Device for adjusting inlet height of hearth

A technology of height adjustment device and furnace, which is applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problems of increased operating cost, waste, high waste, etc., and achieves reduced operating cost, simple and economical structure, and wide range of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

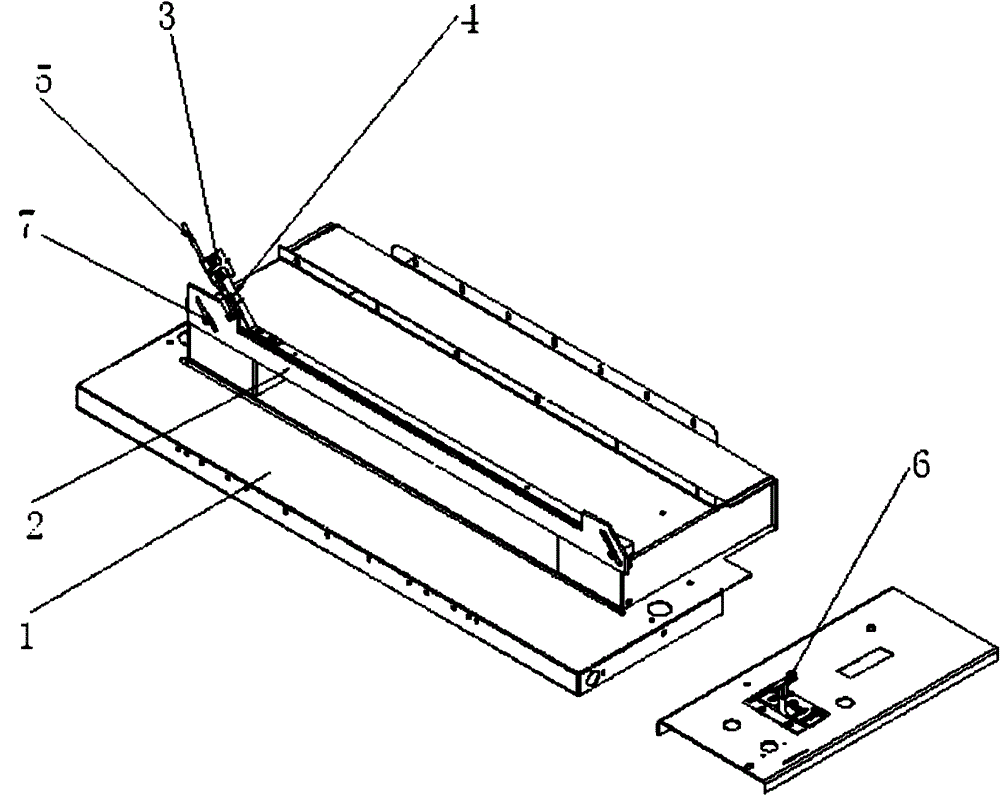

[0020] Such as figure 1 As shown, a furnace inlet height adjustment device includes a furnace 1, a furnace baffle 2, a steel wire 5, a steel wire fixing piece 3, a connecting bracket 4, and a control handle 6. The furnace baffle 2 is fixed on the furnace 1, The connecting bracket 4 is fixed on the furnace baffle plate 2, the steel wire fixing piece 3 is fixed on the connecting bracket 4, and one end of the steel wire stay wire 5 passes through the steel wire fixing piece 3 and the connecting bracket 4 successively to connect with the furnace baffle plate 2 Fixedly connected, the other end of the steel wire stay wire 5 is connected with the control handle 6. The furnace baffle 2 is provided with two oblique long waist-shaped slots, and the furnace baffle 2 is fixed on the furnace 1 through the slots through stepped screws 7 .

[0021] When the operator pulls the control handle 6 downward, the pulling force is transmitted to the furnace baffle 2 through the transmission of the ste

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap