Automatic bar feeder

An automatic feeding and rod technology, applied in metal processing, etc., can solve the problems of low efficiency and high labor intensity of operators, and achieve the effects of high safety, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

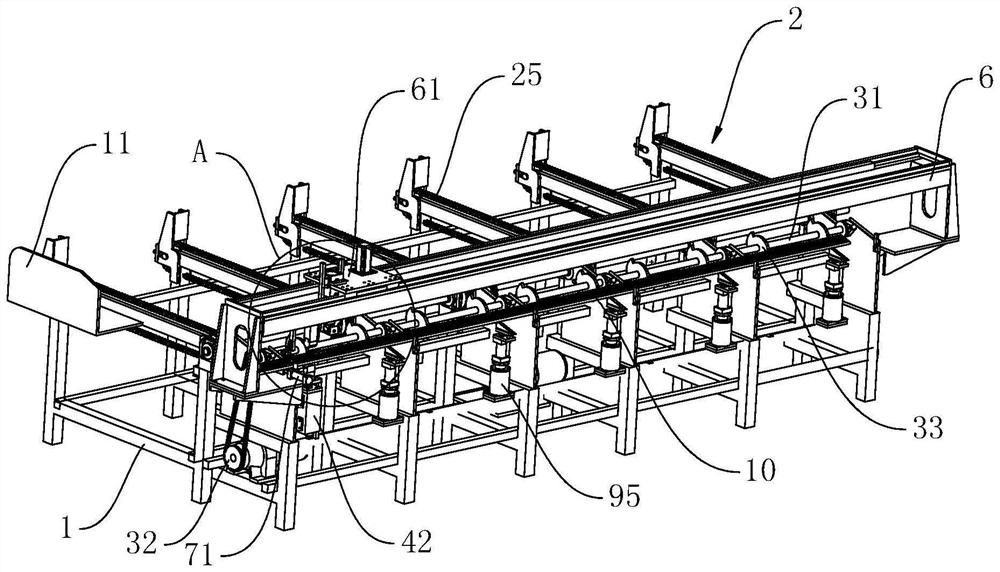

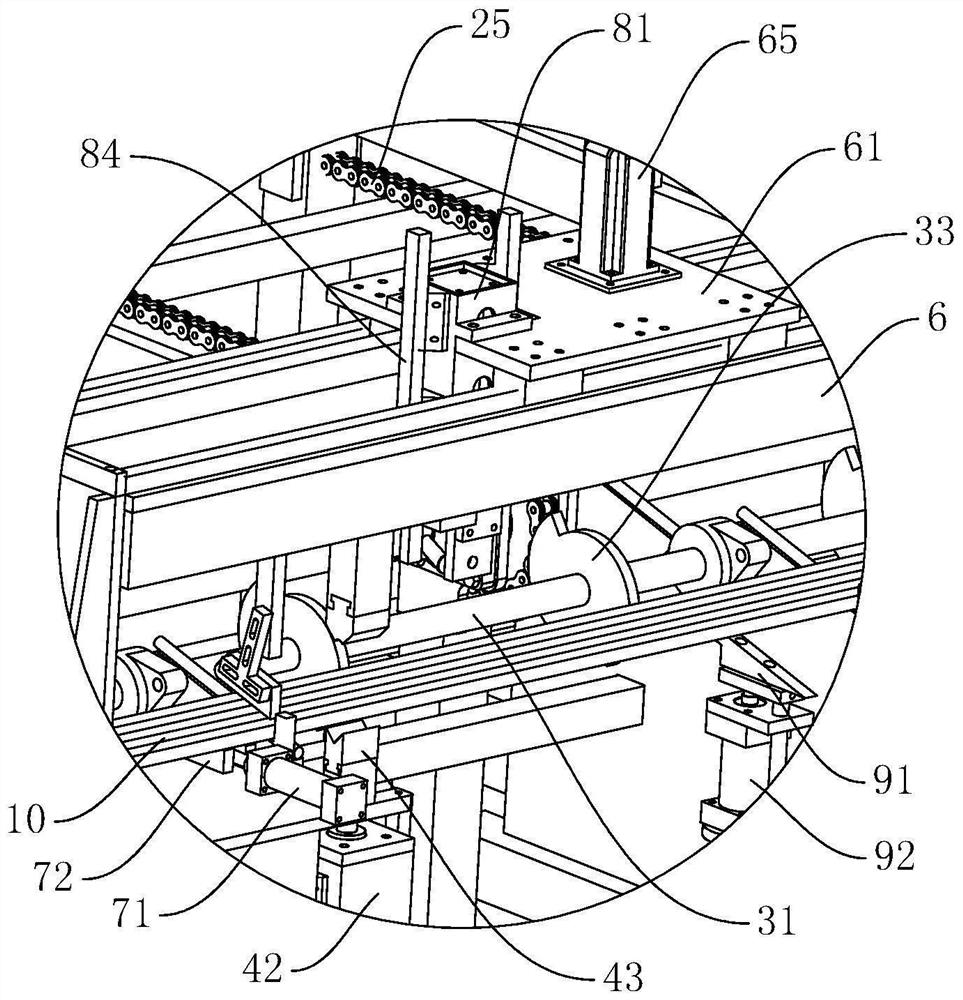

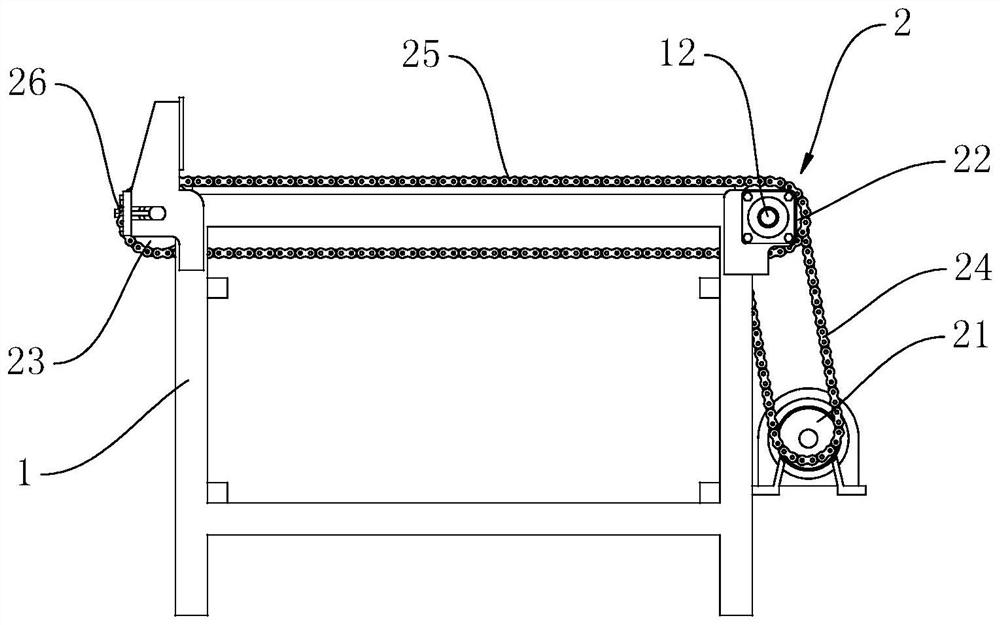

[0030]The bar material automatic feeding machine of the embodiment, as shown in the figure, includes a frame 1 and a chain conveying mechanism 2, a material turning mechanism 3 and a top material clamping mechanism 4 arranged successively on the frame 1 along the feeding direction. One end of the length direction of the frame 1 is fixed with a limit plate 11, the chain conveying mechanism 2 is driven by the first motor 21, and the front side and the rear side of the turning mechanism 3 are respectively provided with a material area 51 to be turned over with a slope and a material area to be topped. In the area 52, the length direction of the frame 1 is fixed with six upright fixed plates 5 at intervals, the material area 51 to be turned over and the material area 52 to be topped are respectively arranged on the upper side of the six fixed plates 5

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap