Transformer oil temperature prediction method based on simple temperature rise model

A technology of transformer oil and prediction method, applied in the field of transformers, can solve the problem of increasing the difficulty of accuracy, and achieve the effect of convenient △T and convenient determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example 1

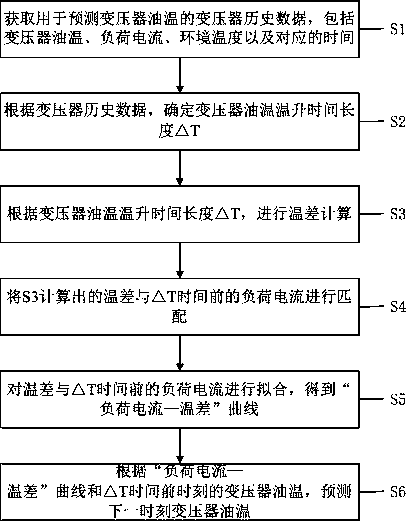

[0035] This embodiment provides a transformer oil temperature prediction method based on a simple temperature rise model, such as figure 1 , including the following steps:

[0036] S1: Obtain transformer historical data for predicting transformer oil temperature, including transformer oil temperature, load current, ambient temperature and corresponding time;

[0037] S2: According to the historical data of the transformer, determine the time length △T of the temperature rise of the transformer oil temperature;

[0038] S3: Calculate the temperature difference according to the temperature rise time length △T of the transformer oil;

[0039] S4: Match the temperature difference calculated by S3 with the load current before the △T time;

[0040] S5: Fitting the temperature difference and the load current before the △T time to obtain the "load current-temperature difference" curve;

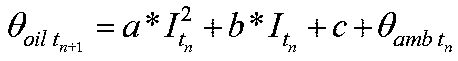

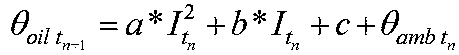

[0041] S6: According to the "load current-temperature difference" curve and th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap