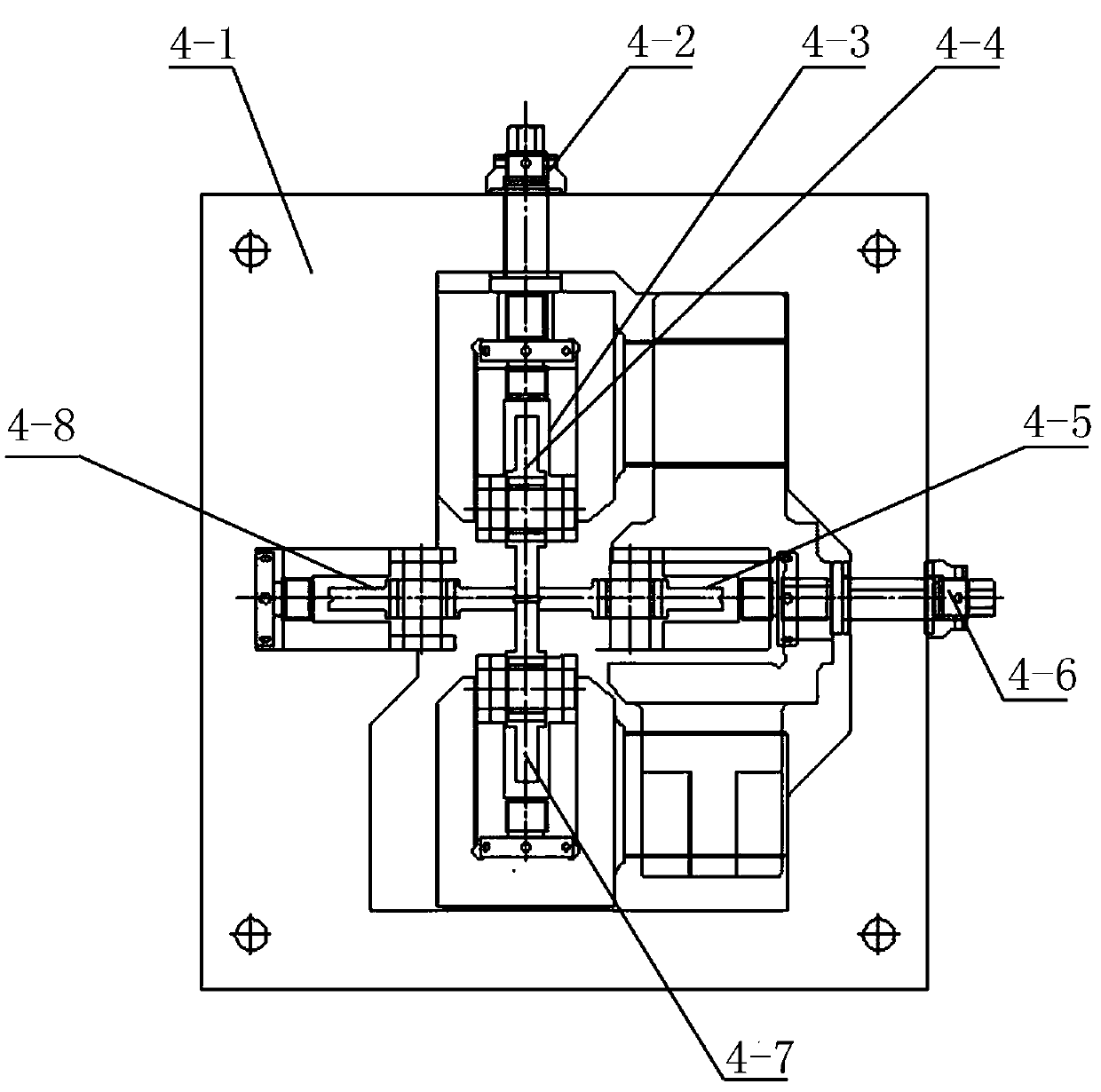

Adjustable wire-drawing die box

Owner:鹤山恒基钢丝制品有限公司

Generation method and device for DAF-attached small substrate, storage medium and electronic equipment

ActiveCN112259473ALow costReduce drawingSemiconductor/solid-state device manufacturingMetal working apparatusEngineeringParticle density

The invention discloses a generation method and device for a DAF-attached small substrate, a storage medium and electronic equipment. The method comprises the following steps: enabling a DAF to be attached to the reverse side, where no circuit is laid, of an initial packaging substrate so as to obtain a to-be-cut packaging substrate; and conducting cutting from the front face of the packaging substratea by using a soft knife blade to obtain the DAF-attached small substrate, wherein the soft knife blade is made of artificial diamond with a particle size ranging from 800 to 1200 and particle density ranging from 40 to 60. According to the invention, after the DAF is attached to the reverse side of the initial packaging substrate without the circuit, the soft knife blade made of the artificial diamond with the particle size of 800-1200 and the particle density of 40-60 is used for cutting, so wire drawing problems can be effectively reduced, cutting twice in the prior art is not needed, process complexity is reduced, labor cost and ubstrate cost are saved, and manufacturing cost is saved.

Owner:BIWIN STORAGE TECH CO LTD

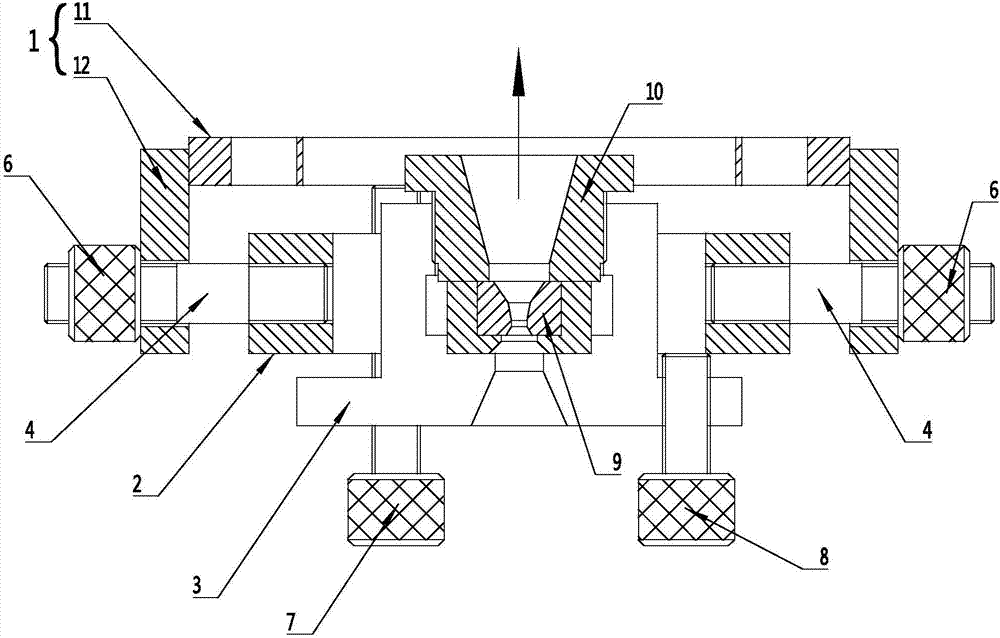

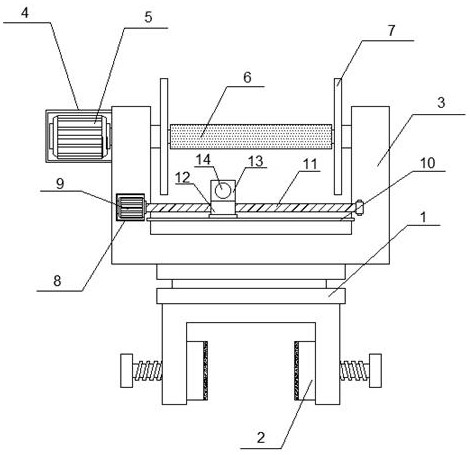

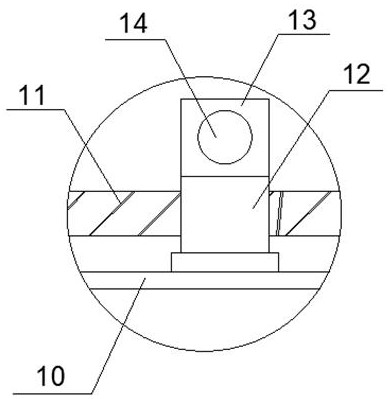

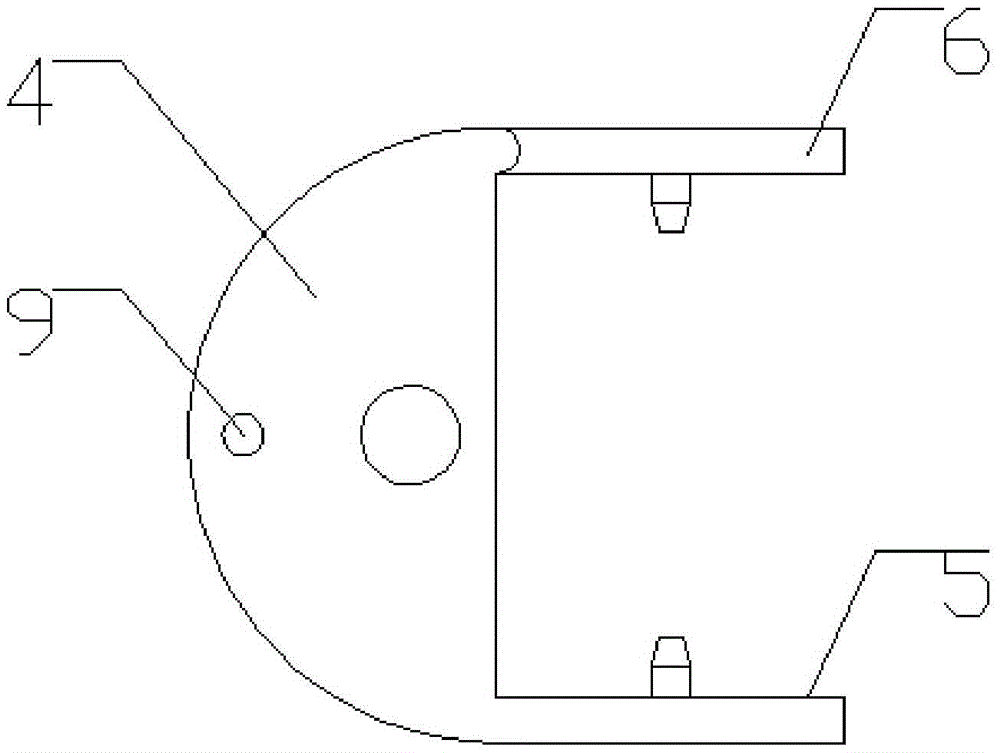

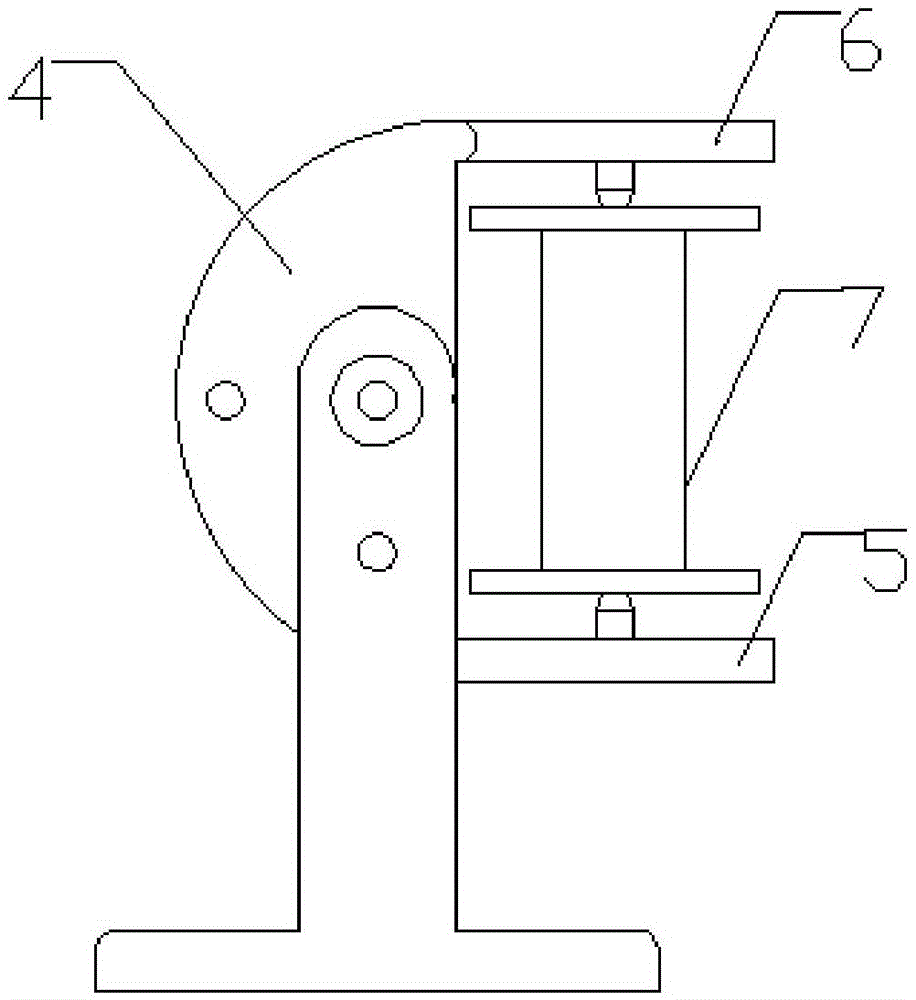

Wire incoming mold box of water tank wire drawing machine

The invention relates to a wire incoming mold box of a water tank wire drawing machine. The wire incoming mold box includes a wire outgoing bucket provided with a mold box bracket, the mold box bracket is provided with a mold box through a pin shaft, the mold box is provided with a wire drawing mold, a mold plug is mounted on one side of the wire outgoing direction of the wire drawing mold, and a channel allowing metal wires to pass through is mounted in the wire drawing mold and the mold plug. The wire incoming mold box is characterized in that: an adjusting bolt is mounted at each of the left, right, upper and lower direction of the mold box, and one end of each adjusting bolt is mounted on the wire outgoing bucket, and the other end presses against the mold box. The lower part of the wire outgoing bucket is provided with a fixing hole for fixing the wire outgoing bucket. The wire incoming mold box of the water tank wire drawing machine can adjust left, right, upper and lower positions of the wire incoming mold box, and thereby adjusting a wire incoming angle of the metal wires and ensuring the drawing effect.

Owner:WUXI PINGSHENG SCI & TECH

Forming method of scraper ring flat steel belt used for piston ring

InactiveCN105499267AHigh shape accuracyHigh dimensional accuracyMetal rolling arrangementsPiston ringSteel belt

Owner:中钢集团郑州金属制品研究院股份有限公司

Environment-friendly water-soluble stainless steel wire drawing liquid

InactiveCN112048364AEffective protectionPrevents minor abrasionsLubricant compositionActive agentSS - Stainless steel

Owner:江苏赢新润滑科技有限公司

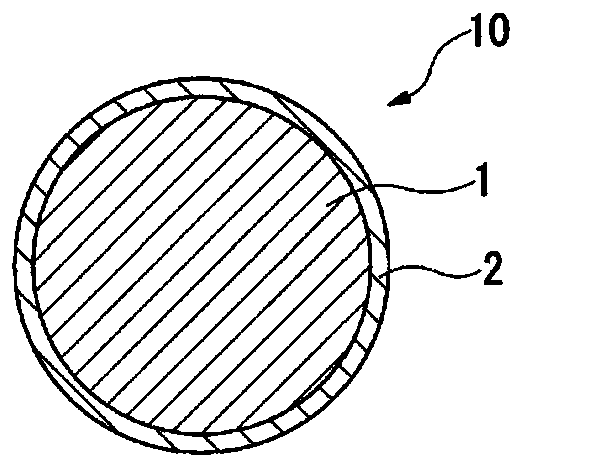

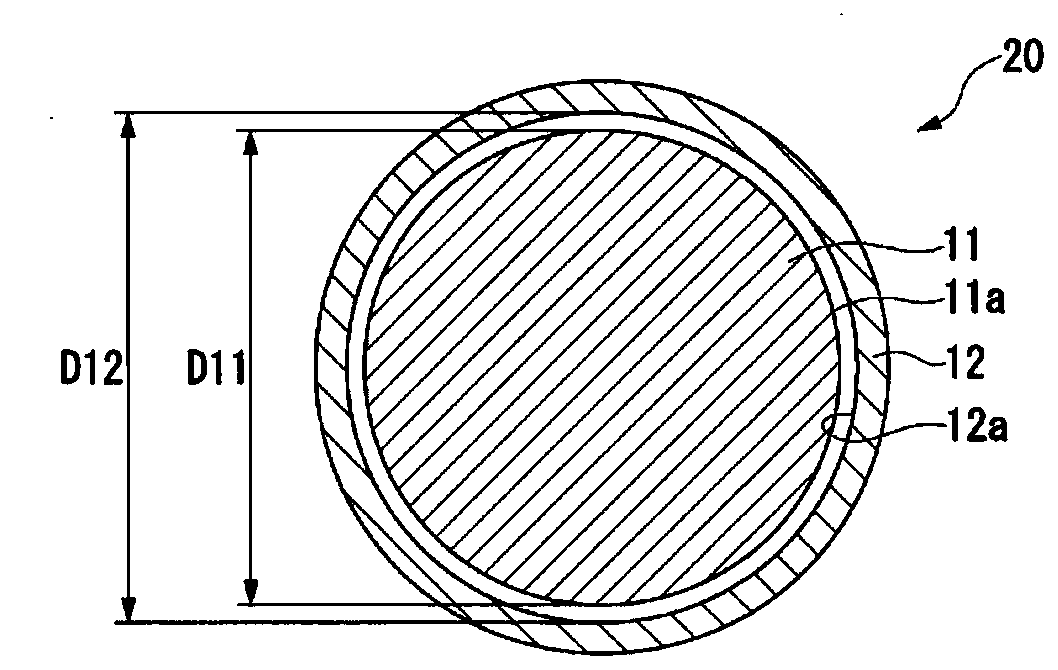

Wire and method for manufacturing same

InactiveCN110382128AReduce hardnessNot easy to breakSingle bars/rods/wires/strips conductorsInsulated cablesElectrical conductorMaterials science

Owner:THE FUJIKURA CABLE WORKS LTD

Solid-liquid separating mechanism for food residues

InactiveCN107376451AEasy to operateLow costGravity filtersStationary filtering element filtersBarrel ShapedEngineering

Owner:张家平

Preparation method of high bonding type salt storage asphalt pavement material

The invention relates to a preparation method of a high bonding type salt storage asphalt pavement material and belongs to the technical field of building materials. According to the technical scheme,heavy saline-alkali soil is adopted as a raw material, and subjected to high-temperature calcining and wire drawing in fusion; by a high-concentration saline-alkali material in the saline-alkali soil, wires are drawn and fibers are collected, and by full bonding with resin particles, the bonding property between the material and resin is effectively improved; by excellent bonding property betweenmixed resin and asphalt, the bonding strength of the material is further improved; in the technical scheme, the saline-alkali soil is adopted as a modifying raw material, organic matters carbonized by high temperature are mostly decomposed, a small part of the organic matters form porous carbide and are loaded to the surface of a fiber material, and by excellent structural property of the surfaceof the carbide, the bonding strength between the material and the resin is improved, so that the bonding property and the mechanical strength of the compound asphalt material are further improved.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Wire drawing equipment for Internet of Things engineering

InactiveCN114684665AImprove the convenience of adjustmentEasy to passFilament handlingElectric machineryDamper

Owner:天津华融金服科技有限公司

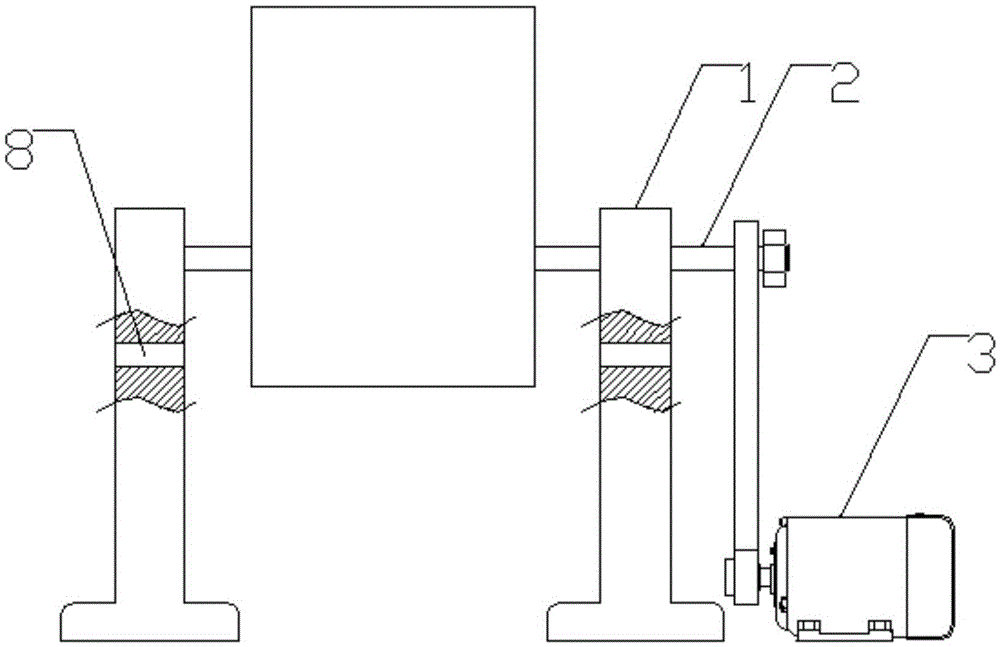

Paying-off equipment of wire drawing machine

Owner:TIANJIN DEXIANGPENG METAL PROD

Device for adjusting inlet height of hearth

Owner:上海朗仕电子设备有限公司

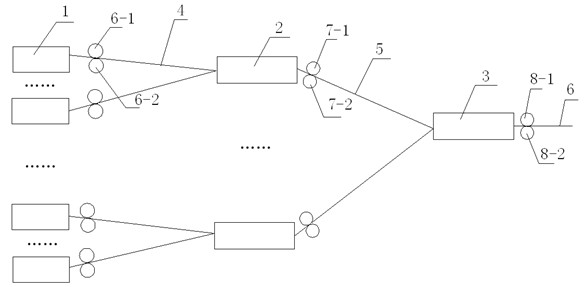

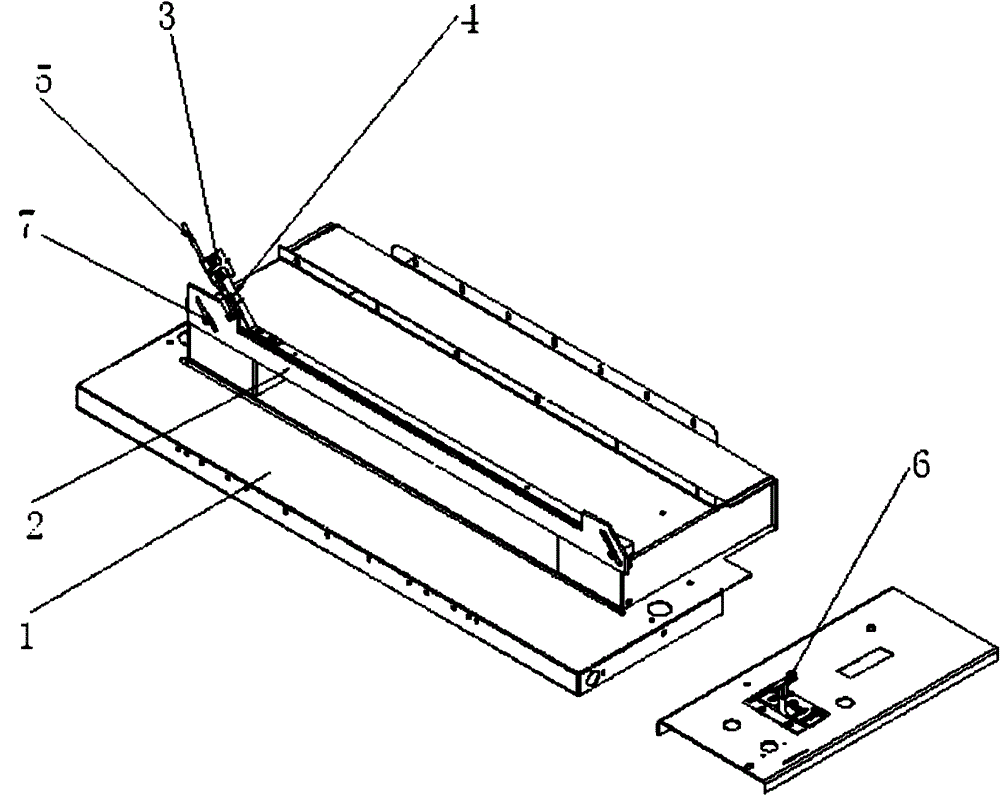

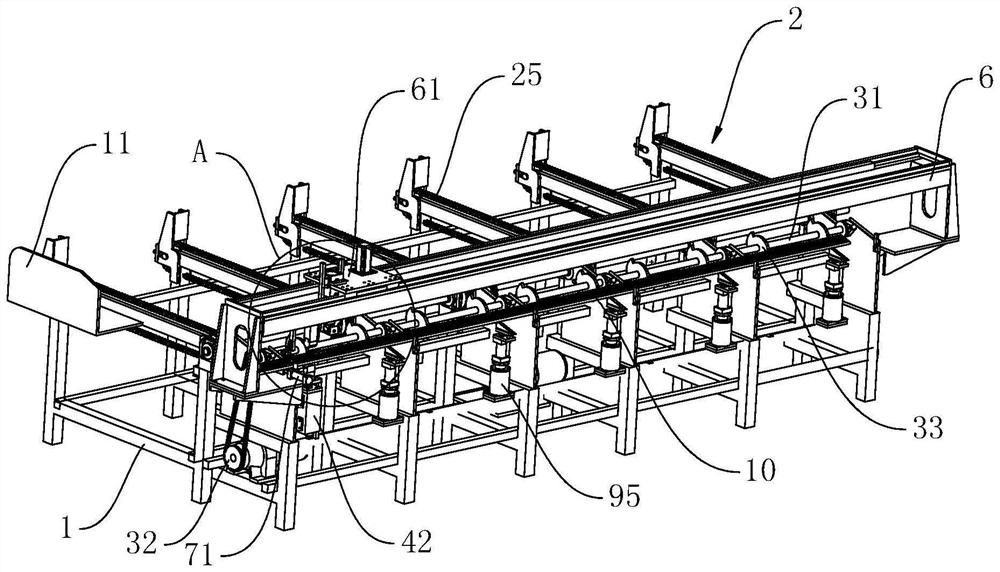

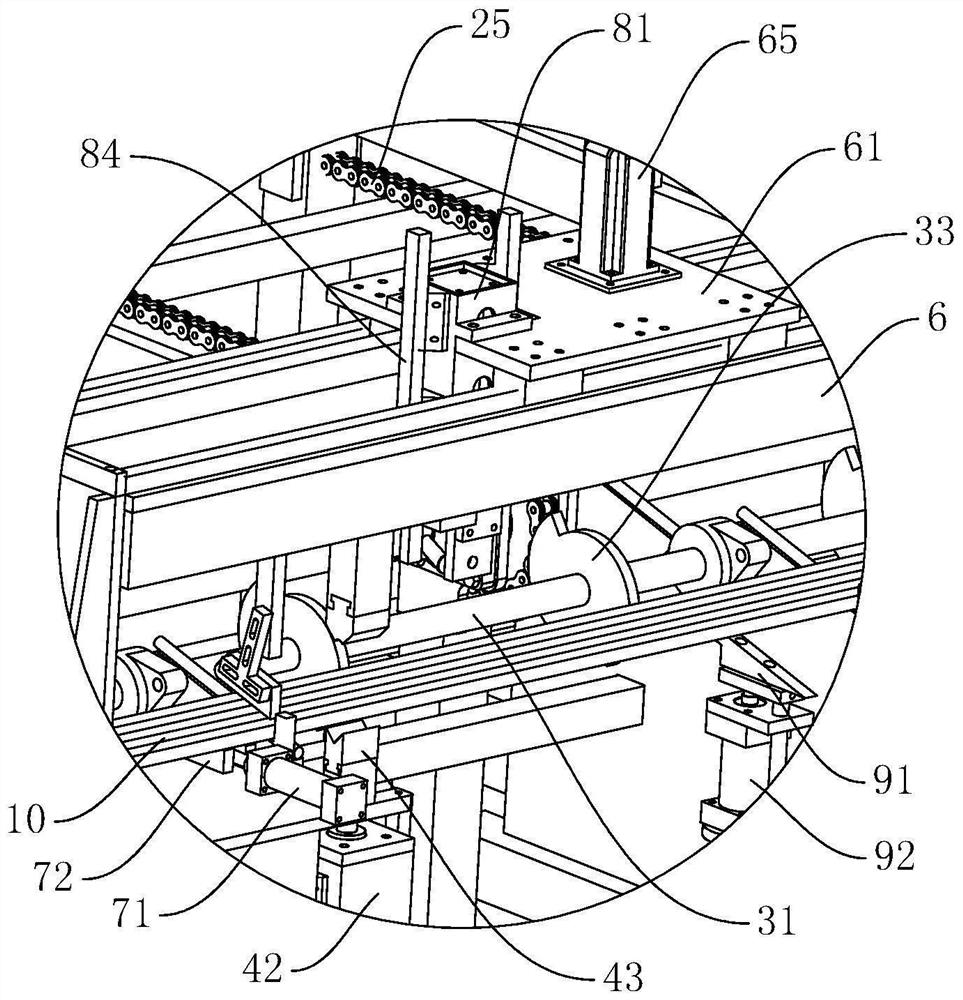

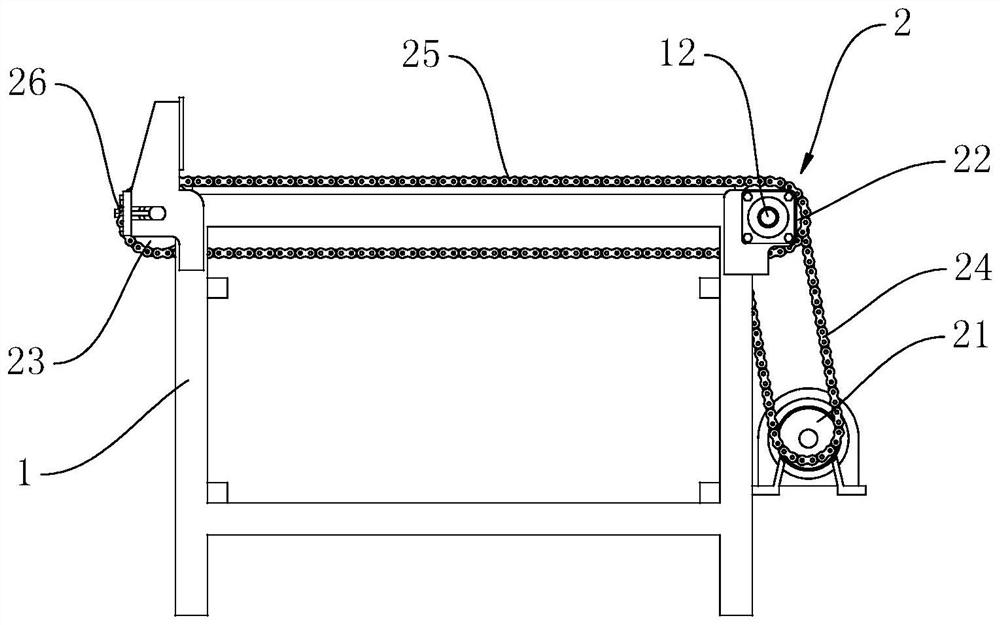

Automatic bar feeder

ActiveCN114346737AEasy to determineEasy to installMetal working apparatusMetal machiningStructural engineering

Owner:NINGBO CHANGZHEN COPPER CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap