Forming method of scraper ring flat steel belt used for piston ring

A forming method and flat steel strip technology, applied in metal rolling and other directions, can solve problems such as high cost, excessive waste, and affecting product quality stability, and achieve the effect of low production cost and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

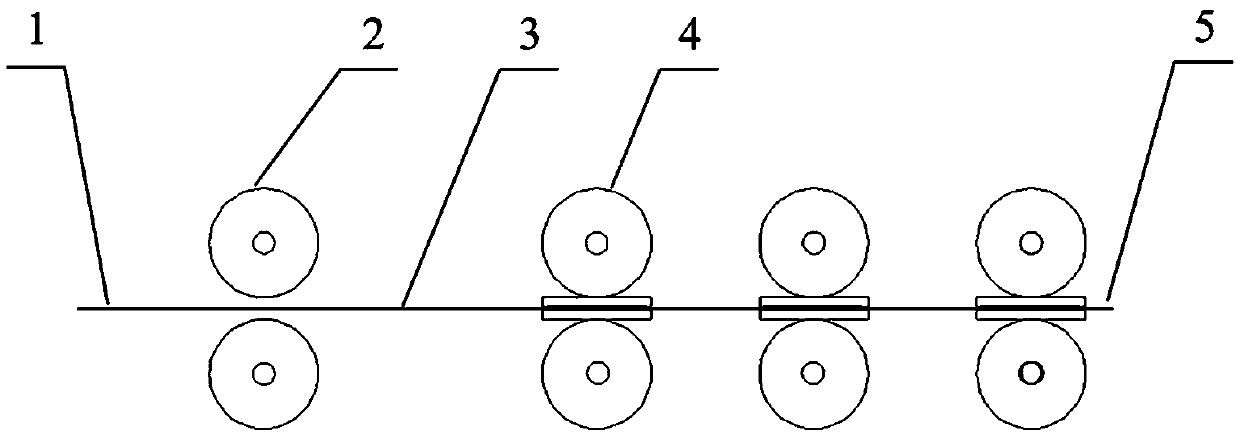

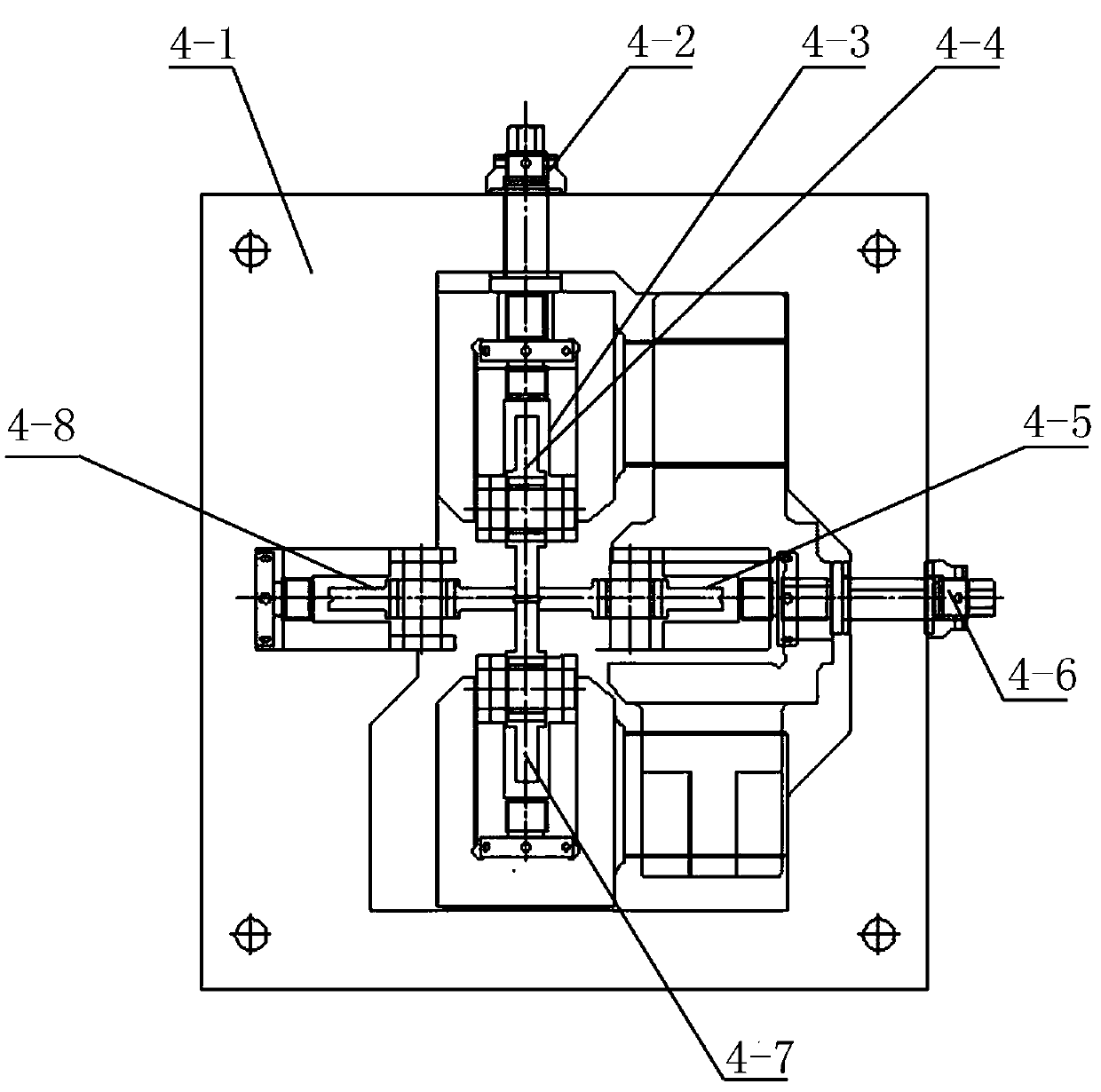

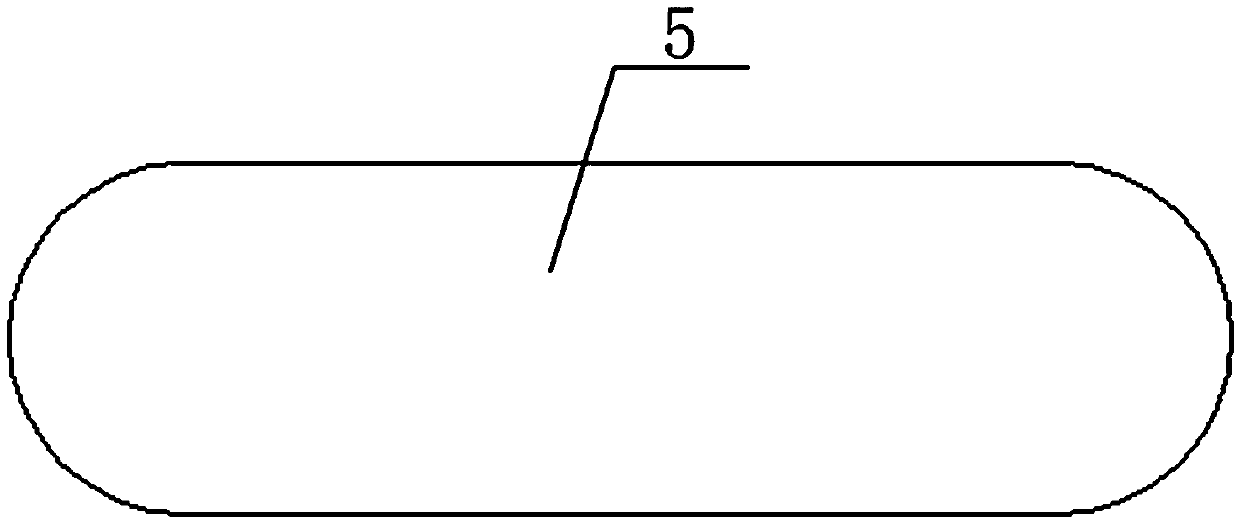

[0016] Such as figure 1 As shown, the forming method of the scraper ring flat steel strip for piston rings of the present invention. The method is to use a qualified round steel wire 1 with a cross-sectional area close to the finished flat steel strip as a raw material, and first pass through a two-roll rolling mill 2 preliminary rolling , to obtain the initial rolled flat steel strip 3 of the required size, the compression rate is controlled at 60%-90%, and then the left and right rollers are respectively provided with the required R The arc shape matches the groove of the grooved four-high rolling mill with 4 multi-pass rolling for size control and R arc trimming on both sides. In order to obtain the finished flat steel strip with the required shape and size, the compression rate of each pass is controlled at 3%. -5%.

[0017] The cross-sectional shape of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap